Week 1

Acknowledgments

ChatGPT logs

https://chatgpt.com/share/68c76324-7418-8007-ad90-89759b46e741

https://chatgpt.com/share/68c85445-04fc-8007-9a8b-5ae33403adb2

Anthony Pennes was super helpful, and he explain to me how to use the machines and helped debug them when I was having some issues!

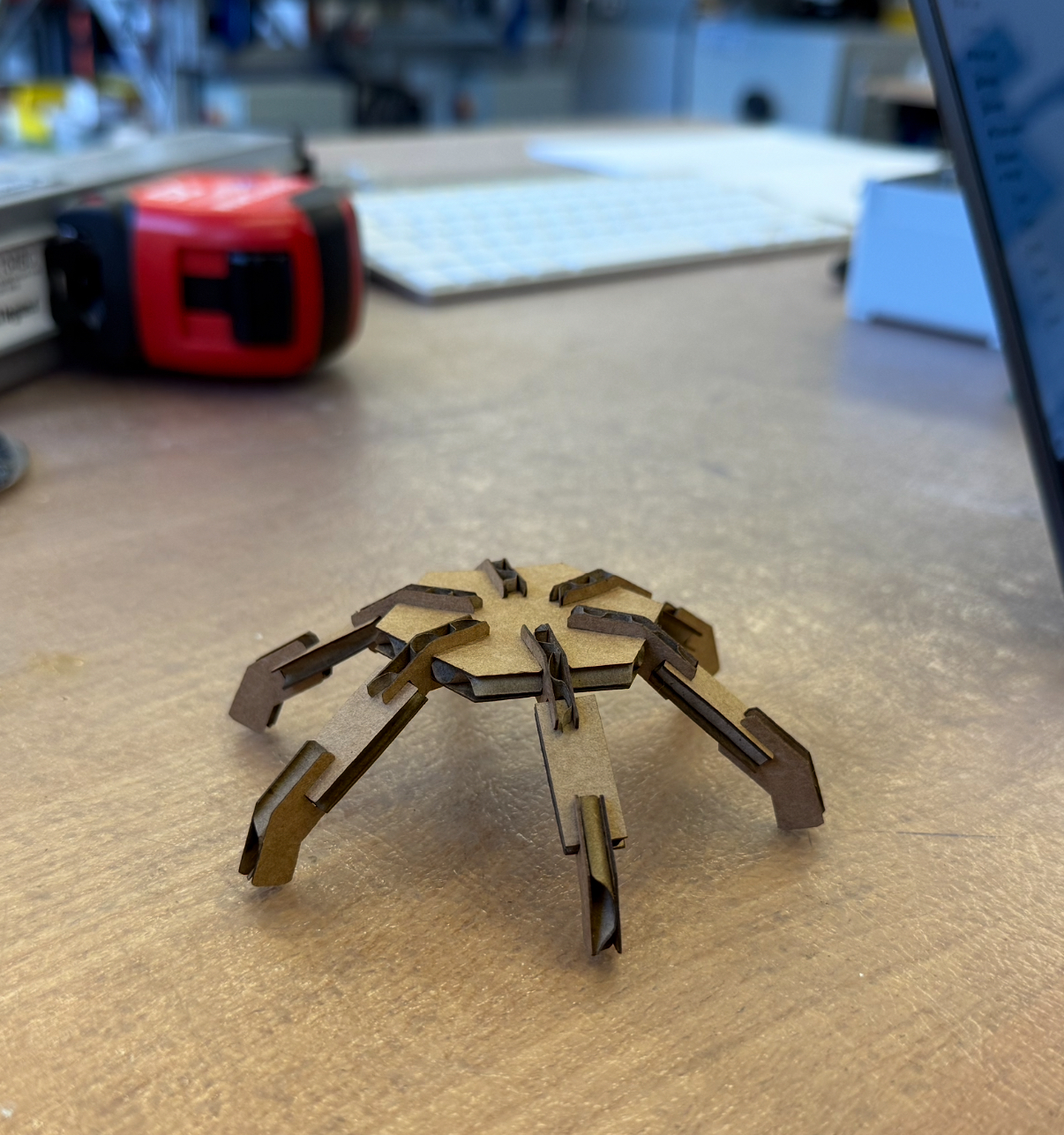

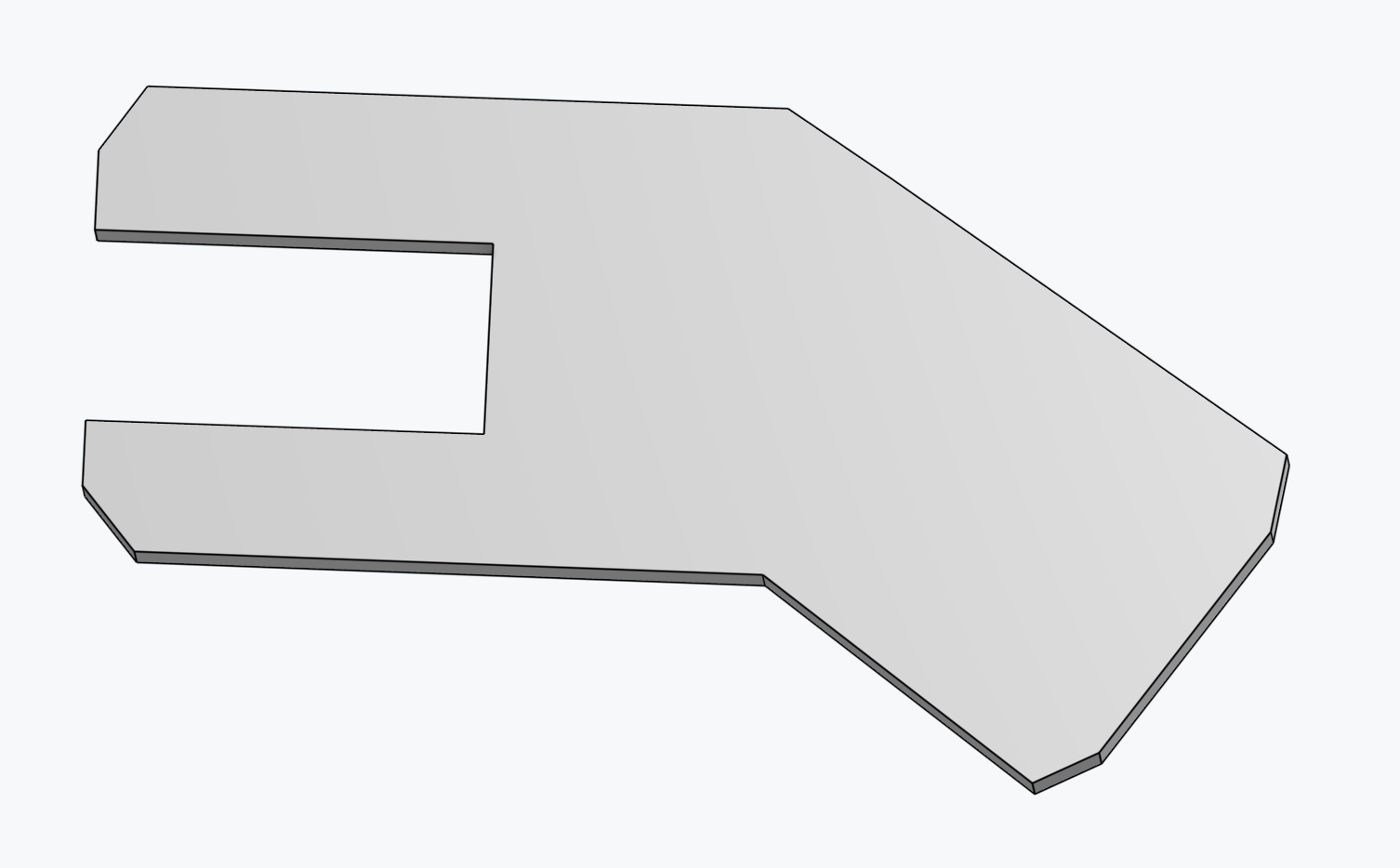

For this week I wanted to utilize the laser cutting assignment to gain some inspiration of robotic forms which is related to my final project. I ended up going with a classical hexapod, and I prefer smaller sized things so I ended up designing a miniature hexapod.

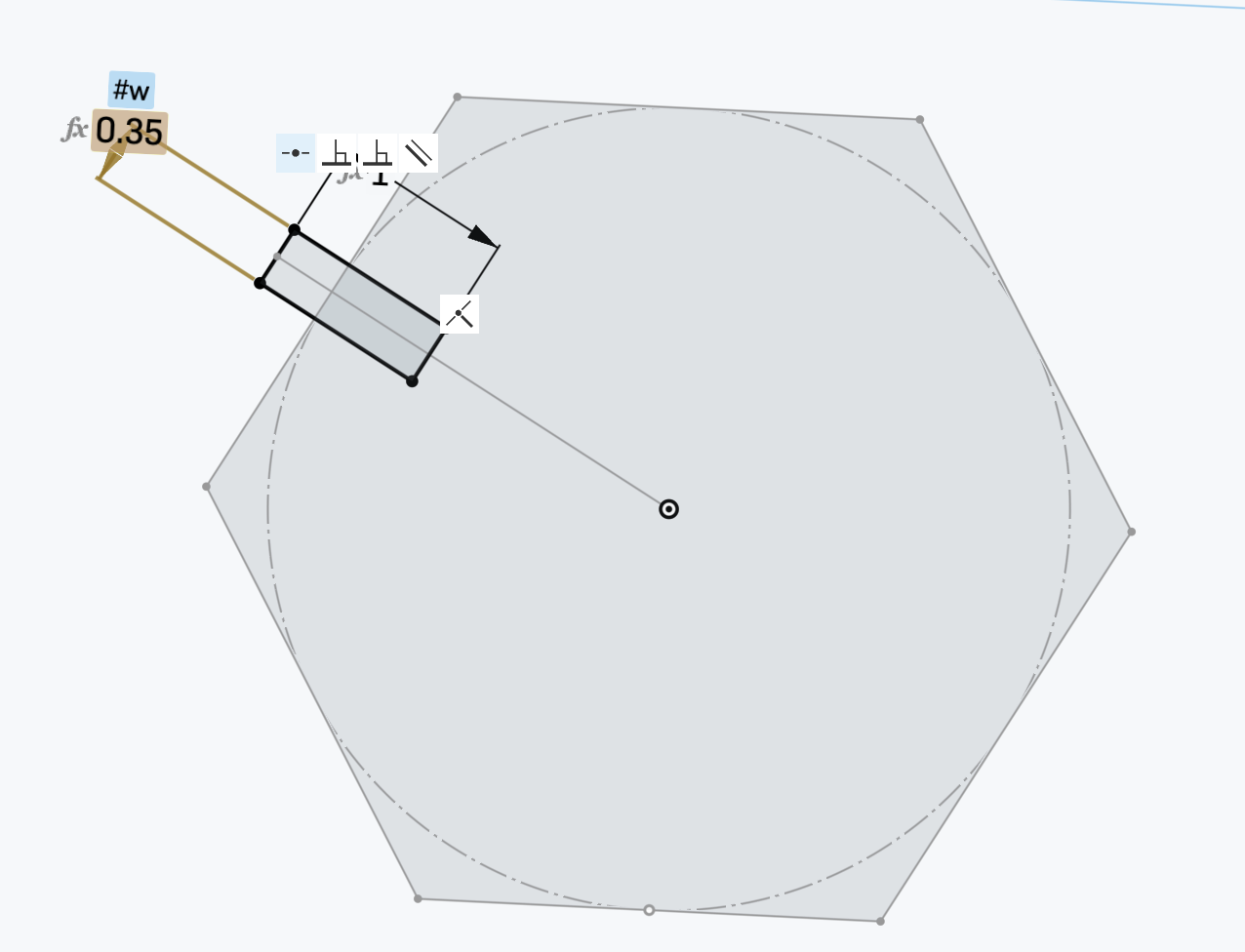

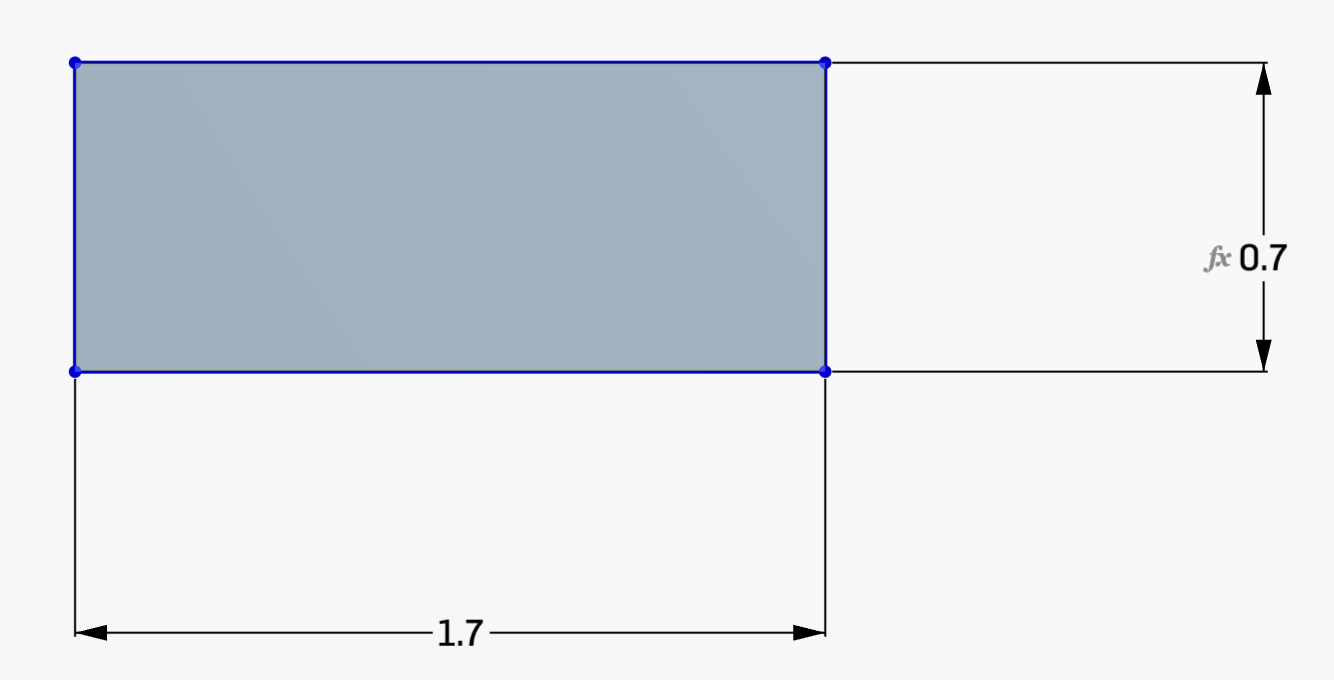

The core part of this assignment was parametric cad design. So I made the width of the slots be a parameter , and although it doesn’t matter as much I made a depth variable (the z dimension) .

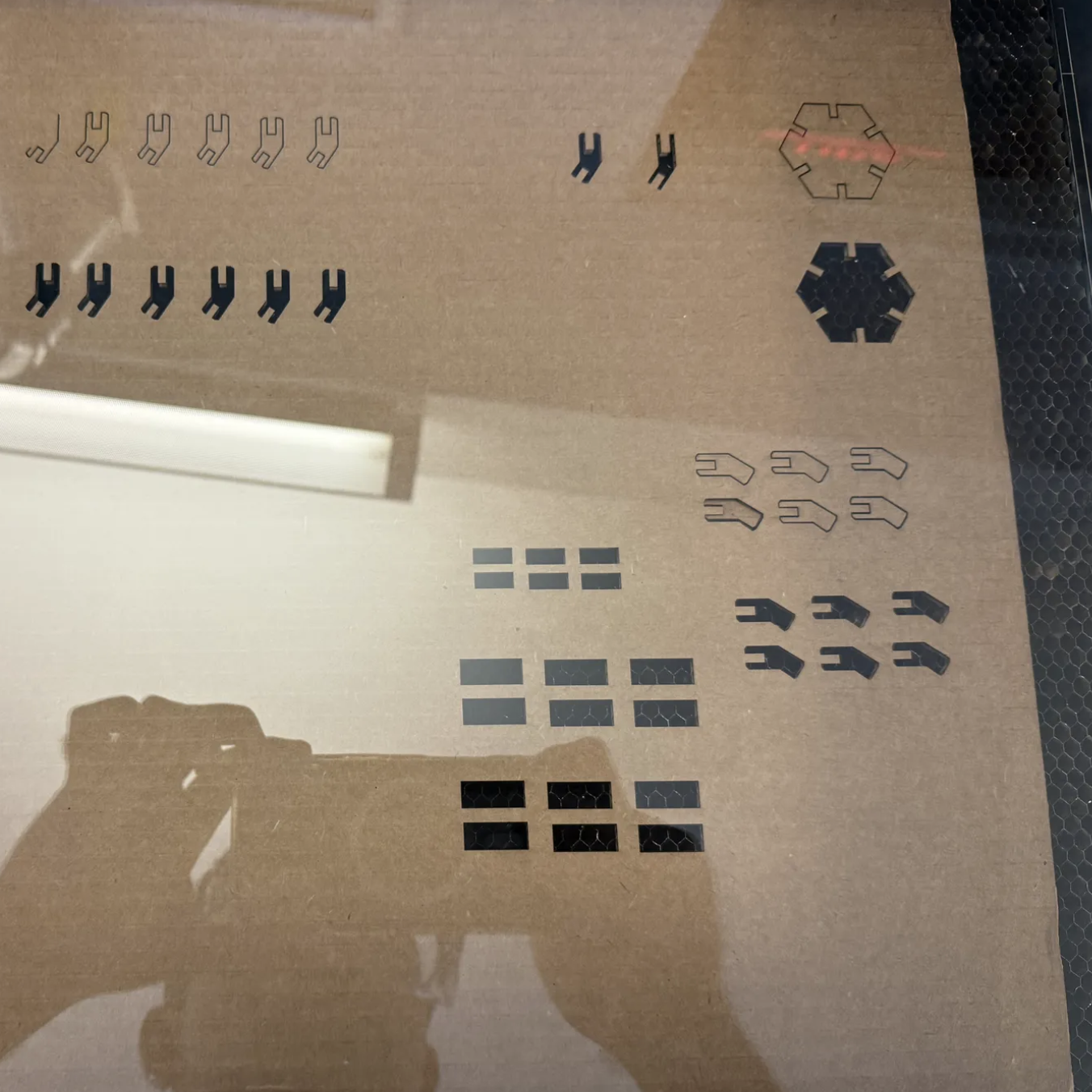

I first laser cut this with . I had obtained this value from measuring multiple cardboards thickness with a caliper then subtracting a small value to make the slot width a tad bit smaller than the cardboard so that it is a tight fit. I noticed that I can pinch the cardboard a bit, so that is why I made the width smaller than the thickness. With Anthony we worked on the laser cutting settings and I converged to 100% power 15% speed. After this I made the first leg joint.

Here is the second version in comparison to the first.

This was much more sturdy and I could now attach the joints to the base.

I reused the same design for the foot, and just covered up one of the holes.

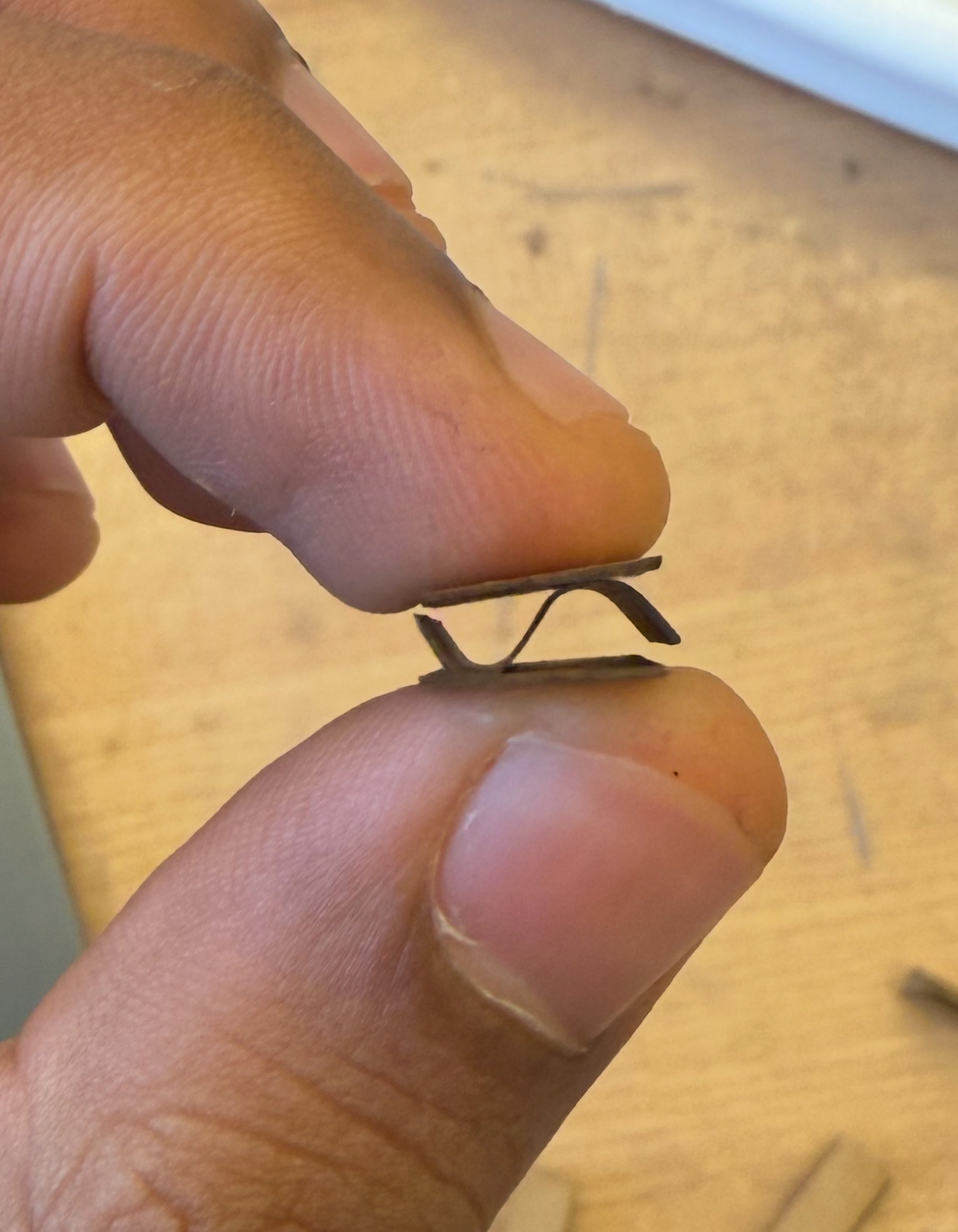

Finally, I needed to make the connectors between the joint. Initially I made it a thin rectangle, which dimensionally made sense, however due to the internal structure of cardboard I ran into issues as shown here. As you can see, the width of the rectangle was too small, to the point where I couldn’t reliably get a full truss inside. I then increased the width to 0.7 cm.

However, even with this there was some pieces that didn’t have a fully connected truss inside, and that depended on where the laser cutting location was. So I just printed more than needed, and took the ones that had a proper truss inside. Finally I assembled everything and then ended up with a mini hexapod!

Files to reproduce.

For the vinyl cutting assignment, I decided to print my Seminar’s name + logo: scale-ml.org.

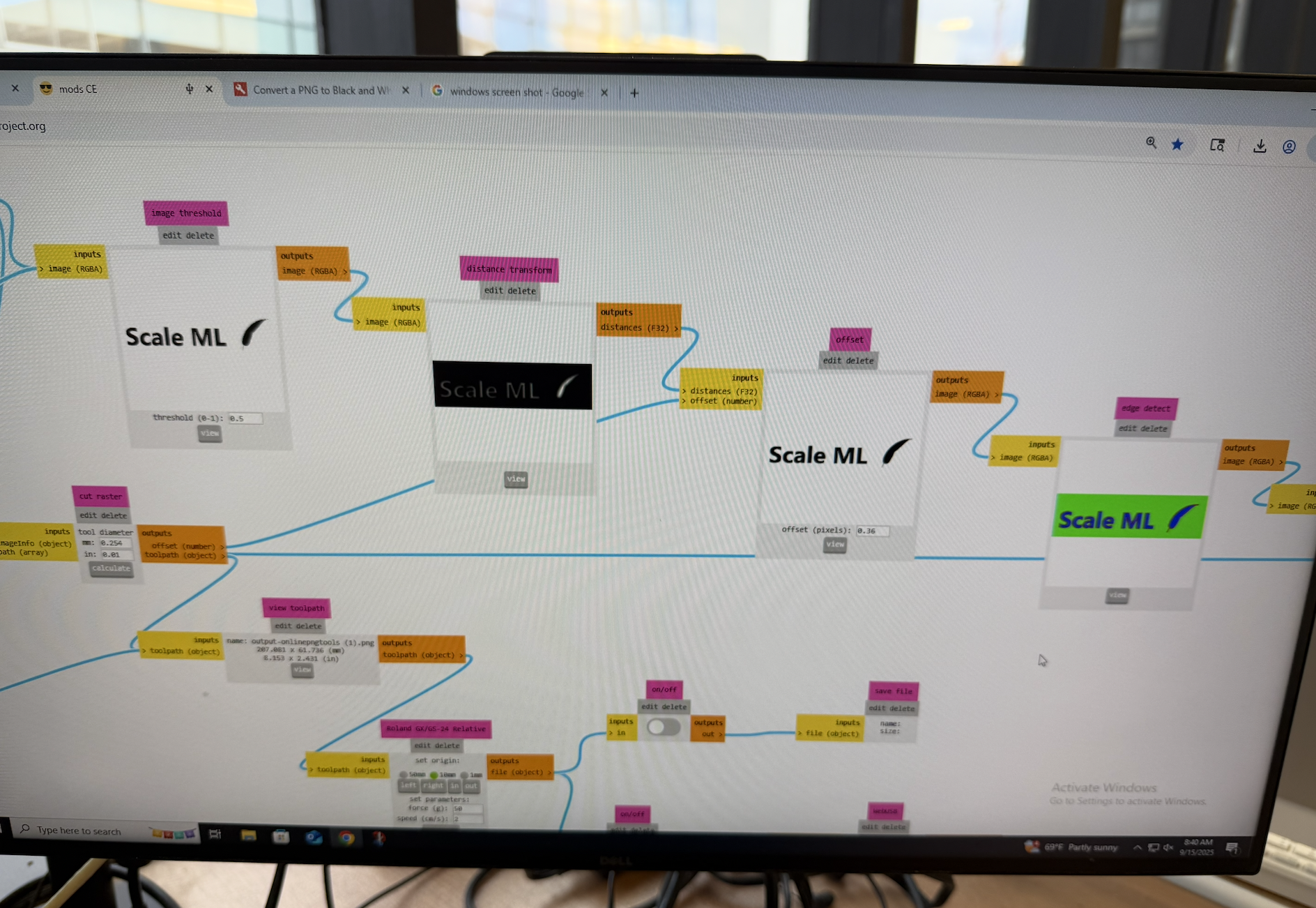

I converted it to a black and white image using this website: https://onlinepngtools.com/convert-png-to-black-and-white. Then I used the modsproject to process the black and white image and send it to the Roland cutter.

Notice the letters are not super smooth - I think that is because the image I used didn’t have a high enough resolution.