Wild Card Week

For this week I chose to do Wire EDM with Anthony. I was very curious about it because online I could see that people made some very tight fitting parts with really good tolerance. The video in the slack folder was very impressive which got my intrigued on how is this possible. (Later I learned a bit to my dismay that this wasn’t cut in one go)

I did some research on how wire edm works before I used the machine. Here is my brief notes after reading: https://en.wikipedia.org/wiki/Electrical_discharge_machining

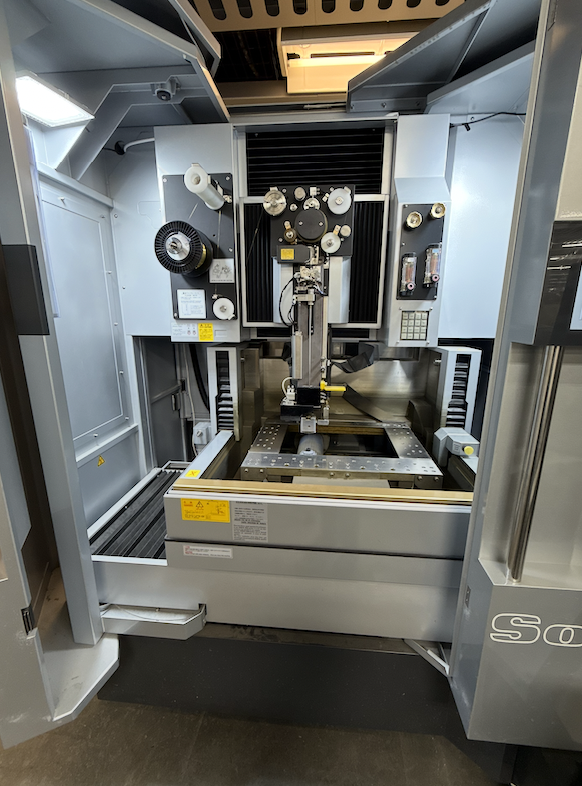

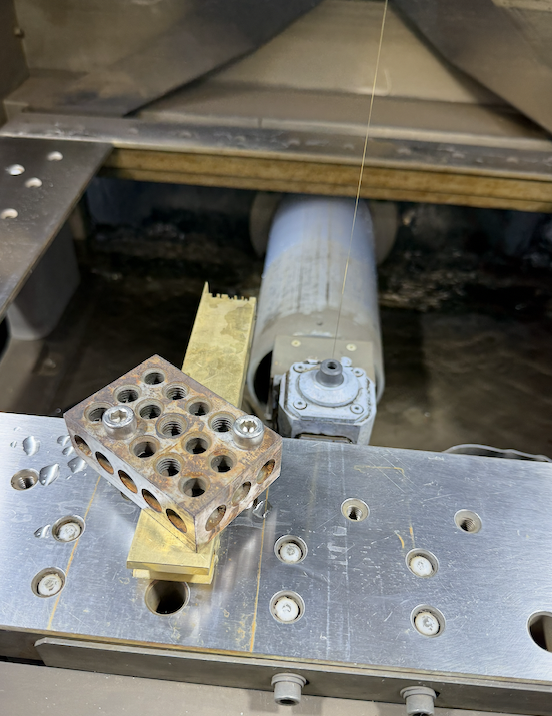

The machine has a wire that runs a high current and there are tiny sparks that come off that wire. Those sparks will erode away at the metal in small quantities. When watching the machine in person I was wondering why is there a spool of brass wire also being pulled and used, I initially thought the wire would be static. Anthony explained that the sparks will erode part of the wire itself, and that’s why there needs to be a feed of wire. Then there is deionized water that surrounds the whole machining to wash away the particles, cool it, and allowing the current to go through it since its dielectric.

The machine we used is the Sodick SL400G Wire-EDM

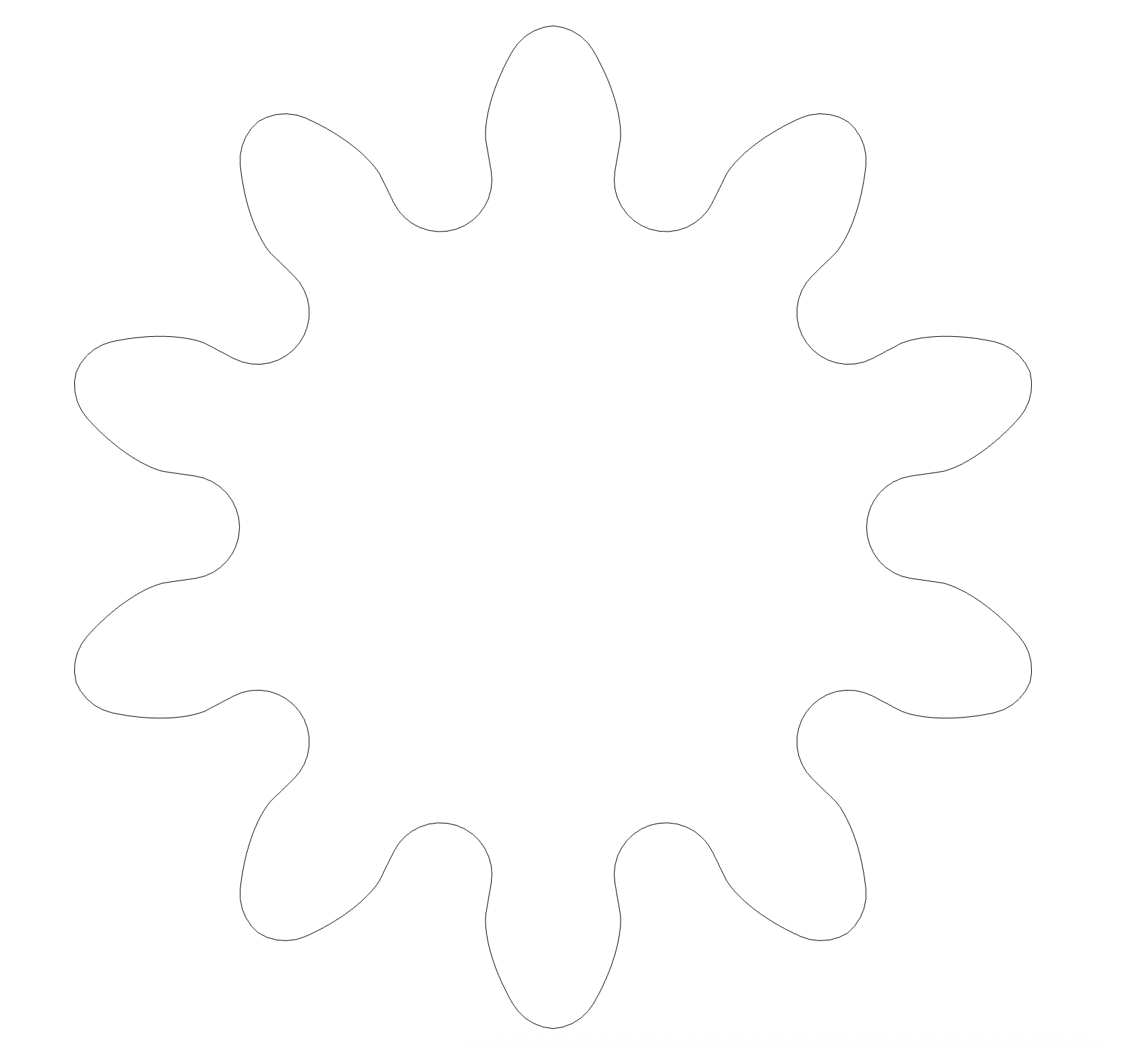

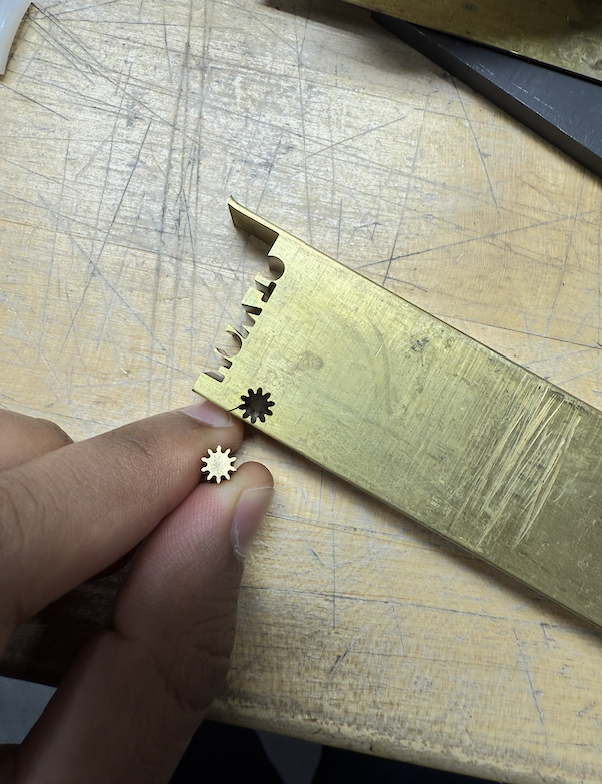

It uses a thin brass wire. Anthony showed me how to home the x,y axis, and also the feature where it can cut and refeed the wire which was cool. I designed this simple Spur Gear in Onshape using the spur gear tool, and then converted it to a dxf file. Visualized using: https://vagran.github.io/dxf-viewer-example/. I wanted to make a small gear because I have always been curious how to make small watch gears. I used this video as a guide to help me use Onshape for this: https://www.youtube.com/watch?v=AxCgO_eJocc&t=161s

Then from the choice of metals (which needs to be conductive) - I chose brass for its color and it looks closer to a watch gear.

We then in the interface set the origin to be the top right of the brass part, and then made the part be on the lower left corner. We determined it would travel clockwise, and after that the walls went up and water filled it. The actual machining process was smooth and after that the walls lowered the water drained. Anthony told me there is a large filters that catch the particles before reusing the water.

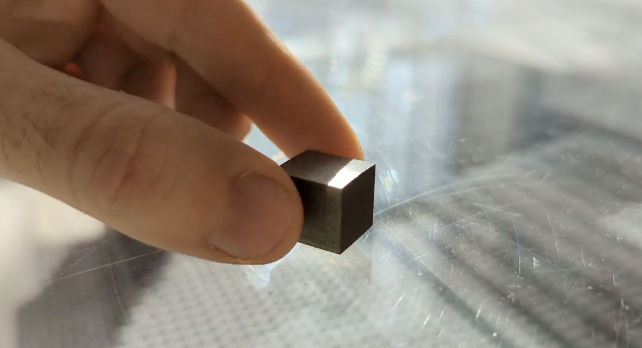

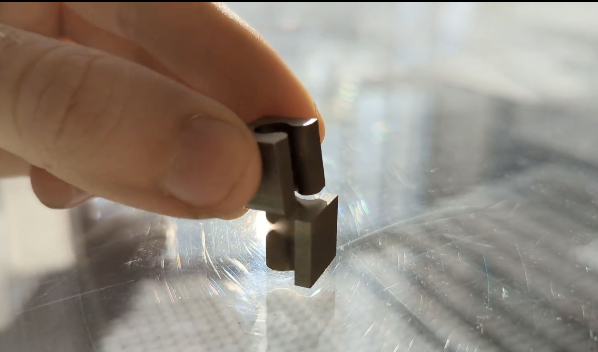

My part came out great! A minor defect was where the wire excited, that tooth had a small extra part taken out of it, but I am not sure if there is a simple way to avoid that since the wire needs to exit somewhere.

File: