Group assignment: kerf-finding with Ray and Sun

Full disclosure: thinking / Googling how to do this beforehand would have saved us a lot of time and effort. But, we had so much fun deriving our experiments from first principles i’m not upset at all! :)

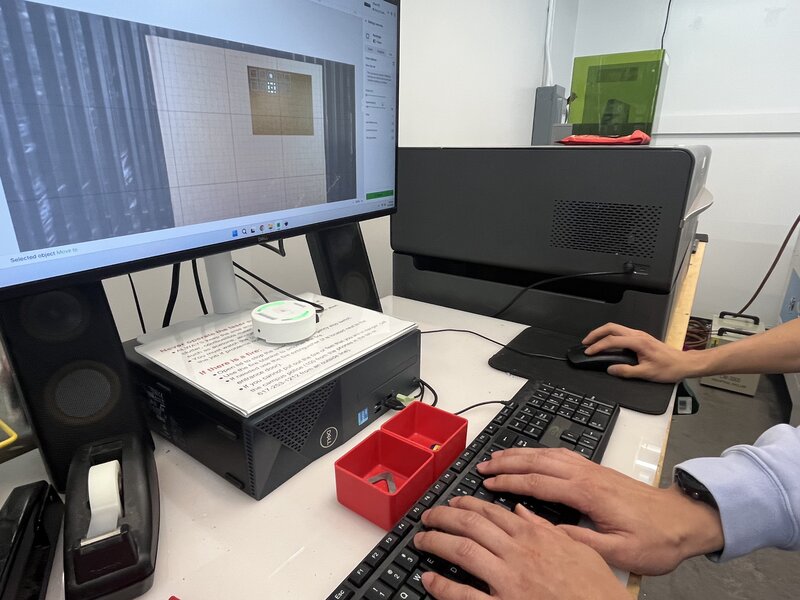

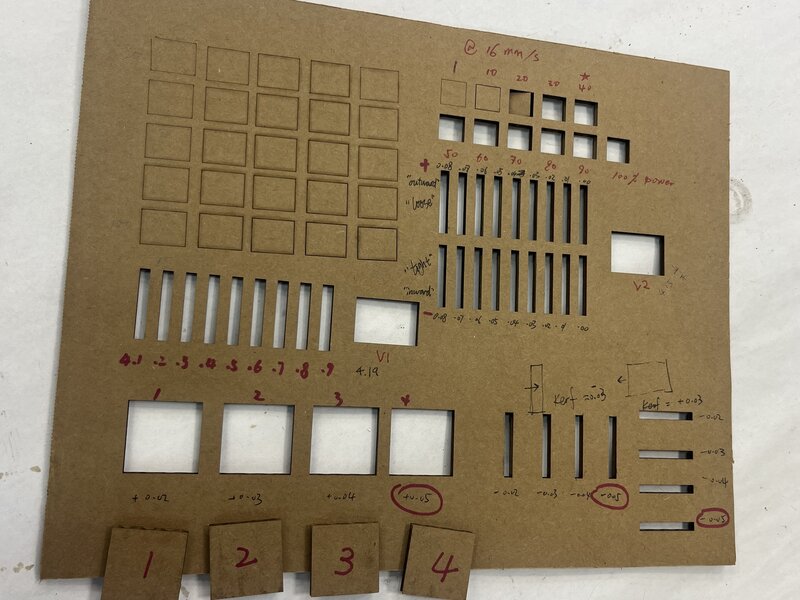

For this assignment we used the XTOOL P2 cutter. Here is the result of all of our experiments, which I describe below:

Power-speed experiment

First, we wanted to know which power / speed to use. We arbitrarily chose a fixed speed (12 mm/s) and made a grid where we varied power from 1% - 100% in 10% increments. In retrospect, we should have made a matrix to test different speeds as well, but we were too locked in on taking the Shortest Path To Kerf Finding. For the XTOOL laser cutter and cardboard from Dan, 40% power at 12 mm/s was about right.

Kerf-finding round 1

First, we made a series of slots from 4.1-4.9mm thick, with 0.1mm increments between them. We measured our material to be 4.19mm thick (after cutting), and the 4.1mm slot fit the best. From this, we estimated our kerf to be around (4.19 - 4.1) / 2 = 0.045mm.

Kerf offset fun times

Next, we wanted to use the “kerf offset” settings on the XTOOL GUI (under the Cut menu) instead of manually setting the width of each rectangle. XTOOL has some confusing language on their interface - “inward” vs “outward” - and we couldn’t tell which direction was which so instead of looking the answer up like reasonable people, we ran another experiment. We wanted to also get better sensitivity on our kerf measurement, as a two-birds-one-stone kind of deal. We found that “outward” (positive kerf offset) makes slots looser, and “inward” (negative kerf offset) makes slots tighter We found that -.03 kerf offset was about right for our slot, for a 4.15mm thick square.

Experiments in joint clearance

Finally, to really test our kerf hypothesis on slot fitting, we deduced that we’d need to make our tabs slightly bigger (to account for the kerf) and our slots slightly smaller. So we made 4 squares, +.02, +.03, +.04, +.05, and 4 slots vertically and horizontally, -.02 to -.05. We found that all of them worked due to the pliability of the cardboard, with the +/-.05 having the least joint clearance (tight) and +/-.02 having the most (loose).