Soft Robotics: Inflatable Structures

From Mechanical Way to Organic Way

While the mechanical linear actuator worked, I couldn't help but wonder: is there a more natural, organic, and interesting way to achieve this? I didn't want the robot to feel like a machine just ejecting a part. Later, I discovered a video demonstrating the use of pneumatics to control soft robot behaviors. This was a major inspiration for me, suggesting that air and inflation could be the key to a more biological-looking birth process.

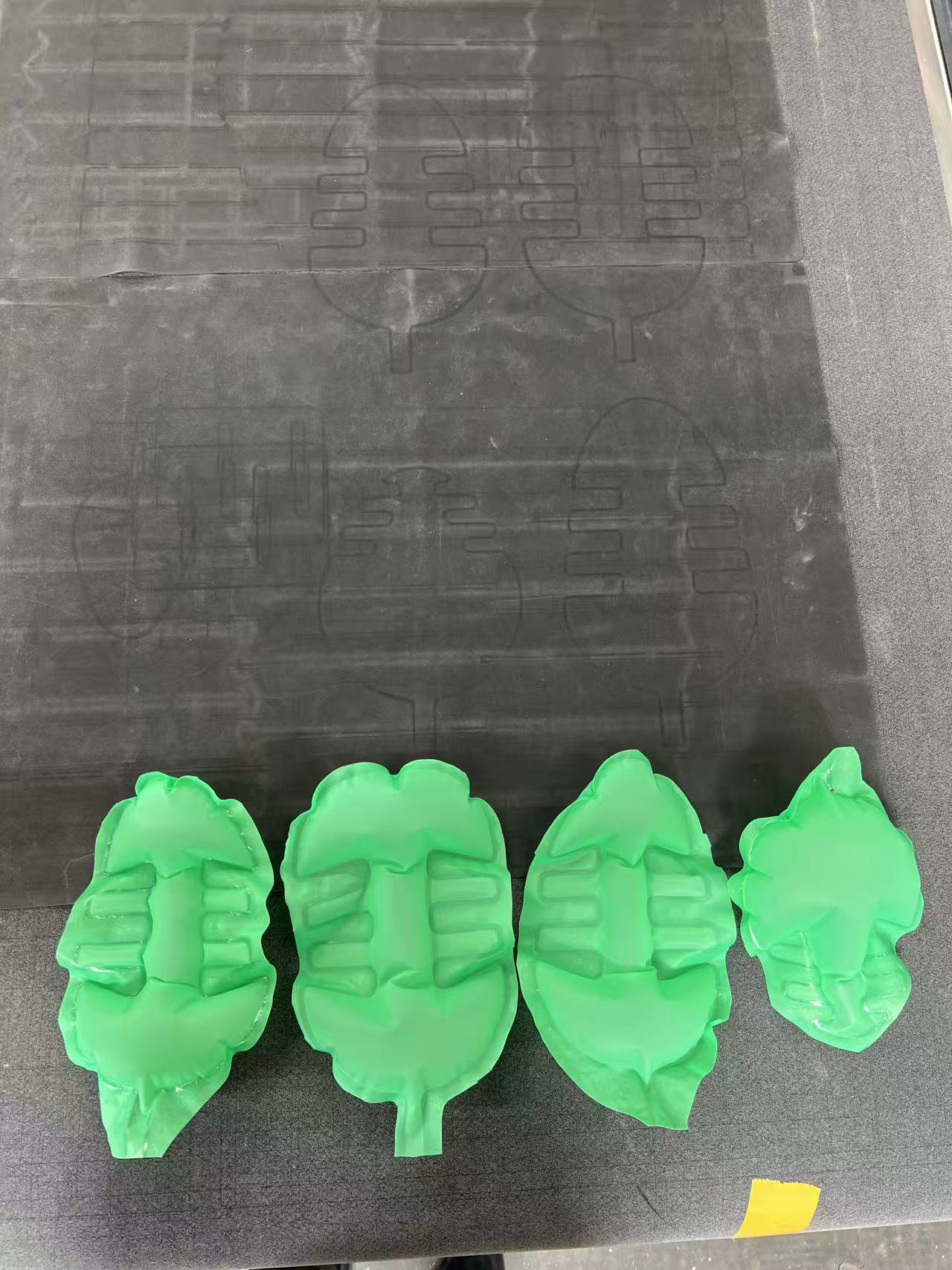

Inspired by this, I wanted to attempt using an inflatable structure to push the baby robot out. This approach aligns perfectly with my goal of creating a more organic and biological mechanism, reminiscent of actual birth processes. So, recalling my previous explorations in Week 15, I decided to revisit those techniques. With a "give it a try" attitude, I experimented with creating some 2D inflatable structures to see if they could generate the necessary pushing force.

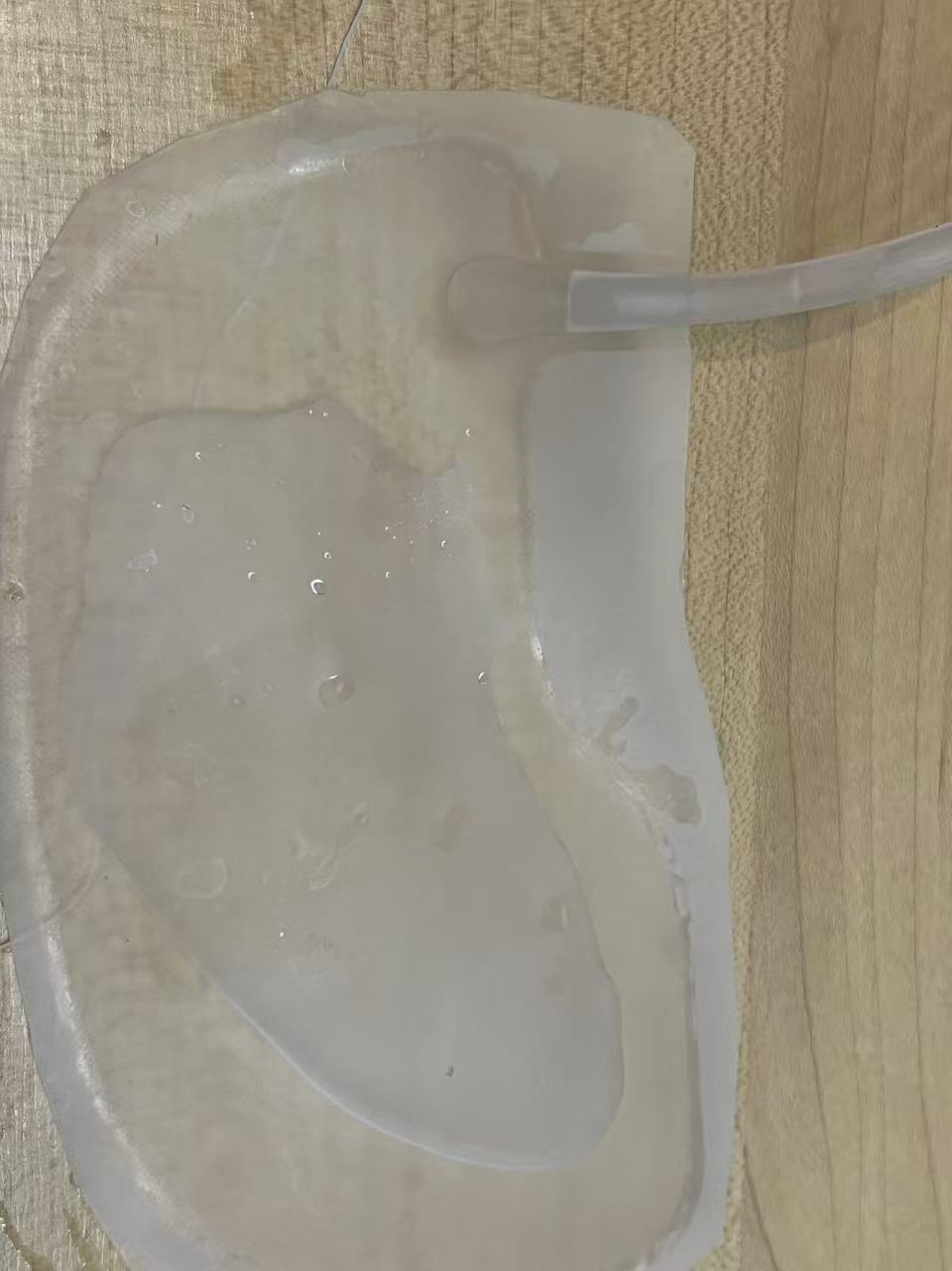

Initially, simply blowing air into the structure wasn't strong enough to push even slightly heavier objects. However, I remembered that I had purchased small water pumps. I realized I could connect a tube to the pump and pump water into the inflatable structure instead of air. I decided to test this by placing the inflatable mechanism inside my previous 3D-printed model and placing a small ball inside to see if it could be pushed out. The result was a success! The water pressure was sufficient to smoothly push the object out from the "belly" of the robot.

I experimented with various methods to connect the tube to the bubble, including using intermediate connectors, heat pressing, and direct insertion. I even purchased specific pneumatic fittings, but I didn't use them in the end. Surprisingly, I discovered that the simplest method was the most effective for waterproofing: directly connecting the tube to the bubble. By using a tube slightly larger than the bubble's opening, the natural tension created a tight seal that effectively prevented leakage without needing complex bonding.

I also created inflatables of various sizes and shapes to test how different geometries affect the thrust force for later stages.