Output Device Strategy

For my final project, I need to design an output system that can physically actuate the "birth" process of my robot. My primary goal is to use DC motors and DC water pumps as the core output devices. I need these actuators to be compact, powerful enough to push the baby robot out, and controllable via a microcontroller.

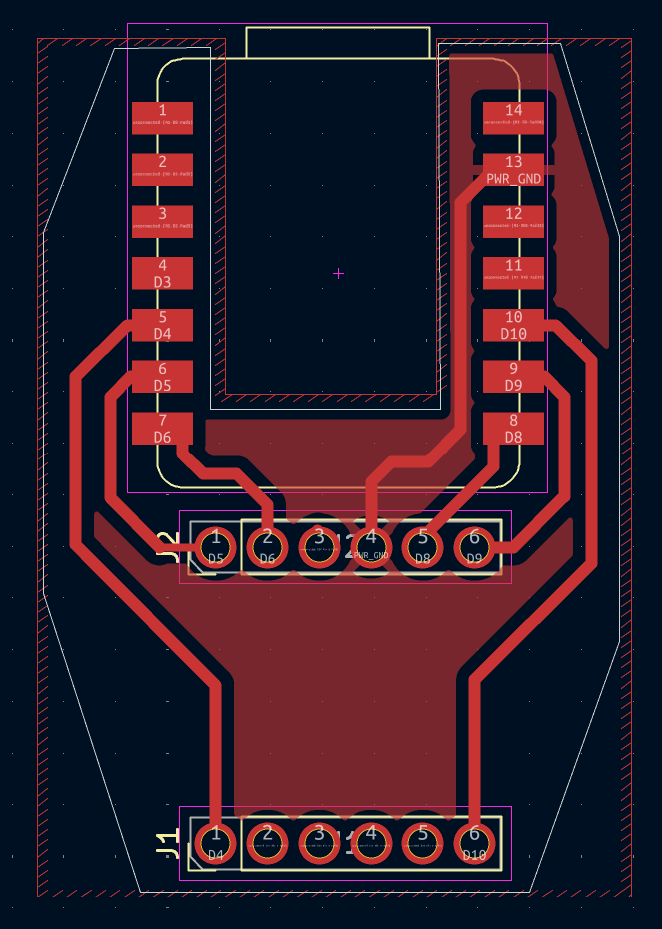

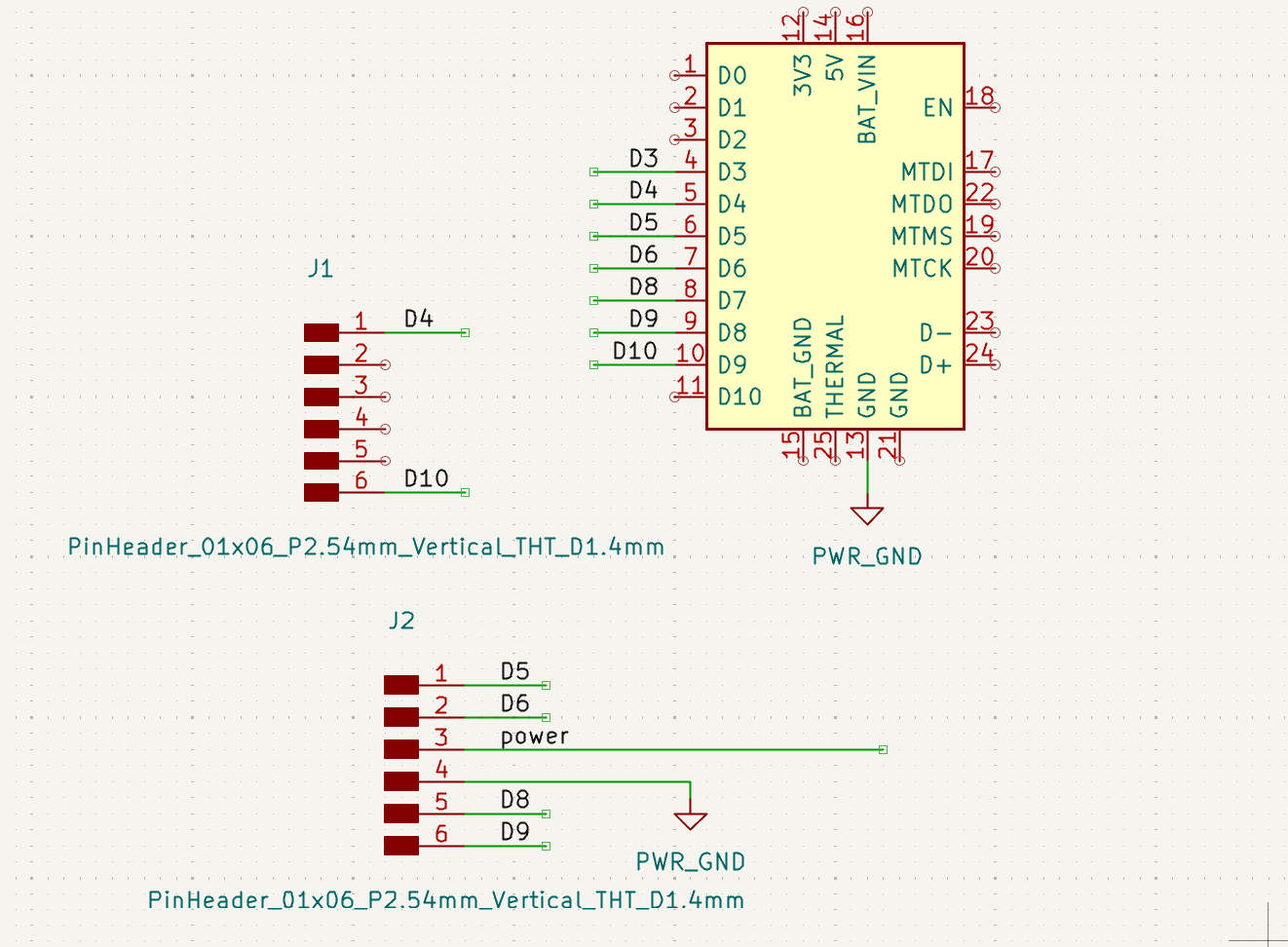

Electronic Design (Motors & PCB)

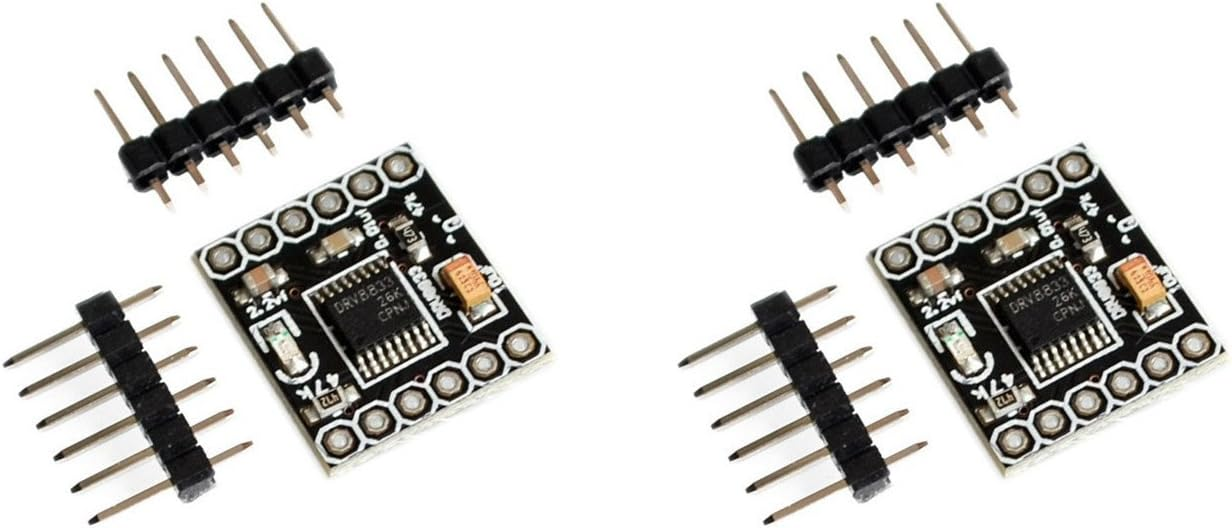

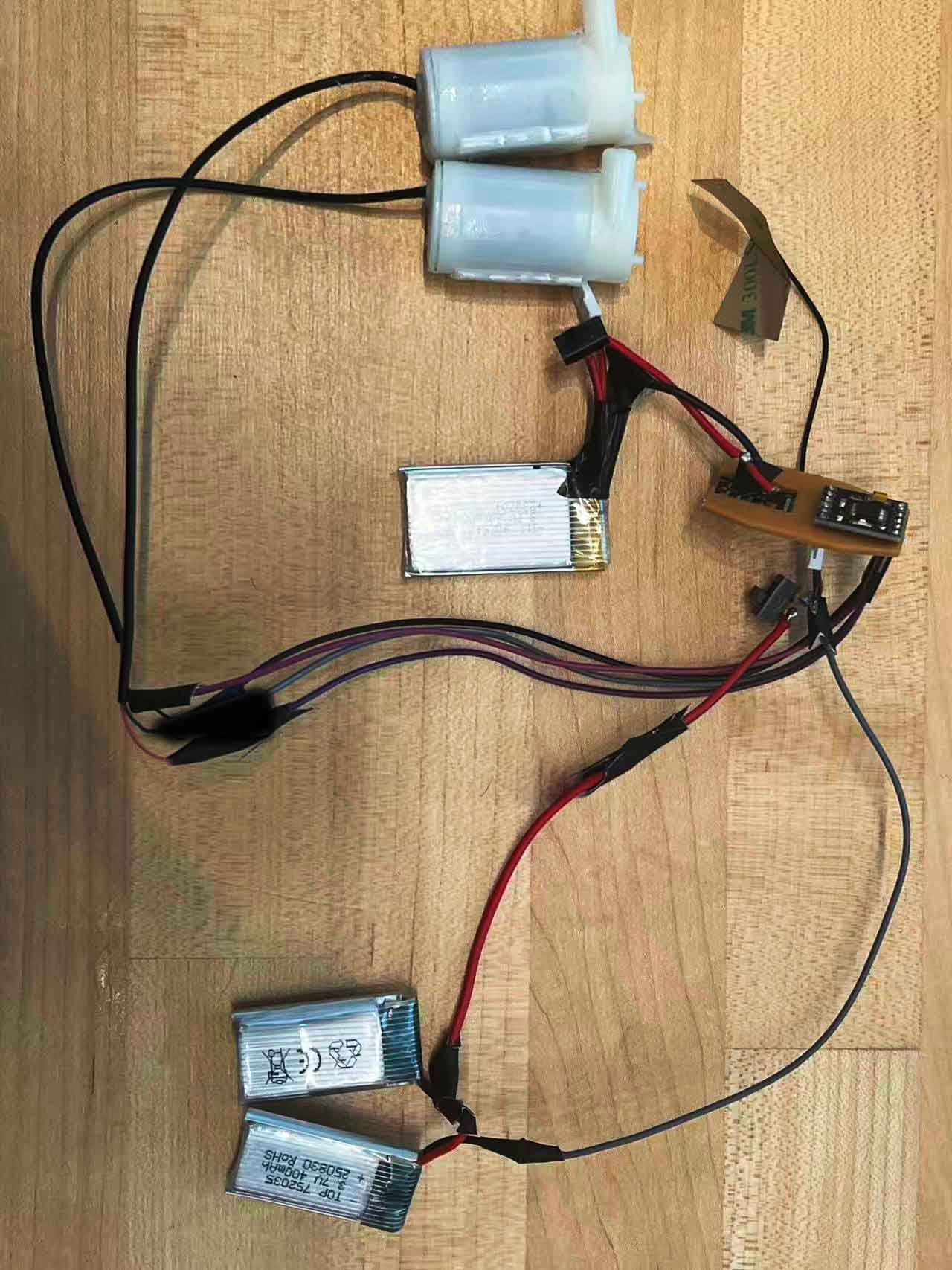

For the output devices—motors and pumps—I needed a reliable driver board. I designed a simplified breakout board for the XIAO ESP32S3 that connects to a DRV8833 1.5A 2-Channel DC Motor Drive Board.

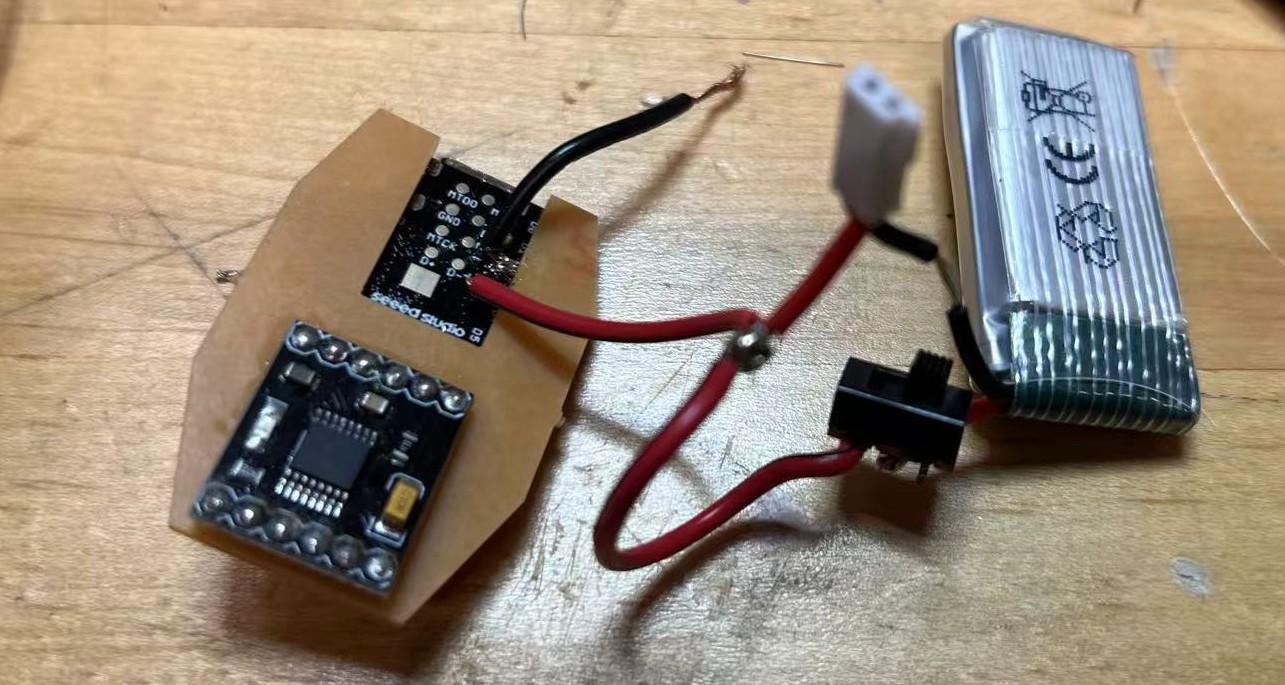

The system is powered by two different types of 3.7V batteries. High discharge rate (400mAh) batteries are used for the motors/pumps to handle the instantaneous current demands, while high capacity (800mAh) batteries power the logic.

The fabricated PCB is extremely compact, designed to fit within the robot's limited internal volume. It routes power and control signals efficiently from the XIAO to the motor drivers.

For the parent robot, which drives two DC water pumps, I connected two 400mAh 3.7V batteries in series to provide 7.4V, ensuring sufficient power for the pumps.

Linear Actuator Mechanism

This is a testing video of the mechanism. The electronics here are very simple: I'm just using a Xiao microcontroller to control two basic DC motors directly.

I utilized small DC water pumps to pump water into the inflatable structure. The water pressure created was sufficient to smoothly push the object out from the robot's "belly".

Final Integrated Testing

This video demonstrates the final integration of all output devices working in unison. It validates the effectiveness of the custom PCB driver and the power management system. You can see the immediate responsiveness of the DC motors driving the wheels and the water pumps inflating the mechanism. This seamless control proves that the chosen outputs—compact motors and hydraulic pumps—were the correct strategy for achieving the organic "birth" motion I envisioned.