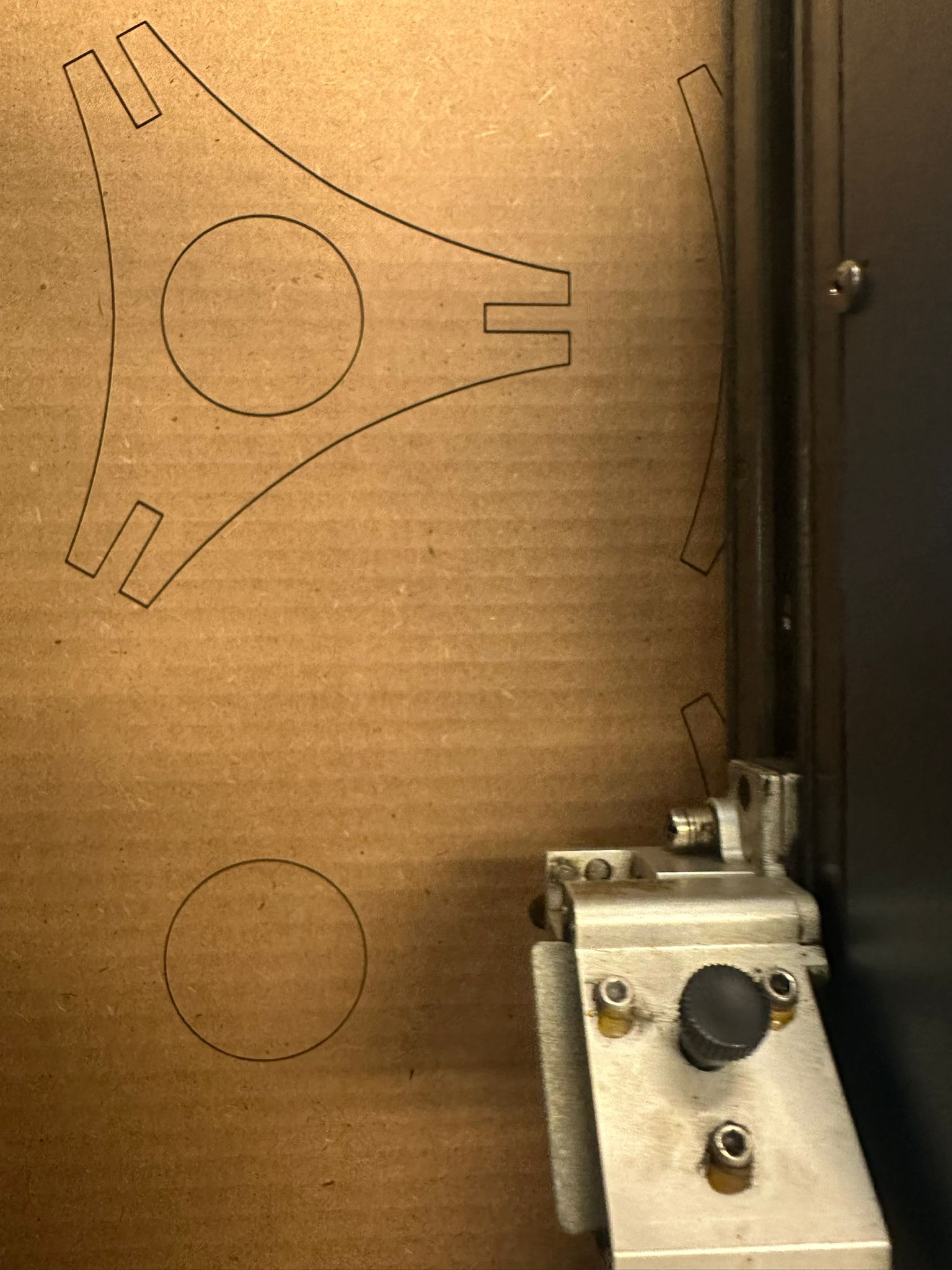

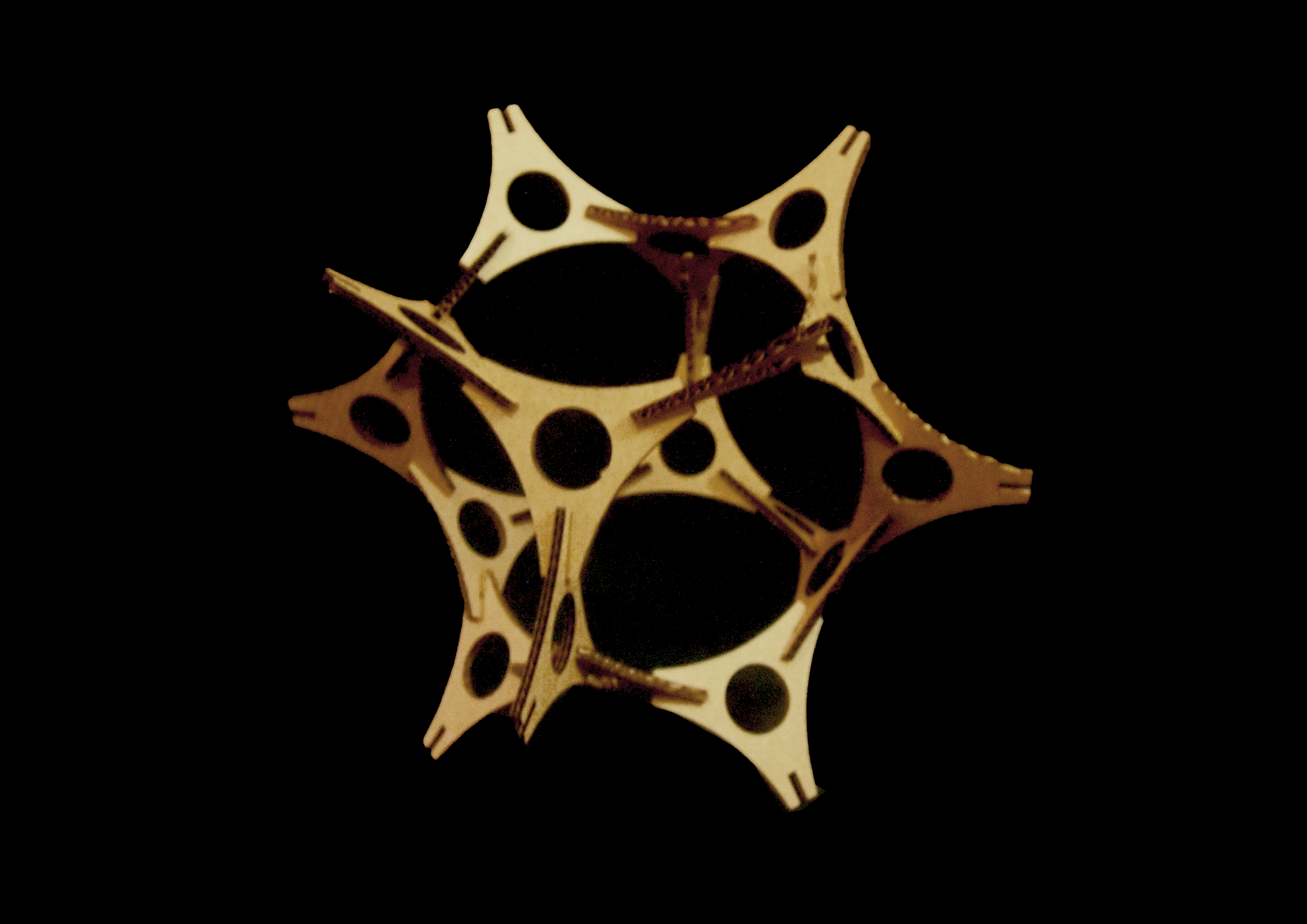

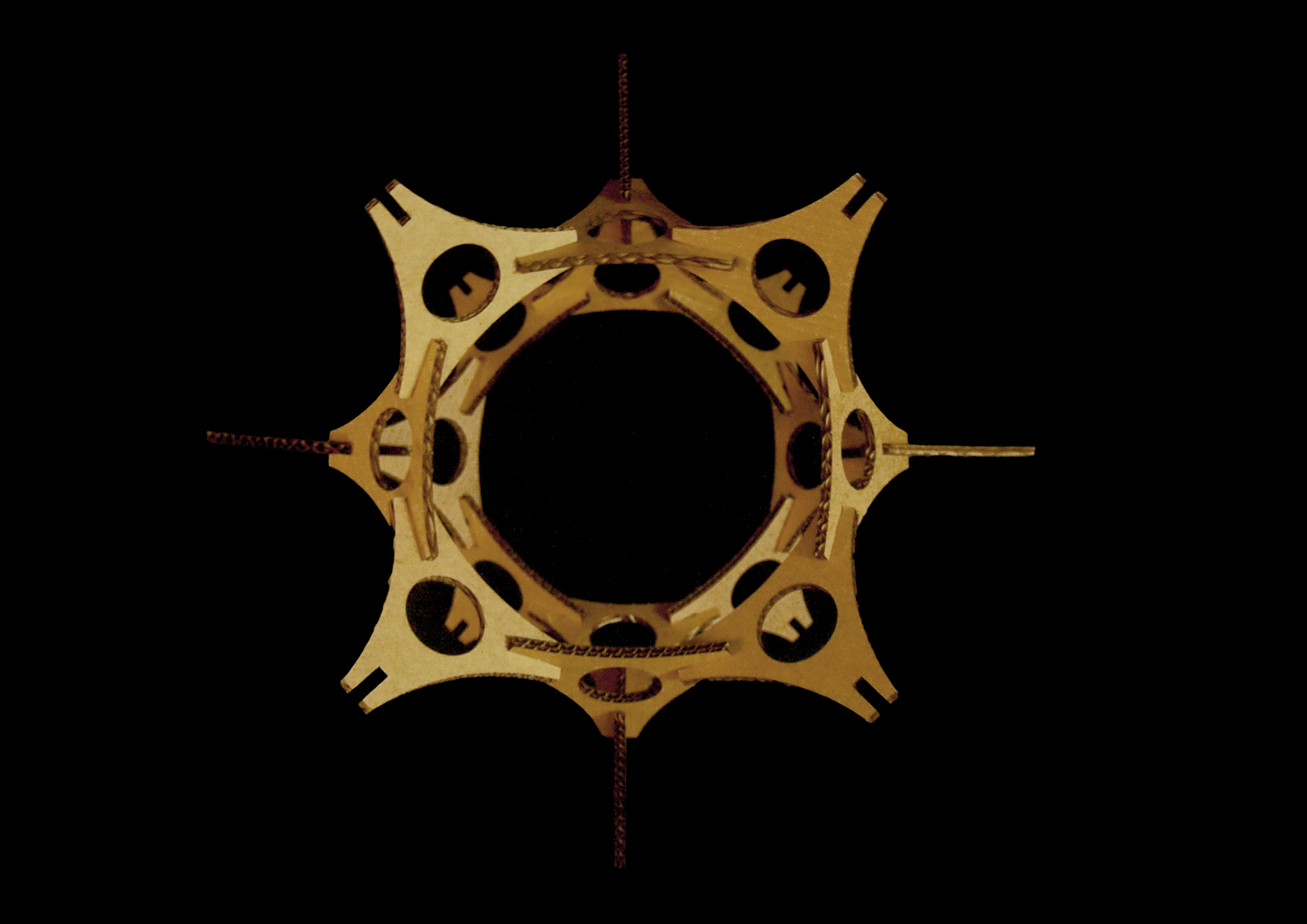

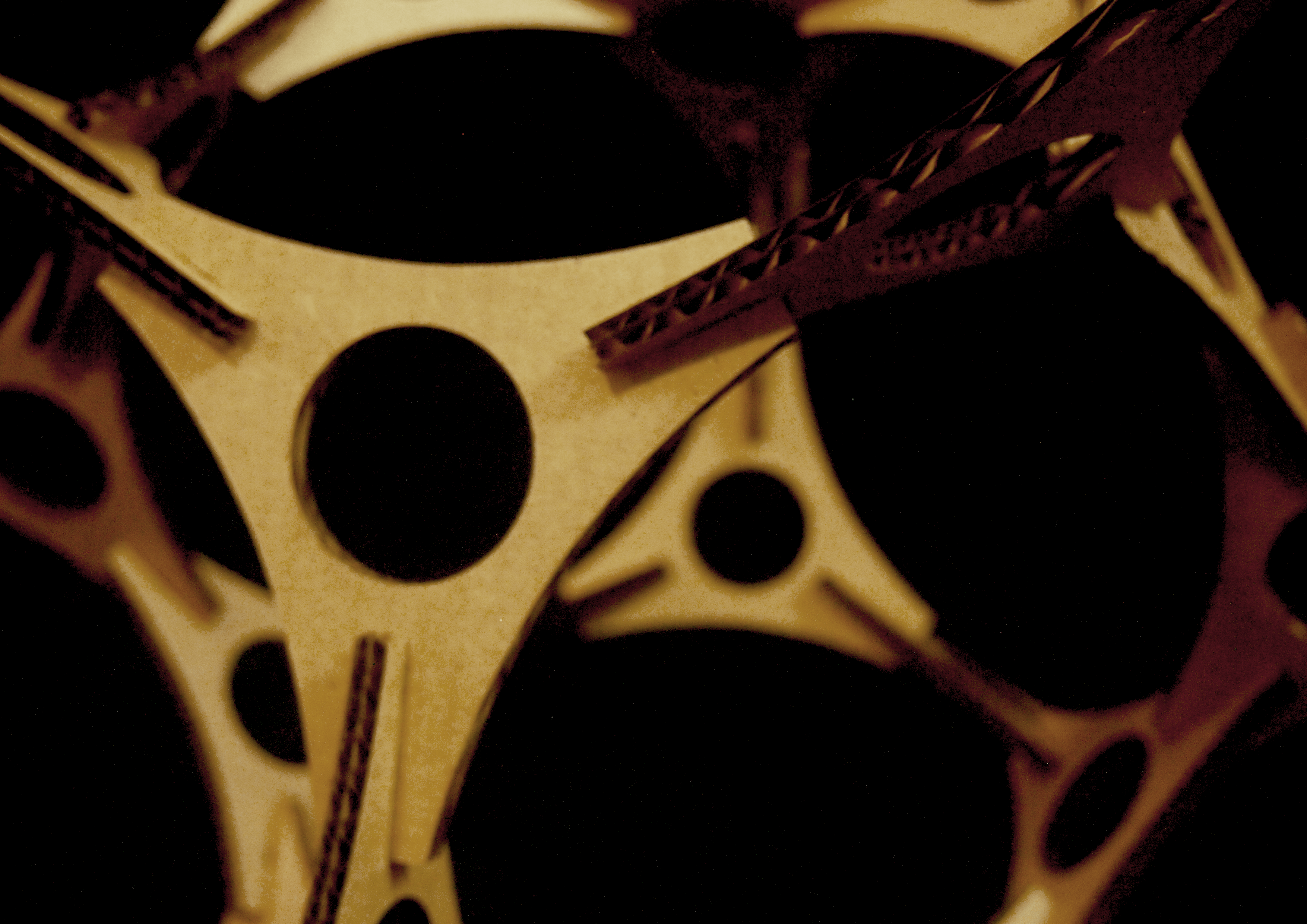

This week I experimented with laser cutting as a way to quickly prototype structural ideas. I started with simple 2D sketches and translated them into cut patterns, testing different thicknesses and joint details. The process allowed me to explore how flat sheets could transform into three-dimensional structures through slot connections and flexible hinges. By assembling multiple modules, I began to see how geometric repetition could create more complex mechanical forms. These early experiments gave me a better understanding of material tolerances, accuracy, and structural behavior, which will be essential for building future moving prototypes.

Process

I prepared digital drawings for the laser cutter, experimenting with different kerf settings, material thicknesses, and joint designs. Through cutting and assembling, I observed how small variations in the slot dimensions affected the overall stability. The workflow was highly iterative: sketch → cut → assemble → adjust. This hands-on cycle helped me quickly refine the geometry and understand the structural limits of the material.

Gallery

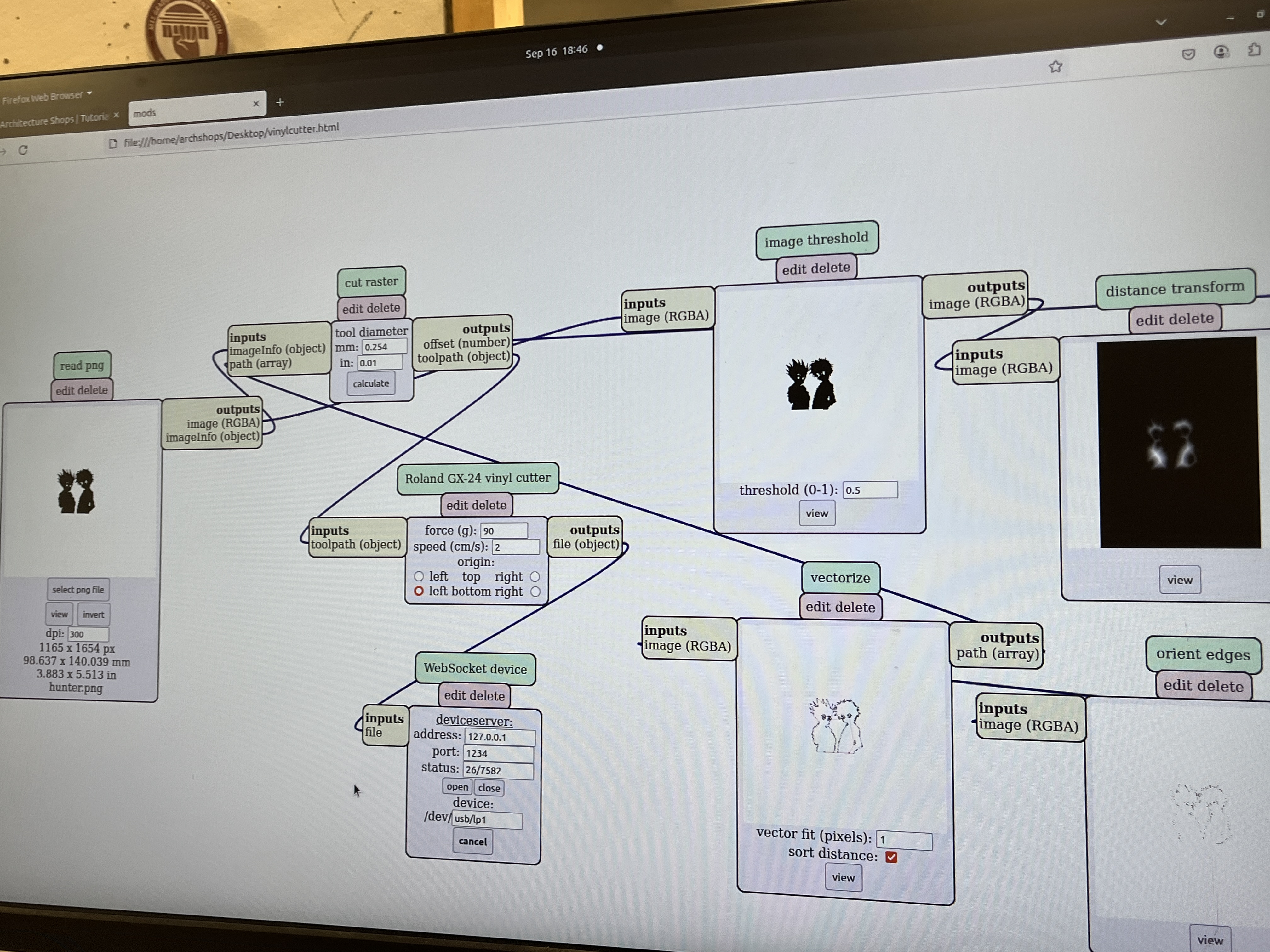

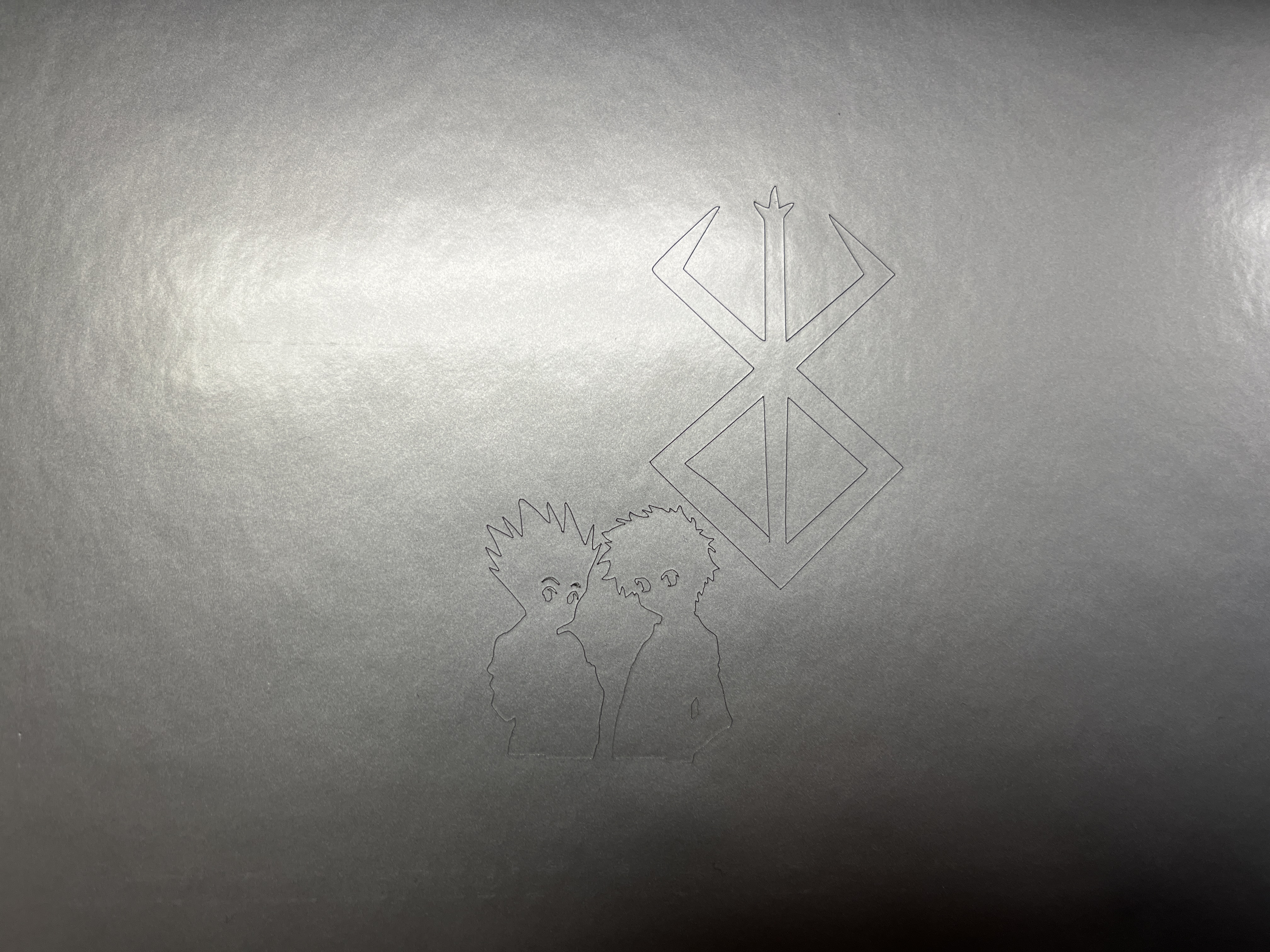

Vinyl Cutter

For this part of the assignment, I cut the silhouettes of my favorite anime characters — Gon and Killua from HUNTER × HUNTER. This experiment was not only a technical test of the vinyl cutter but also a way to bring in a more personal and playful element to the fabrication process.