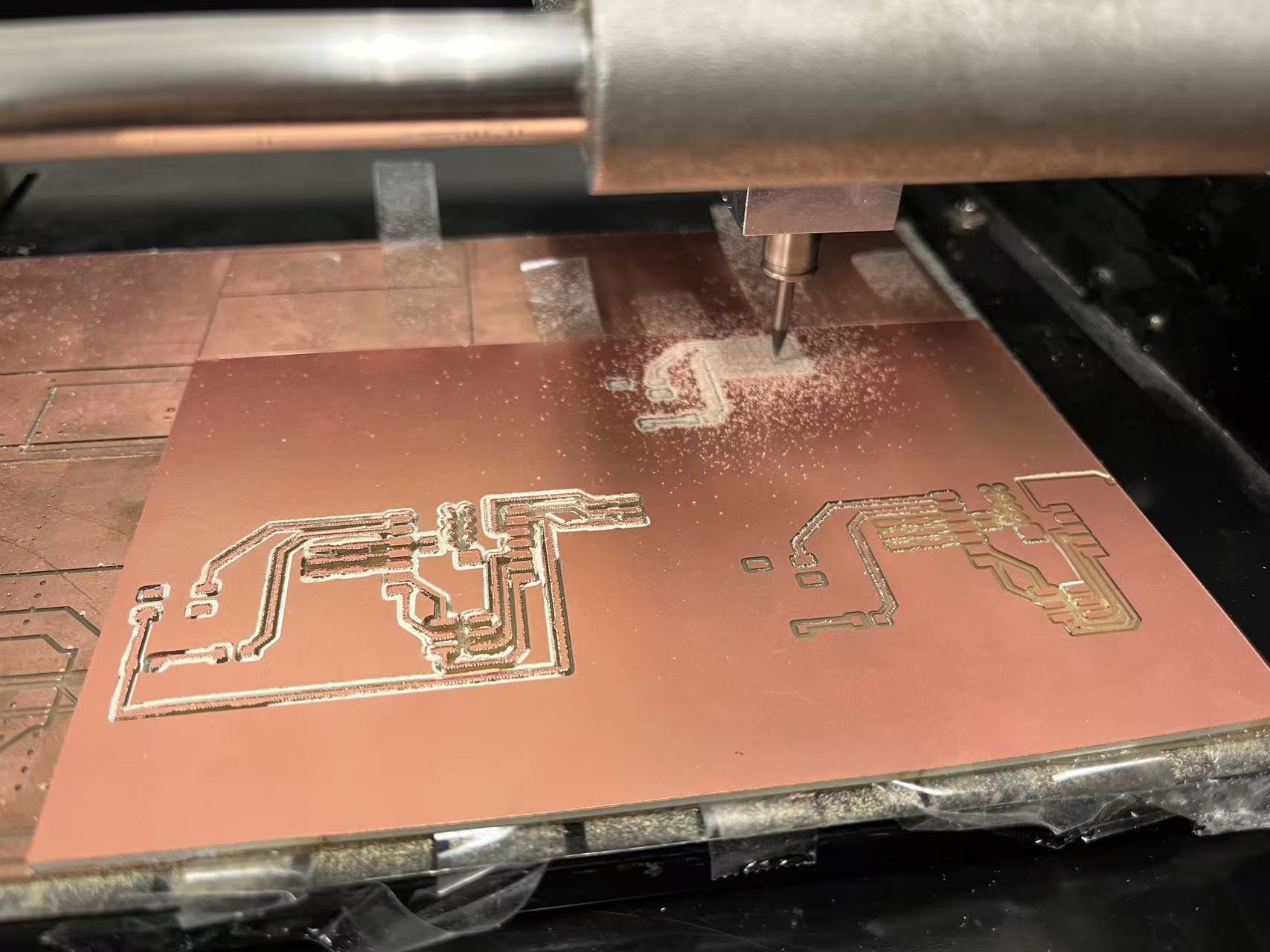

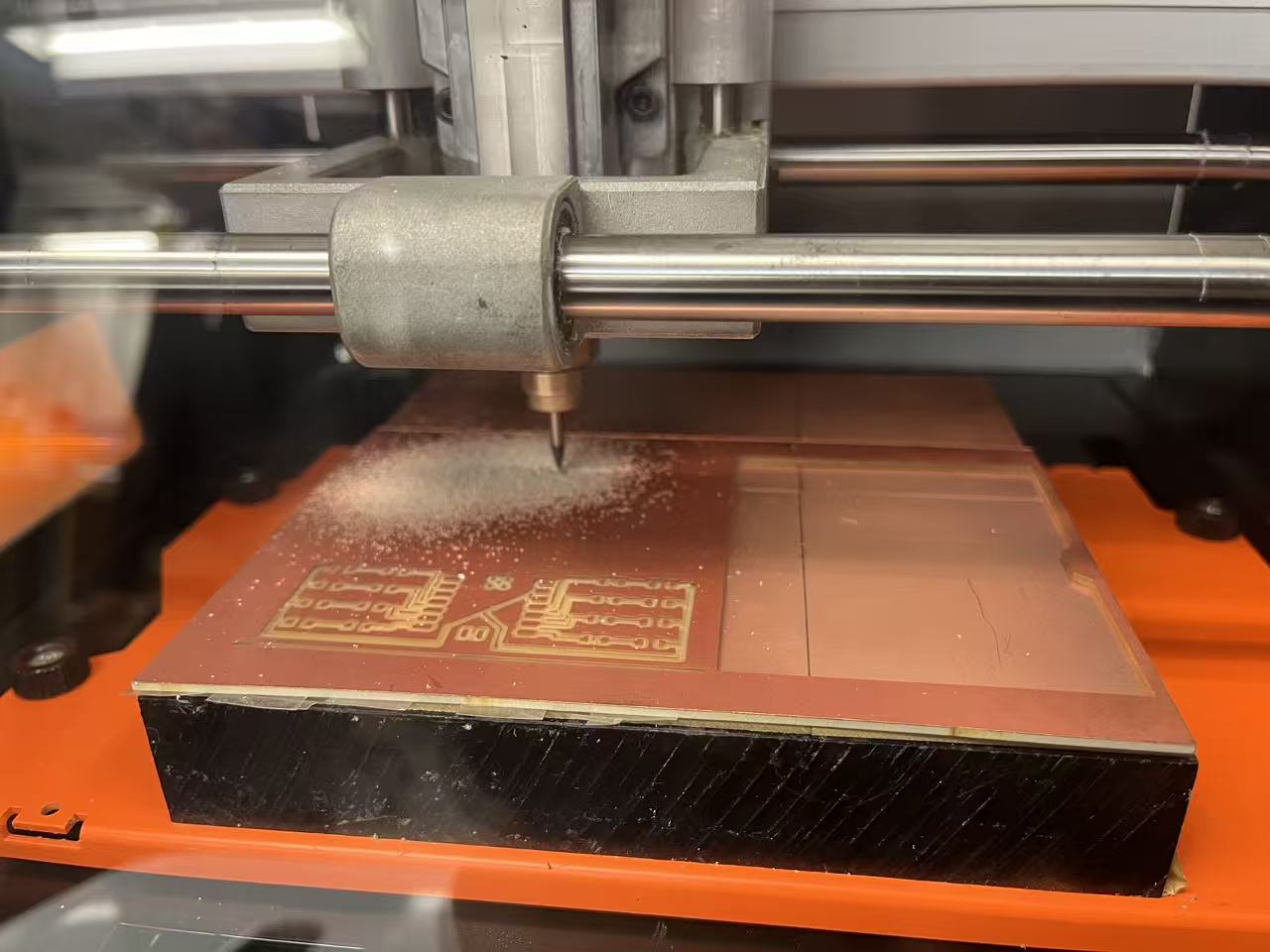

This week was about turning PCB designs into real boards. As a group we characterized our in-house PCB design rules and sent a reference design to a board house. Individually, I went through several failed milling attempts before finally producing and testing my own microcontroller board.

Assignments

- Group: characterize in-house PCB design rules; submit a PCB to a board house.

- Individual: make and test an embedded microcontroller board that I designed.

Group assignment (1–3)

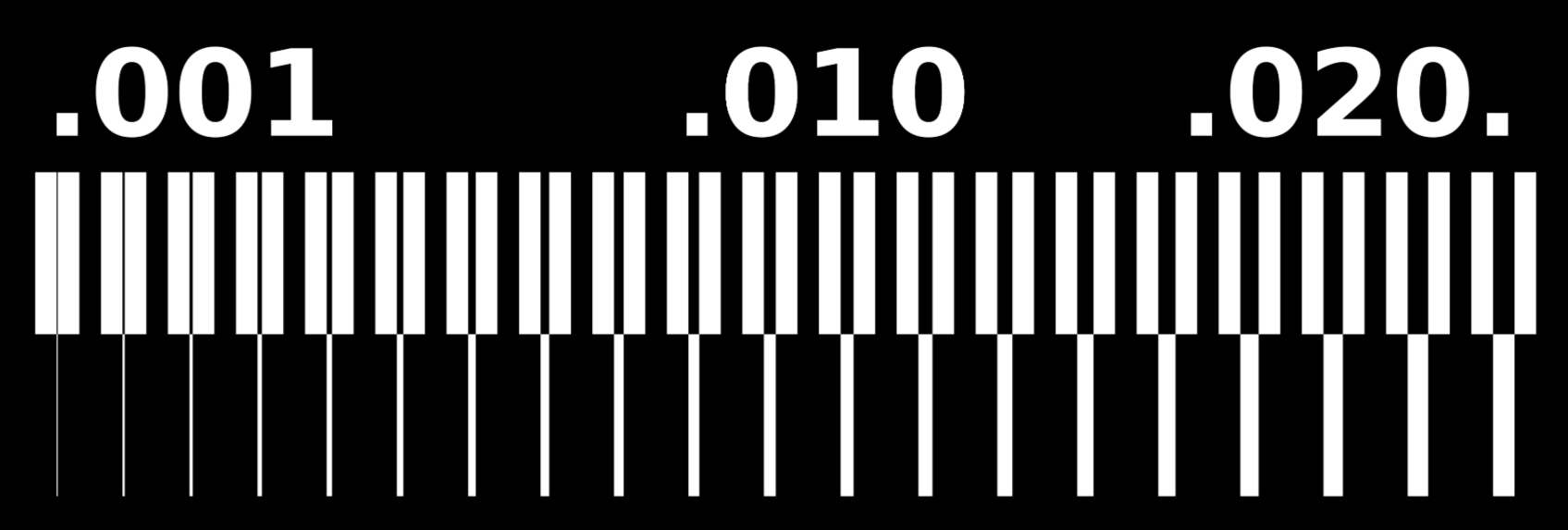

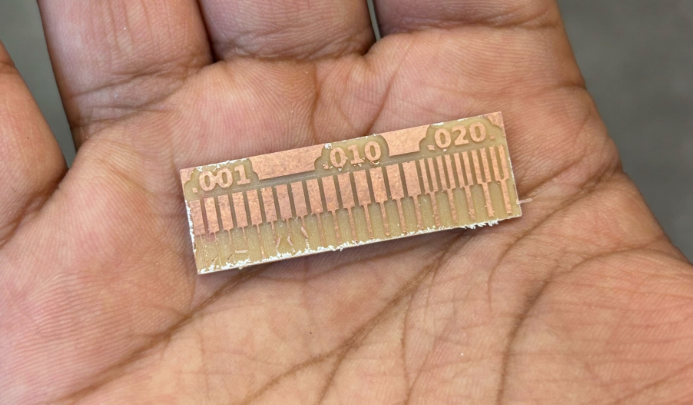

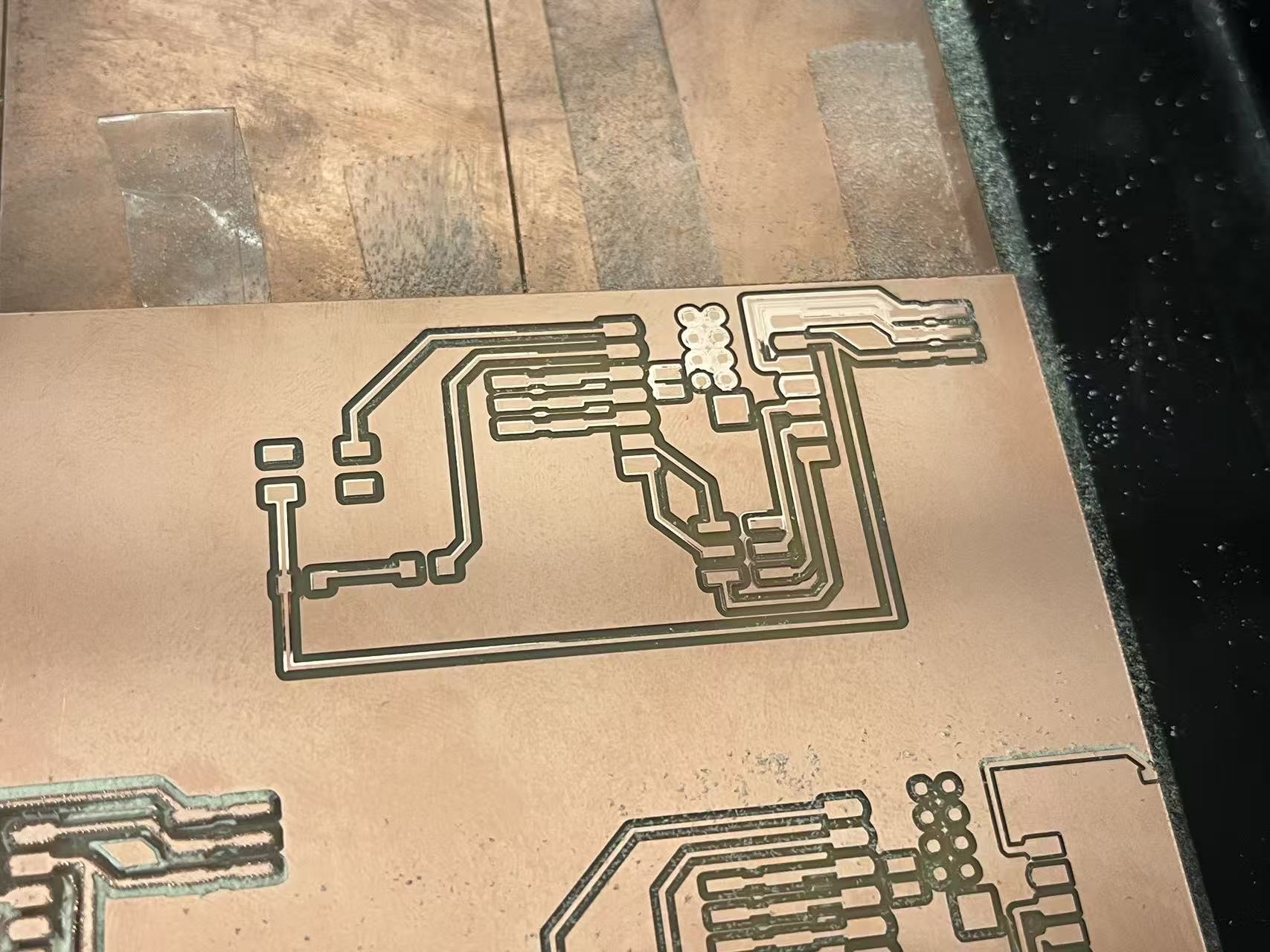

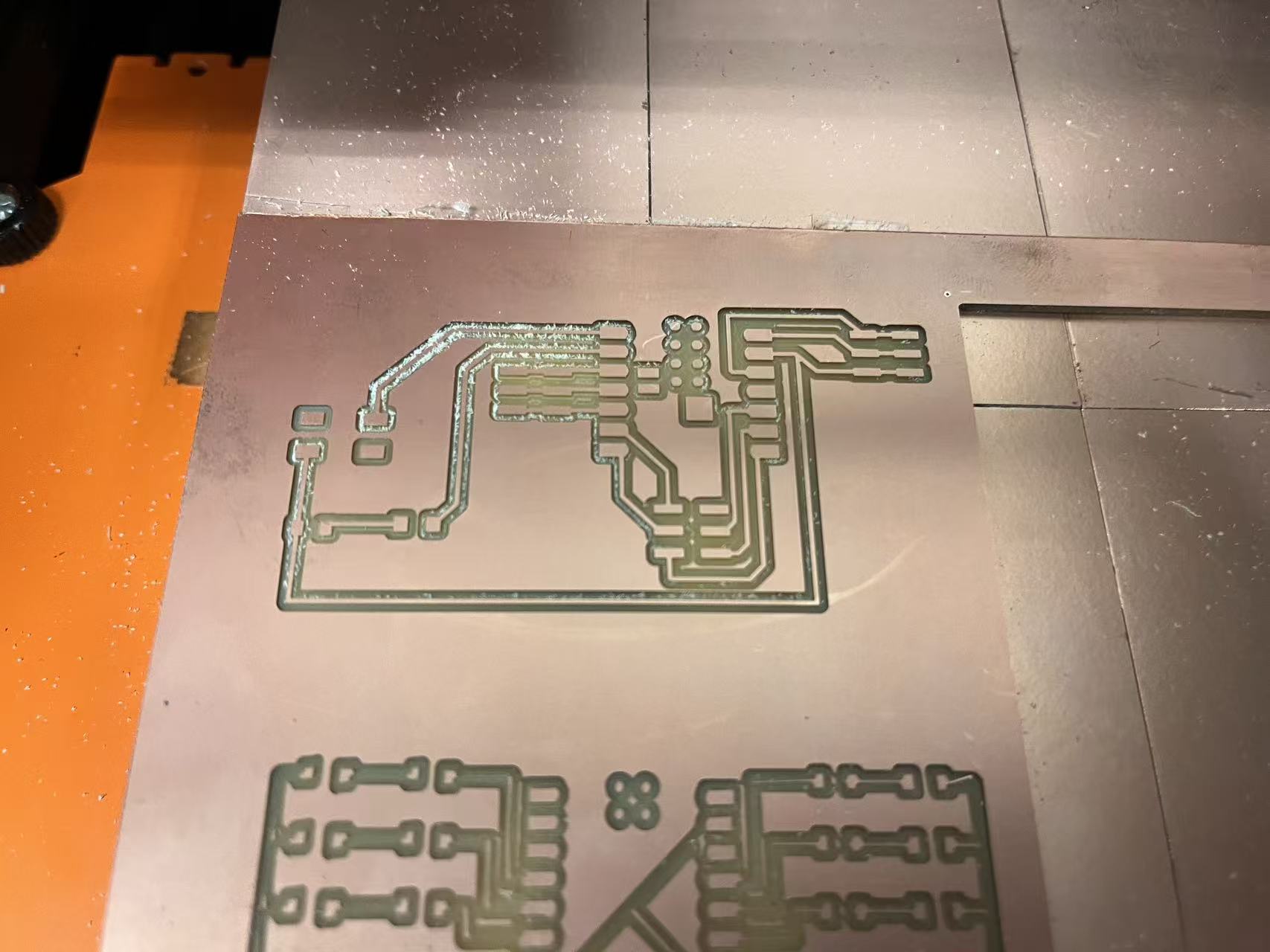

We ran a design-rules check for our in-house mill: measured trace/space and clearance using a calibration ruler, then confirmed what reliably cuts on our copper stock with 1/64″ and 1/32″ tools. In parallel, we exported a reference PCB (Gerbers/NC drill) and submitted it to a board house to compare finish, mask, and solderability.

Individual assignment (4–20)

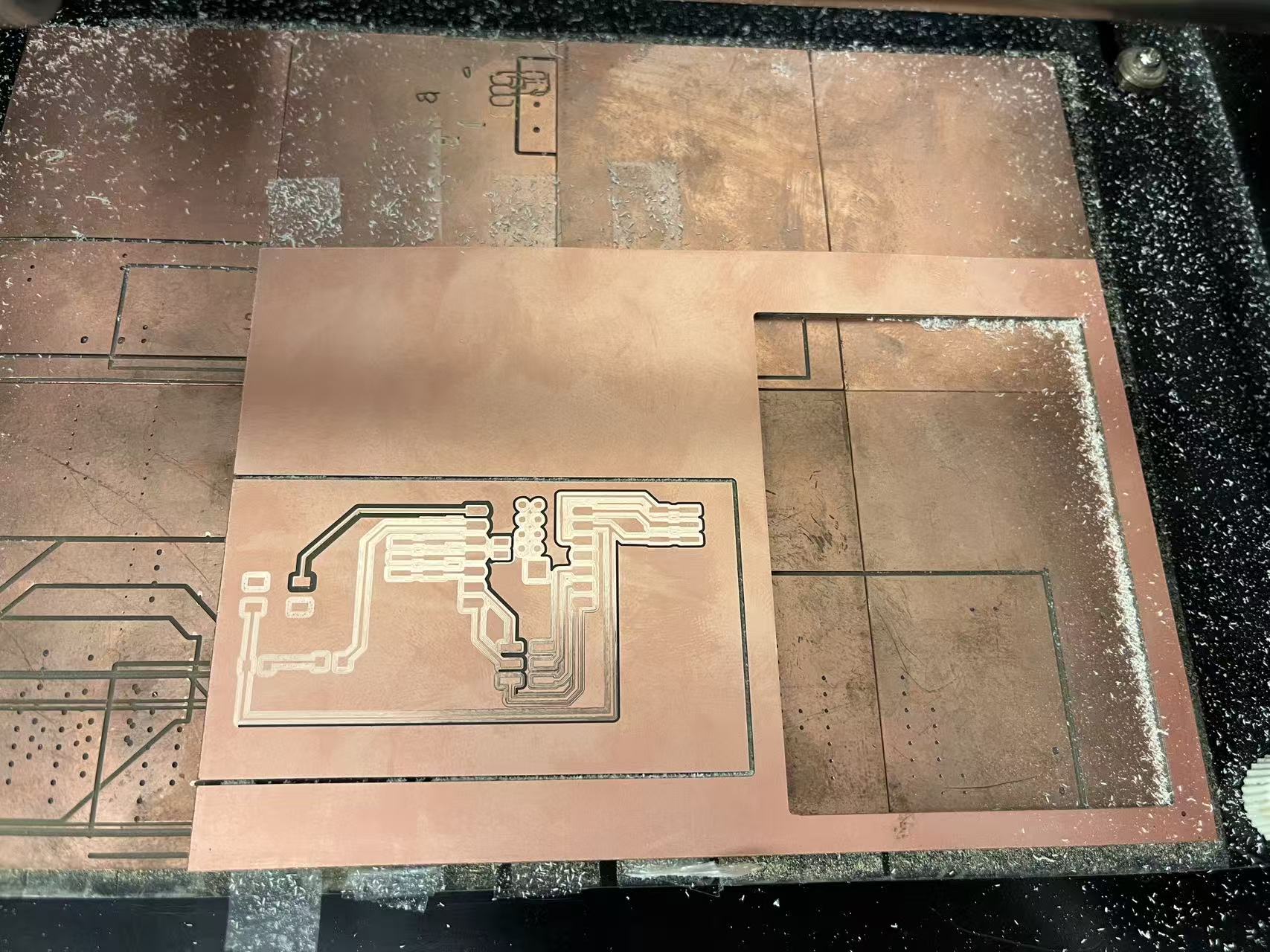

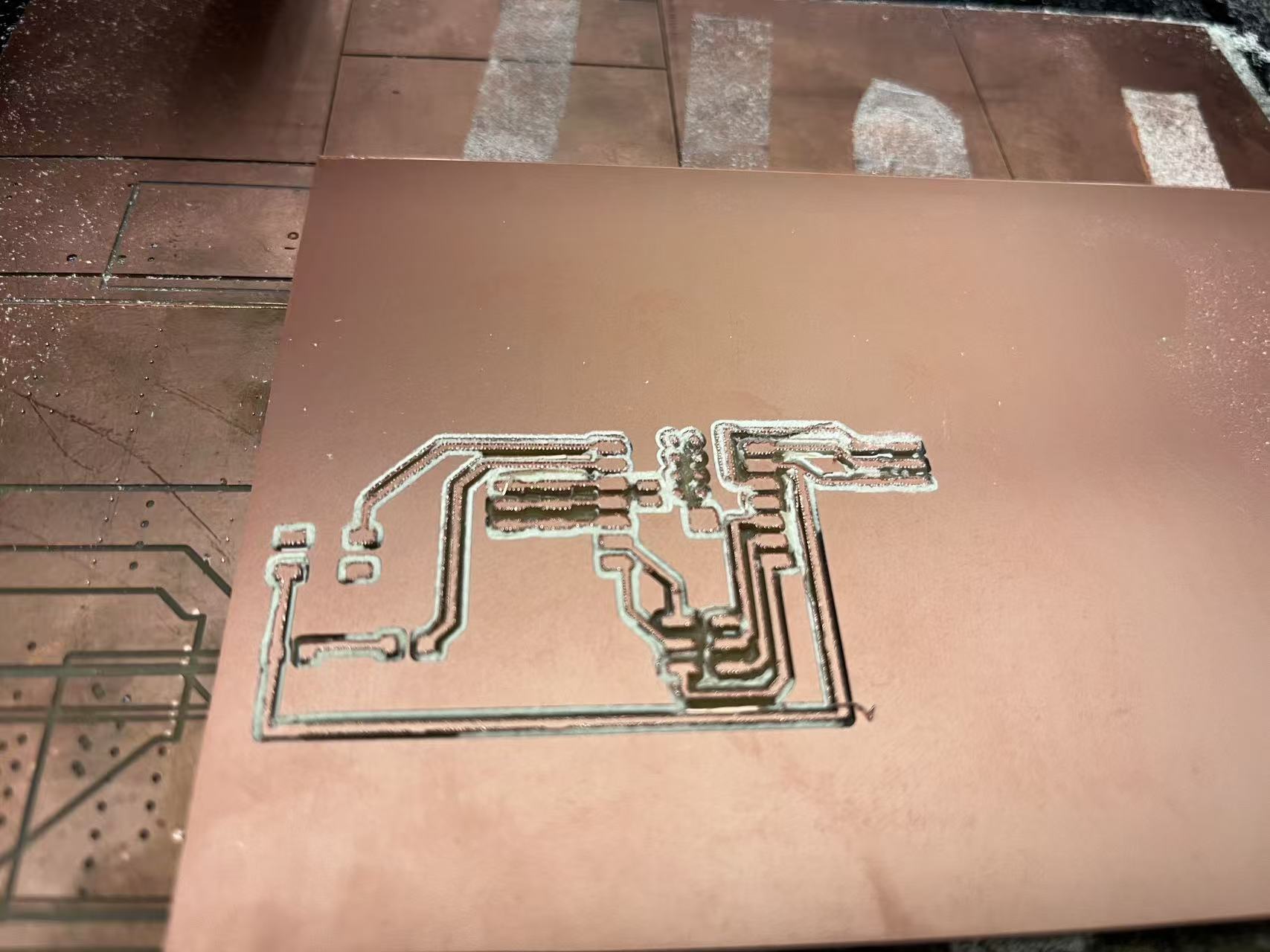

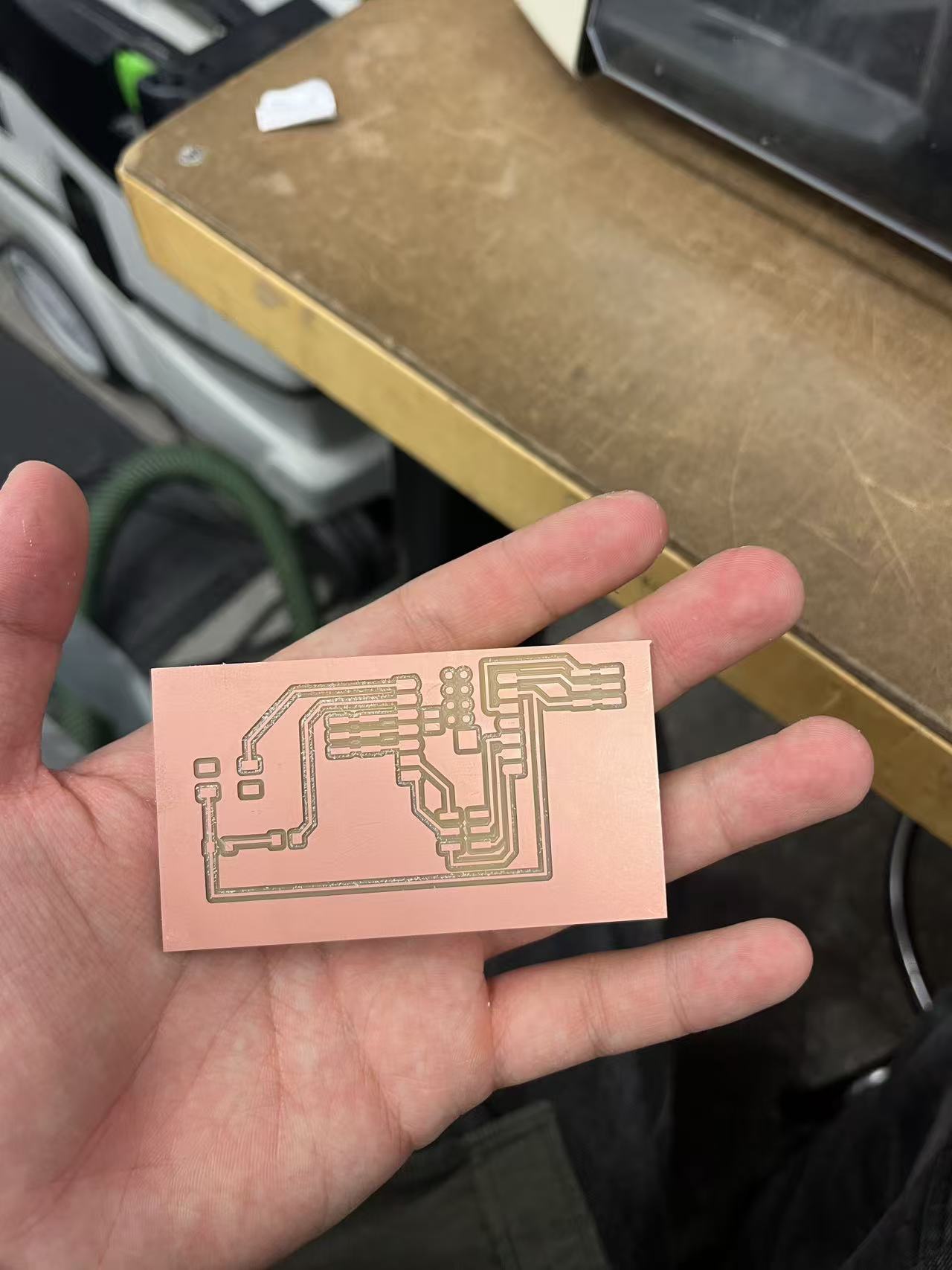

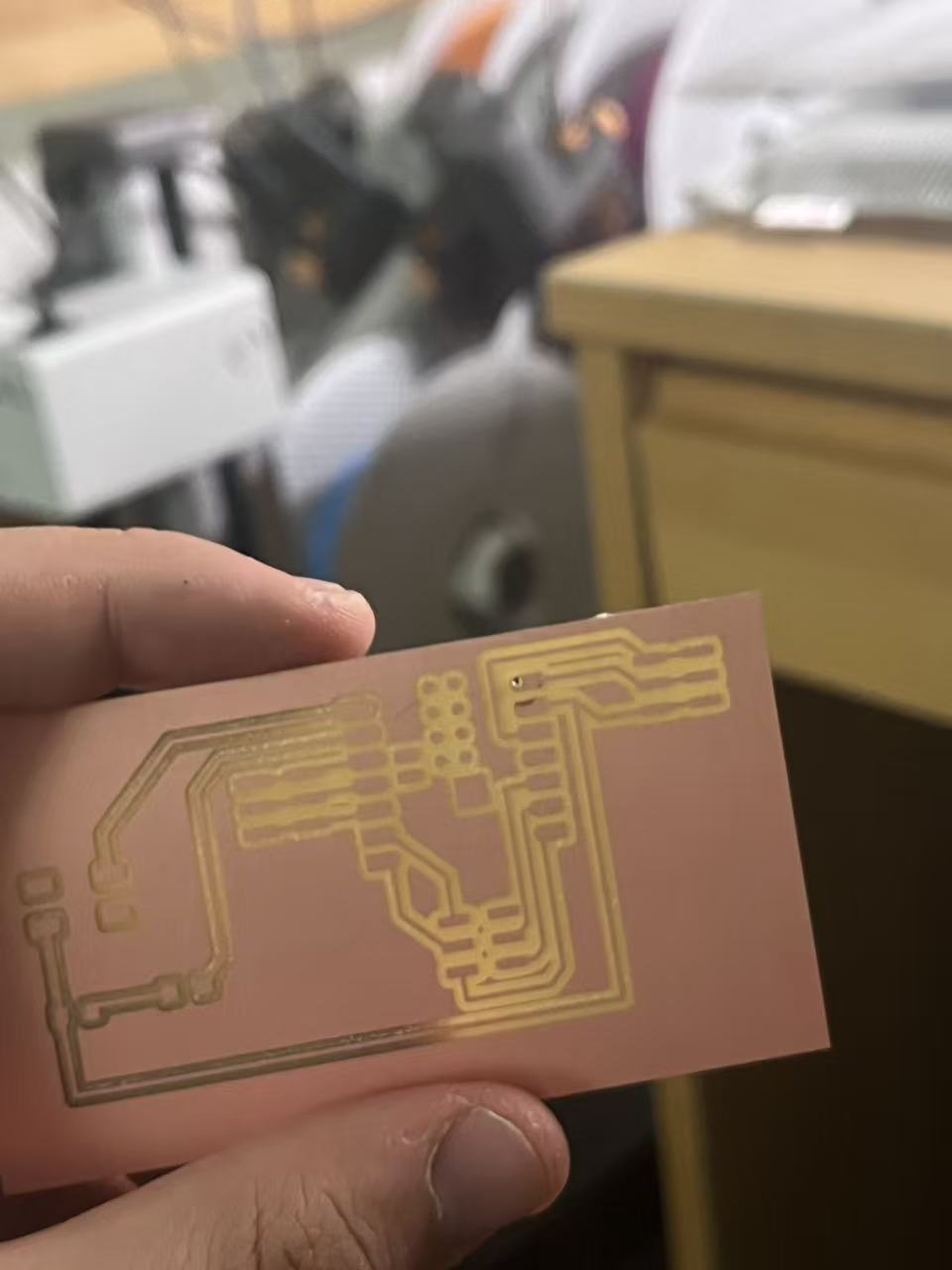

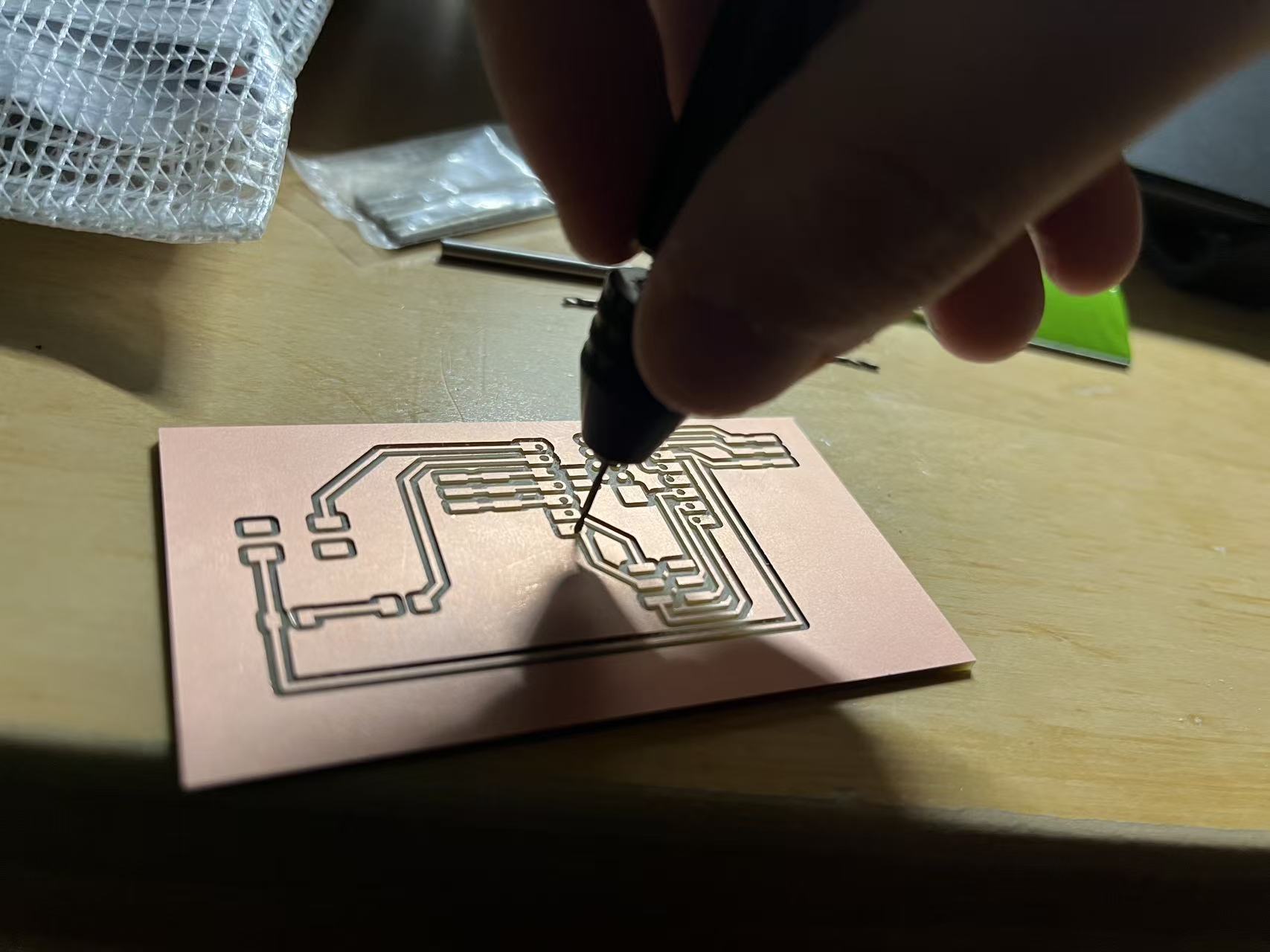

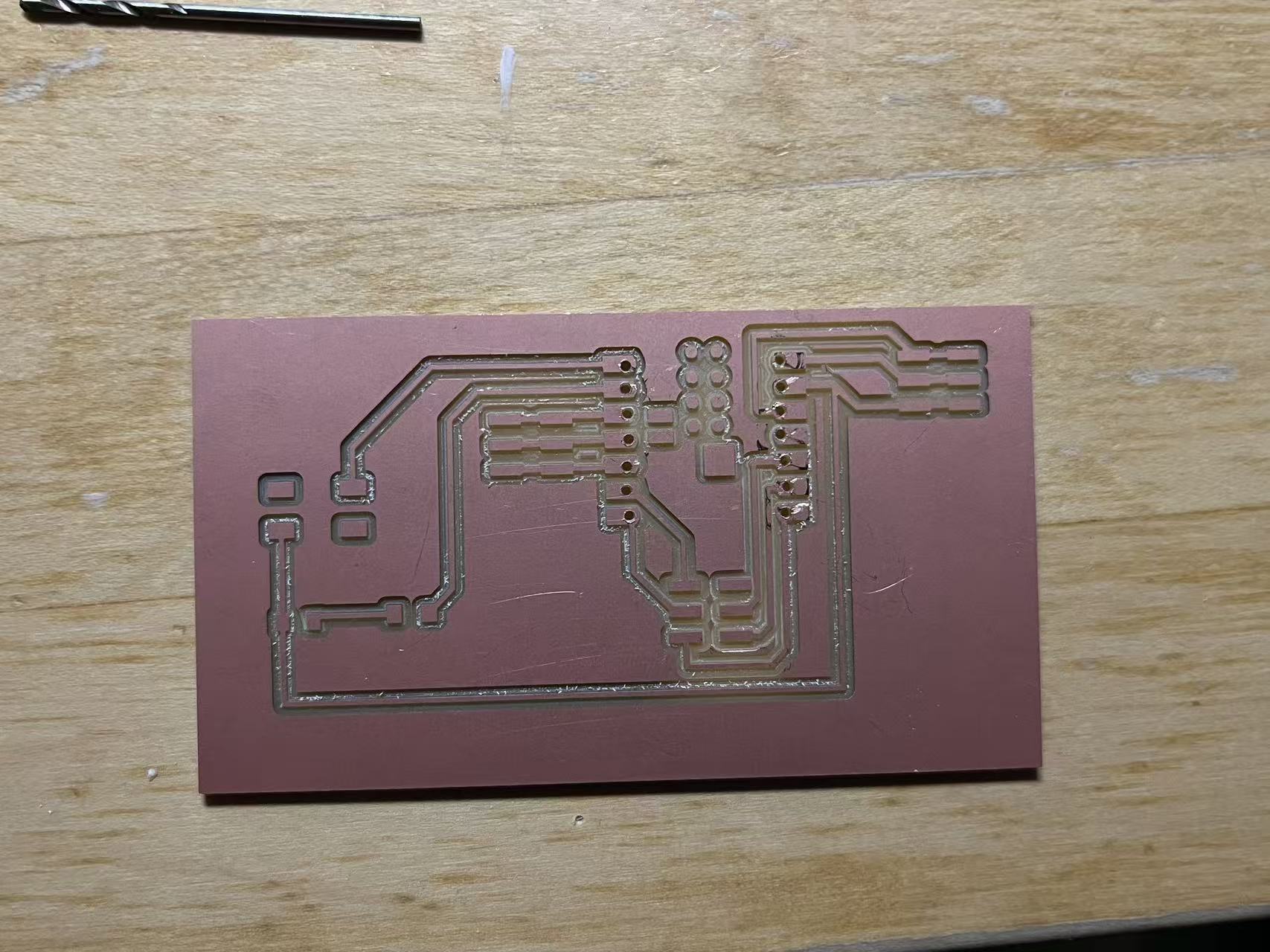

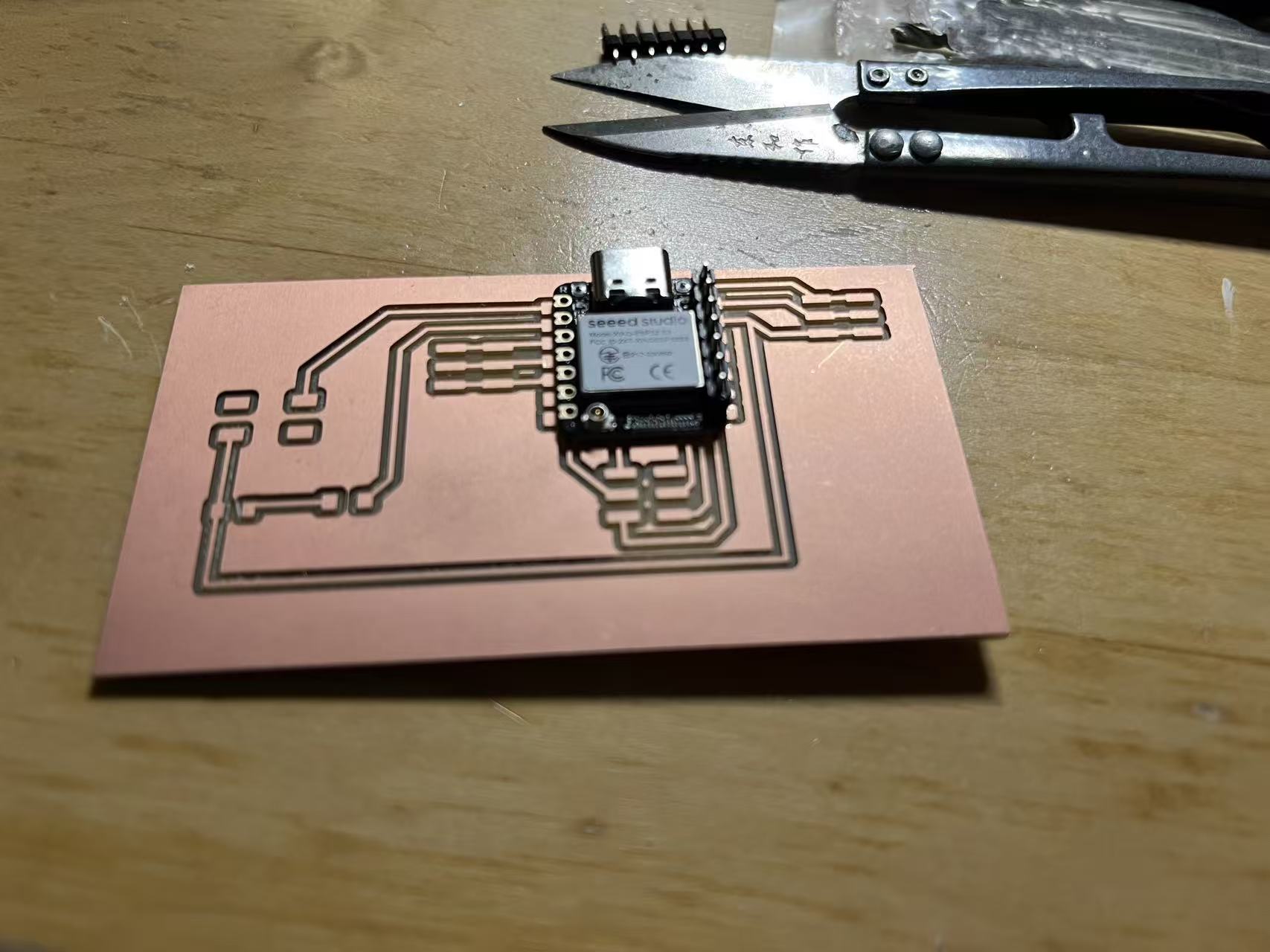

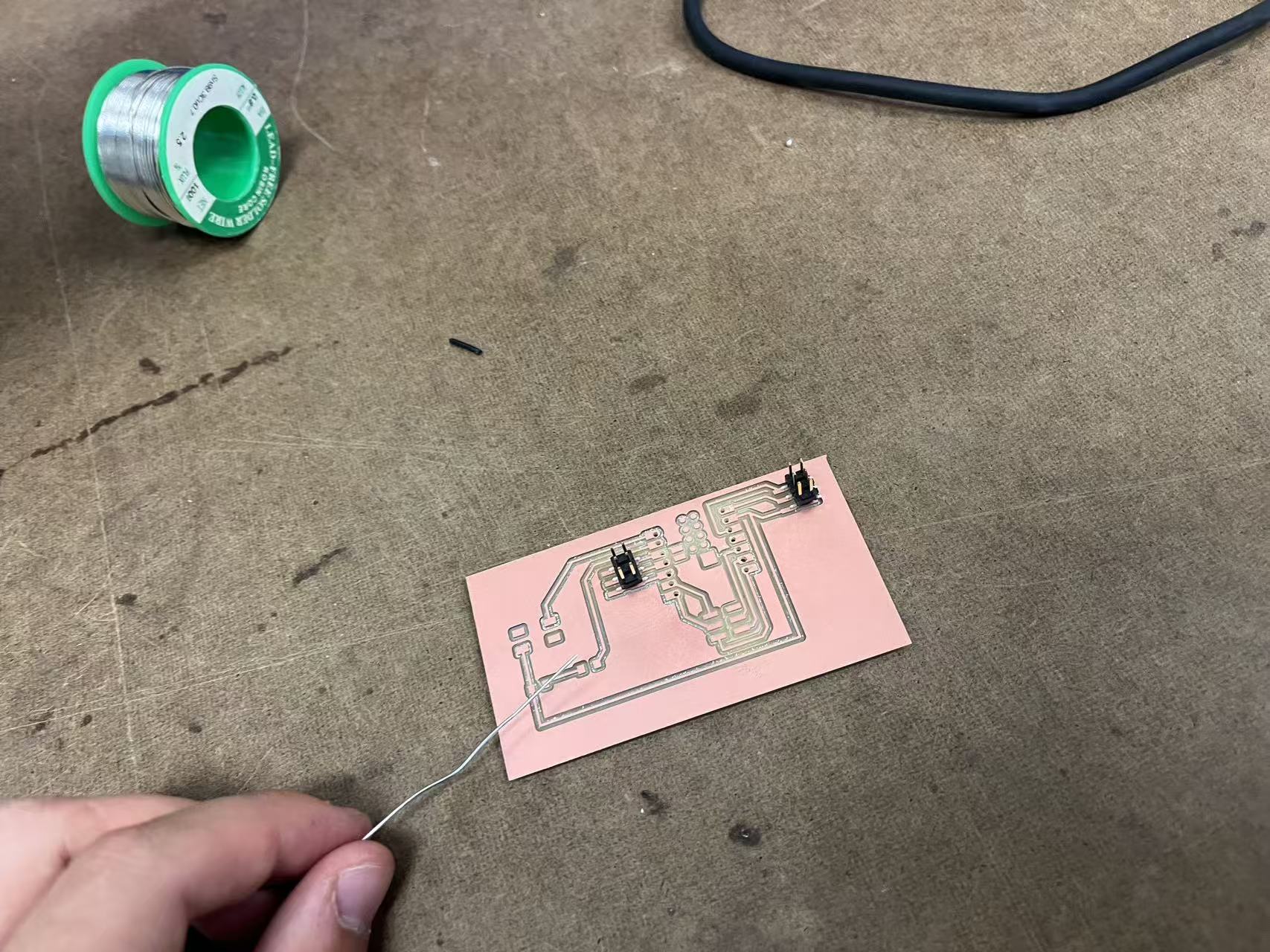

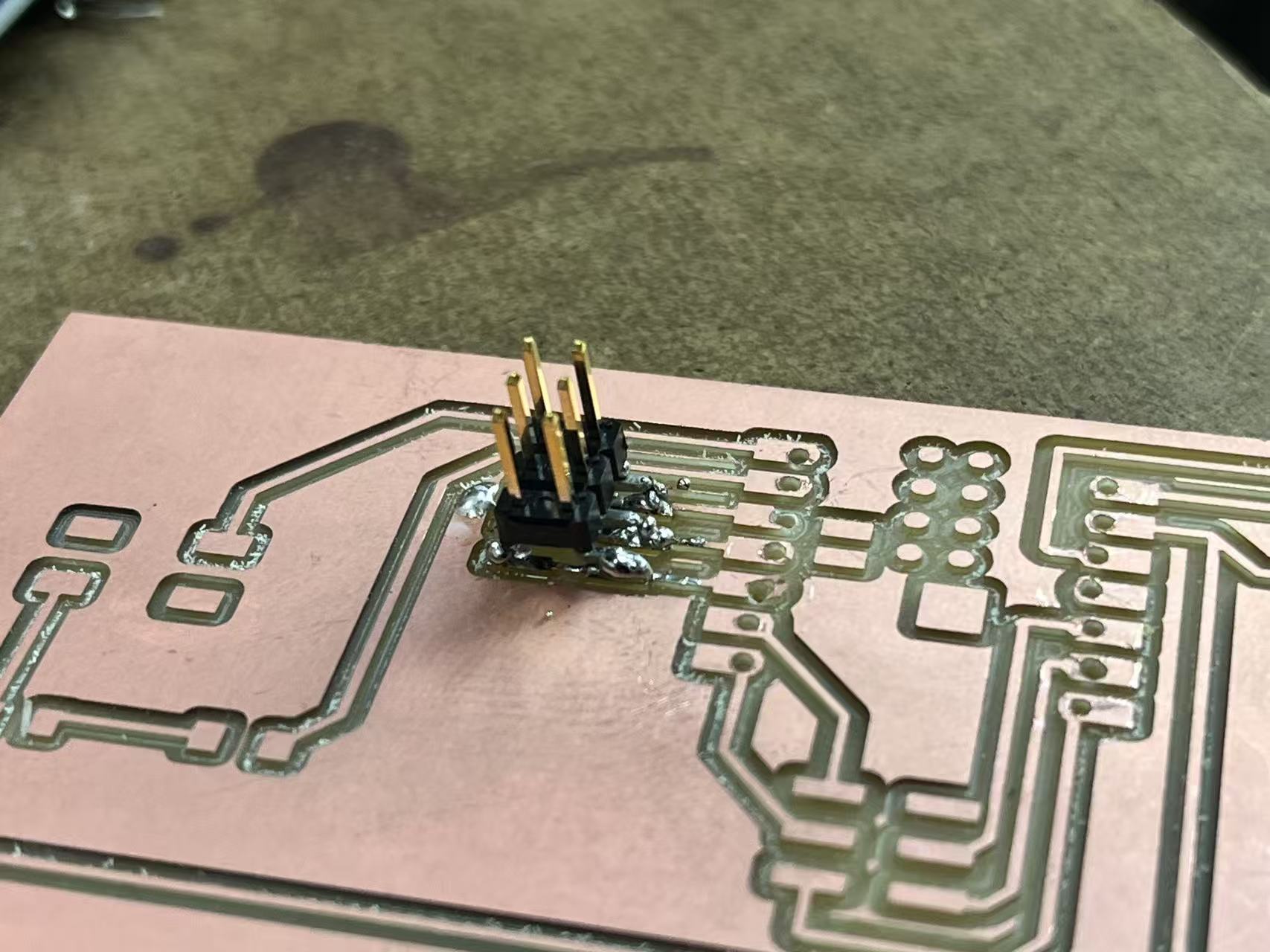

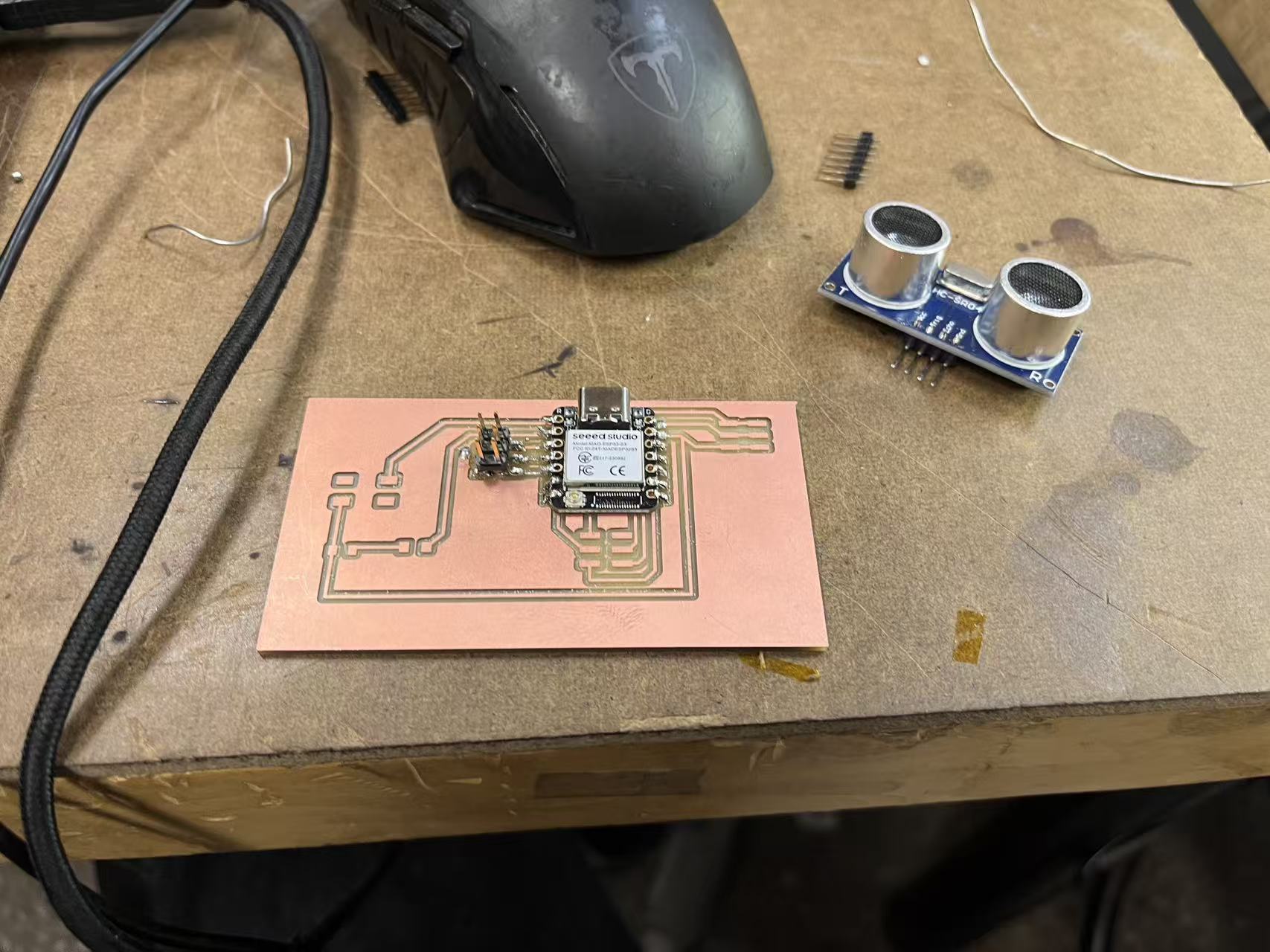

For my own board, I tried to mill a small microcontroller design. I failed multiple times: poor Z-zeroing, worn bits, traces peeling during cleaning, and a couple of shorts from copper dust. After re-leveling the sacrificial layer, replacing the 1/64″ tool, slowing the feed, and increasing clearance in CAM, the board finally milled cleanly. I deburred, checked continuity, then soldered the components and verified power, reset, and USB/UART communication.

Notes

Stable recipe on our mill: 1/64″ for traces at shallow DOC with a new bit; 1/32″ for outlines; vacuum + brush mid-cut to reduce shorts from dust; IPA wipe after milling; quick continuity check before soldering. Most of my early failures were about Z-height and worn tools, not the design itself.