This week was about full-scale subtractive fabrication: learning how to safely run the shop’s CNC router and using it to mill something big. For the group part we characterized the machine and cutting parameters. For the individual assignment I designed and built a flat-pack wooden stand for my architecture models.

Assignments

- Group: lab safety training; test runout, alignment, fixturing, speeds/feeds, materials, and toolpaths.

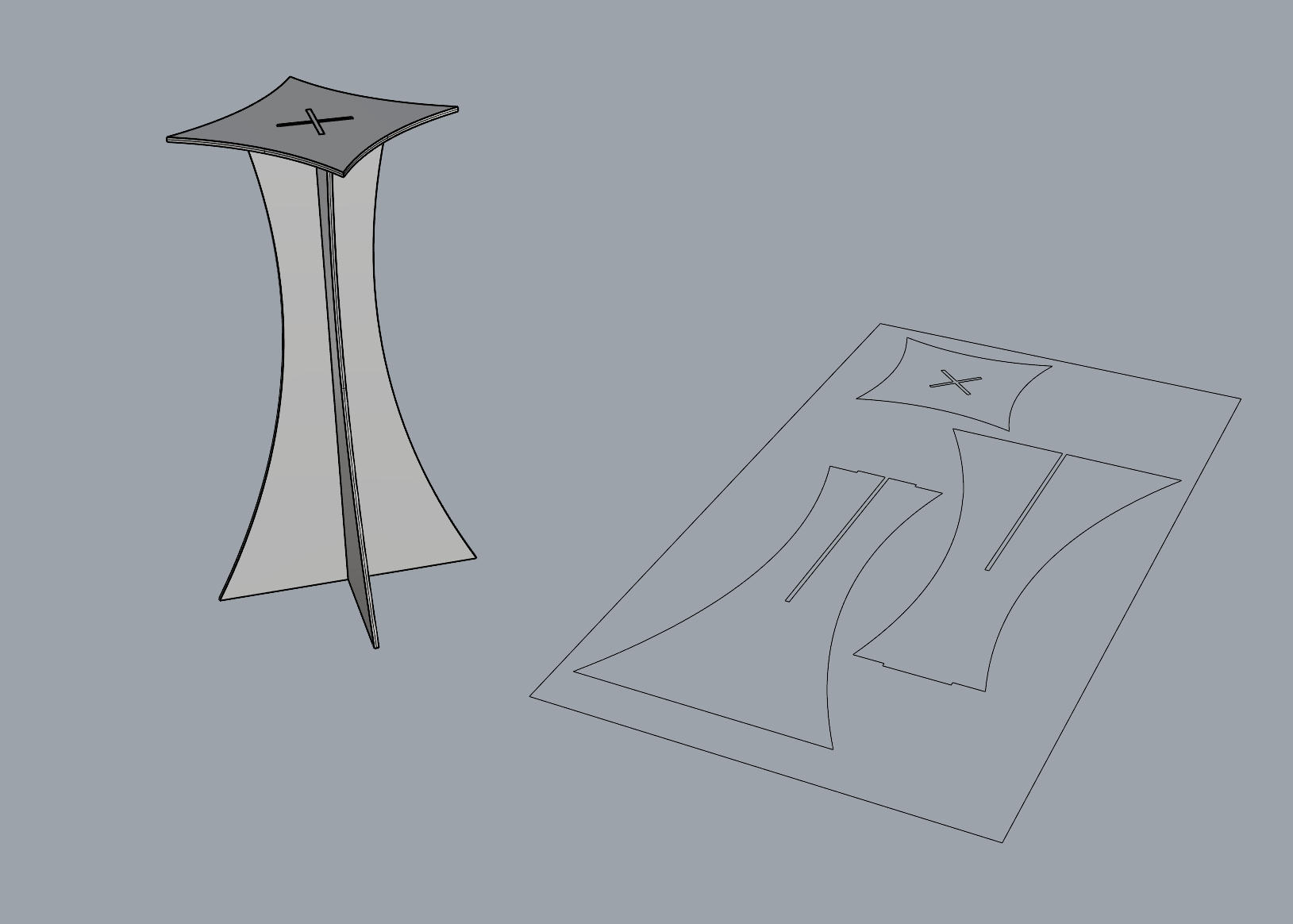

- Individual: design, mill, and assemble something big (~meter scale). I made a wooden model stand.

Group assignment (1–6)

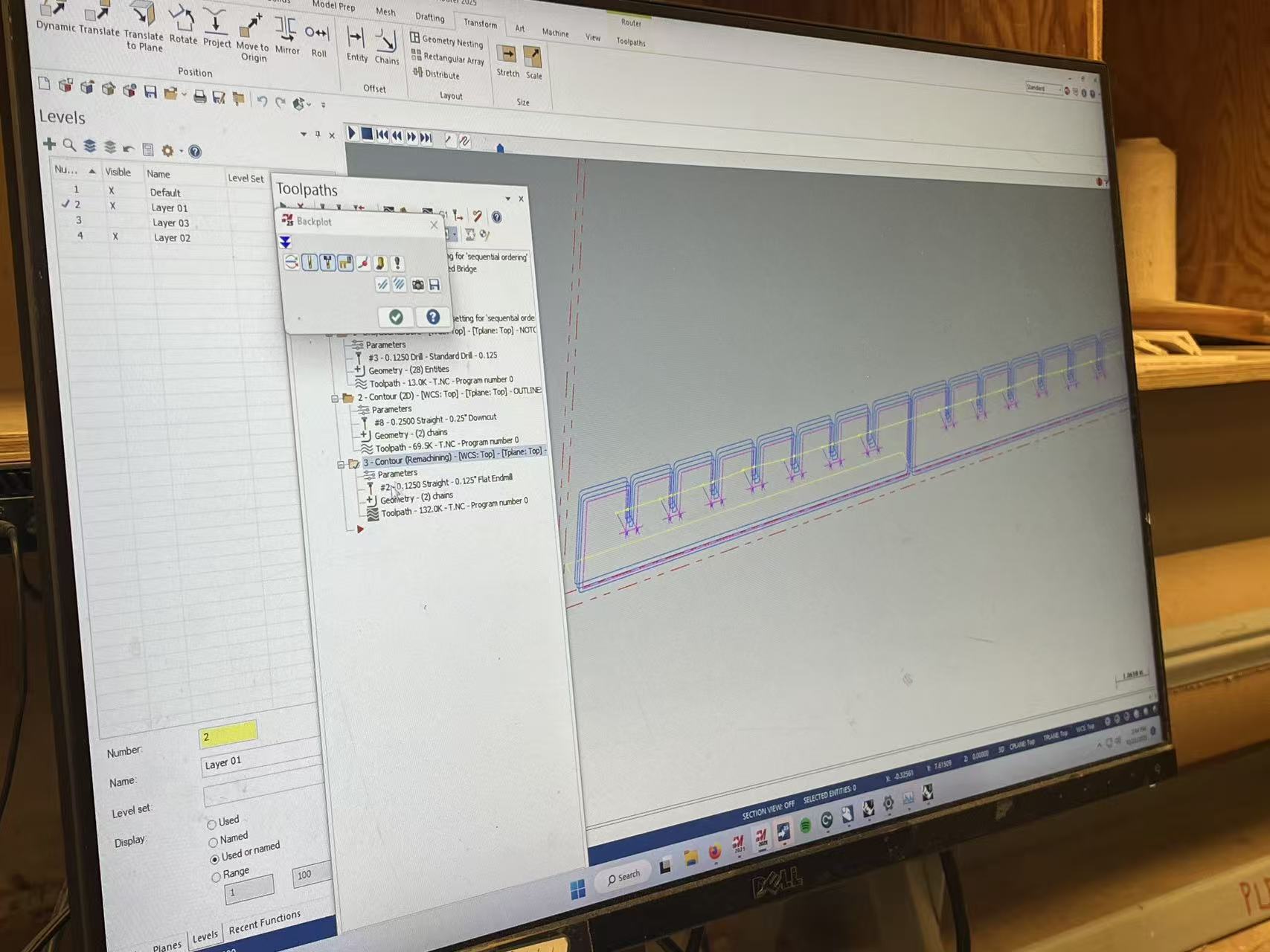

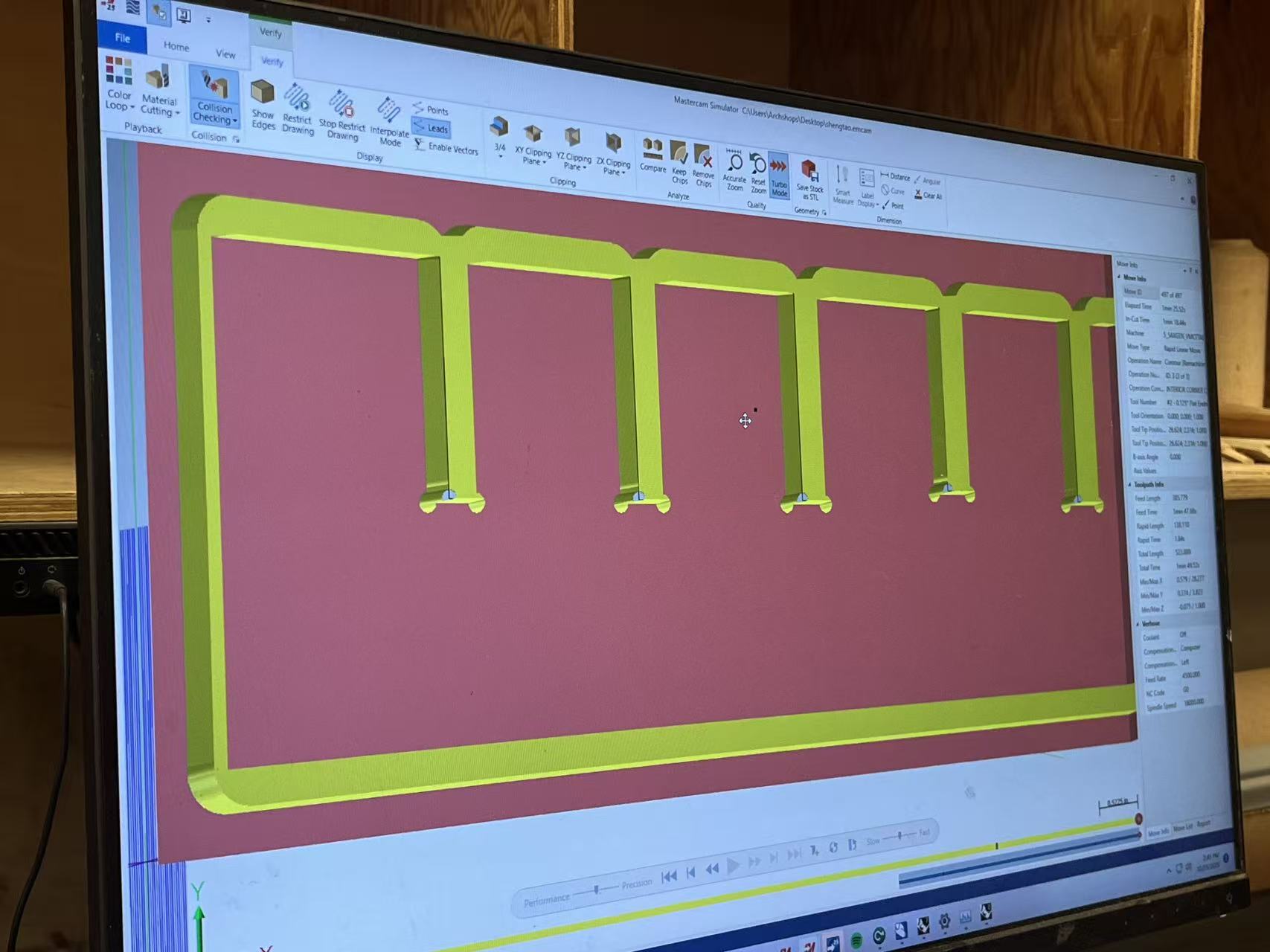

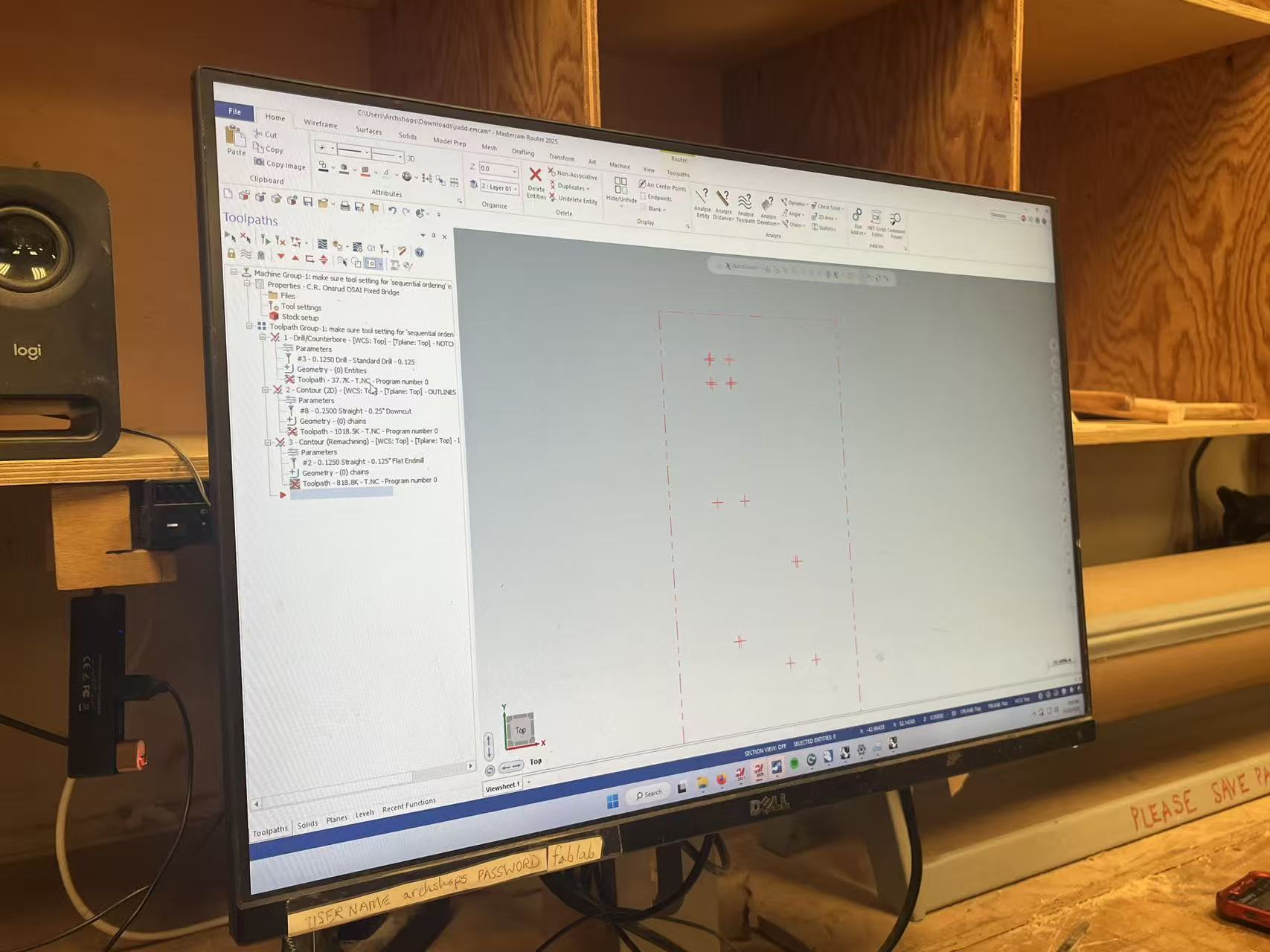

I was traveling during the main lab session, so I completed the group work later with Chris. We walked through safety, checked spindle runout and alignment, tried different fixturing strategies, and cut a series of test toolpaths on plywood/OSB using a 1/4" end mill to see how different feeds, speeds, and depths of cut behaved.

Individual assignment — flat-pack model stand (7–22)

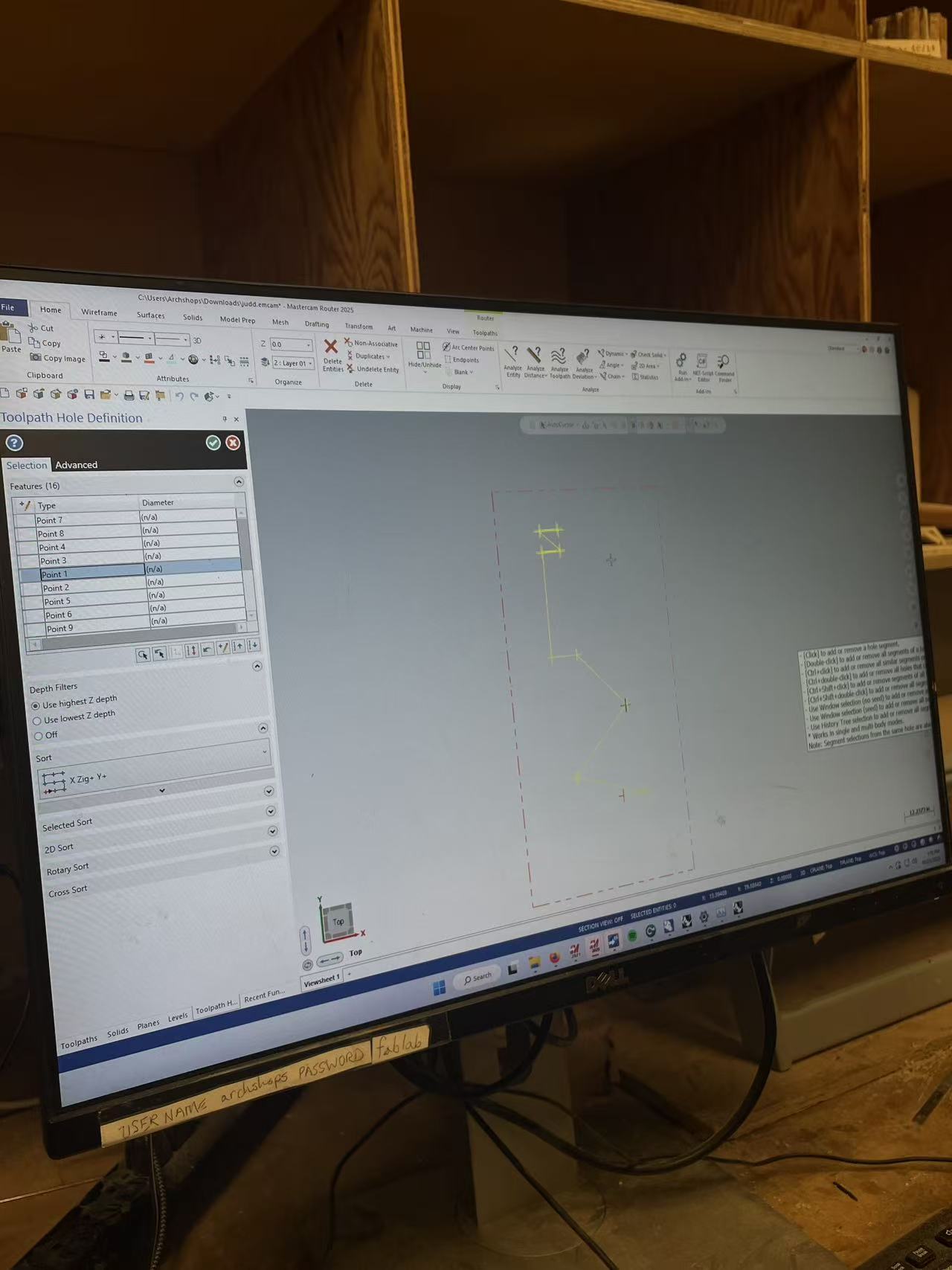

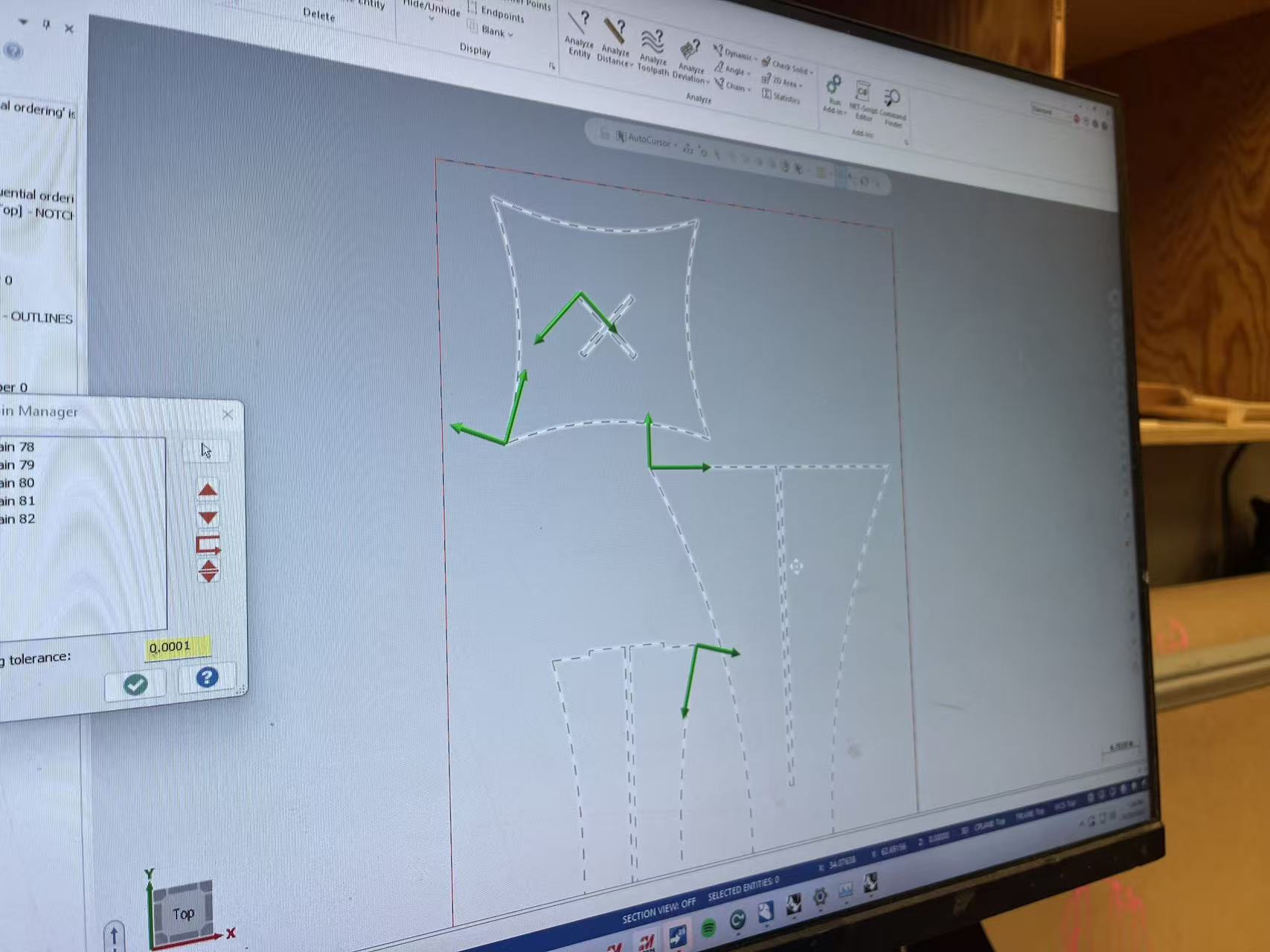

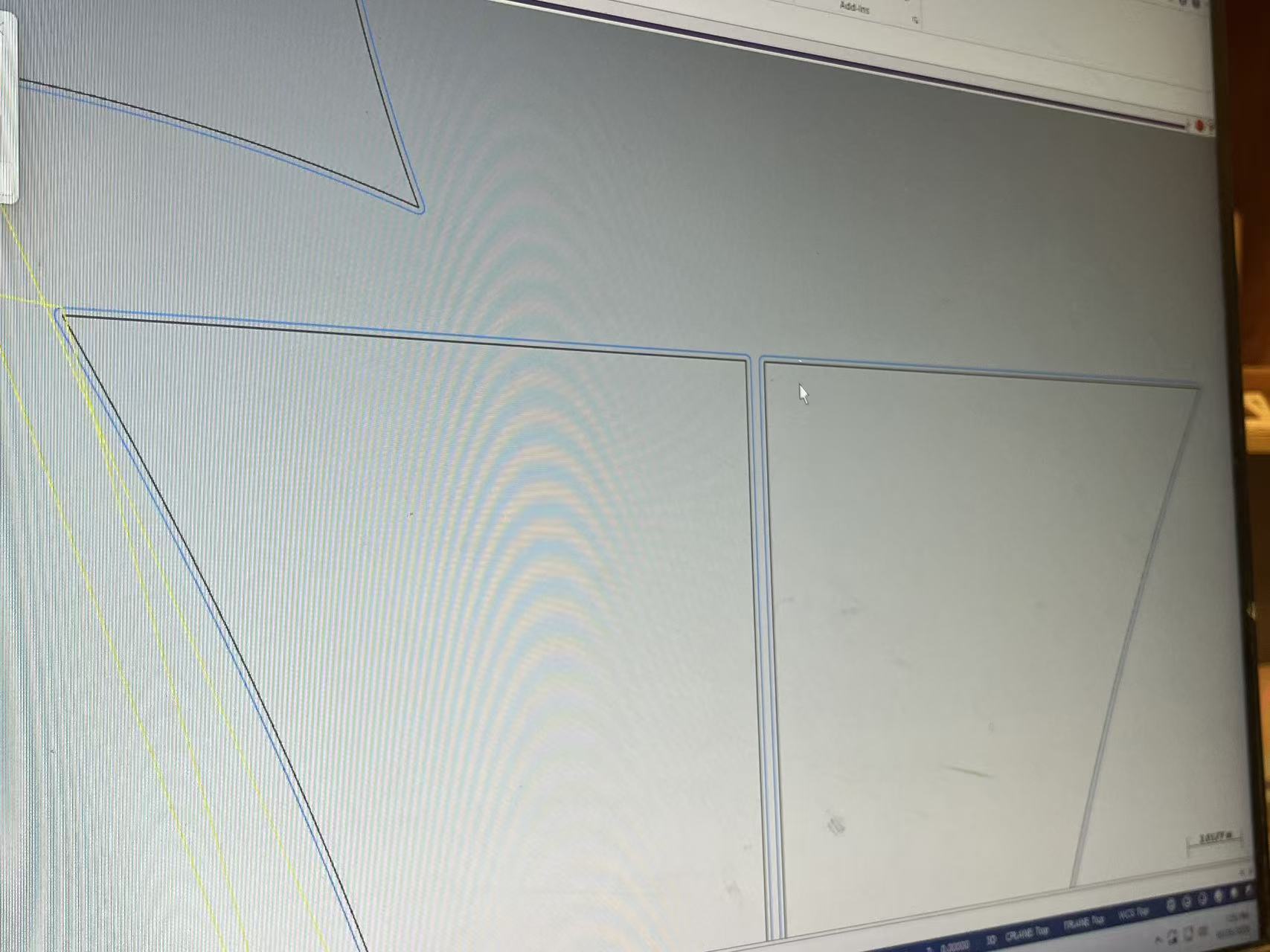

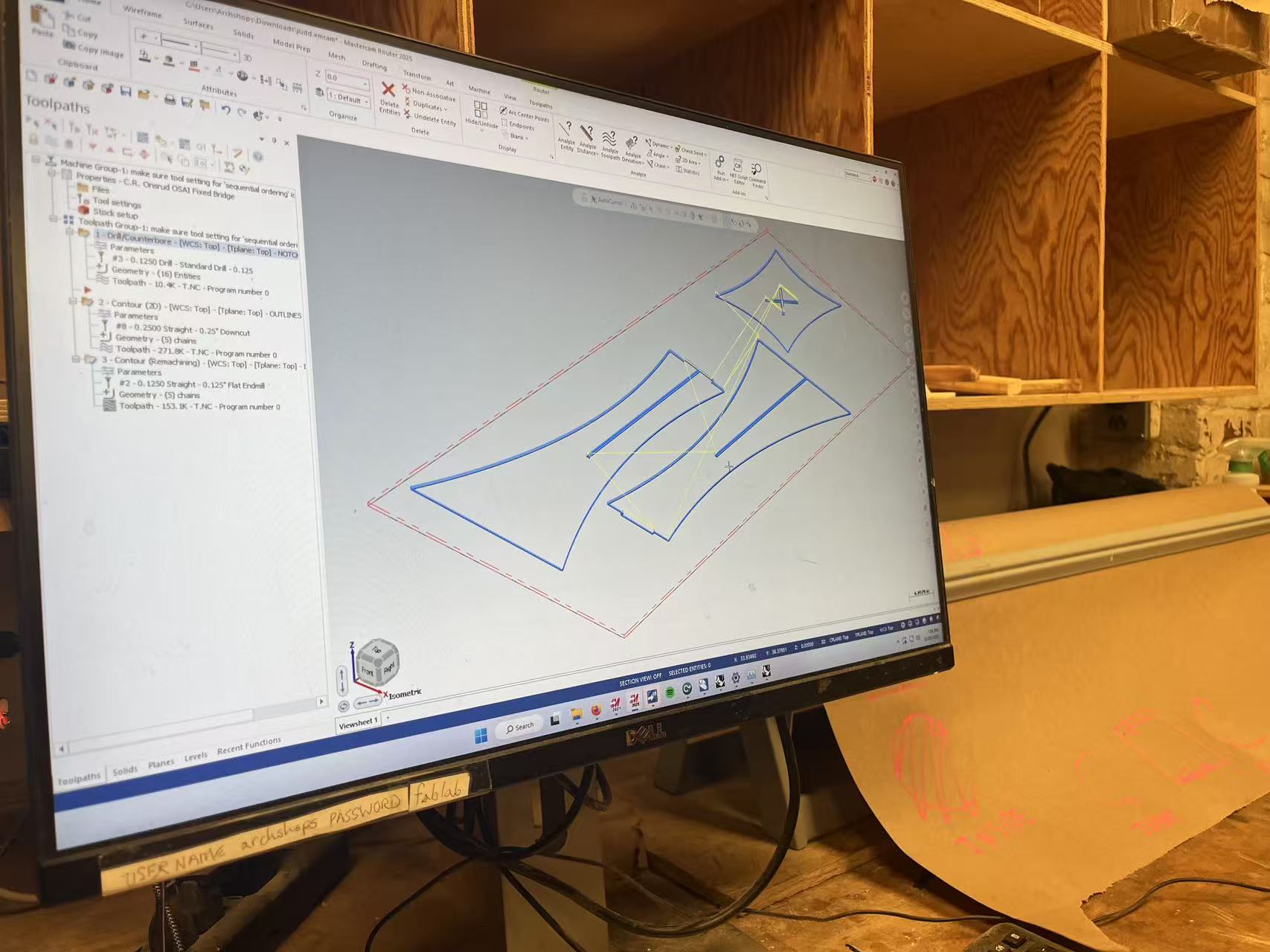

For my own piece, I designed a flat-pack model stand. The idea was to have something that could be milled from a single sheet, assembled without glue in the lab, and later reconfigured in studio. Key steps: measure the real plywood thickness, set parametric joints, add dog-bones to inner corners, plan tabs and clearances, nest parts, then CAM separate pocket/profile passes for a 1/4" tool.

Notes

Stable recipe: 1/4" end mill, 2–3 mm depth of cut, climb milling for profiles, and generous tabs to keep parts from moving. The most sensitive steps were measuring real material thickness and making sure there was enough clearance in the slots—too tight and assembly becomes a hammer exercise.