This week I focused on input devices: as a group we probed an existing motion-sensor board with an oscilloscope, and individually I connected a PIR sensor to my own board and read it from firmware. The goal was to see real analog/digital behavior on the scope, then close the loop with code running on my microcontroller.

Assignments

- Group: probe an input device’s analog levels and digital signals.

- Individual: measure something — add a sensor to a microcontroller board I designed, and read it.

Group assignment (1–3)

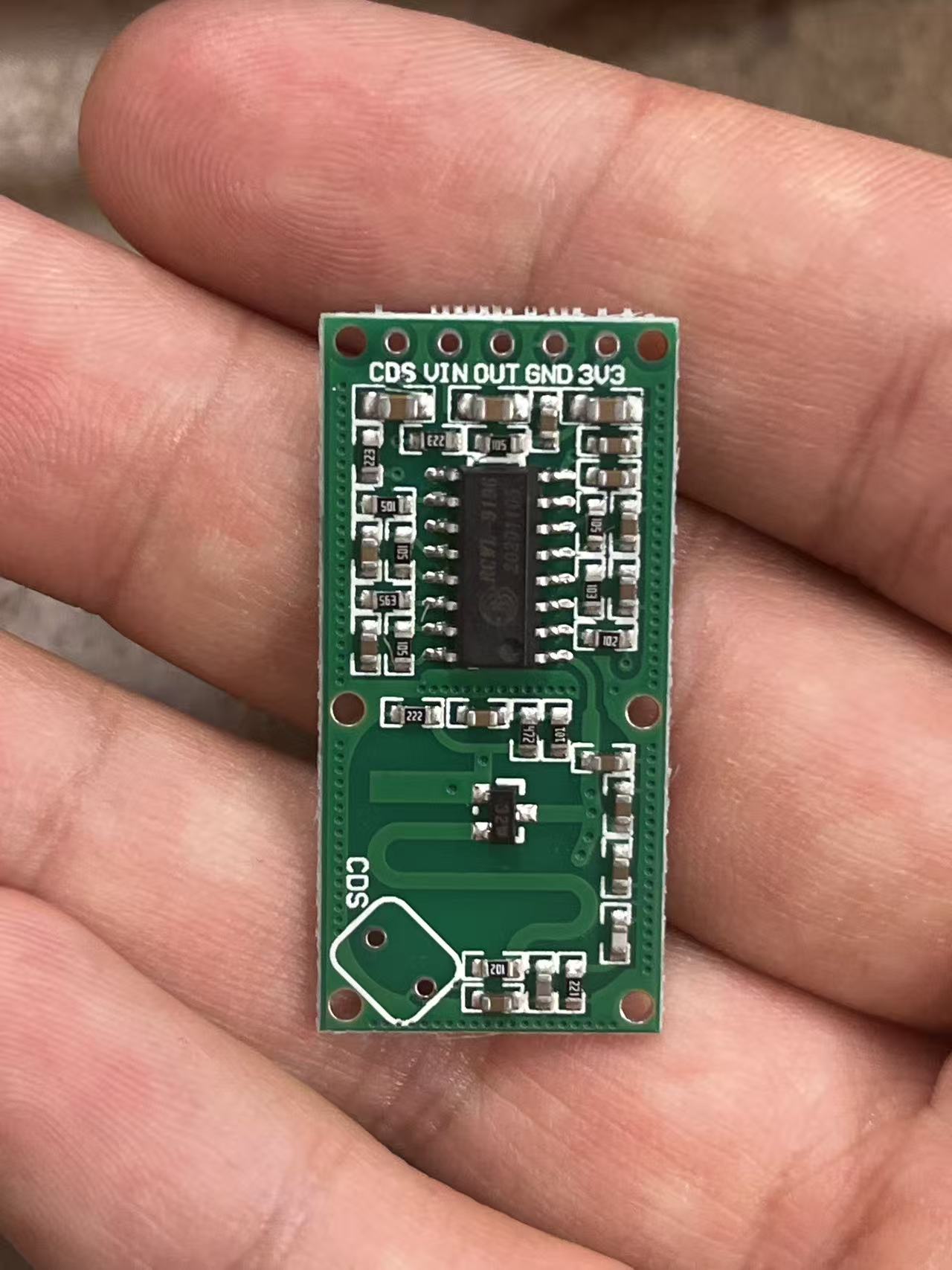

We used the oscilloscope to examine a motion-sensor board. Following the clock line helped us understand the timing; we also probed several random GPIO/test pads. Some pins showed noticeably higher switching frequencies than others, which suggested different sub-circuits (clocked logic vs. slow I/O or interrupts). It was a fast way to “reverse read” behavior without having the full schematic.

Individual assignment (4–11)

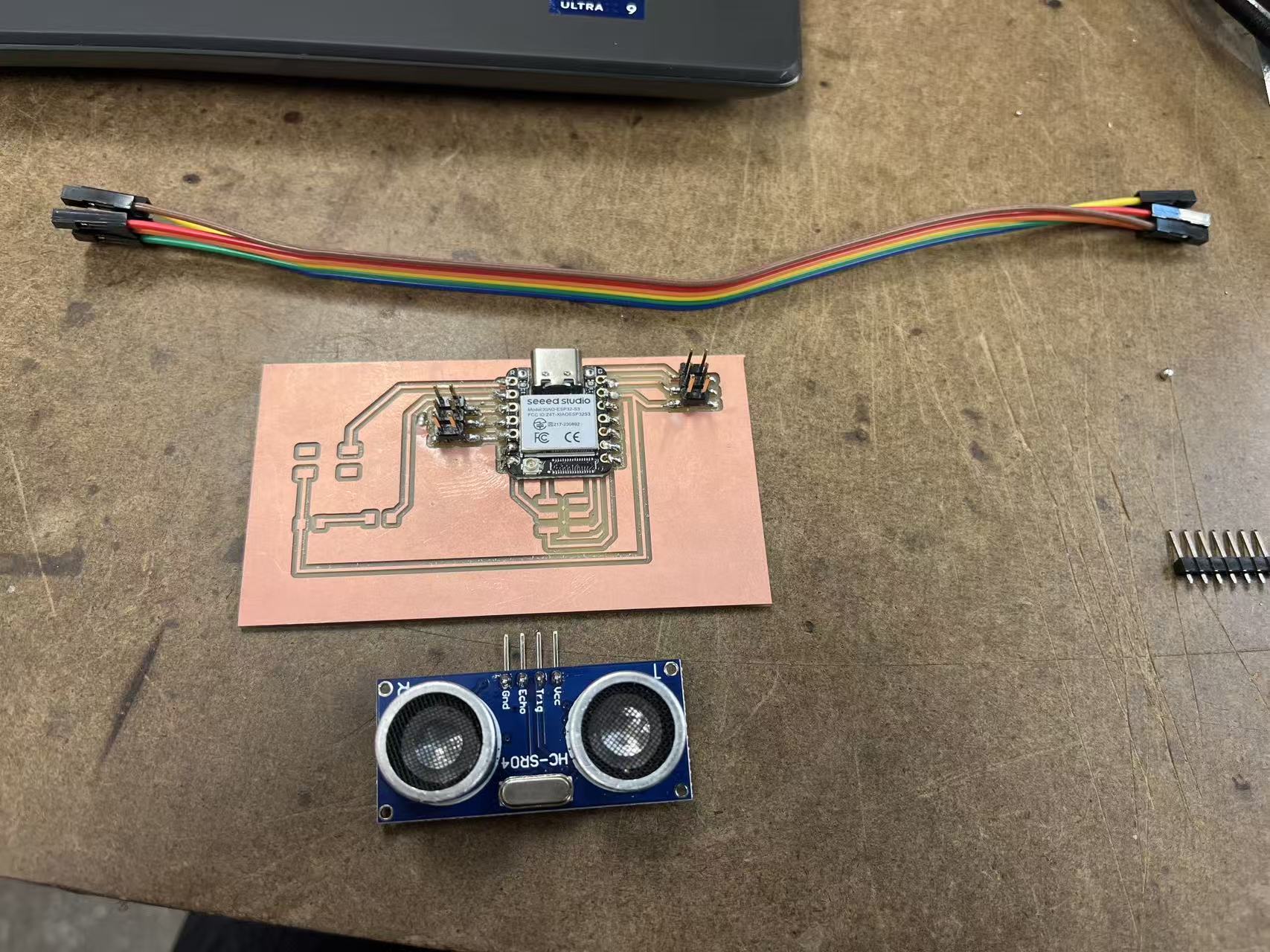

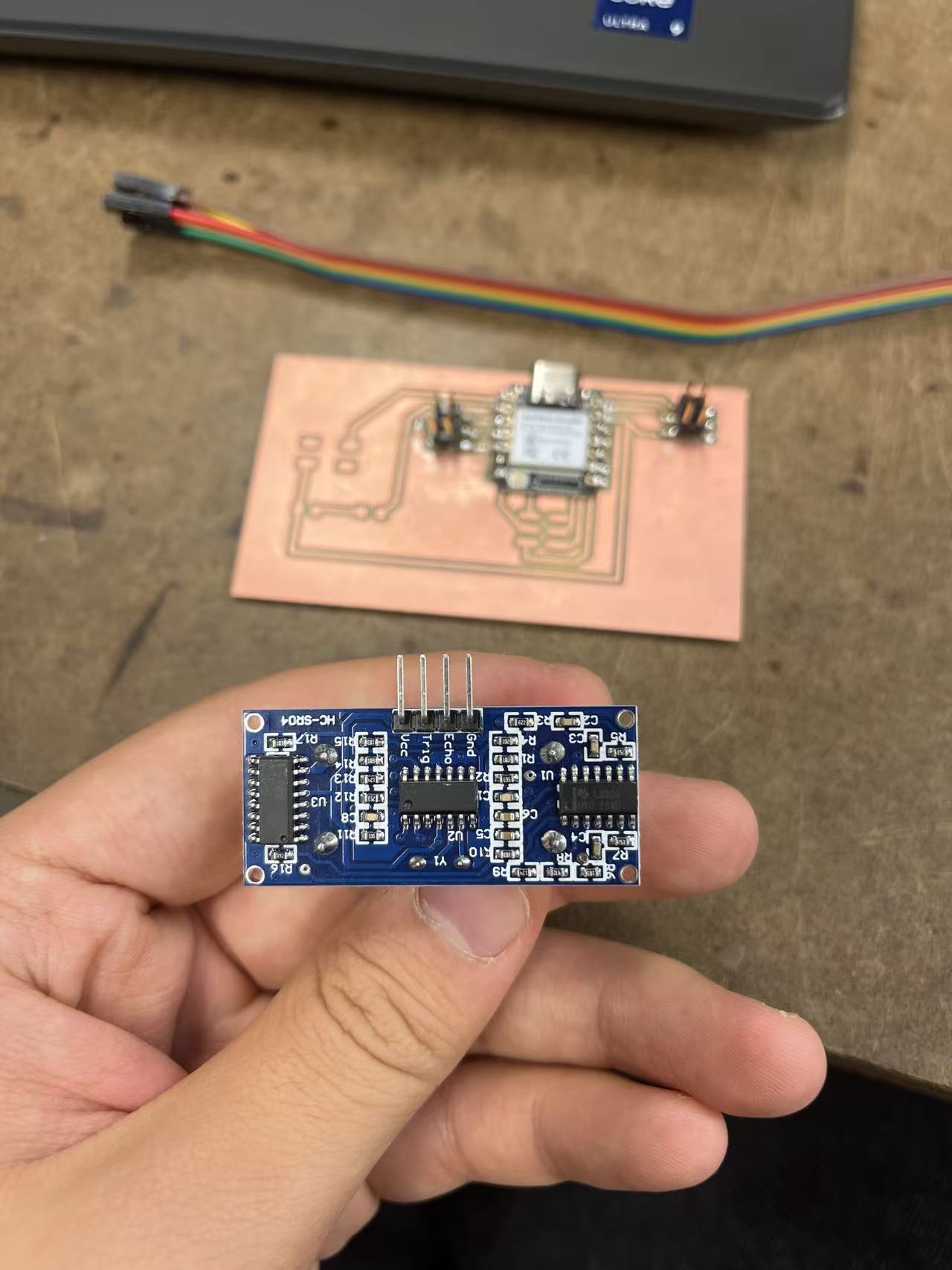

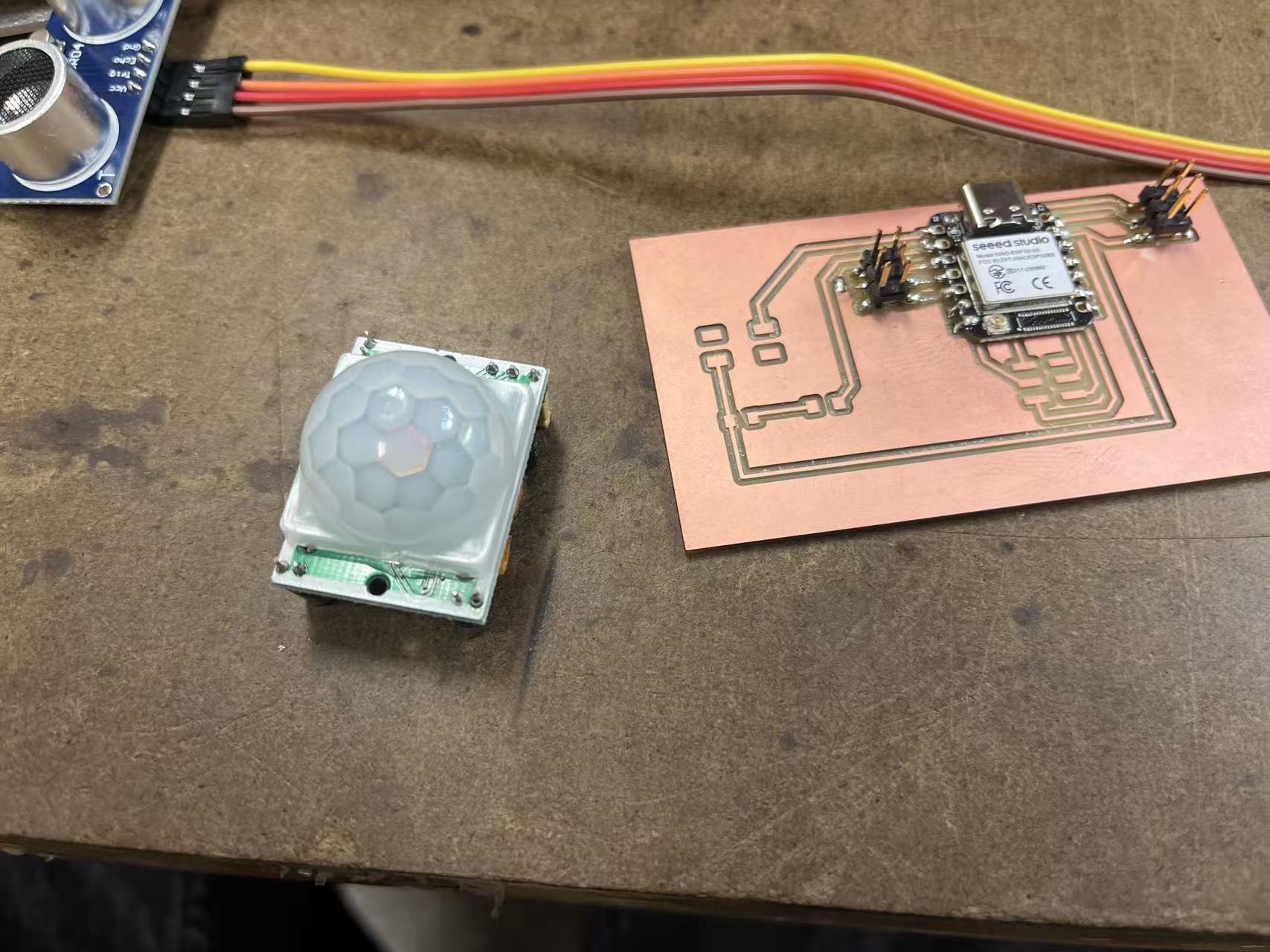

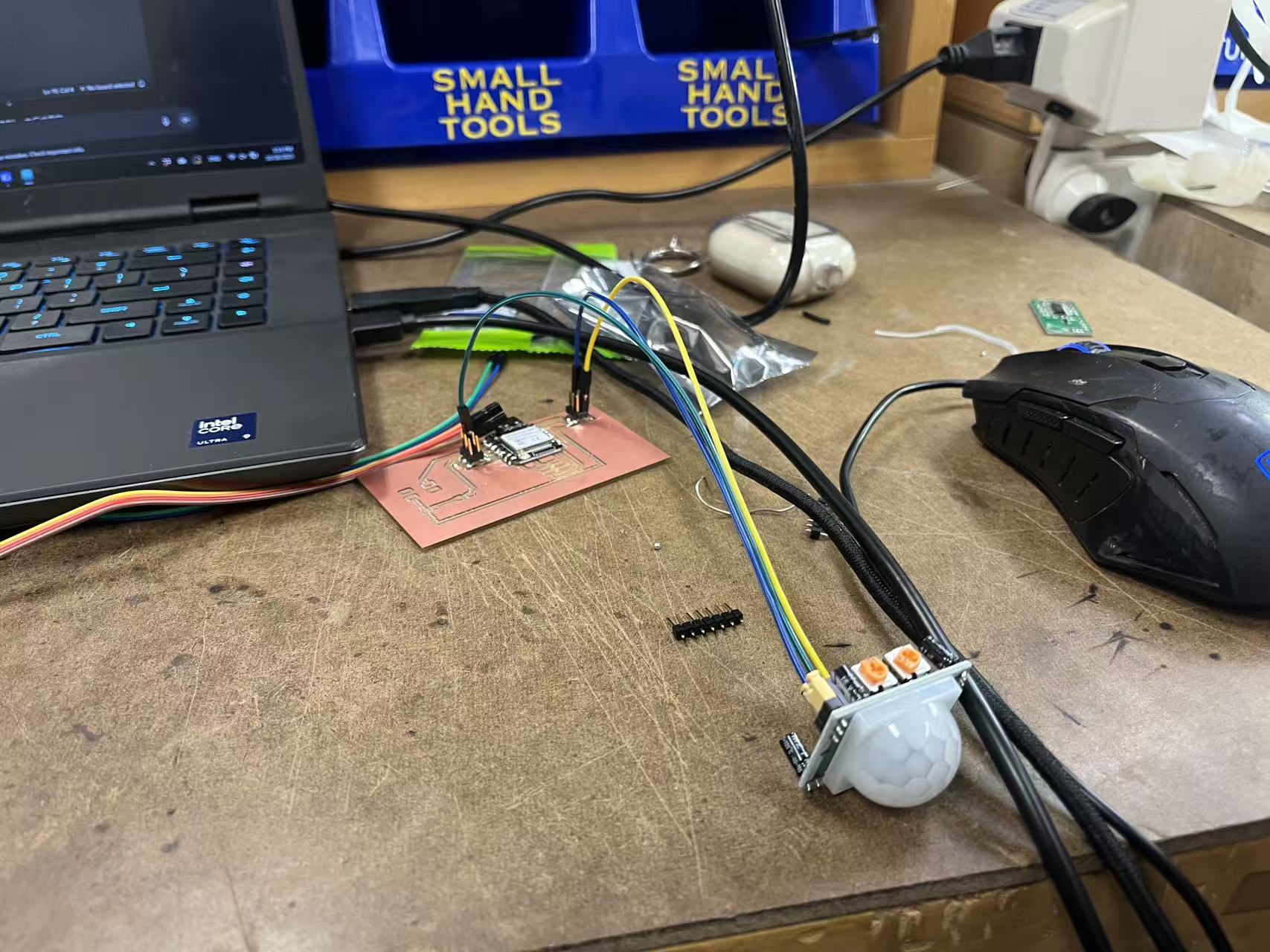

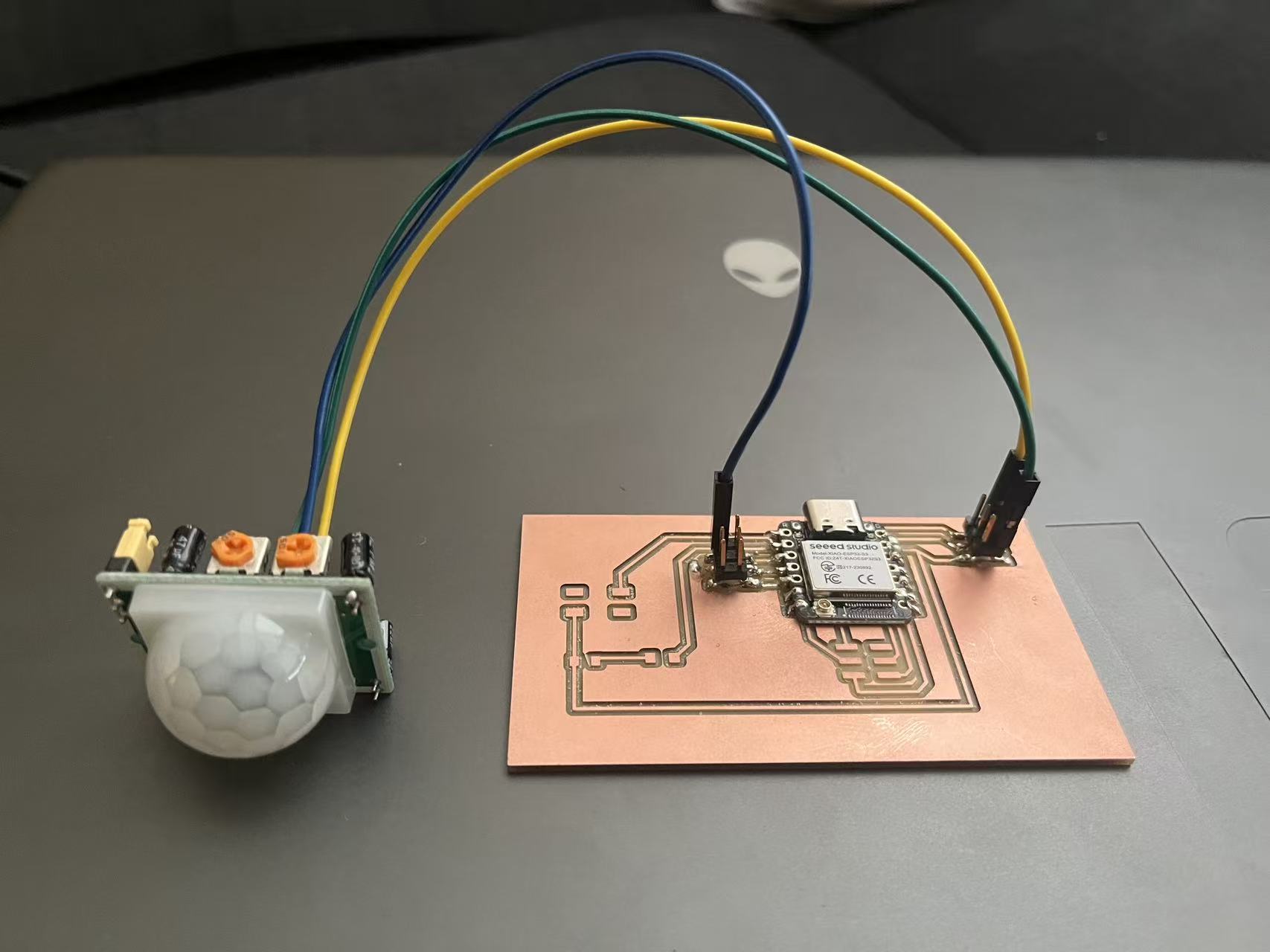

For the individual part, I connected a PIR motion sensor to my own board and read it from firmware. I first checked the sensor on a milled test board, inspected solder joints, and then wired the signal to the MCU headers. After validating power and I/O levels, I logged the readings over serial and confirmed responsiveness by waving my hand in front of the sensor.

Firmware — PIR motion test

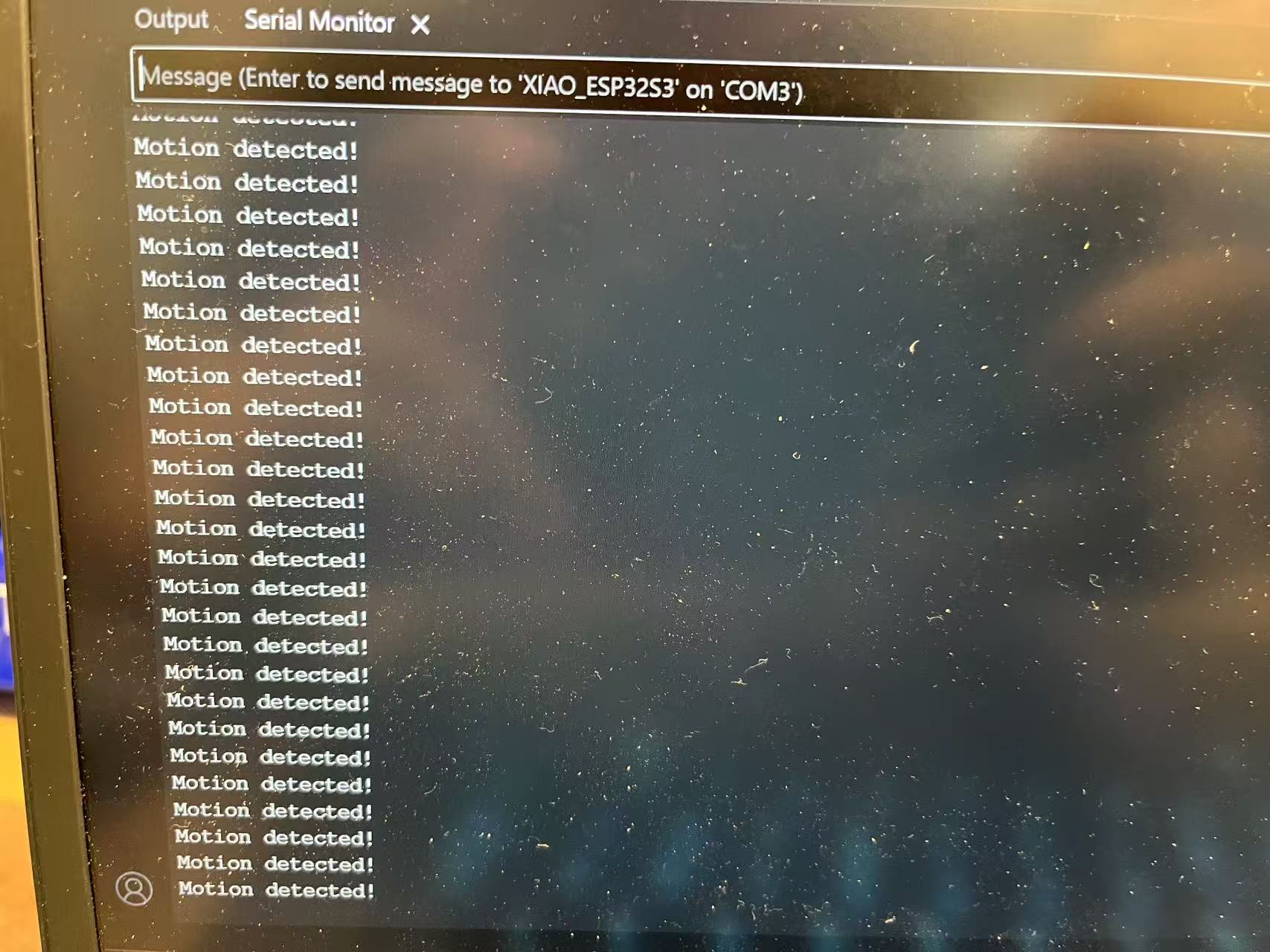

I tested the PIR sensor with a simple sketch. I haven’t soldered the LED yet, so the program

uses the Serial monitor (115200 baud) for feedback; the LED pin is already defined and

will light once the LED is added. Wiring used: PIR signal → D2, PIR VCC →

3V3, PIR GND → GND.

const int PIR = D2;

const int LED = D3;

void setup() {

Serial.begin(115200);

pinMode(PIR, INPUT);

pinMode(LED, OUTPUT);

Serial.println("PIR sensor test start...");

}

void loop() {

int motion = digitalRead(PIR);

if (motion == HIGH) {

Serial.println("Motion detected!");

digitalWrite(LED, HIGH); // LED will work after it’s soldered

} else {

Serial.println("No motion");

digitalWrite(LED, LOW);

}

delay(500);

}