For Wildcard Week, we explore digital fabrication processes not covered in other assignments. I chose to work with 2D Inflatables using Ultrasonic Welding.

My goal was to design a flat 2D pattern that, once inflated, creates a complex 3D geometry through air pressure and material tension.

1. The Logic: Ultrasonic Welding

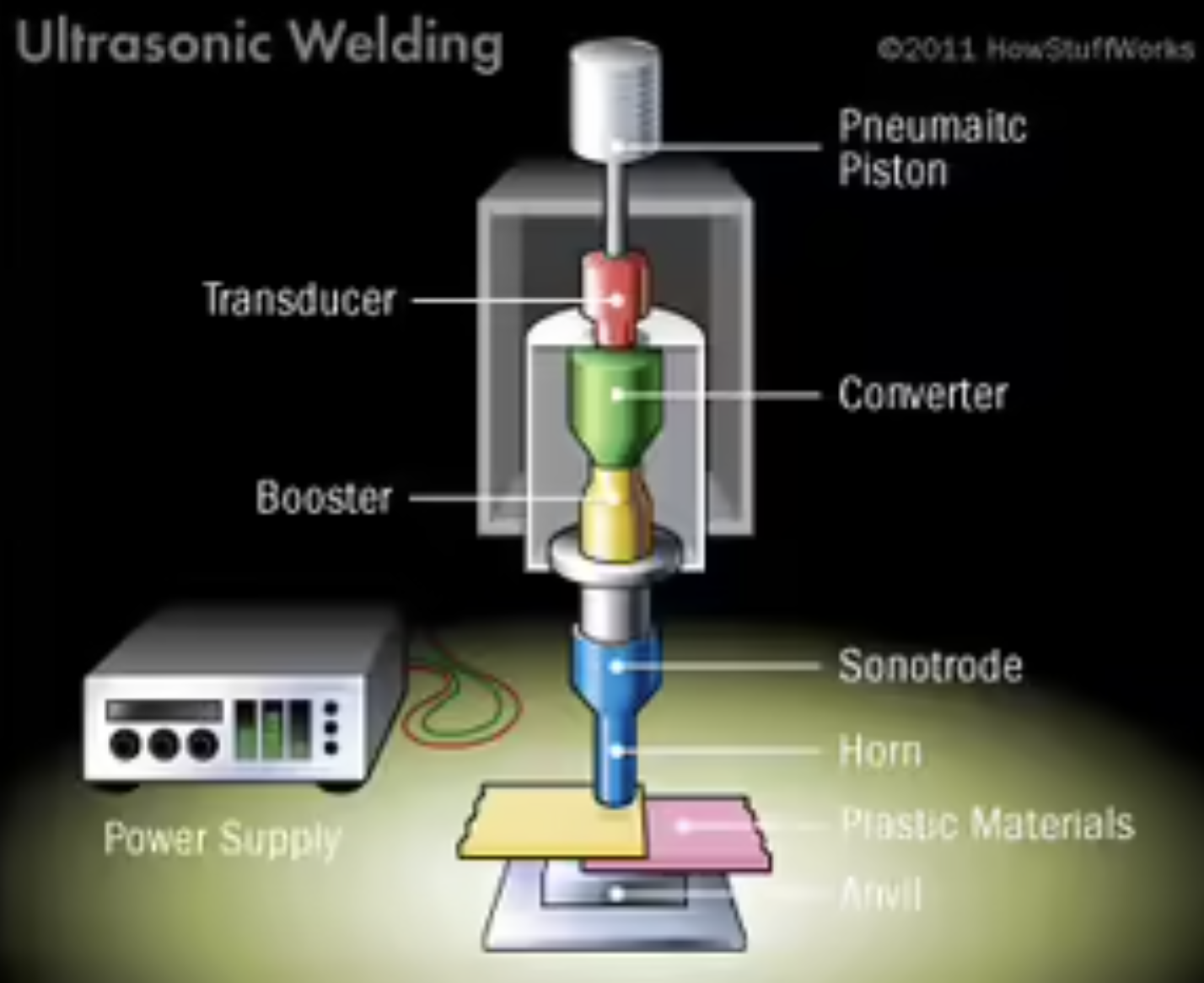

Ultrasonic welding uses high-frequency acoustic vibrations to create a solid-state weld. Instead of using glue or external heat, the machine vibrates the layers of thermoplastic (like TPU or Nylon) against each other, creating localized friction and heat that fuses them together.

2. Process & Demo

We were guided by Alfonso, who demonstrated the workflow. The key is to control the speed and power of the sonotrode (the welding tip). If it moves too slow, it burns through the material; too fast, and it doesn't seal air-tight.

We used TPU (Thermoplastic Polyurethane) because it is airtight, elastic, and welds consistently.

3. Design: The Self-Curling Spiral

For my design, I wanted to experiment with actuated geometry. Instead of a simple pillow shape, I designed a continuous spiral curve.

The Hypothesis: When air is forced into the spiral channel, the inner radius and outer radius of the curve will expand differently. Because the material is constrained by the weld lines, the expansion forces the 2D flat sheet to curl up into a 3D structure automatically.

4. Fabrication & Results

After the welding process was complete, I cut out the spiral shape and attached a valve for the air pump.

Summary

This week demonstrated the power of soft goods fabrication. By simply designing the air channels strategically (in a spiral), I was able to program physical movement and 3D form-finding into a completely flat material.