Assignments

🔧 Parametric Construction Kit

Design and fabricate a modular construction kit using parametric design principles and laser cutting techniques.

📄 Vinyl Cutting Project

Create a vinyl sticker or decal using vector graphics and vinyl cutting techniques.

📚 Documentation

Document the complete design and fabrication process with detailed explanations and images.

🛡️ Safety Training

Complete laser cutter and vinyl cutter training and safety certification.

Tools & Materials

🖥️ CAD Software

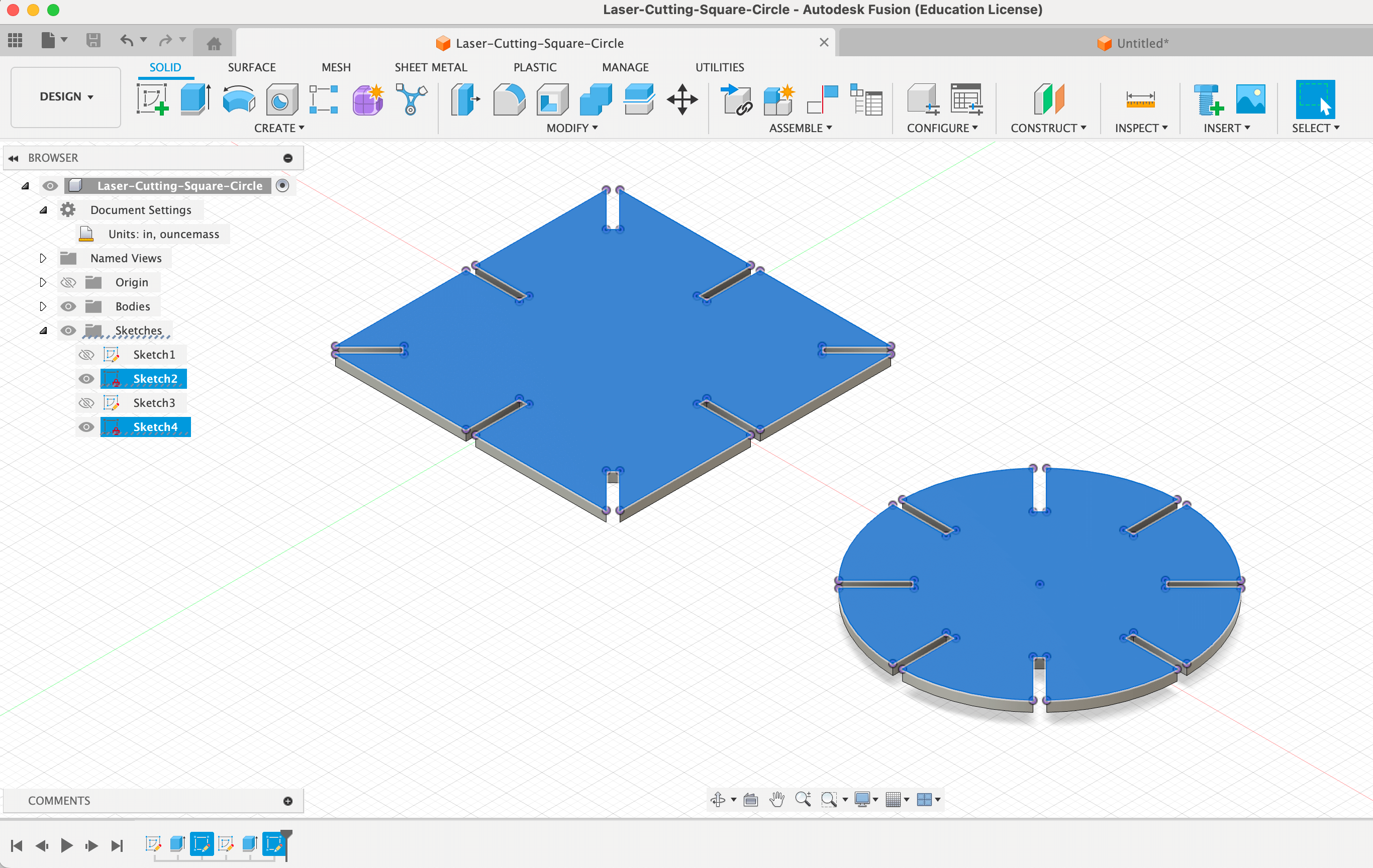

Autodesk Fusion 360 - Used for parametric design, sketch-driven modeling, and preparing vector files for cutting.

⚡ Laser Cutter

Universal Laser Systems (ULS) CO₂ Laser - High-precision cutting for cardboard and other materials.

📄 Vinyl Cutter

Roland Vinyl Plotter - Precision cutting for adhesive vinyl graphics and stencils.

🧱 Materials

Corrugated Cardboard & Adhesive Vinyl - Primary materials for both cutting assignments.

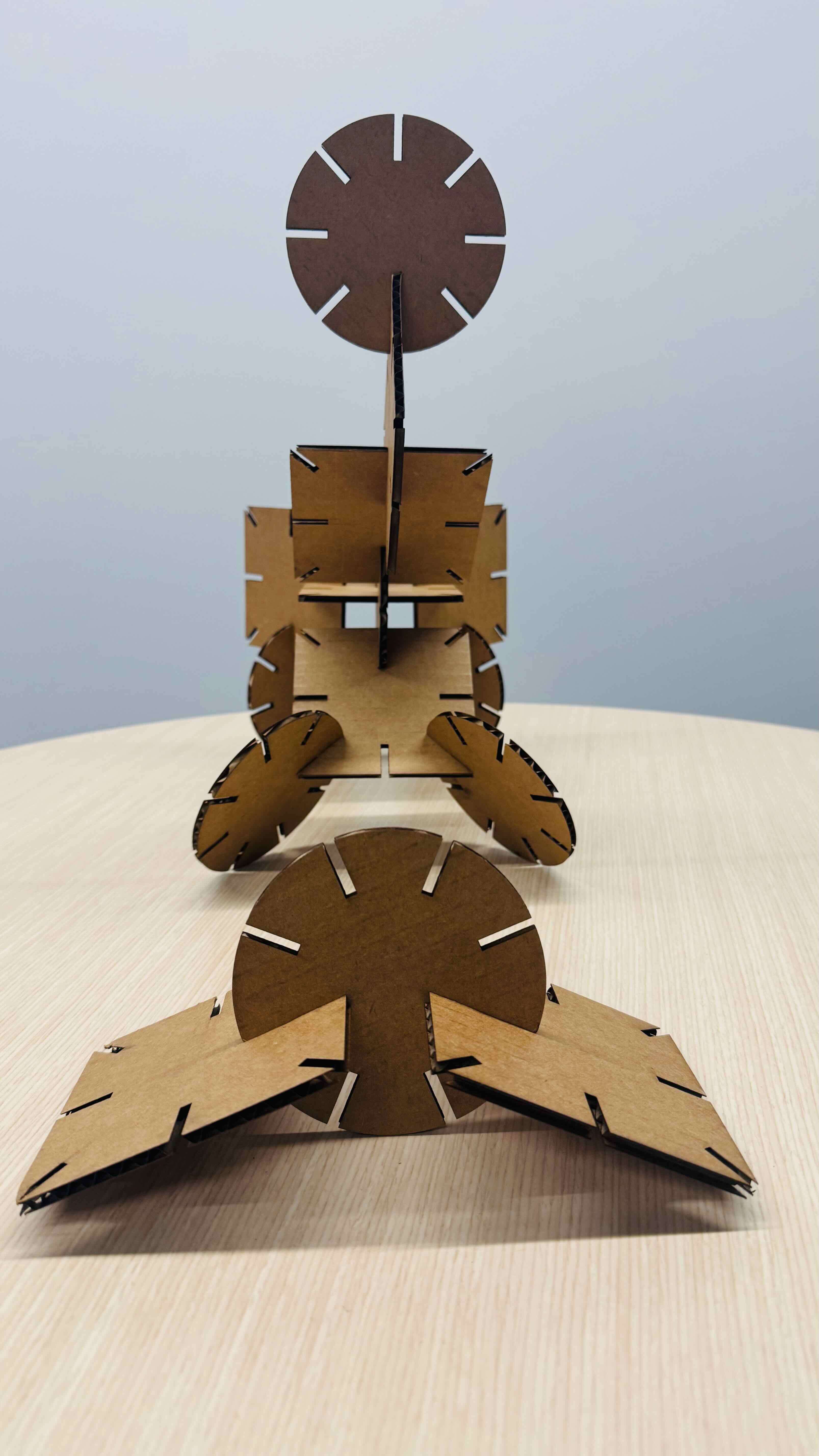

01 · Parametric Joinery → Cubist Dog

When designing press-fit parts, one issue is that perfectly square slot edges can make it hard to insert pieces without damaging the corners. A simple solution is to add a tiny finishing cut that slightly widens the ends of the slots, giving the material room to slide in cleanly. In Fusion, this can be done automatically by extending the toolpath or adding a straight-line cutout at the edge of each slot. This “clean edge” adjustment doesn’t change the overall joint fit but prevents corners from binding and tearing. The result is a more forgiving slot where the force of assembly is distributed evenly, instead of concentrated at sharp edges. By integrating this feature directly into the CAD model, the laser produces slots that are both precise and easy to use, eliminating the need for manual filing or rework after cutting.

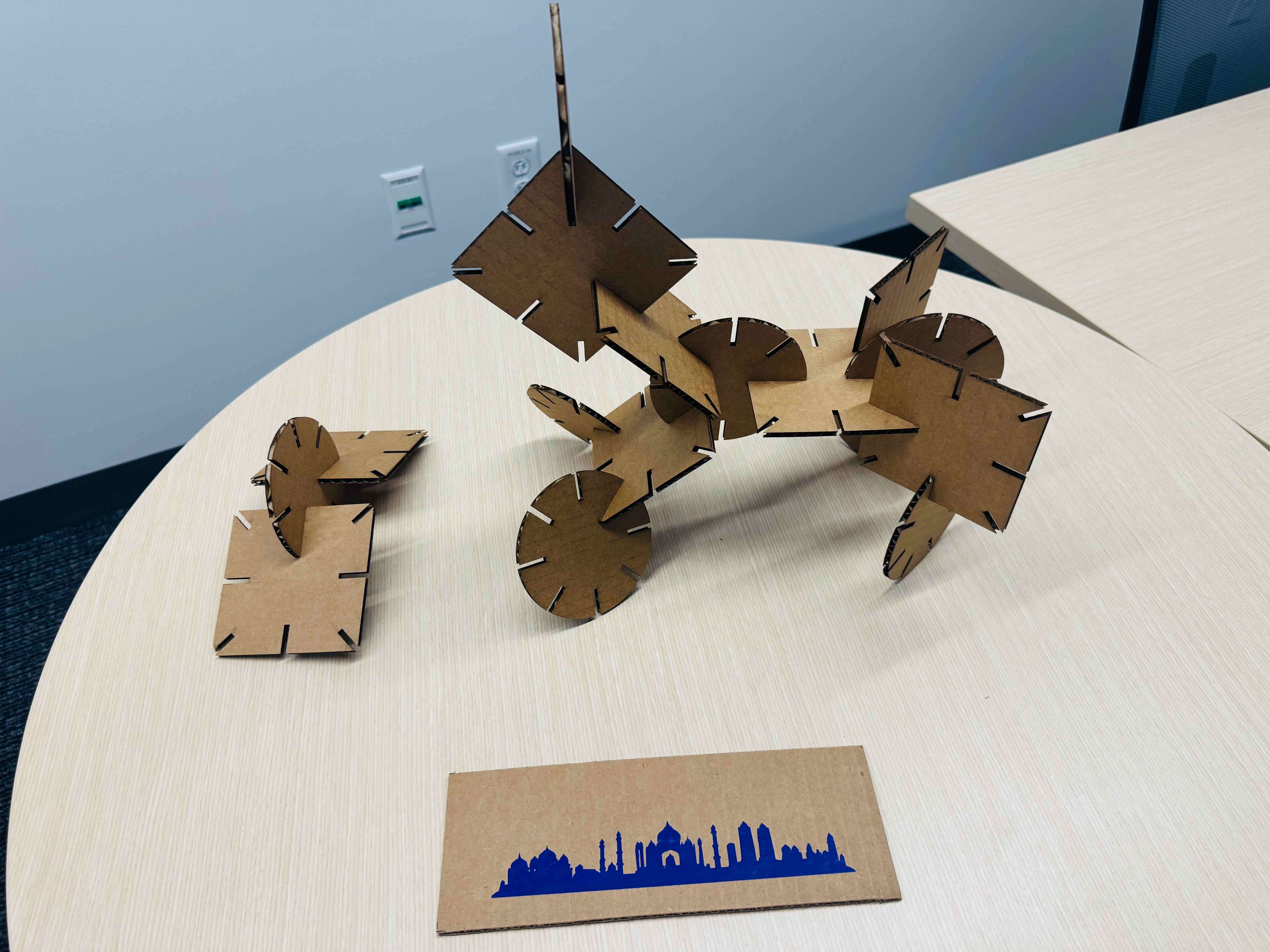

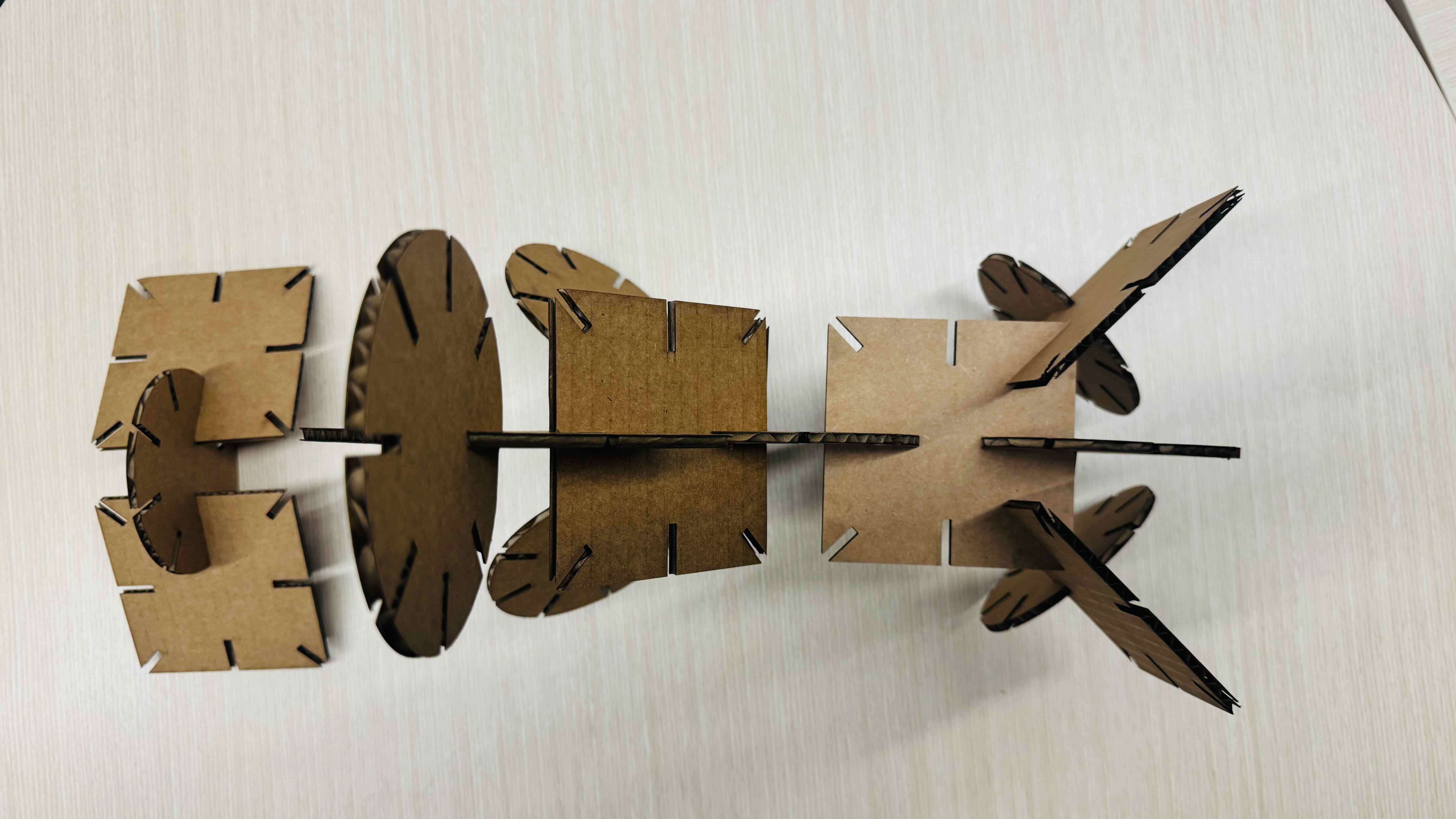

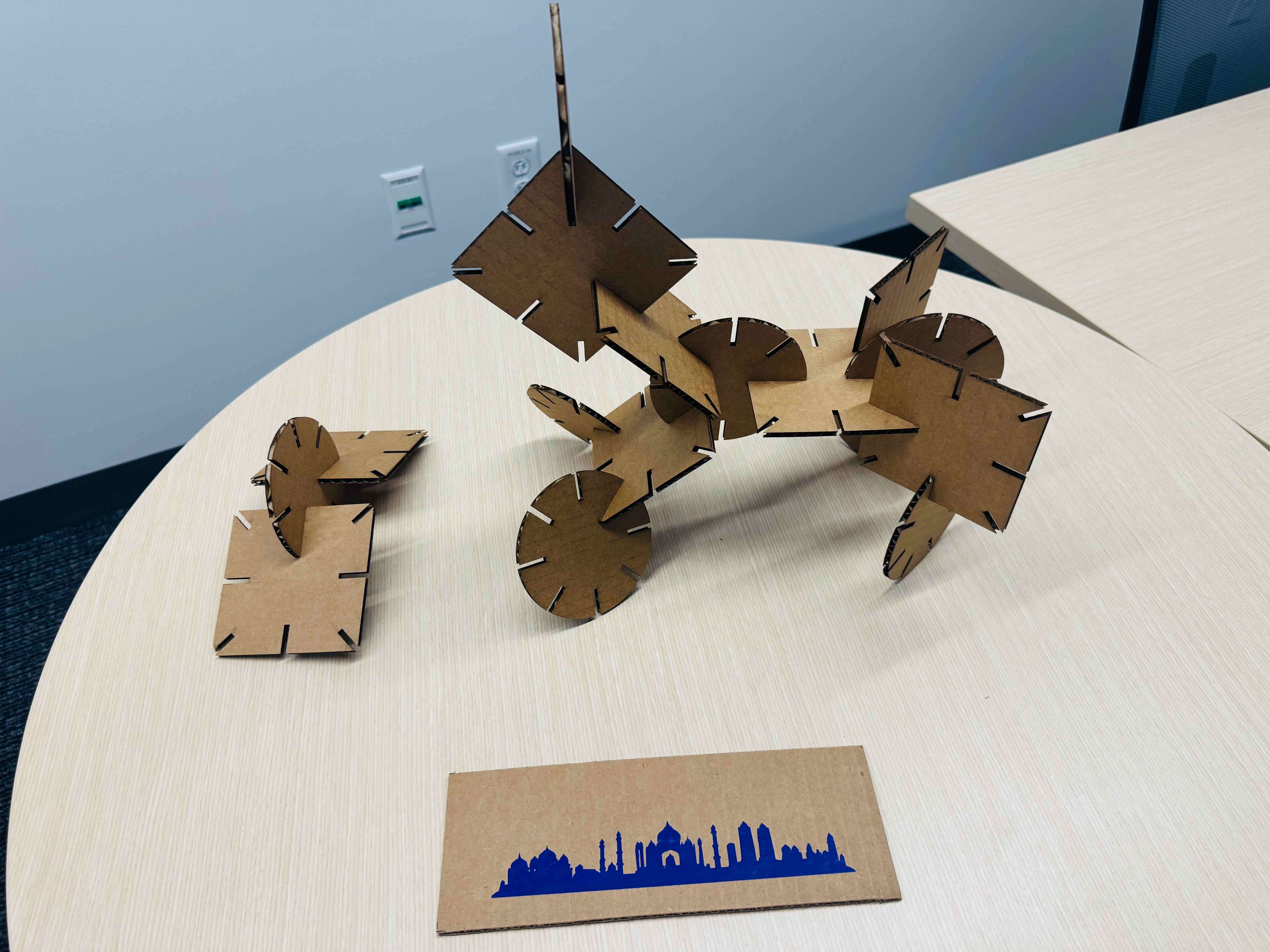

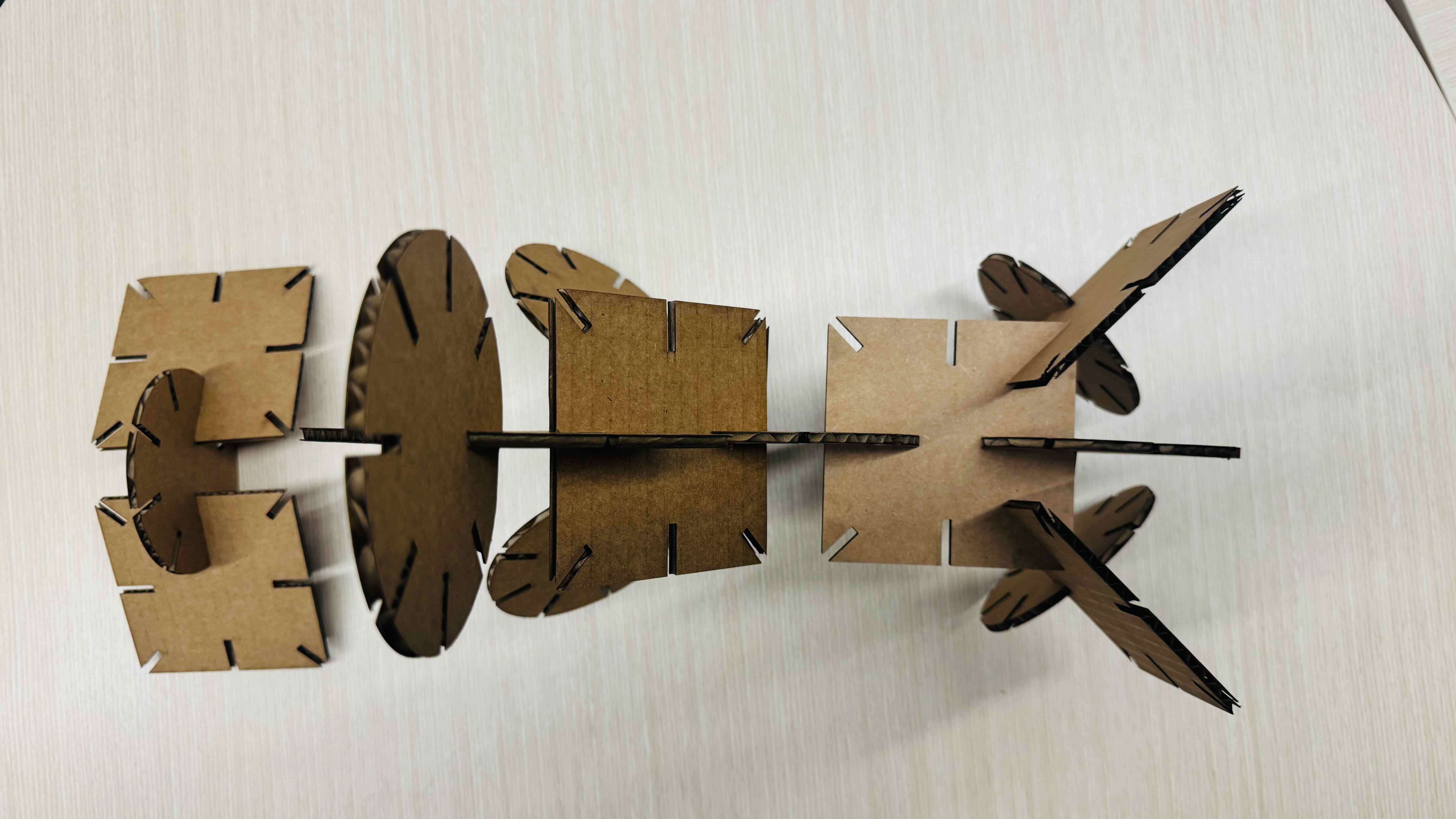

ßI modeled a family of lego‑like plates in Autodesk Fusion and tuned slot geometry so that laser‑cut parts friction‑fit into a rigid, self‑supporting structure. The pieces assemble into a playful, cubist dog while maintaining repeatable, orthogonal joins.

Fusion workspace showing the square/circle plate set with repeated slot features.

Laser‑cut corrugated cardboard; no glue. The slot system locks planes in place for a tight fit.

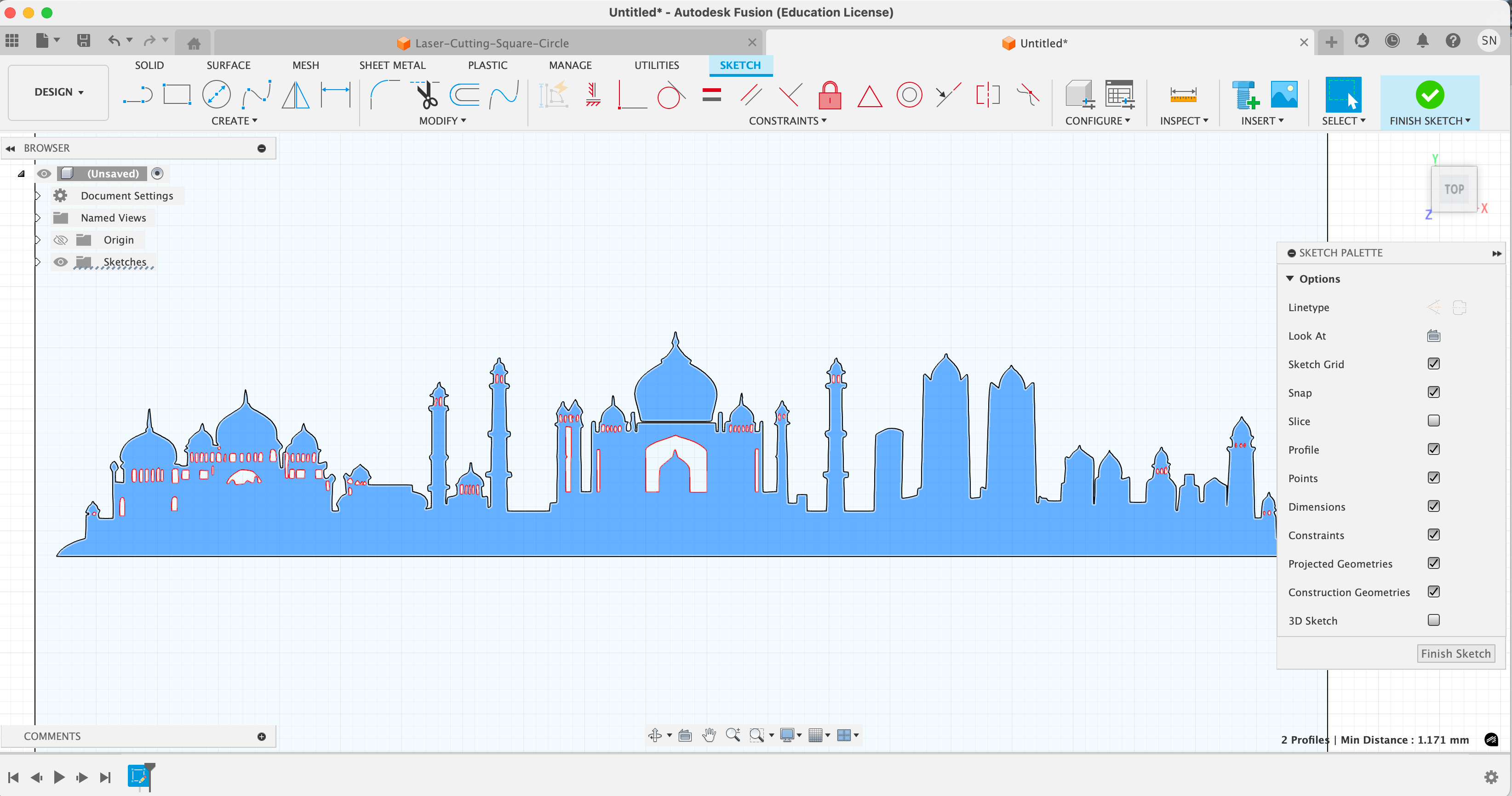

Source sketch traced and cleaned in Fusion as a single closed profile for reliable cutting.

02 · Delhi Skyline — Vinyl Cut

For the second exercise I prepared a clean Delhi skyline silhouette. After verifying the outline as a single continuous path, I exported the vector, cut it on the vinyl cutter, and mounted the graphic on a cardboard panel for contrast.

Shown below in the gallery is the skyline panel next to the cubist dog prototype.

Final Results Showcase

Both assignments completed: Parametric laser-cut joinery (cubist dog) alongside the Delhi skyline vinyl cut panel