Chris trained me on how to use the N51 wood shop and their procedures for havign students use the cnc.

- test runout, alignment, fixturing, speeds, feeds, materials, and toolpaths for your machineThe N51 wood shop requires that someone is there to run the CNC machine for you. During our training, we cut out two sample pieces of our material to find the ideal kerf. We also used these pieces to practice using the router. We measured our obs wood as .433 inches thick and were told that people had been doing joints that are .43 inches +/1 inch. I chose .43 as my joint width.

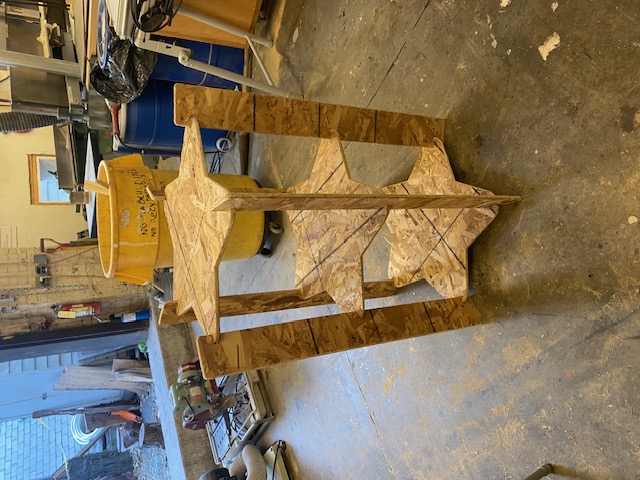

For the assignment, I wanted to make a fun shelf that can be used in my house to store various items. I decided to make my shelf more fun by making it shaped like a star. I was warned that the wood we were using was not the most sturdy, so I made the legs quite big. I do wish that I made the joints longer and had the legs go in more. After designing it in fusion 360, I got my file approved by a TA and sent it over to be milled. A mistake I made was making the drill points on the same layer as the end mill lines, but this was easily fixed in Rhino before my file was milled.

After milling my design on the cnc, I used a razor blade to cut out the wood from the obs board, as there was a thin layer of wood left. After cutting my pieces out. I used the razor to carefully trim any extra pieces of wood inside the joints. Then I used the router to clean up the edges of my pieces of wood. Then I assembled my shelf. One thing I noticed was that you can see the wood warping a lot in the legs of the shelf. I did not push all of the joints in all the way as I needed to disassemble the shelf to transport it home. The shelf feels relatively sturdy, though I do not trust it to hold anything particularly heavy.