Lap Timer

Electronics Production Project

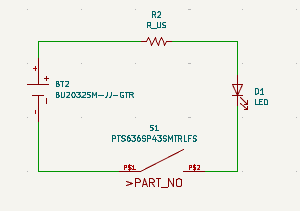

Board Design

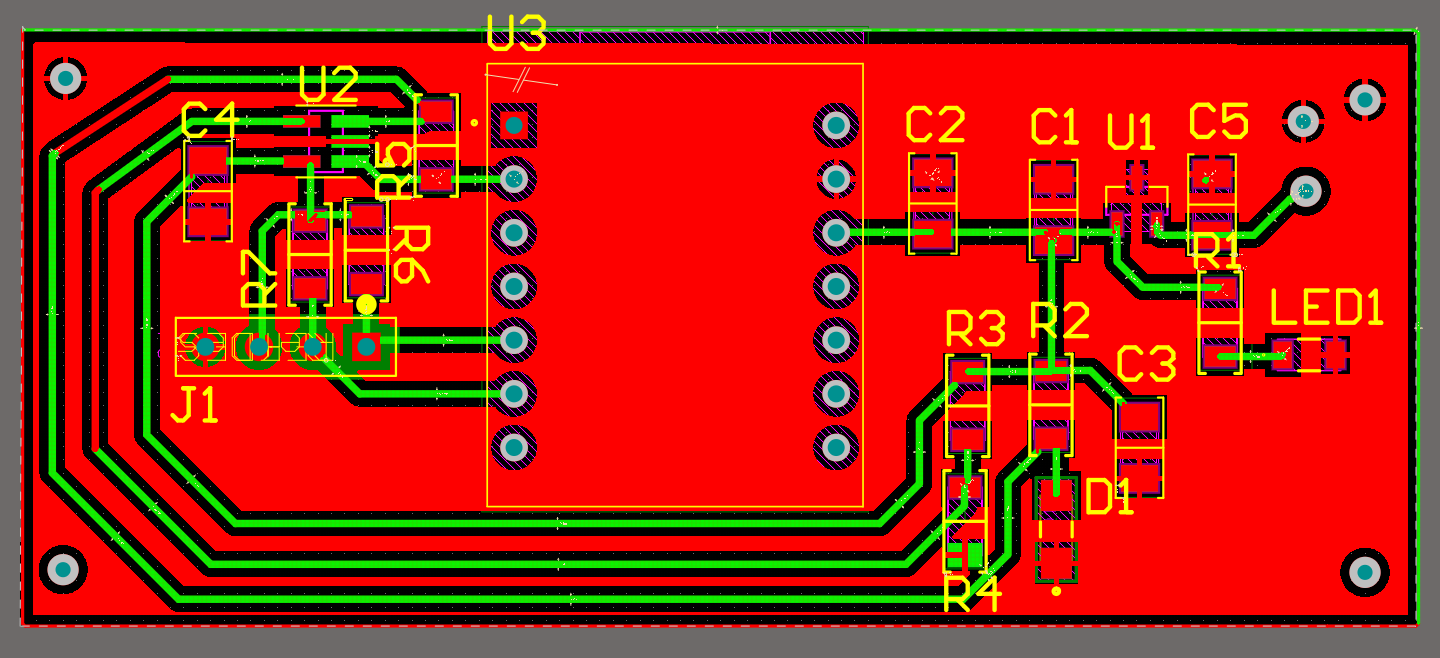

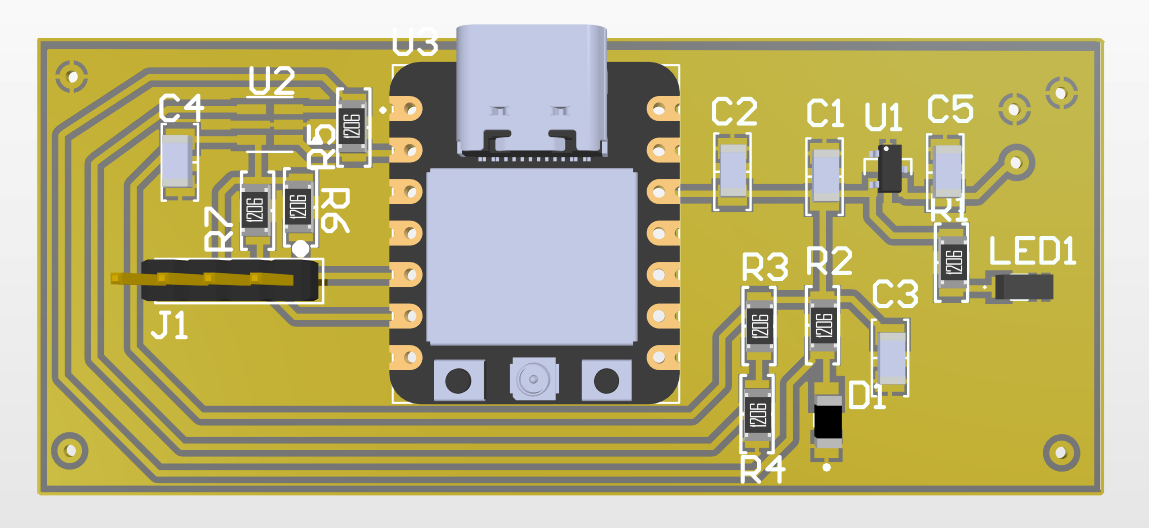

This week is a continuation of lap timer project from last week, moving from design to production. I started by refining the board schematic and layout (cleaning up traces and adding mounting holes). I also corrected the input logic on the ESP32, which had been reversed.

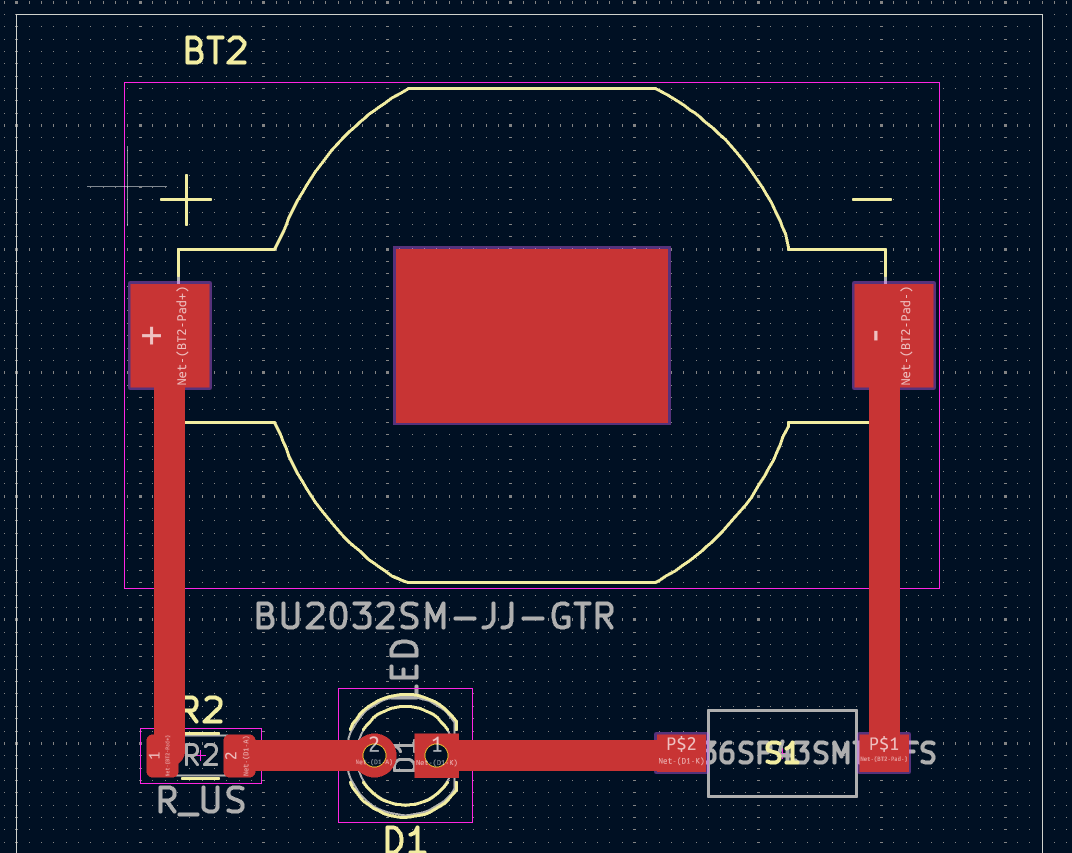

The final board design, shown below, was used for milling and assembly.

Layout

Milling

I milled the board using the Roland SRM-20 in the Architecture shop.

The goal was to cut the copper traces cleanly, drill through holes and mounting holes, then outline the board for removal.

I followed the protocol discussed in our required lab session and the Architecture shop milling tutorial.

I also found this Aalto Fablab Youtube video helpful for milling the through holes.

Steps:

- Prepare files

- Export the .png traces, holes and outline from Altium

- Use modsproject.org → Programs → Open Server Program → PCB → Roland SRM-20 → mill traces (1/64).

- Set the cut depth to 0.004 in and tool diameter to 0.0156 in (1/64 in) for traces.

- For the outline, switch to mill outline (1/32) and set depth to 0.012 in.

- Set up the machine

- Take the FR-1 board down firmly on the sacrificial bed using double-sided tape, pressing evenly so it's flat.

- Mount the 1.64 in end mill in the collet.

- In VPanel, set the XY origin at the lower-left corner of the board.

- Lower the Z until the bit barely touches the copper surface. Loosen the screw slightly, press it slightly into the surface, and then tighten again.

- Mill the traces

- Load the traces file in Mods and send the job to the mill.

- Watch the first few passes to make sure the copper is being cut away cleanly (not just scratched) and that the bit isn't cutting too deep.

- Use Pause and Resume in VPanel (DO NOT UNPLUG THE USB).

- Change tools for the drilling

- After milling the traces, raise the Z and switch to the 0.1 in. end mill.

- Re-zeo the Z in the same way.

- Switch to the through hole file in Mods and send the job.

- Change tools for the outline

- After milling the through holes, raise the Z and switch to the 1/32 in. end mill.

- Re-zero the Z in the same way.

- Switch to the outline file in Mods and send the job.

- Remove and Clean the Board

- Carefully pry the board off with a spatula.

- Clean of the tape residue with isopropyl alcohol.

- After Milling

- Check each pad under the microscope to make sure there's no leftover debris from milling.

- Check continuity between all connected pads using multimeter.

- Use deburring tool to smooth board edges.

Soldering

After milling and cleaning the PCB, the next step was soldering all of the components onto the board.

I used the soldering iron in the Architecture shop with Pb-free solder following the instructions discussed in our required lab session and this Architecture shop soldering tutorial.

Steps:

- Organize components

- Stick all components onto a strip of double-sided take so they don't roll away or get lost.

- Label each part with its reference (e.g., R1, U1) so that it is easy to find while soldering

- Set soldering station temperature

- For most parts, I set the temperature to 350°C

- A few components, like the IR LED and photosensor, included solder temperature profiles in their datasheets. I adjusted the soldering temperature when soldering those components to ensure that I don't go above their reflow peak (point where splder melts and creates the necessary connection without exceeding the maximum temperature ratings of the component).

- Apply flux to pads

- Flux helps the solder to "wet" the pad and component leads by cleaning oxidation and improving surface tension.

- Plack and tack one side of the surface mounted component using tweezers

- Apply a tiny bit of solder to one pad on your PCB.

- Hold the surface mounted component with tweezers and position it over that pad

- Rehead the same pad with soldering iron while gently pressing the component into place. The solder will melt and hold that one side down.

- Verify that all polarity sensitive parts (LEDS, phototransistors) are oriented correctly.

- Reflow the other side by heating the opposite pad and applying a small amount of solder.

- Keep the soldering tip tinned and clean to avoid dull joints.

- If a joint looks frosty, reflow it with flux because it's likely oxidized.

- Avoid reheading the same pad multiple times

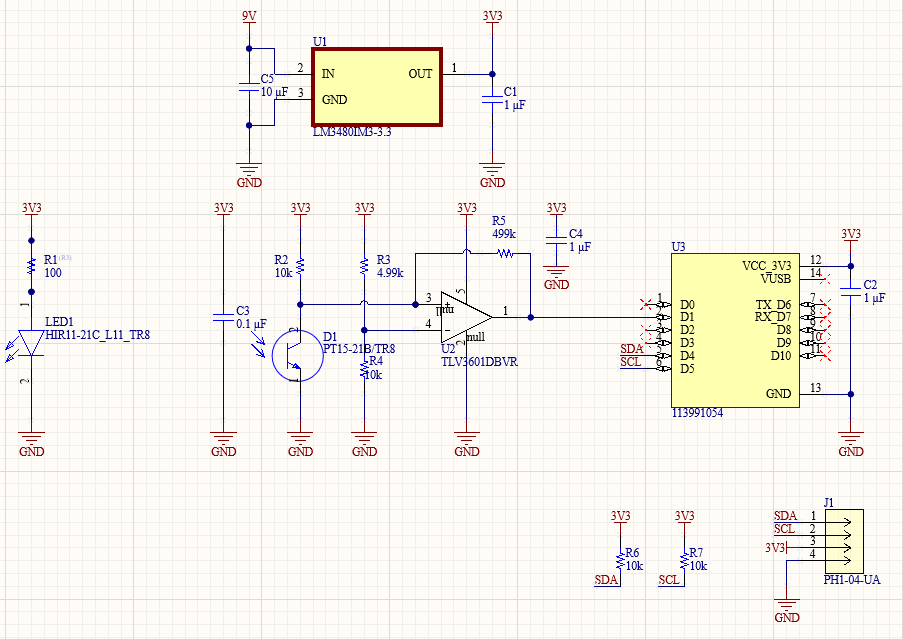

- Inspect each connection under the microscope after soldering. The solder joint should resemble the one in the image below:

- After Soldering

- Clean the board using isopropyl alcohol and soft brush to remove leftover flux reside.

- Check for bridges used multimeter.

Final Product