<br>

[MAS.865](../../index.html) > [Motion](../../motion) > Piezoelectric Actuators

## Piezoelectric Actuators

#### High stress, High Bandwidth

---

### Basic Theory of Operation

The basic piezoelectric equation relates the electric field across the material to an induced strain:

$$\frac{\Delta h}{h} = n * d_{33} E$$

where $n$ is the number of layers, $ d $ is the piezoelectric coefficient, and $E$ is the electric field across each layer. $ d $ is typically on the order of 500um/MV (500 *10^12 m/V). This means, given a maximum field strength of 1-2 V/um (limited by dielectric field strength), typical values for $\frac{\Delta h}{h}$ are approximately 0.1%. This means with a 1mm tall actuator, you should expect to get in the realm of 1um of deformation.

In order to not have to supply kilovolts to the actuator, piezo actuators are commonly manufactured as stacks of thinner elements with interleaved electrodes. Because the distances between each electrode is much smaller, the voltage necessary to create a certain field is much reduced. It's common to find piezo chips in the 75V-150V range.

### Modes of Operation

Piezo actuators can use several different kinds of deformation in order to create motion and force.

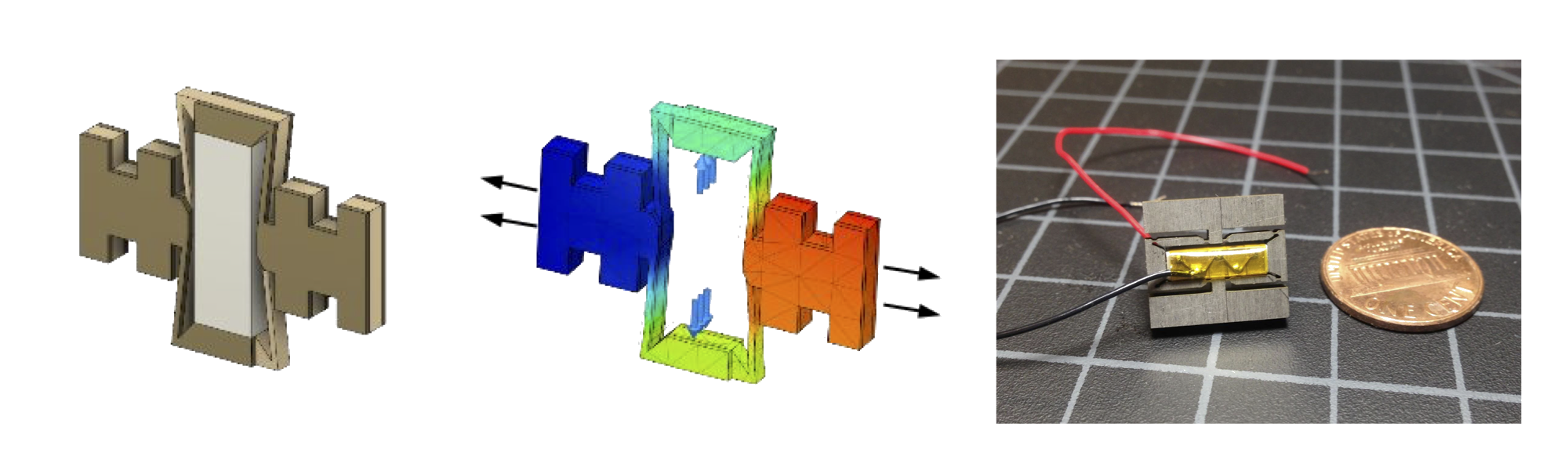

#### Amplified Stacks

The simplest, as shown in the cutaway above, is a simple piezo chip or stack which uses the compressive mode of deformation (when voltage is applied through its thickness). Because the strains are so small, it's common to use some kind of mechanism to amplify the motion.

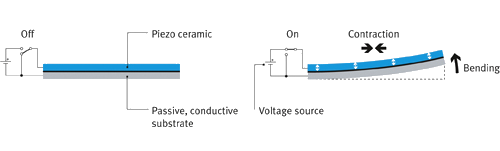

#### Piezo Benders

An alternative strategy to tradeoff force for added displacement, is to use the elongation/contraction mode of displacement in a bending configuration.

Piezo benders have much higher strains, typically on the order of ~1% of their length (a 10mm bender will often deflect about 100um in quasi-static operation). They exist in both unimorph (one layer of PZT) and bimorph (two layers of PZT) configurations and are usually mounted on a passive flexing layer (like carbon fiber) which is used to convert the longitudinal strain into a bending deflection.

There has been lots of interesting recent work which has looked to optimize the energy density of these actuators by [tuning their shape](https://micro.seas.harvard.edu/papers/SA04_Wood.pdf). They're being used to power small things [that fly](https://www.seas.harvard.edu/news/2017/10/new-robobee-flies-dives-swims-and-explodes-out-of-water) and [position very quickly](https://news.harvard.edu/gazette/story/2018/01/millidelta-robot-combines-micrometer-precision-with-speed/).

To get started with piezo benders, you can make them by cutting up piezo buzzers.

<video controls src="https://gitlab.cba.mit.edu/calischs/kiri-tww/raw/master/piezo/pc-200v-340hz-7019fps-small.mp4" width="640"></video>

#### Inchworm / Walking Actuators

Another way of achieving larger displacements is by exploiting the very high bandwidth capability of the piezo actuators and making lots of small cyclic motions. These inchworm or walking actuators effectively take lots of small steps to move a rotor or linear plunger.

<img src="inchworm_stack.gif" width="500">

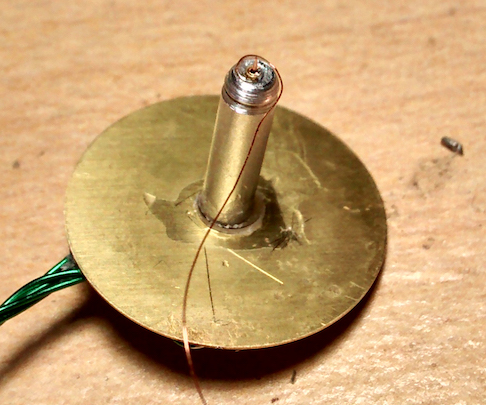

I experimented with making my own walking actuator a while ago. The individual motions are so small that they're virtually imperceptible, but the motion of the moving bar is clear:

<div>

<img src="experimental_setup.jpg" width="480"> <video controls src="piezo_walker_working.mp4" width="480" style="vertical-align:middle"></video>

</div>

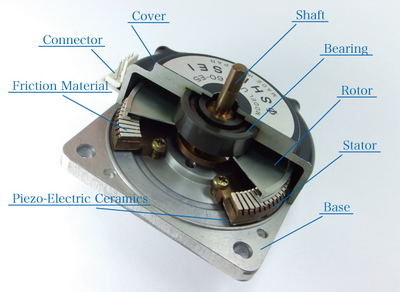

#### Ultrasonic/Resonant Actuators

Ultrasonic piezo actuators work by exciting resonant modes of the piezo material to create an effective surface acoustic wave that propels the contacting rotor via friction. They're often made of a single monolithic piece of piezo ceramic with teeth cutout to define the resonant modes.

<img src="ultrasonic_principle.gif" width="500">

These actuators can be highly efficient since they exploit the large deformations granted by using the actuator at resonance. They are often used in high-end DSLR cameras for focusing since they can be made very flat, compact, and hollow.

#### Atomic-scale Motion

- https://www.media.mit.edu/nanoscale/courses/AFMsite/positioning.html

- https://dberard.com/home-built-stm/scan-head/

#### Driving piezos

One of the biggest challenges to getting started prototyping with piezoelectric actuators is driving them. You must generate and modulate high voltages (~100s of volts).

In the regime of fracture limited driving (causing as much strain as can be tolerated by the material), reverse drive will depole the PZT ceramic. Therefore, we can restrict our attention to unipolar drives!

<a href='http://micro.seas.harvard.edu/papers/SA11_Karpelson.pdf'>This is a fantastic article</a> about miniaturized drives for piezoelectric bending actuators that takes advantage of capacitive energy recovery to increase efficiency.

To get started, these [low cost drivers](https://www.piezodrive.com/) are easy to work with.

#### Other Resources

If this kind of actuator interests you, I'd encourage you to read up more on them with

[this really good, more in depth tutorial](https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=5030).

- [raw sheets of PZT](http://www.piezo.com/)

- [elliptic resonant motors](https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=10461)

- [piezo stack actuators](https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=8040)