01

Machine

This section focuses on machine developement to support the material explorations.

Background Papers

Liquid Crystal Elastomer Fiber Single Photoinitiatiors

First Steps

One material I am particularly interested in fabricating with is Liquid-Crystal Elastomers. I want to make a continuos process to make fibers of arbitrary length.

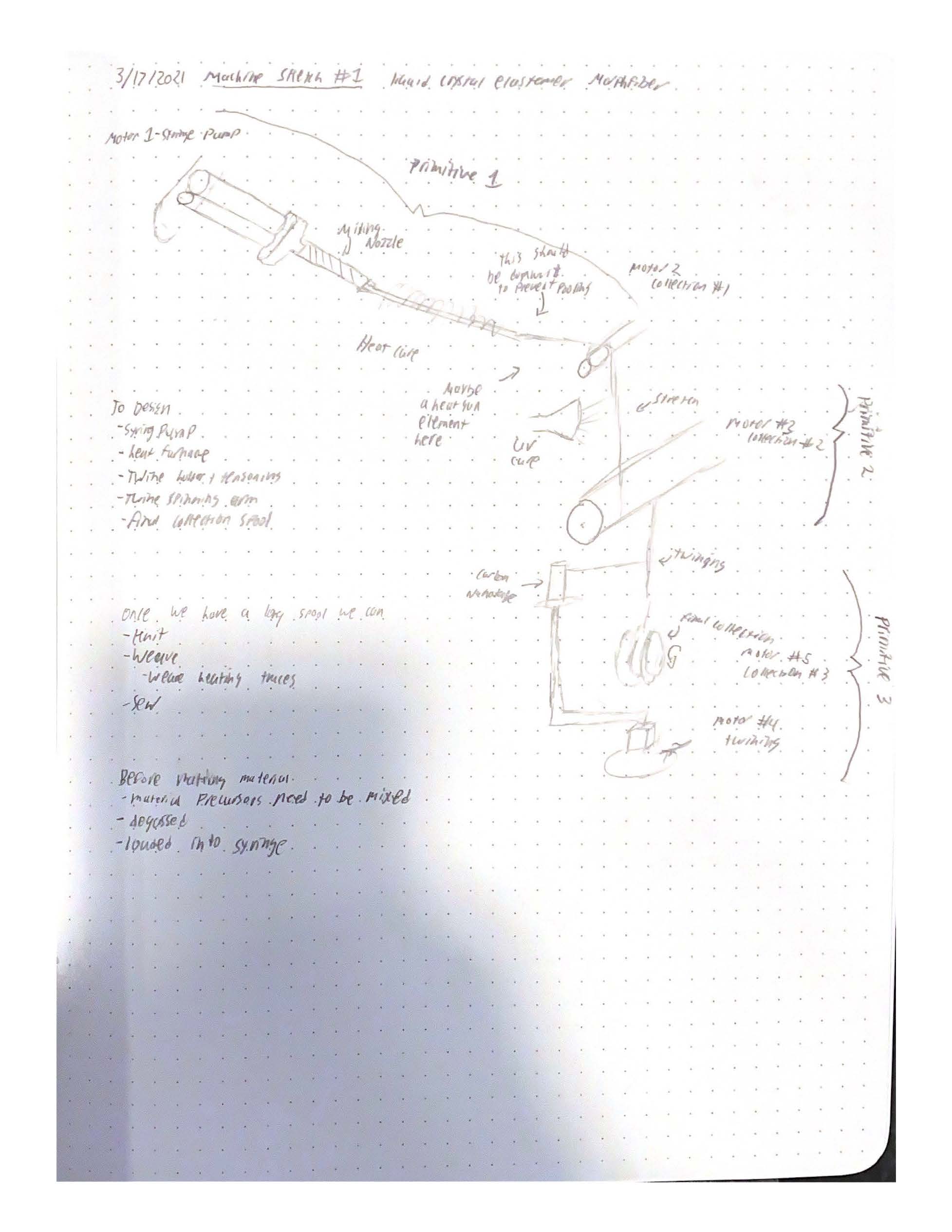

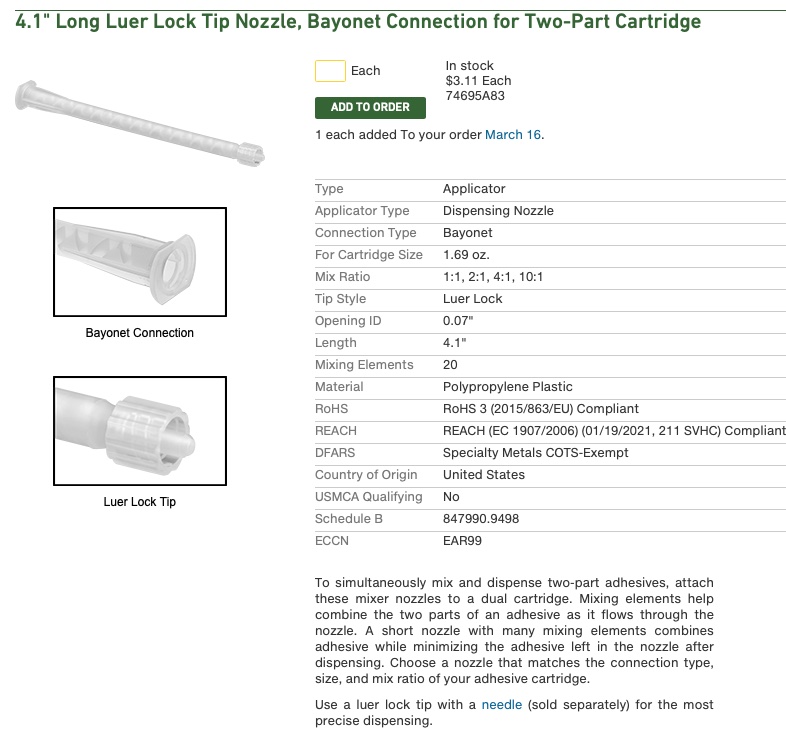

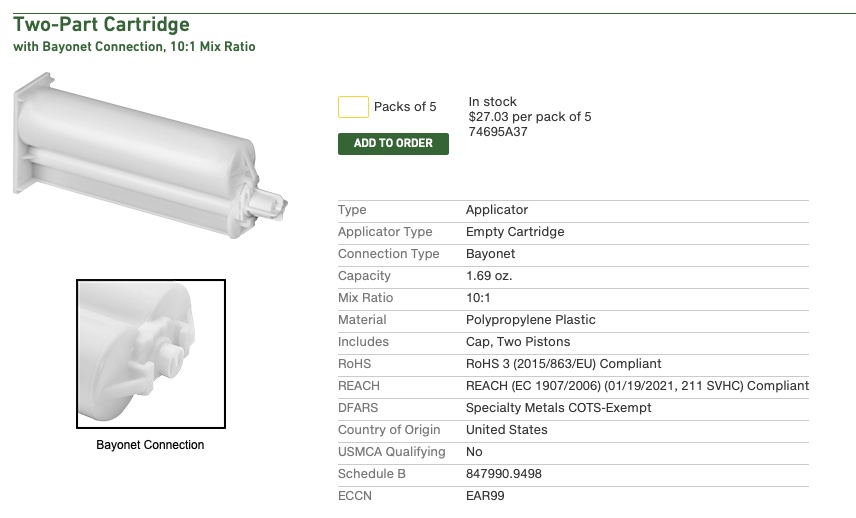

I went ahead and ordered these materials for these fibers.

So for the class I (and Cedric) am interested in creating a contuous molding process for liquid crystal elastomer fibers. The two parts of the elastomer are first extruded through a mixing nozzle using a syring pump. They are then pushed into thin heated tubing where the first curing process occurs. Once pulled out of the nozzle and onto a mandrel they are collected, then stretched by pulling onto another mandrels rotating at a faster speed. During this stretch a secondary UV curing process occurs - which alligns the LCE's. The fiber is then collected onto a final spool after a conductive heating element is wrapped around the fiber.

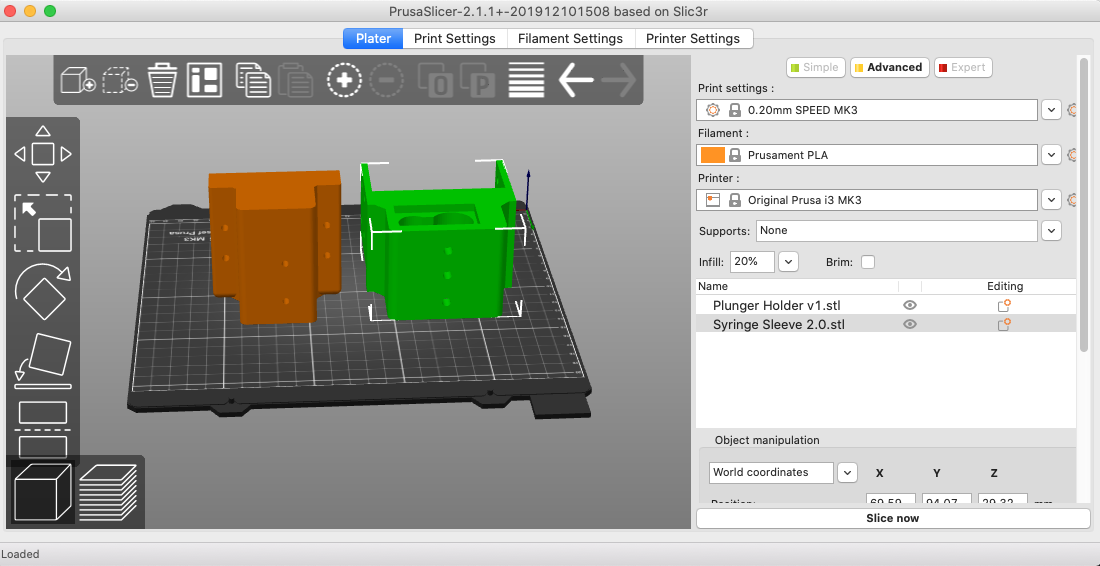

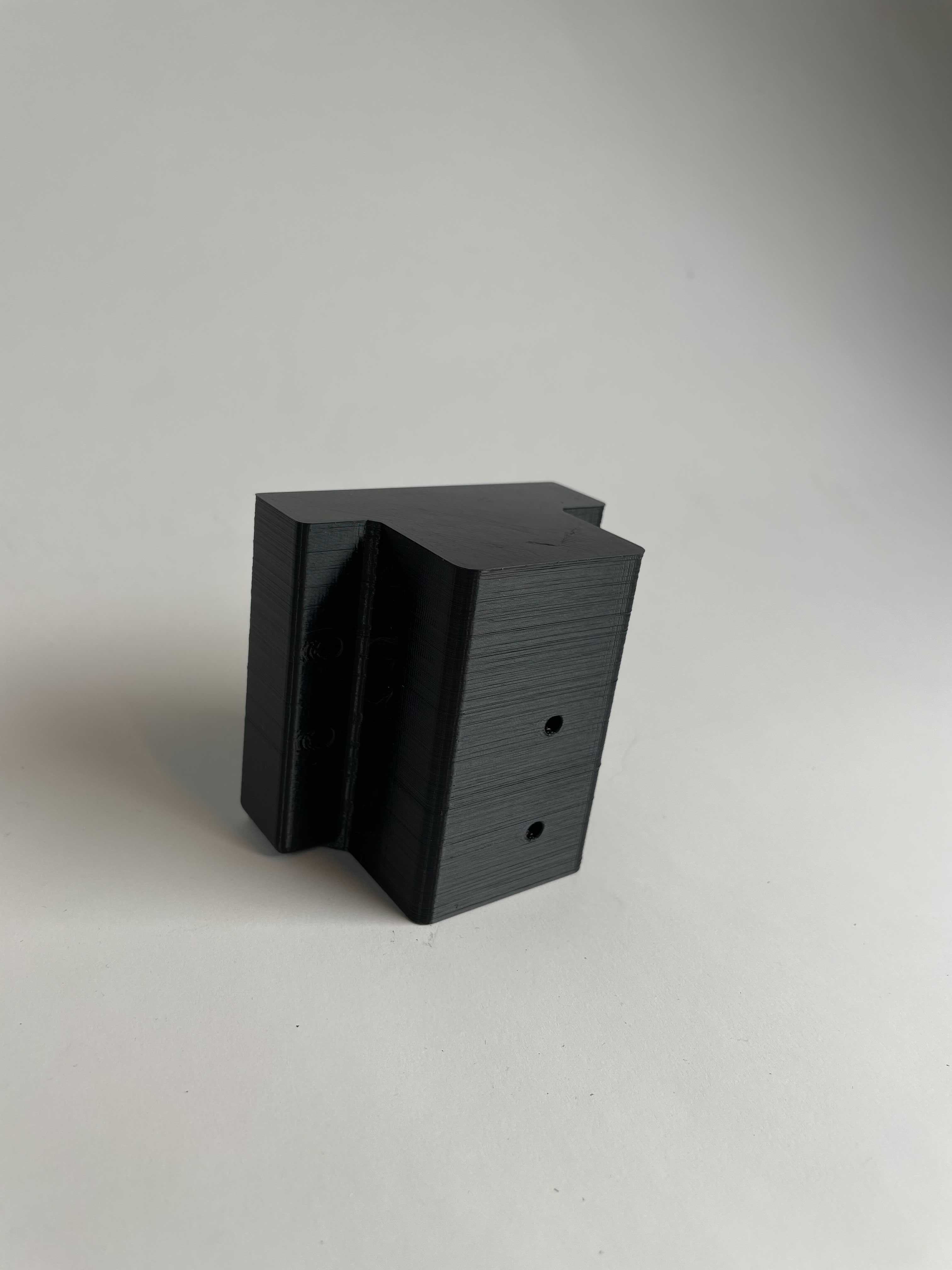

My UROP, Jackson Zhang and I began working on the syringe pump to extrude the resin into the nozzle. Filippos kindly shared the CAD model of the bioprinter, which we modified to fit a dual nozzle extruder and syringe pump. We did a few round of interation until everything fit snug, and the photos are below.

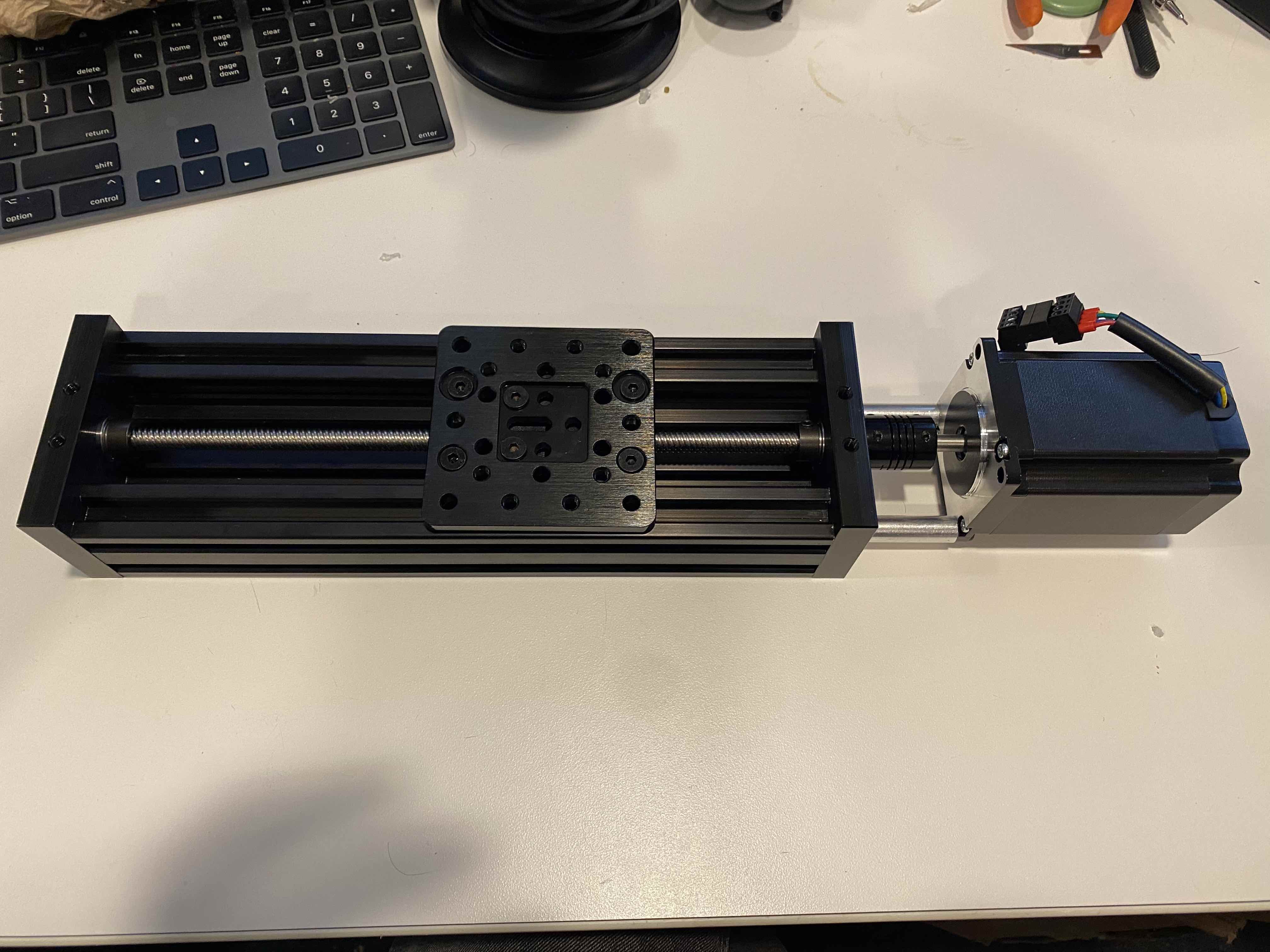

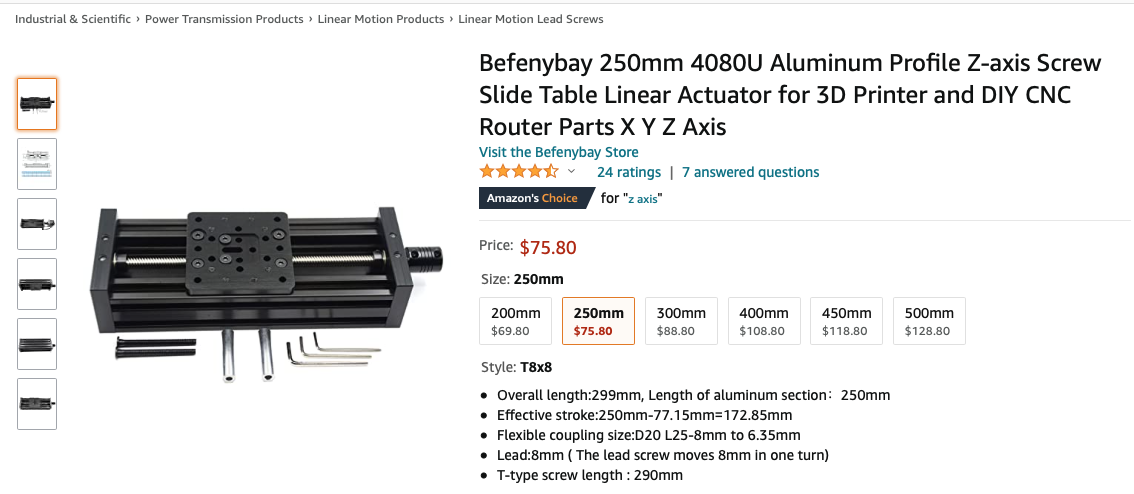

We also wanted to build a linear actuator, we started looking at parts on mcmaster, then realized we can just buy it on amazon so we did that!

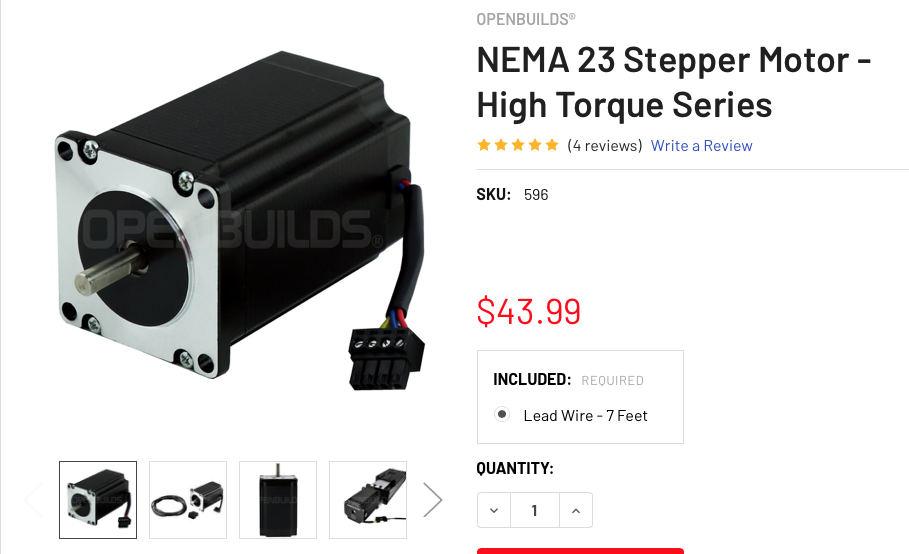

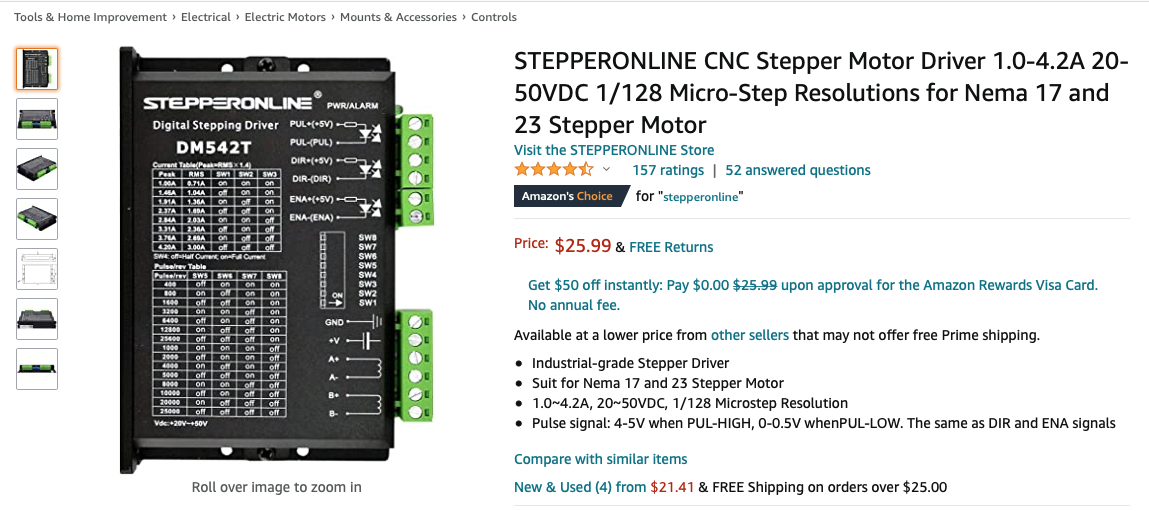

Since the extruded resin can be quite thick, we got a high torque NEMA 23 andf mounted it to the linear actuator. We also ordered a motor driver which comes later this week.

I went ahead and attached the motor to the linear actuator.