21.05.27 DTS Final Presentation

Demo Video:

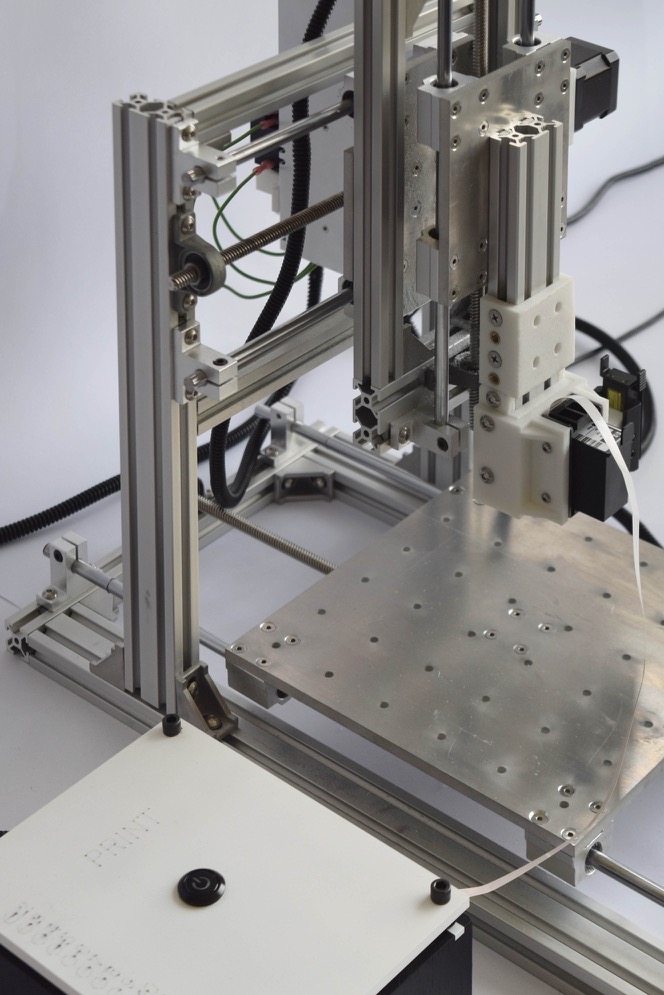

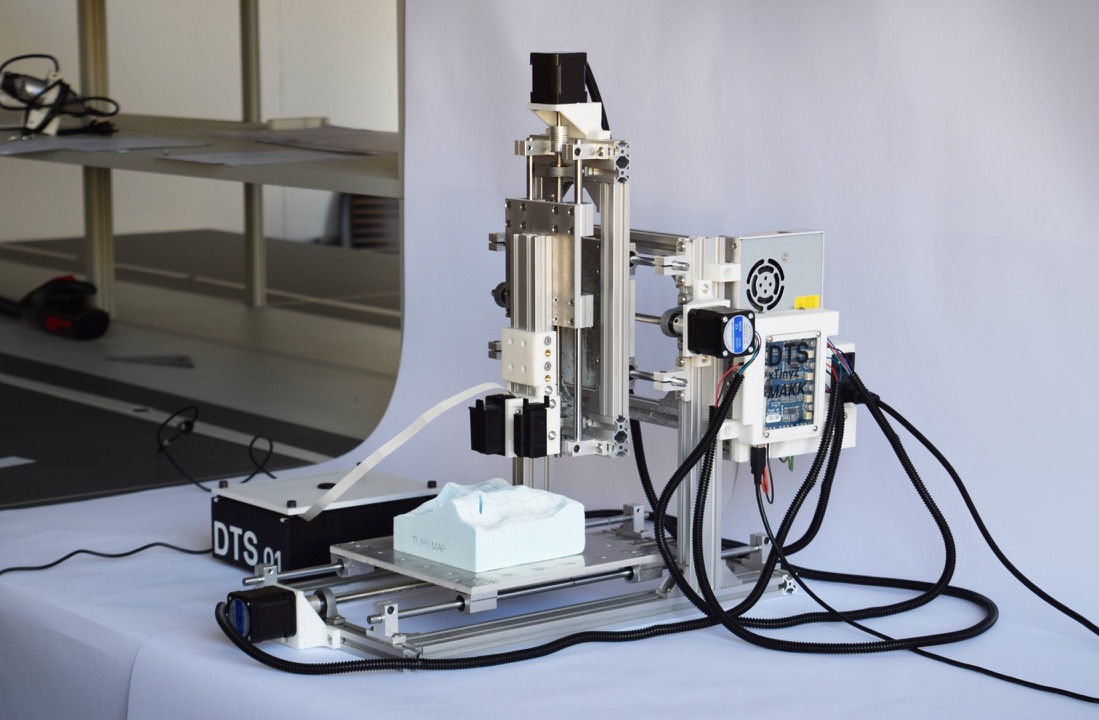

Current Machine:

Current Machine:

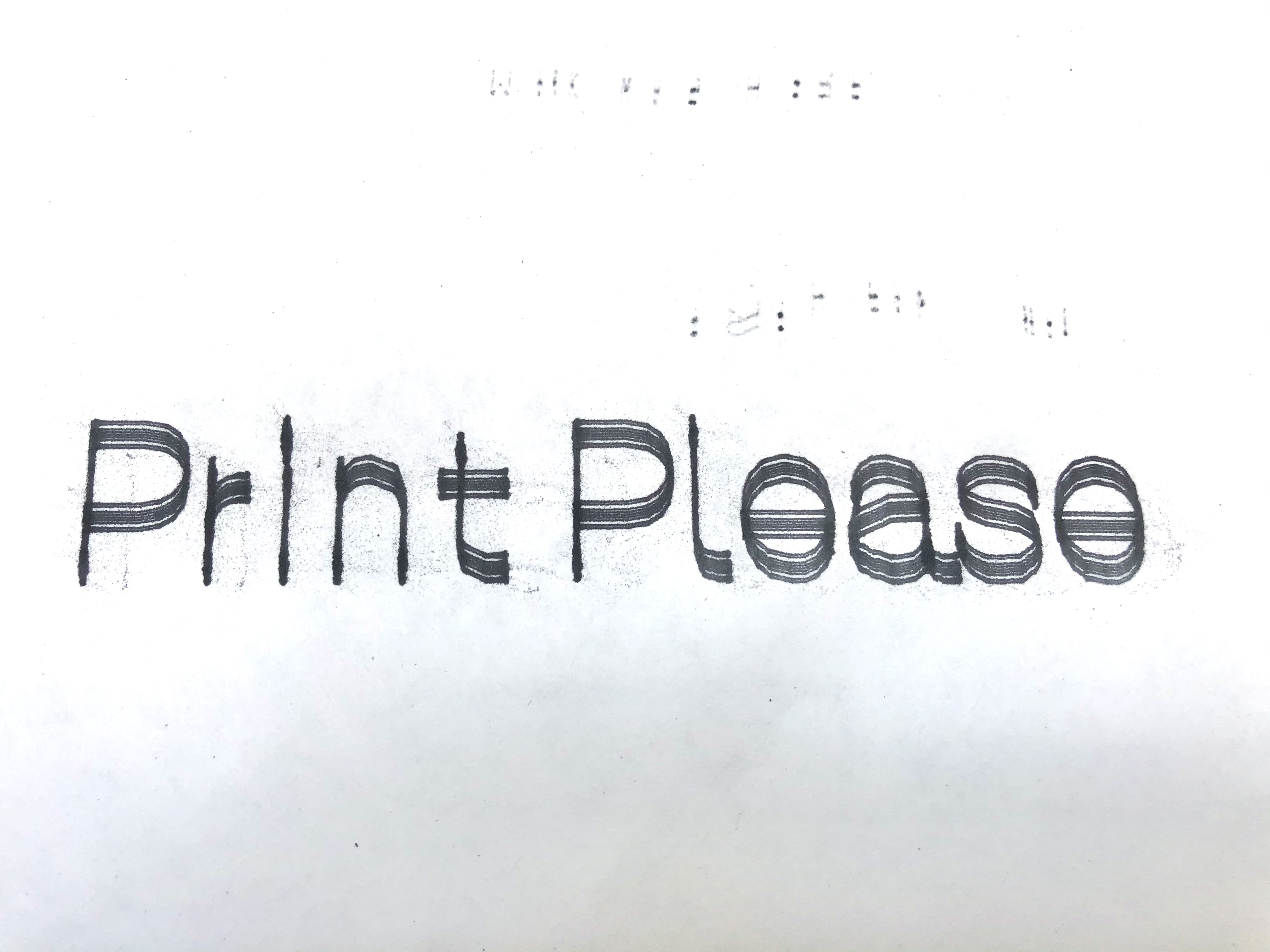

12 Nozzle Print using Arduino functions:

The code that made the print above, using TinyG board as an Input, and the Arduino functions:

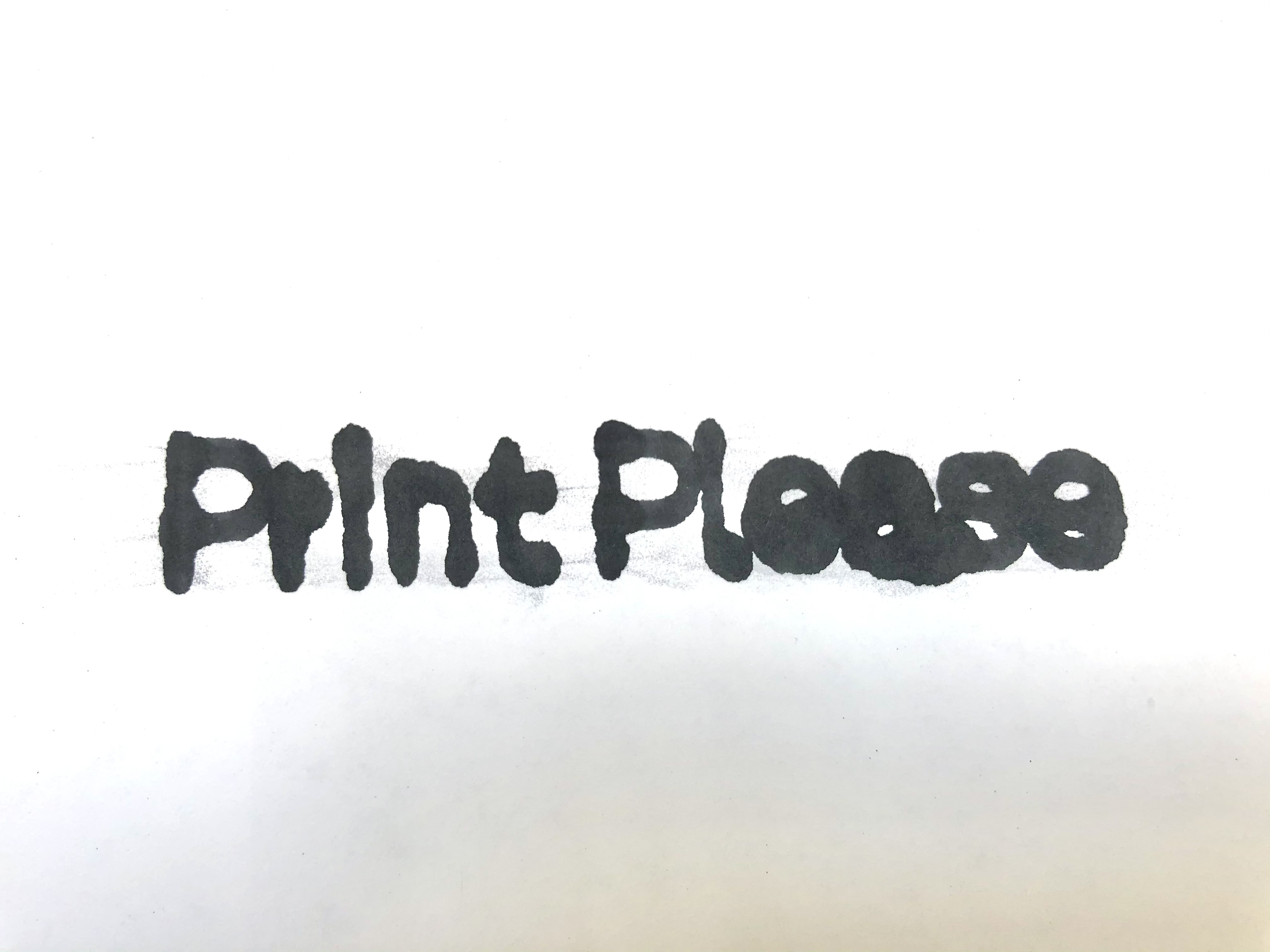

Updated method using direct port manipulation on the Atmega chip. Same print with 12 nozzles using new method - results are a lot faster and more ink:

The code that made the print above, using TinyG board as an Input, and direct port manipulation:

With the direct port manipulation, there was also an idea about producing a print more like machine produced calligraphy.

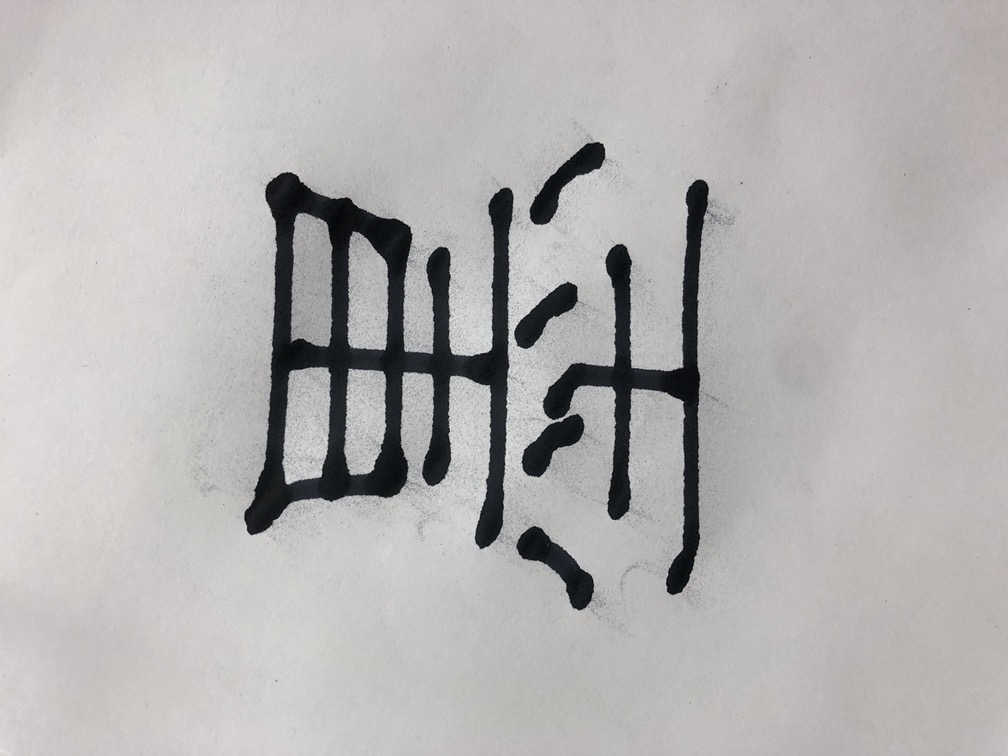

Printing Kanji above:

Results above, printed at an angle to almost get a brush like effect.

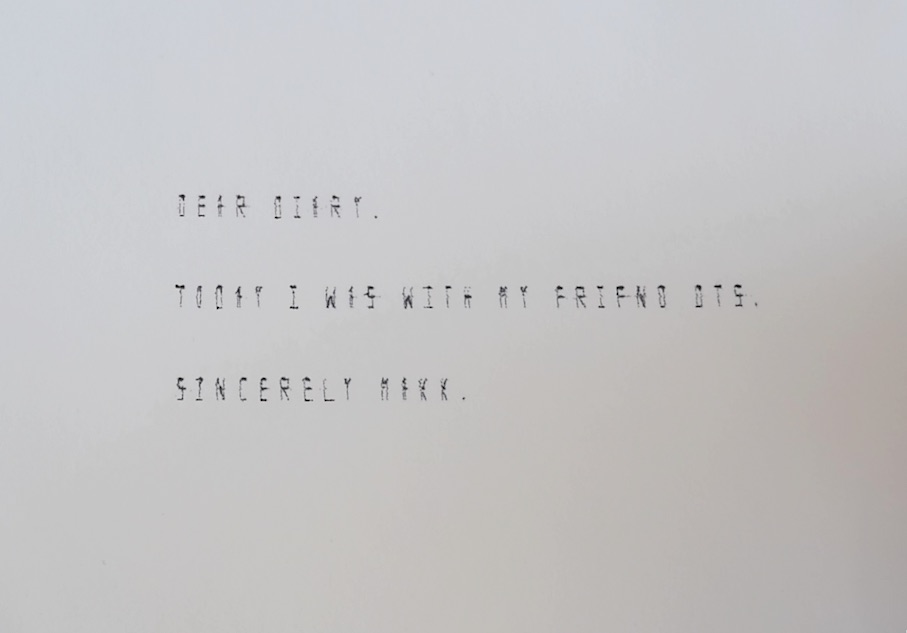

Considerable efforts were also put into programming the printhead to do things like print letters with all 12 inkjets. We now have written the code for all 26 letters of the English alphabet, 0-9, and some punctuation as well, so full sentences can be written with the machine.

Above is a printed example of where our letters have ended up. Below is the code for printing this example and letters "D" and "E" to show what the main code is referencing.

Letter "D":

Letter "E":

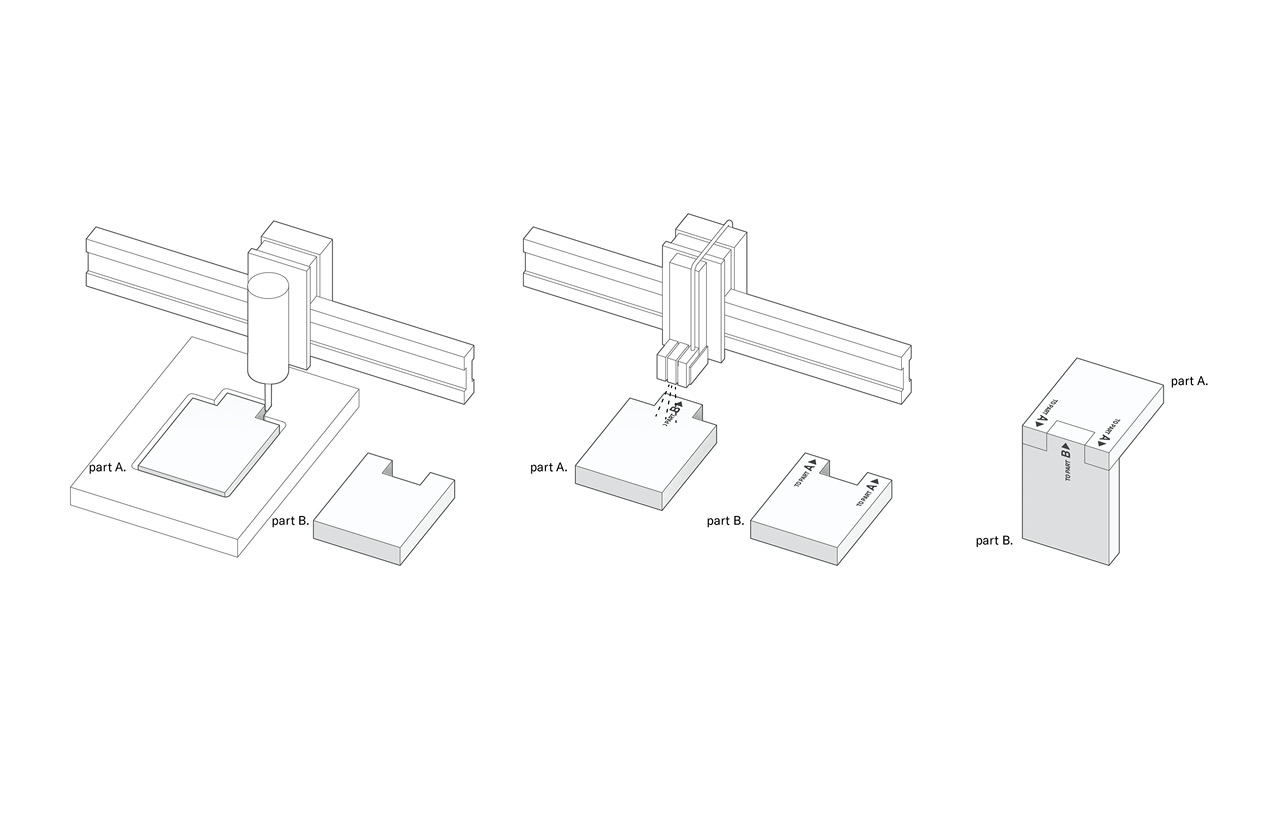

While this works mainly in concept, the idea here (below), is that the machine is capable of printing on its own parts.

This piece then becomes the top of the electronics box, and includes a label for the power button and "2-13" to indicate the orientation of the inkjets for programming.

However, the implications of this idea conceptually is to suggest that the further development of this machine could produce capabilities of milling parts and then printing assembly guides/instructions on the discrete parts to later be assembled by a different user.

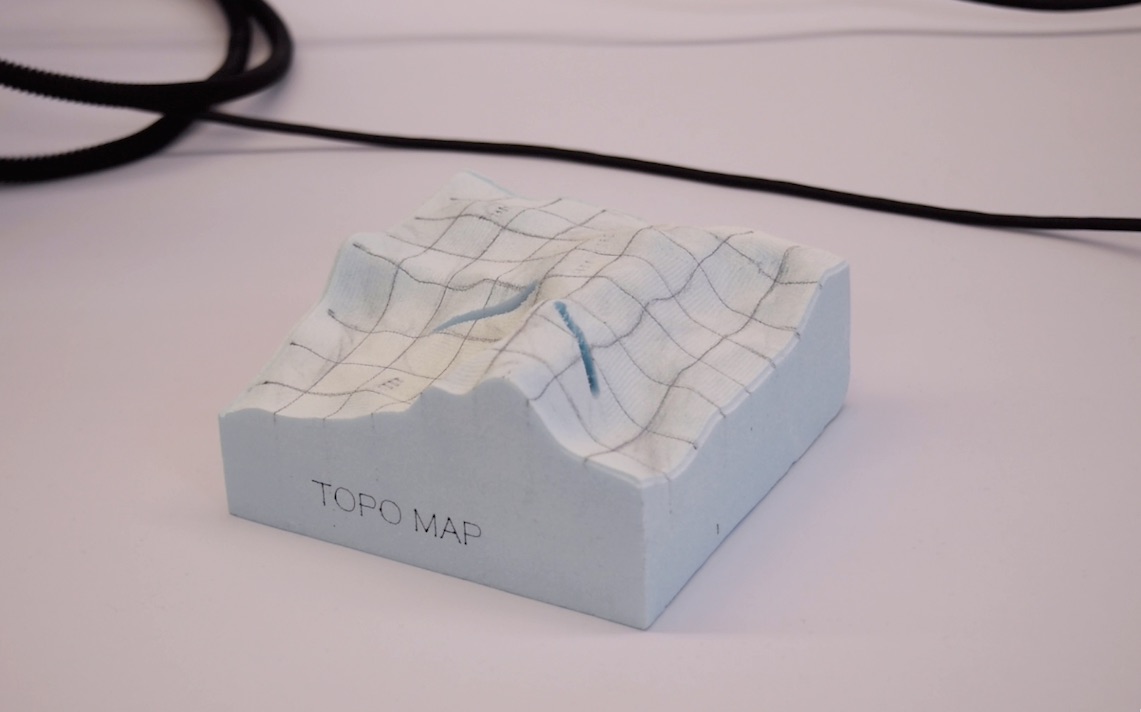

Lastly, one of our major goals was to print on a complex 3D surface. We milled this piece of foam on our machine, and then generated a matching gcode that follows a 3D path to print on top of it.

Below is that print where we have also printed on more than one face of the object.

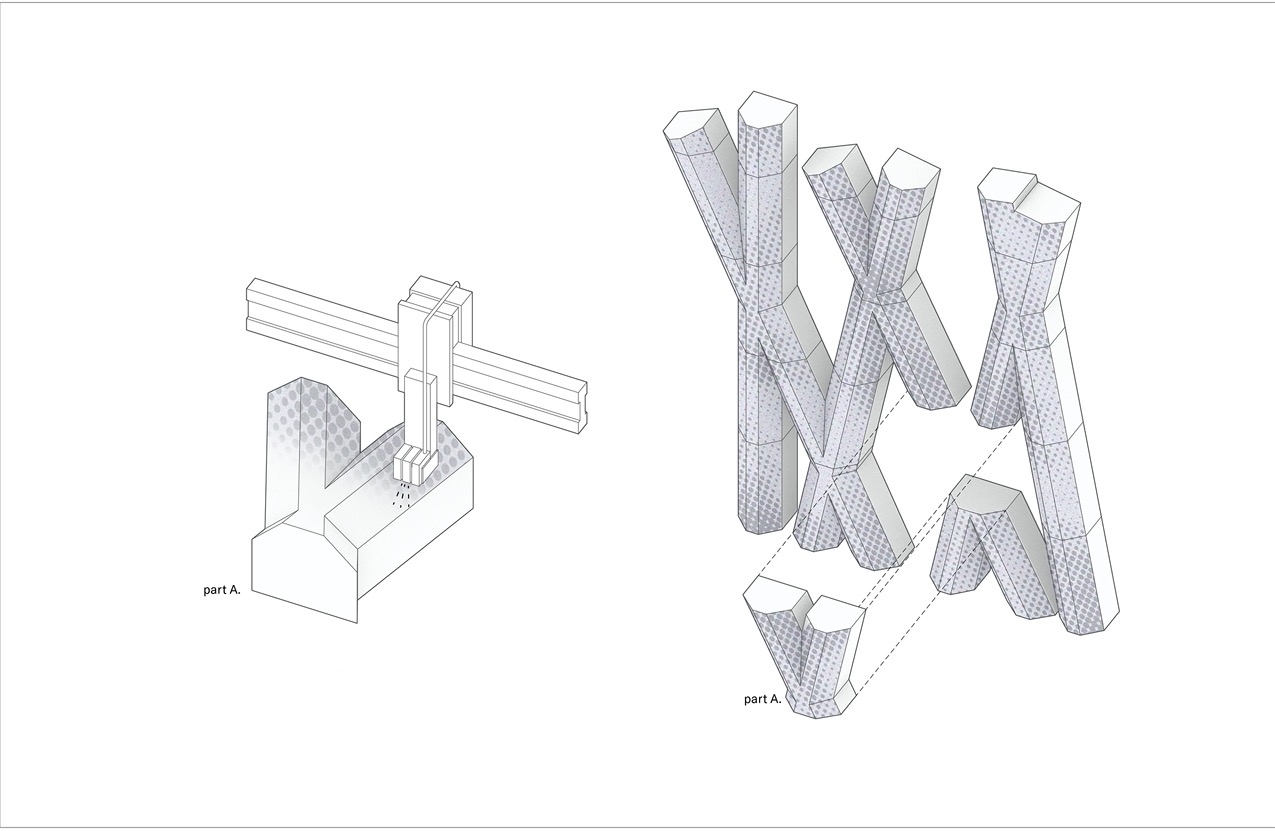

This at a larger scale also has implications we have been thinking about. If our machine was scaled up, we could be looking at machine that prints on larger 3D dimensional parts that could eventually become architecturally scaled components.

Fin.