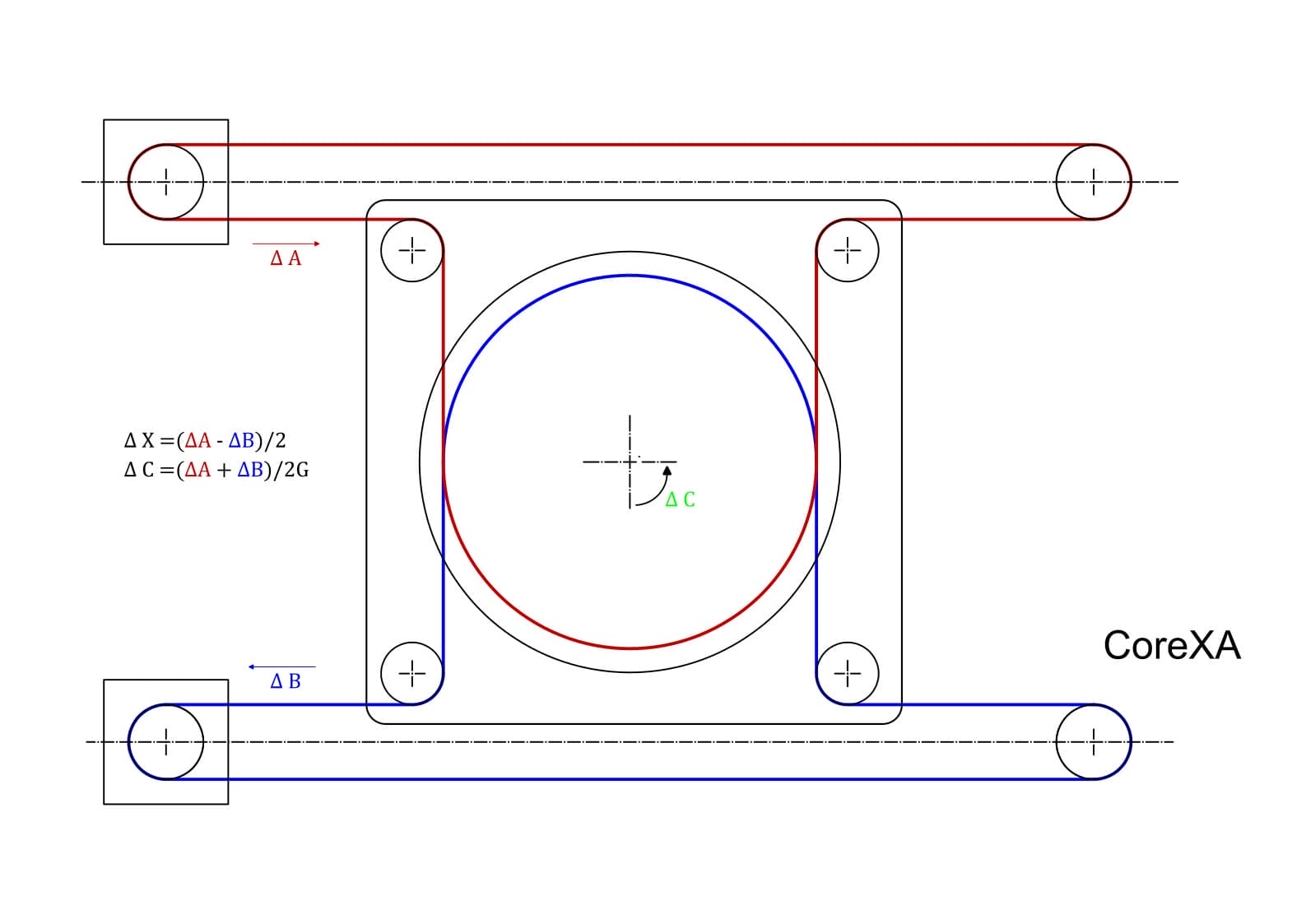

CoreXA

A simple implementation for combining a linear and rotary axis into a compact setup. It provides a gear-reduced infinite rotation axis and coupling the efforts of two motors to provide greater force for motion.

Motivation

Building a 5-axis CNC has been a dream of mine for a long time. For this I need good Rotary axes that are incredibly accurate, can hold up to the stresses of machine. This can be extended to fit 5-axis non planar 3D printing.

I've tried building rotatry joints from, flexures, cycloidal, planetery etc. Belts seem to be a good compromise between accuracy and cost. The next challenge is packaging the whole unit into something small.

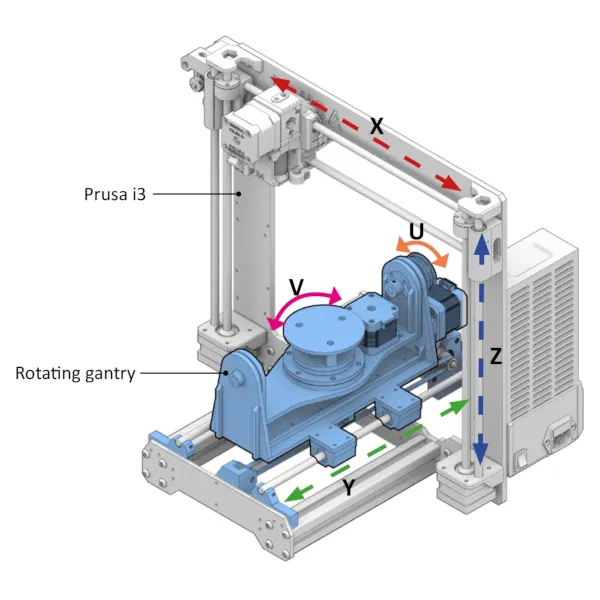

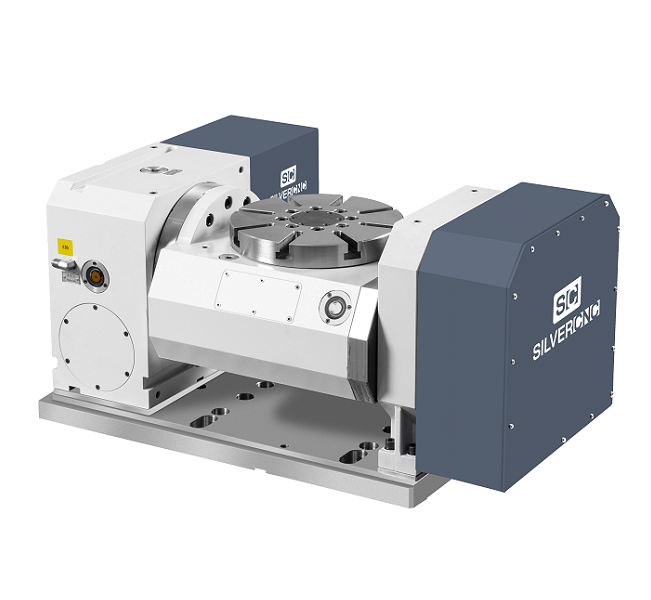

Most common layout for a 5 axis is a Trunnion table. But this is Bulky and takes up a lot of work area.

Basic layout

Specifications

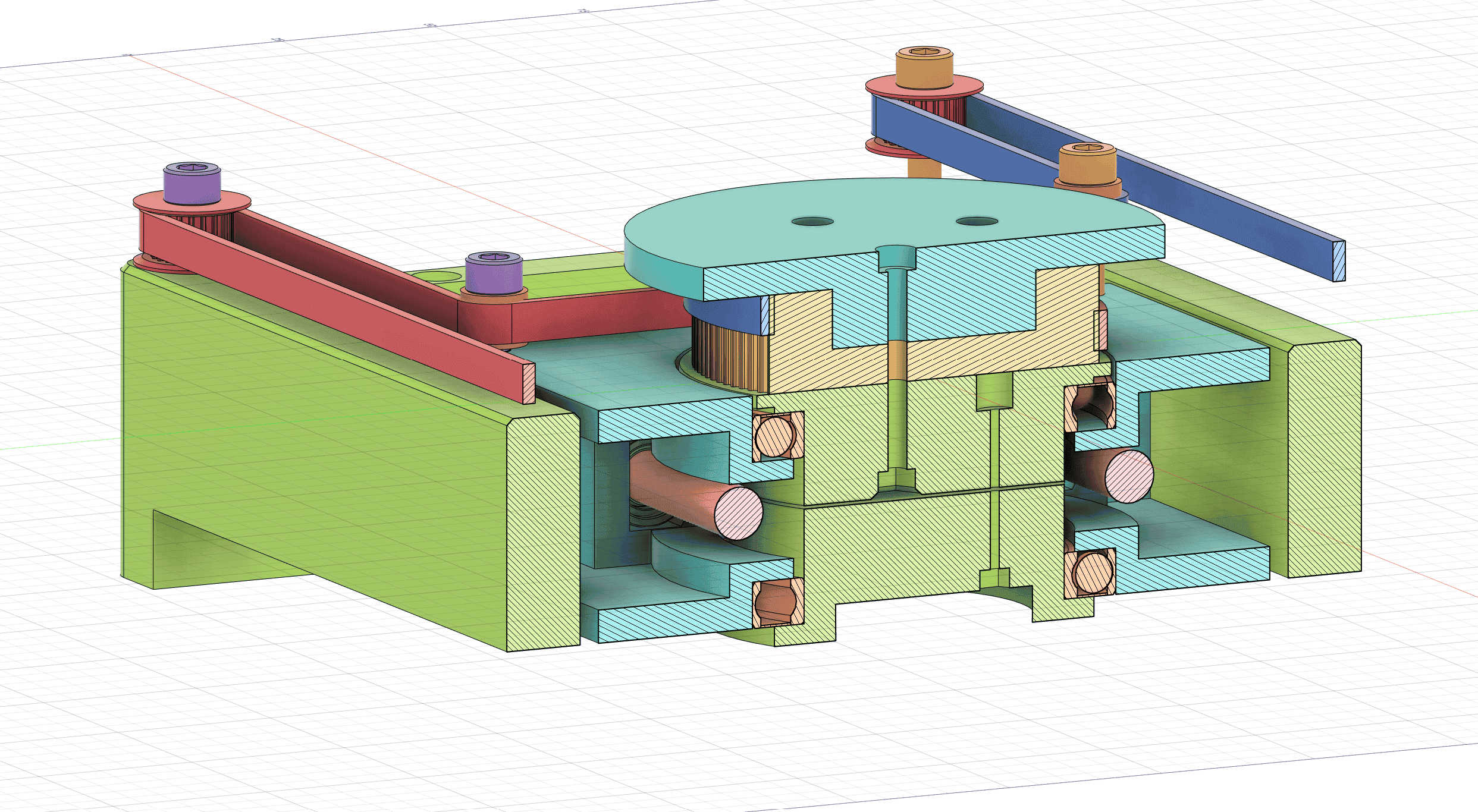

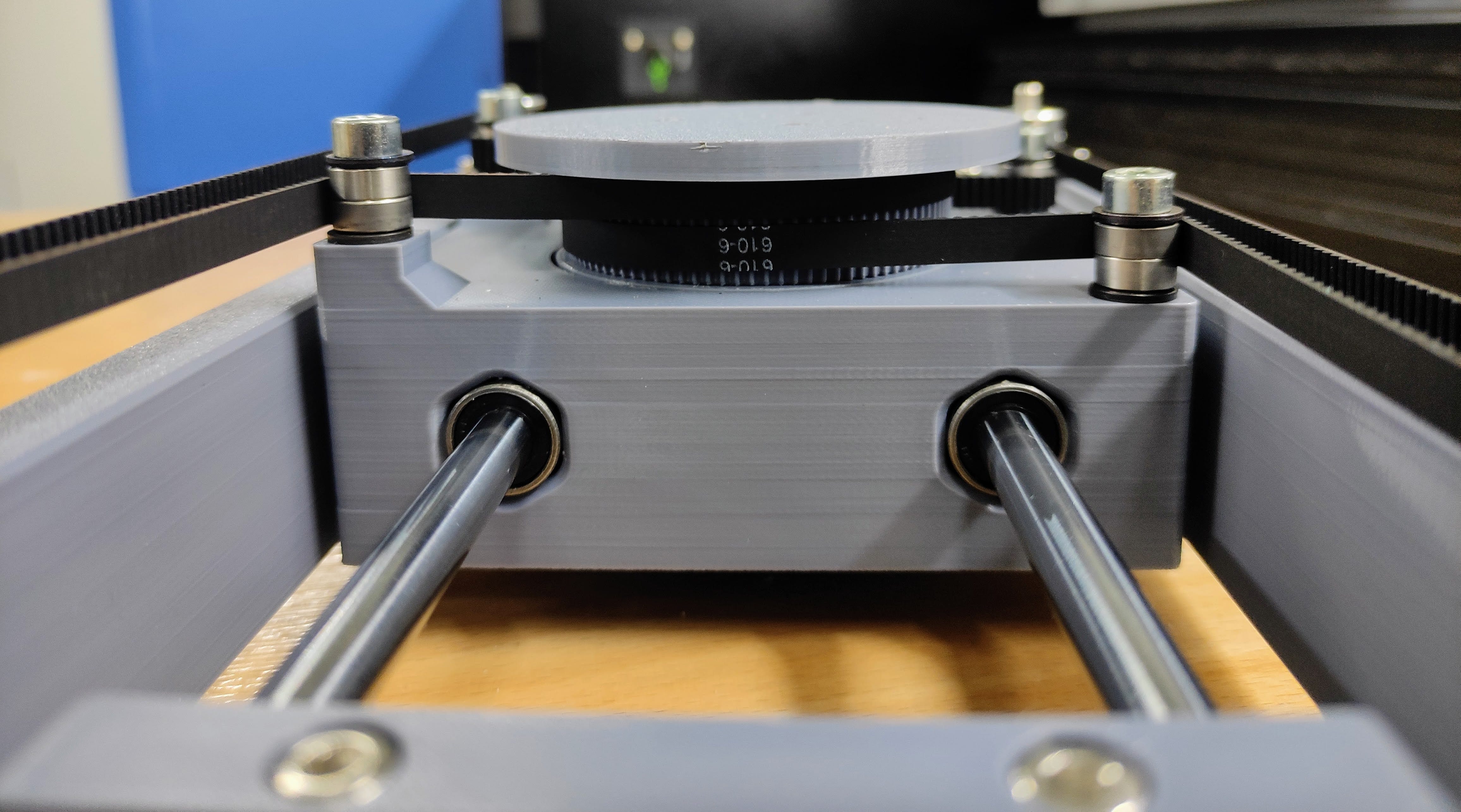

- Infinite rotation possible because of two closed loop belts at two heights.

- A gear reduction for the rotational axis of ~1:5 based on the motor and drive gear pulley. Giving a theoretical resolution of 0.046 degrees under a 1/8th microstep.

- Free space in the middle of the rotational axes providing longer work holding options like 5c collet style clamps.

- Larger travel distance with Off-board motors and combined efforts for linear as well as rotary motion

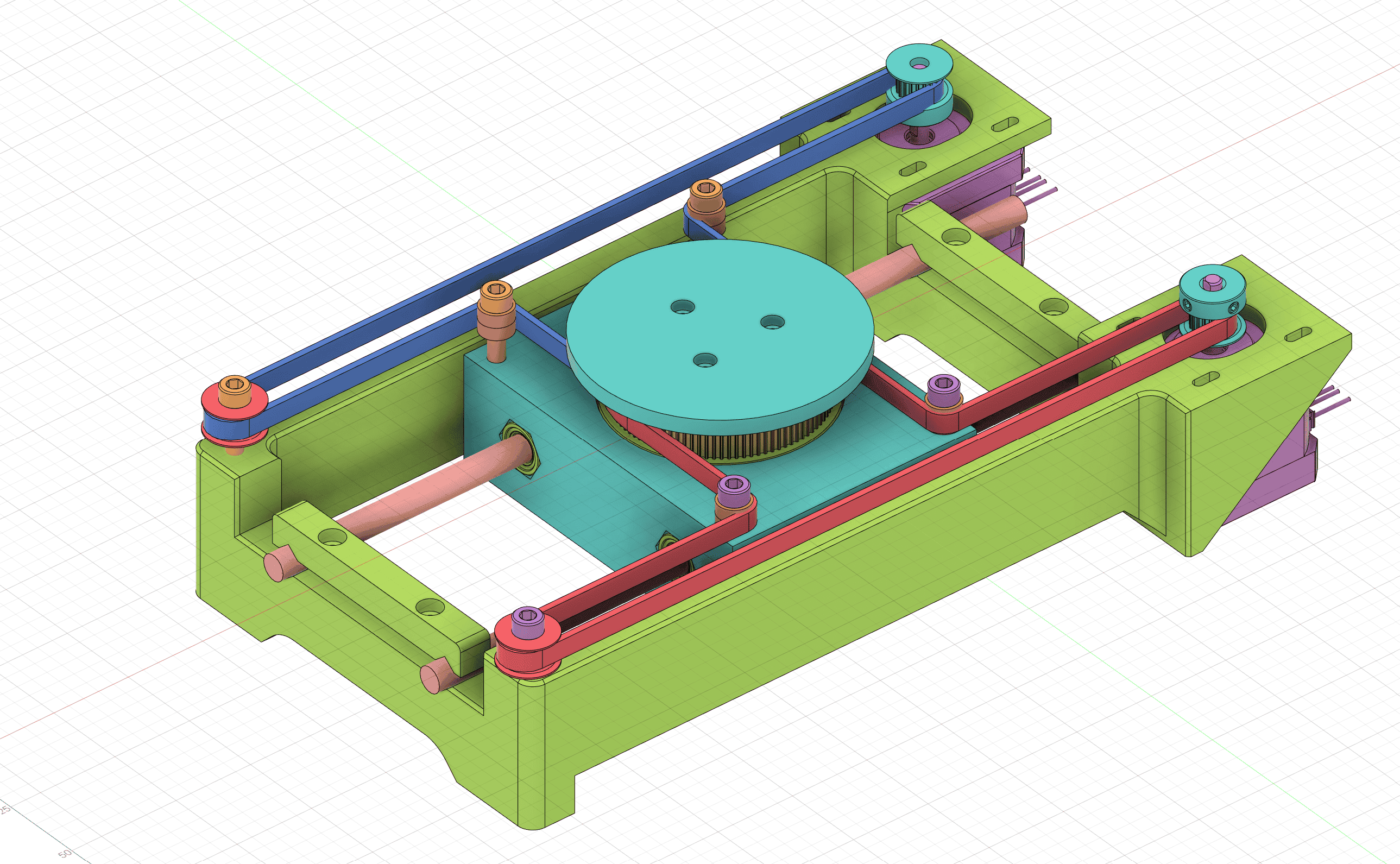

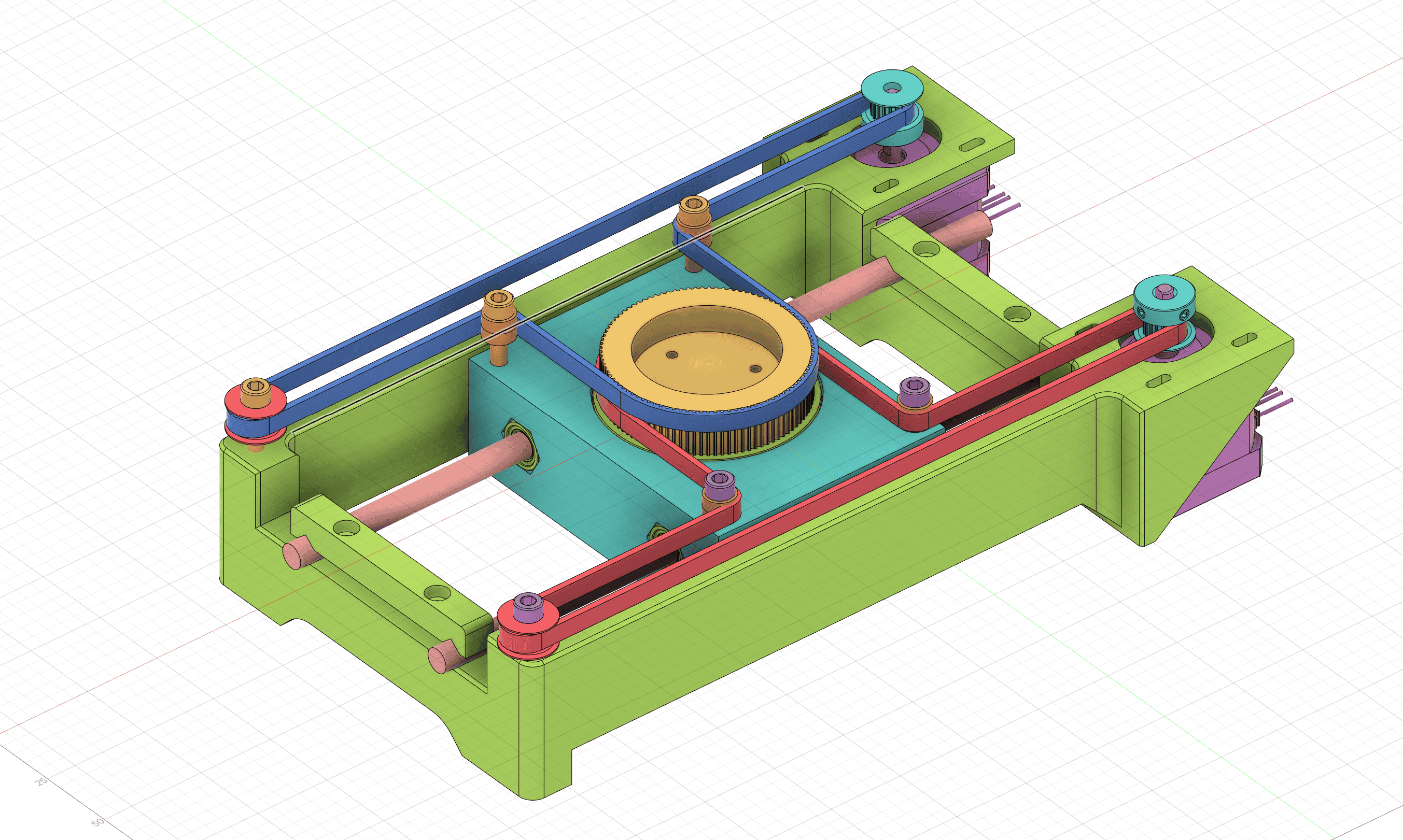

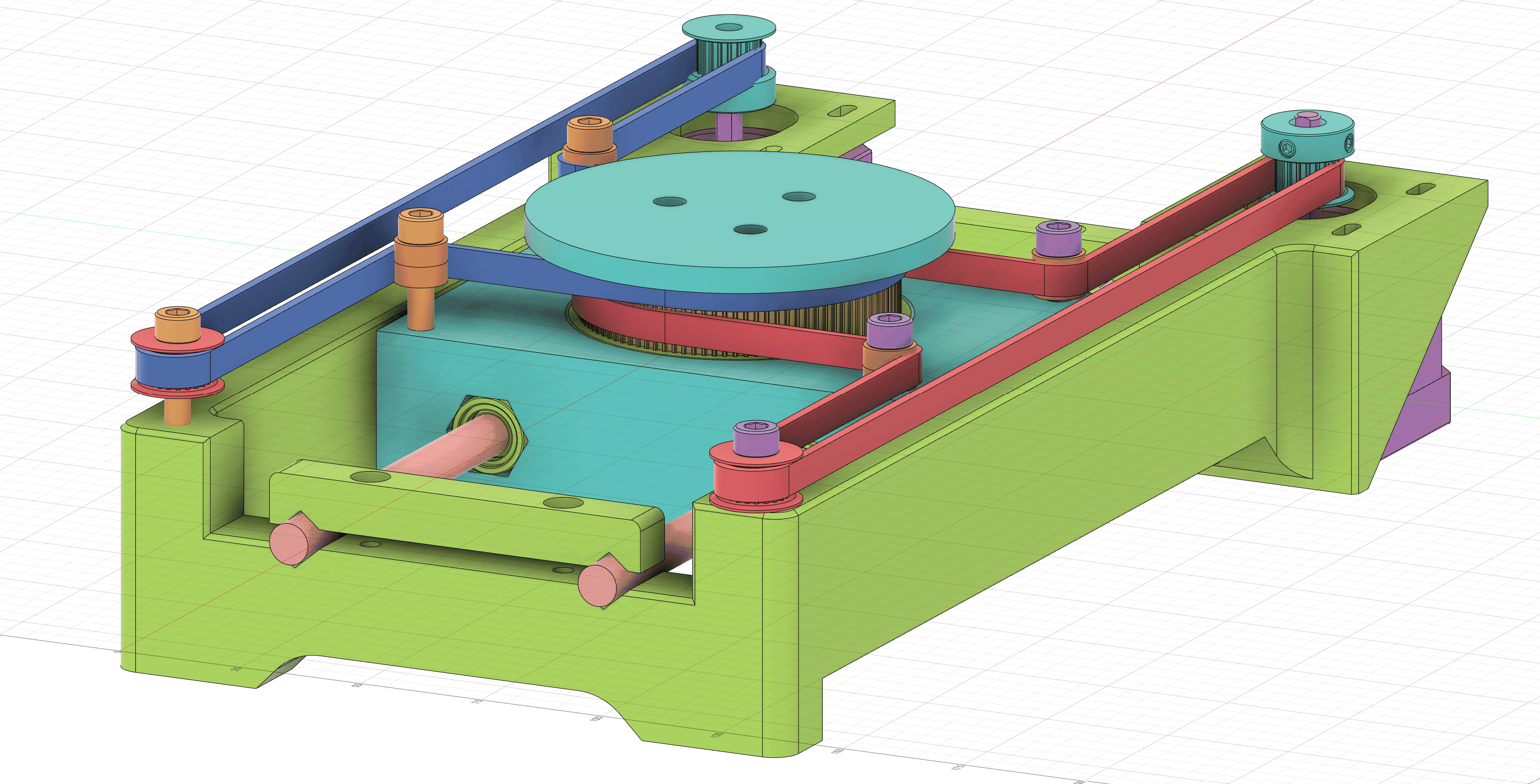

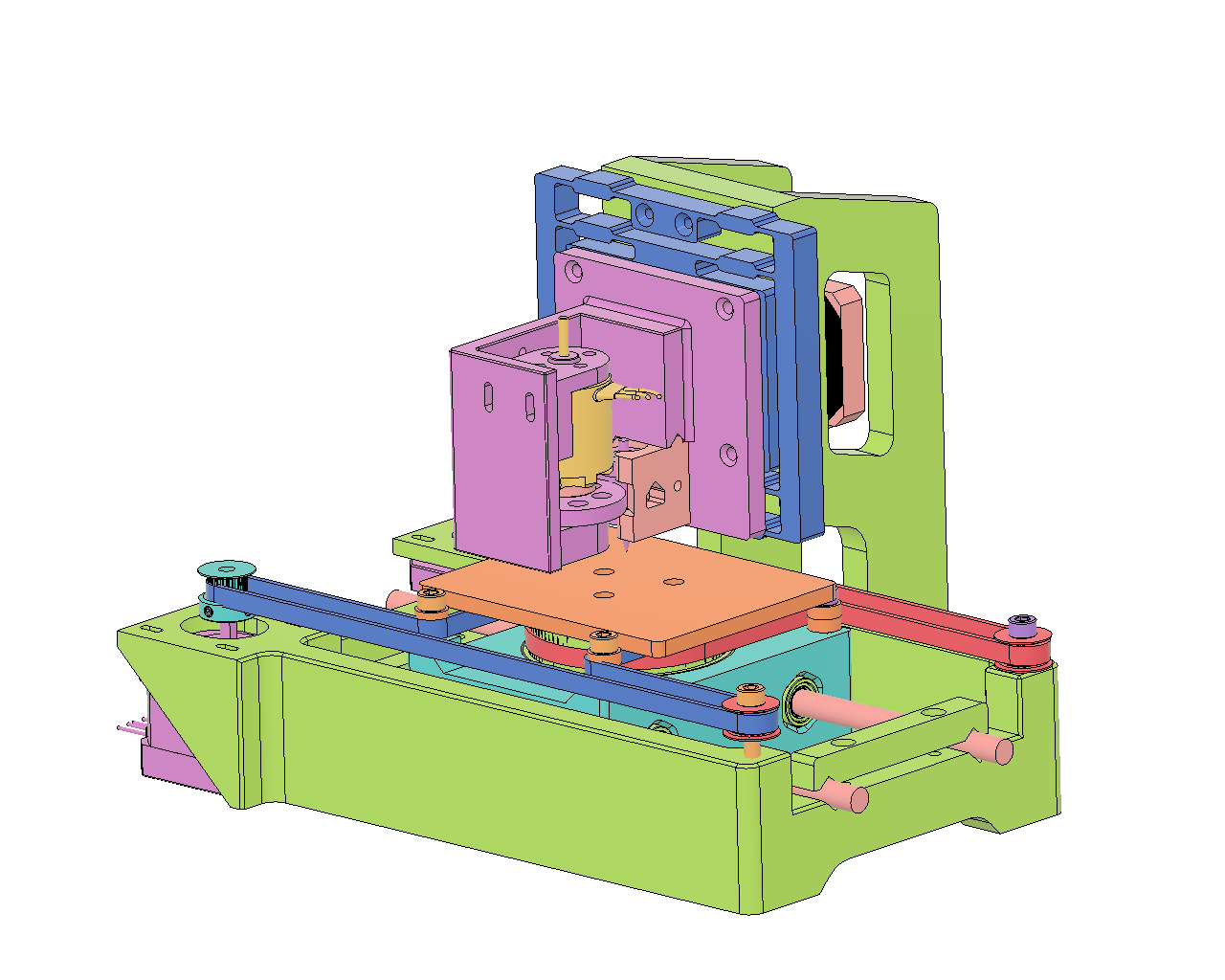

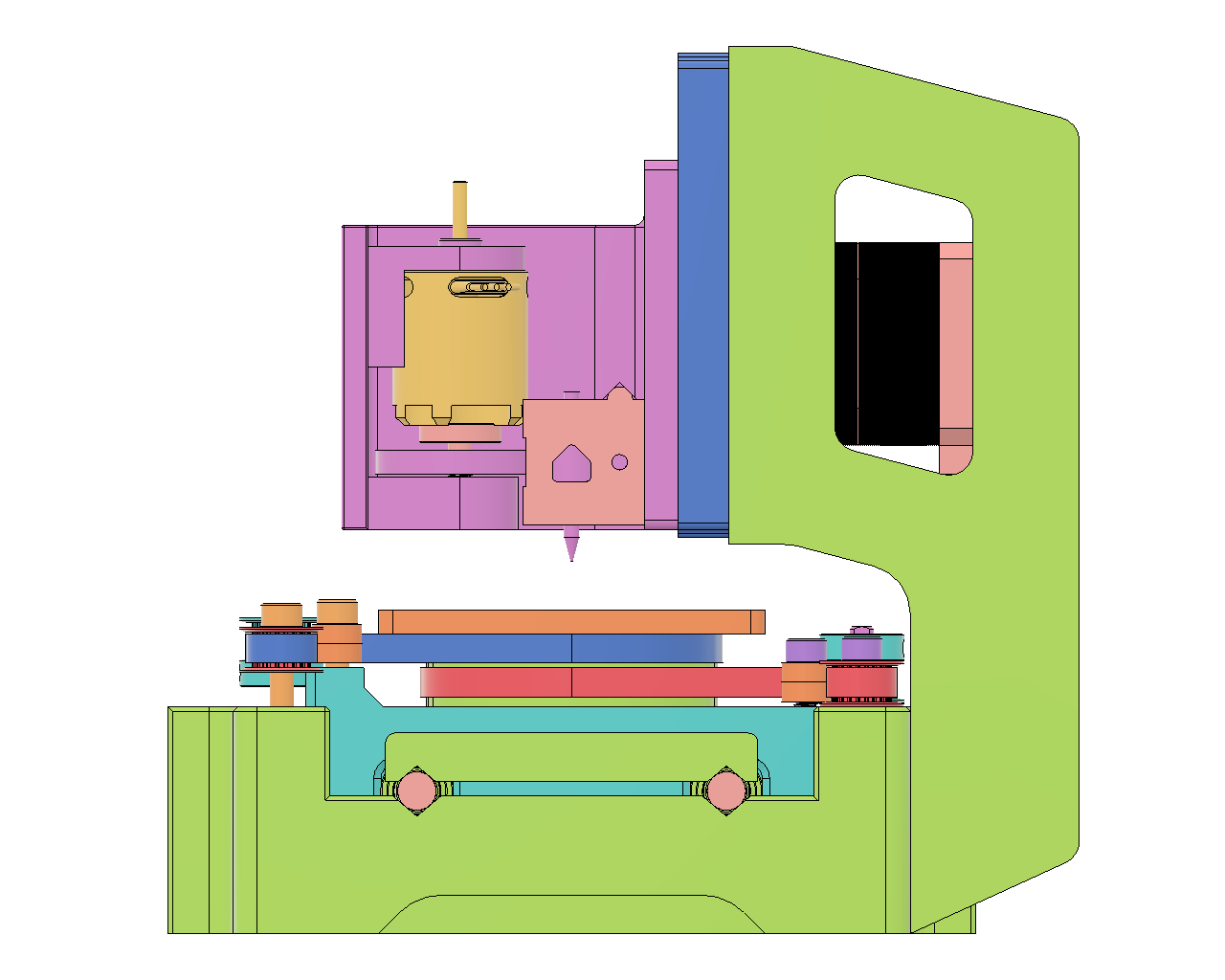

CAD Implementation

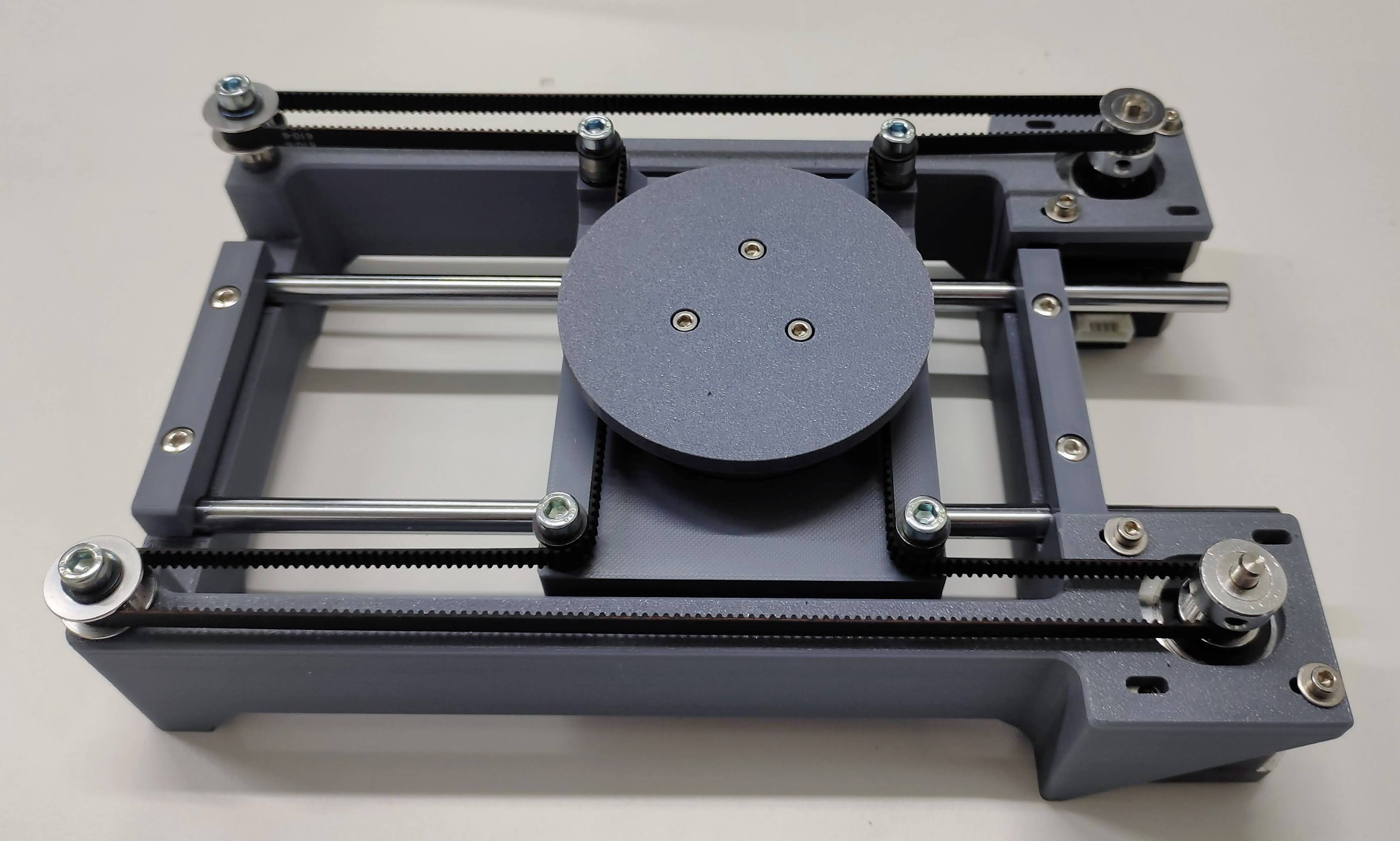

A simple 3D printed Axis that demonstrates the functionalities of the layout.

A 3D printed gantry and frame with a 95 Teeth 3D GT2 pulley as the base for the rotary axis.

The lack of motor in the middle allows space for large bearings that can take big moment loads. A 5C style collet can also be implemented allowing for longer workpieces and holding cylindrical pieces.

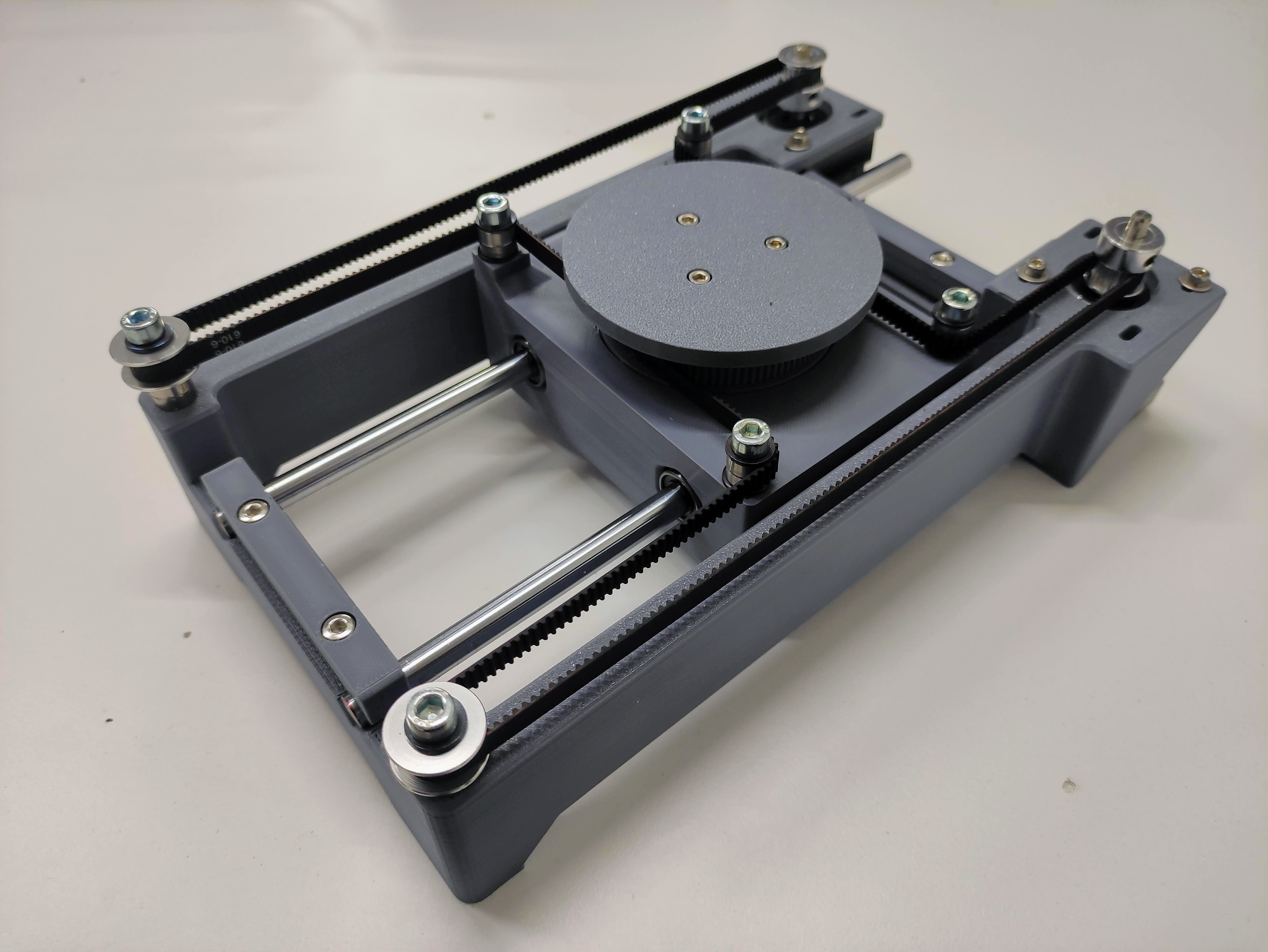

Prototype

The single stage prototype is printed with PLA on a Bamboo Printer.

Infinite Rotation possible bacause of the closed loop belts.

Applications

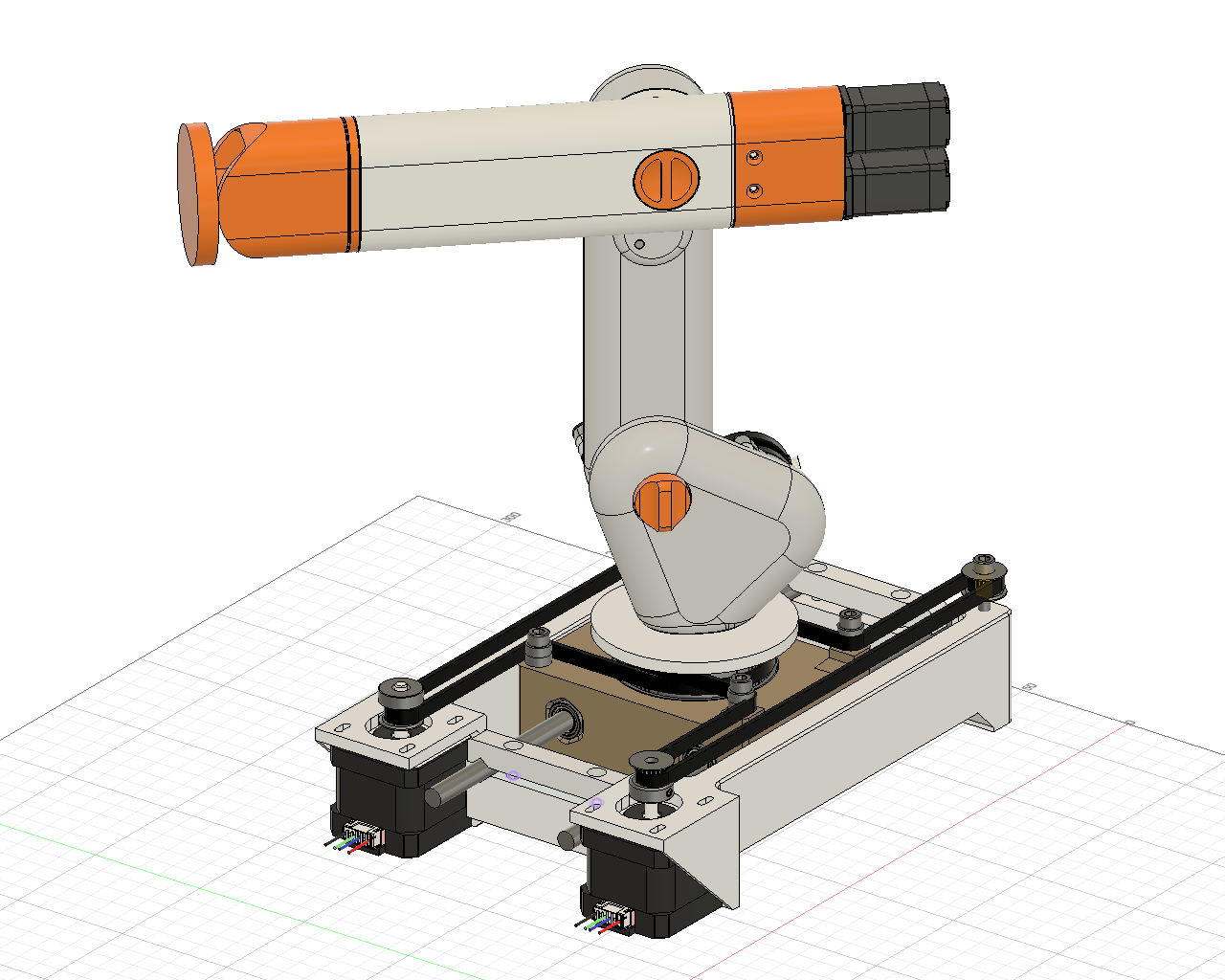

Robot Arm Base

Arm desgined by Marc Schömann

Arm desgined by Marc Schömann

CoreXA is potentially a great base for building robot arms that can rotate as well as translate within the given volume.

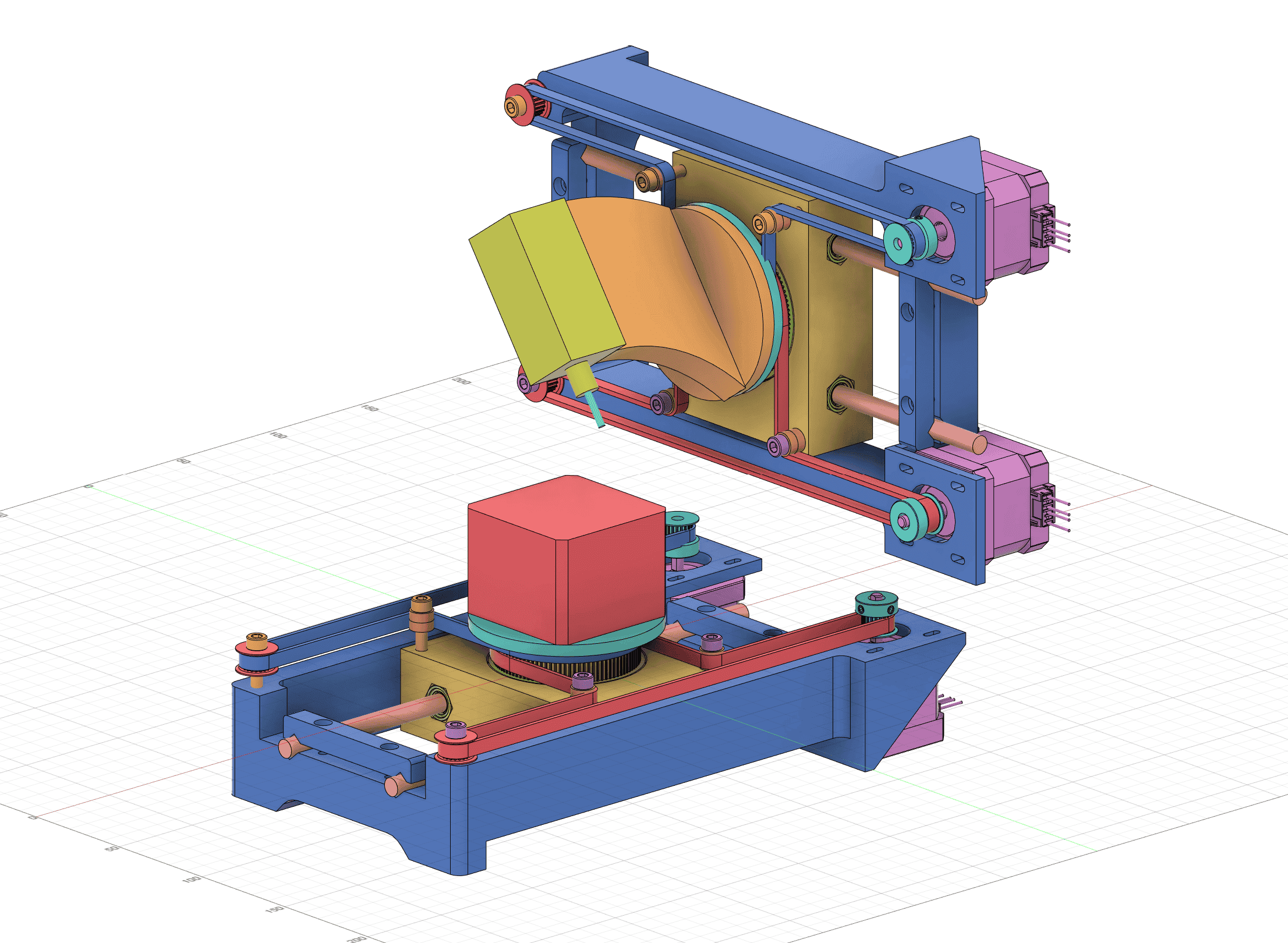

5-Axis Configuration

A possible 5 axis config with the addition of a Z axis would make it possible as a printer or a CNC mill.

PicoPolar

A Polar Pico variant with the Flexure Z-axis and CoreXA as the base provides a tiny machine with an even smaller footprint. Polar kinematics needs to be explored for the use as a PCB mill.