Week 5: Optical Steering with Stiff Thermal Actuators (Idea)

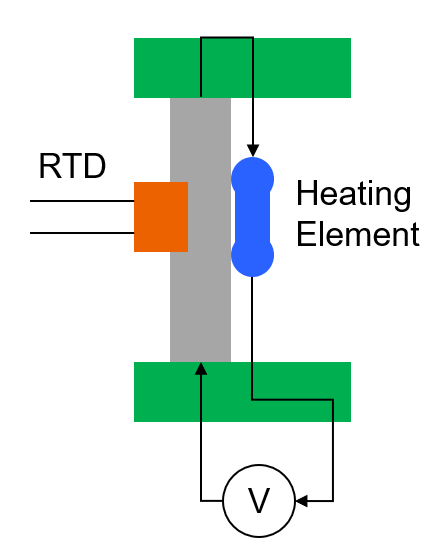

This week, I've been exploring an idea for optical steering using stiff thermal actuators. The key features of this approach include:

- Micrometer adjustments via PID-controlled temperature (or optical detector)

- Low cost and low mechanical complexity by utilizing thermal expansion for movement (using a post made of aluminum, which has a high thermal coefficient of expansion)

- Using an RTD (Resistance Temperature Detector) to measure temperature, allowing for precise control within 0.1°C or potentially lower

- Prioritizing stable positioning over rapid movements

- Incorporating Joule heating along with the heating element

The goal is to replace piezo actuators and potentially create a Stewart platform-like system with six thermally expanding posts. PCBs can be placed on the top and bottom to move the optical elements around.

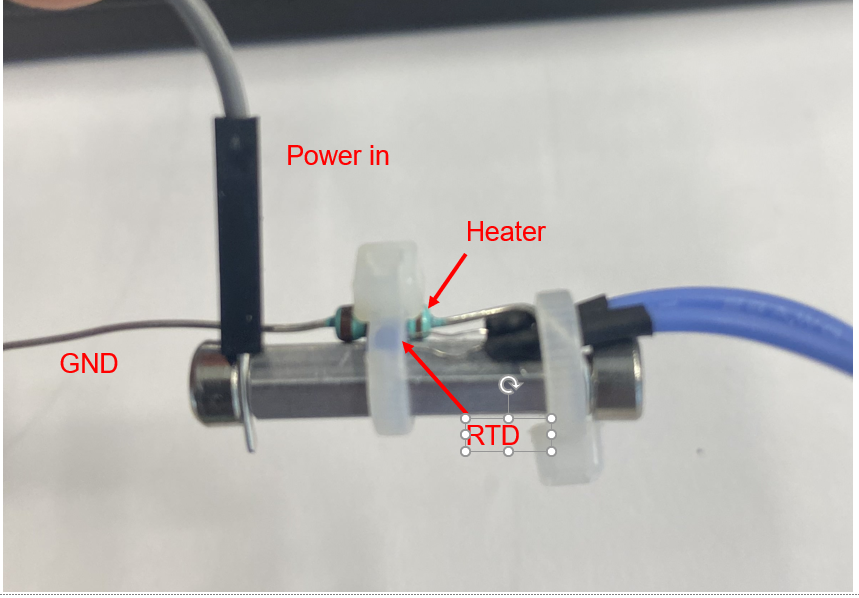

I created a quick prototype using Tinkerforge elements, specifically the Industrial PTC Bricklet and the DC Bricklet V2. I also used a random resistor as a heating element and a Pt1000 sensor. Here's a picture of the prototype system:

Initial tests suggest that the system works well. The next step is to compile all of these circuits into a main board for multi-axis control. This approach has the potential to provide a cost-effective and mechanically simple solution for precise optical steering.

Week 4: Manual Dispensing Test

This week, my friend Olivia and I attempted to manually dispense the resin instead of using the automatic dispensing system. We mixed water and glycerol in a ratio that would provide a neutral density for the Formlabs Durable resin we had on hand. Our goal was to create a convex lens of some sort, and it worked! Here's a picture of the result:

It's important to note that Formlabs Durable resin is somewhat cloudy, so the lens quality is not optimal. However, this quick and dirty test provided valuable insights. We observed that achieving a strong attachment between the resin and the frame is crucial for success.

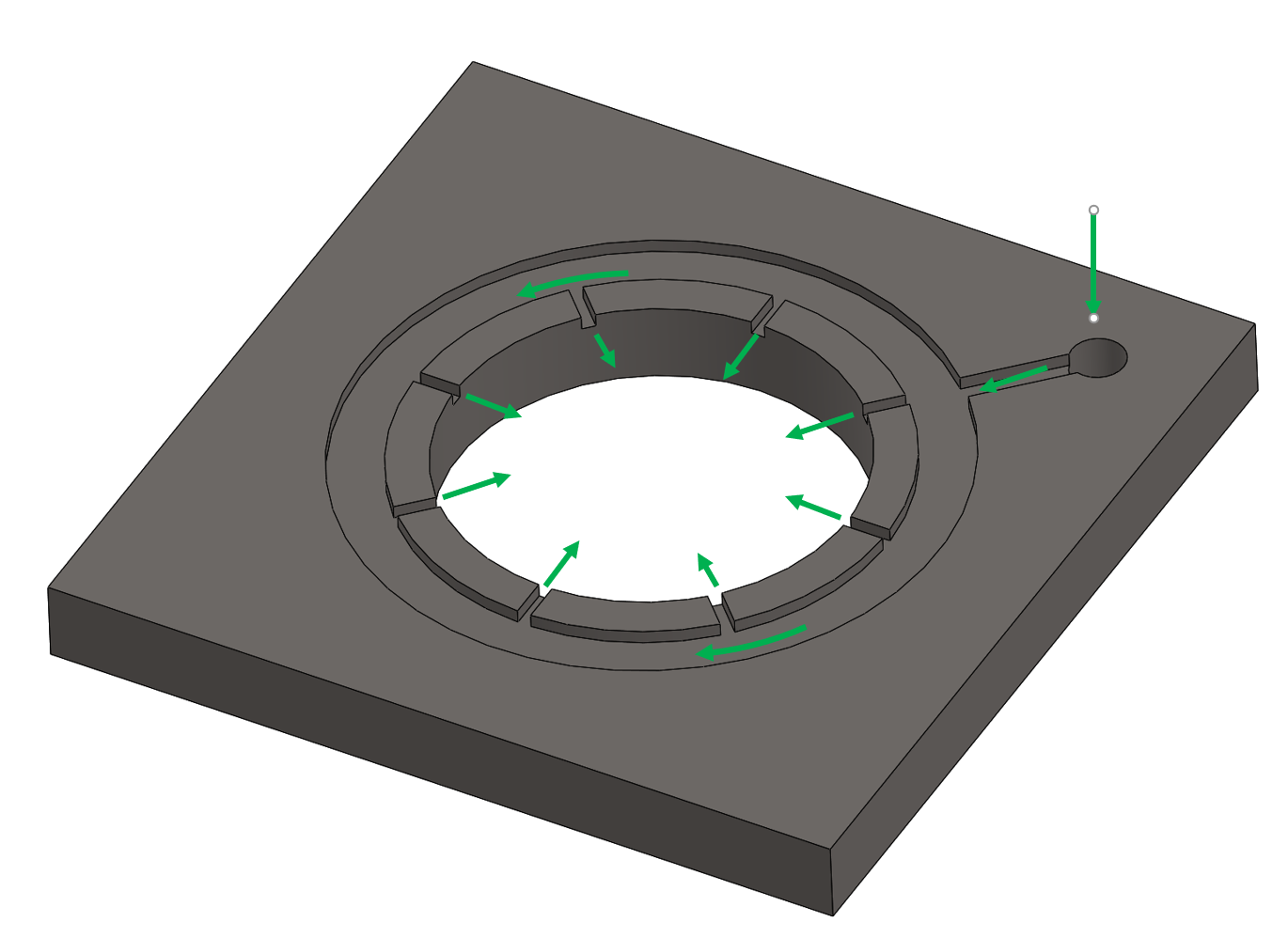

To address this, we're considering creating a microfluidic chip, similar to this design:

This chip design would allow the resin to be dispersed evenly around the perimeter, potentially improving the attachment and overall lens quality. Moving forward, we'll continue to refine our approach based on these findings.

Week 3: Parts Arrival and Build Commencement

This week, we've been busy receiving parts from our suppliers. Most of the components have arrived, but we're still waiting on the valves. In the meantime, we've started the initial build process.

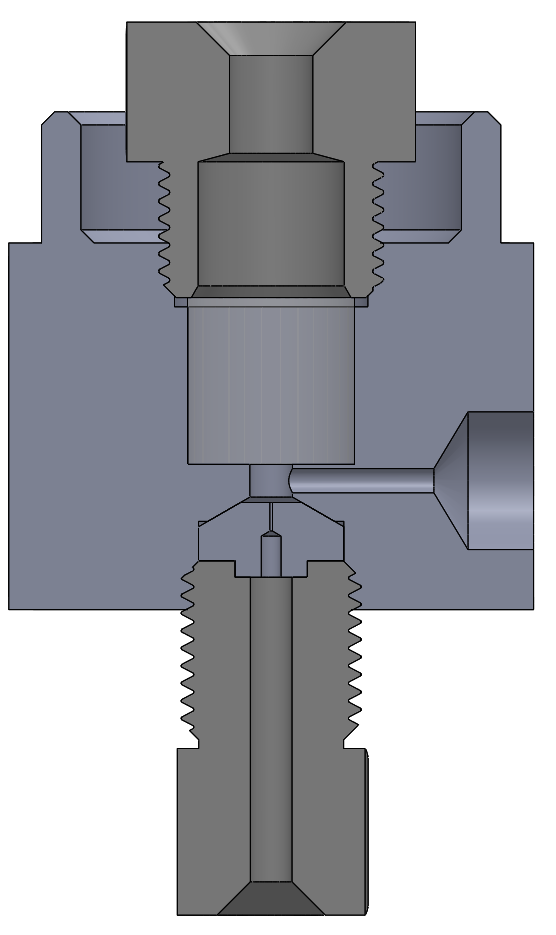

Aside from my own project, I've also been assisting Max with the Laser Micro Jet. Here's an image showcasing the cross-section of the laser head:

We've made some notable improvements to the design. The sealing is now achieved through coaxial threads, allowing the pressure cone from the screw to distribute evenly across the seal. This change has reduced the number of bolts that need to be tightened and torqued down, simplifying the assembly process.

The laser head will interface with a 30mm optical cage system, which will house the focusing optics, camera assembly, and laser. I've also created a laser-cut XY flexure prototype for laser alignment. In the future, we might consider using EDM (Electrical Discharge Machining) or waterjet cutting for this component to enhance its precision and durability.

Week 2: CAD Development and System Updates

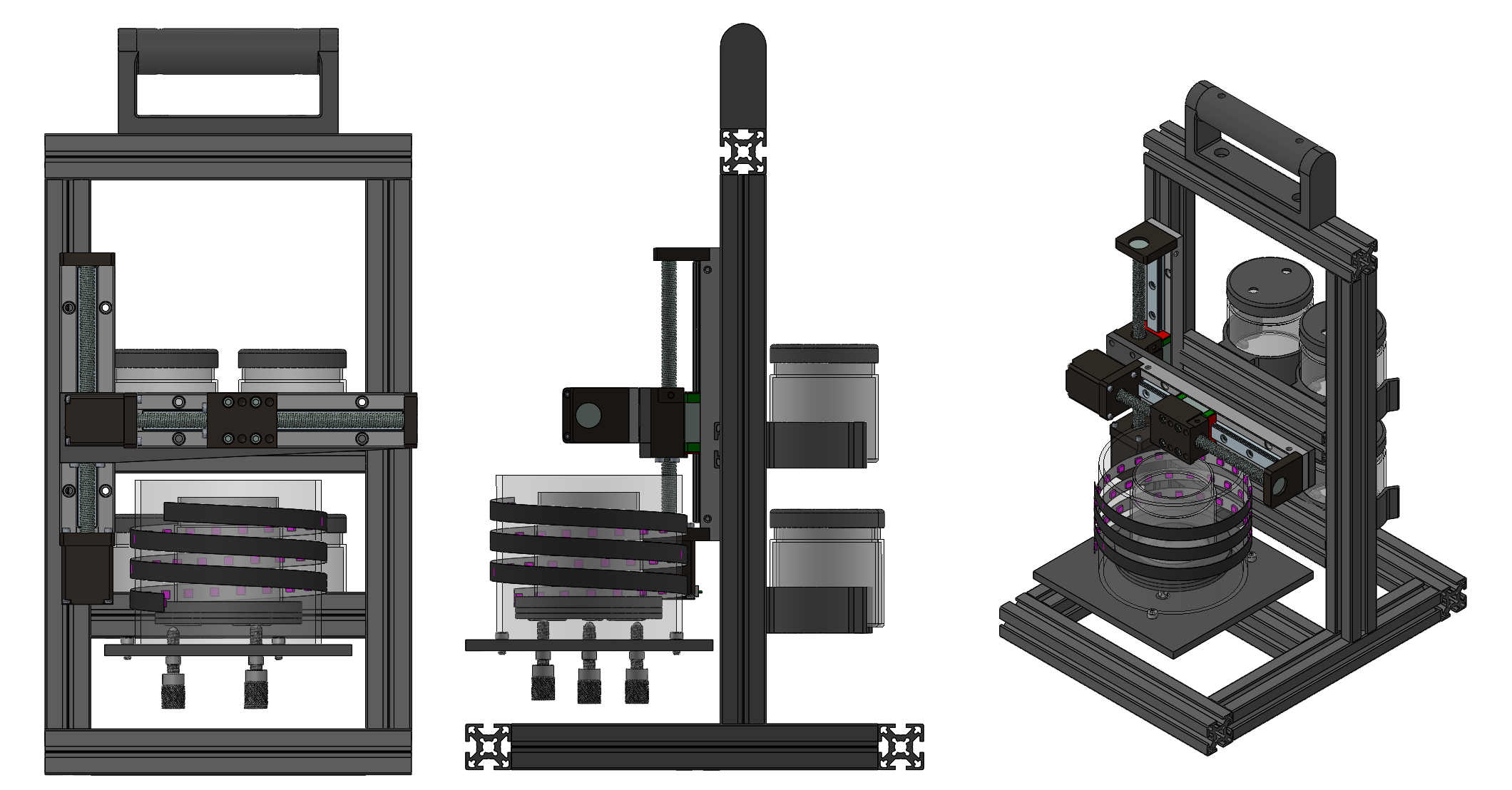

This week, we've made significant progress on the design front. I started working on the CAD models to bring our conceptual ideas into a more tangible form. Here's a preview of the current CAD design:

I've implemented some changes to the initial system design to optimize our fabrication process. Notably, I've integrated two FUYU actuators attached in series, providing both X and Y movement capabilities. This adjustment will enhance the precision and flexibility of our dispensing system.

Additionally, I've decided to shift from using individual syringe pumps for each fluid to a more streamlined, pressure-driven system for dispensing the fluids. This system will utilize micro valves from the Lee Company for precise control over the flow of each liquid. You can learn more about these dispensing valves at The Lee Company website.

The pressure regulation necessary for this system will be managed by a Festo LRP regulator, ensuring that we can maintain consistent pressure in the headspace of the liquid reservoirs. This approach allows us to accurately regulate the volume of dispensed fluid by modulating the opening time of the valves.

For the liquid container, we plan to use a durable, sealable container suitable for our resin and other components. A perfect example is available on Amazon: Eternal Moment Clear Plastic Jars.

The resin of choice for our optical lenses is Loctite 349, which offers the necessary properties for our fluidic shaping process, including UV curing capabilities.

Week 1: Project Kickoff and Planning

The first week was all about laying the groundwork. We started by defining the project scope, including the technical specifications for the lenses we aim to produce. This work is inspired by the Moran Bercovici's group, which you can learn more about here.

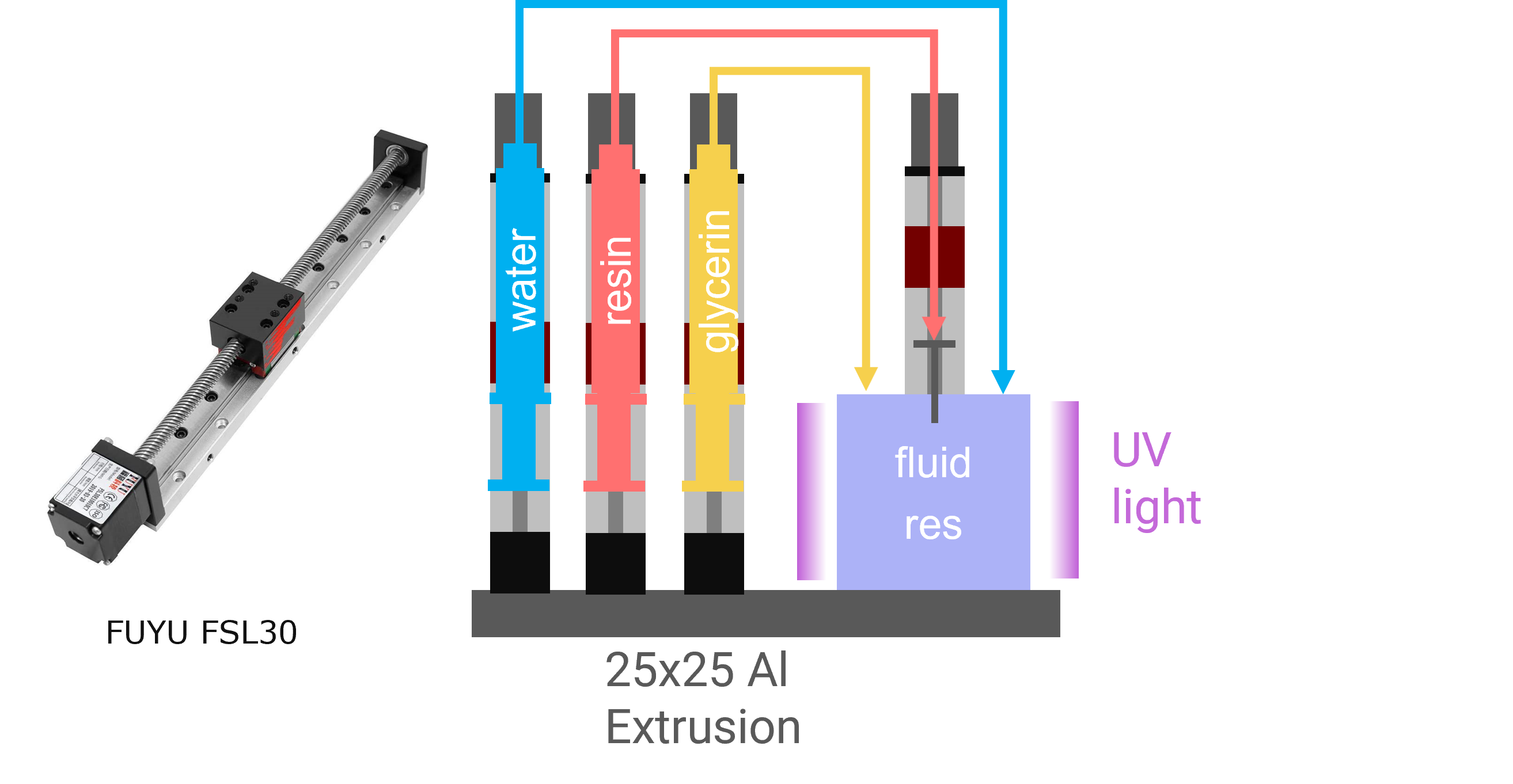

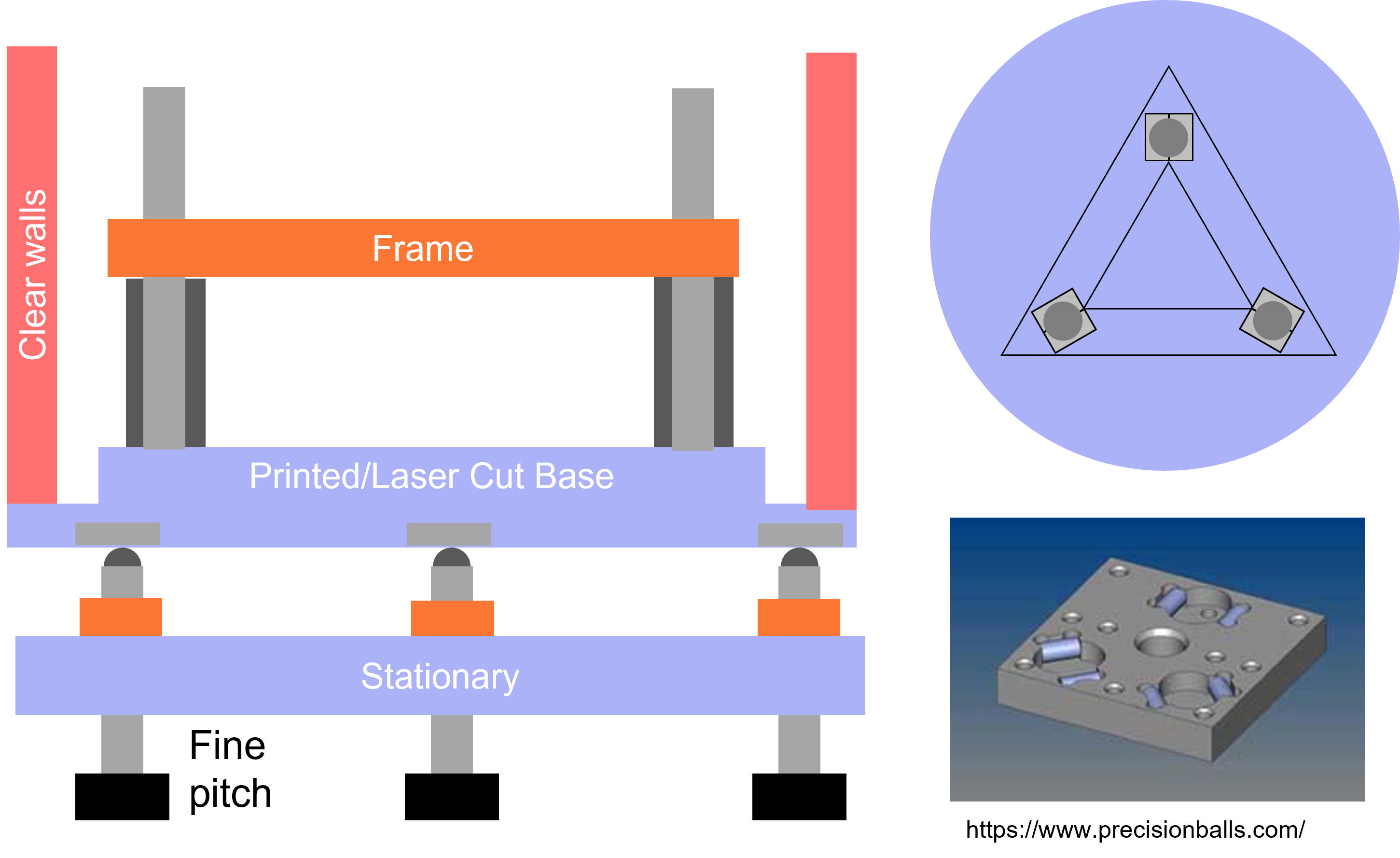

The goals are to make lenses of 25 mm diameter, using UV curable optical resin, constrained in a printed/fabricatable holder, and using the surface tension of the resin and the surrounding fluid (glycerin-water mixture) as well as control of the fluid volumes to create the profile of the lens. This surface tension effect allows us to get extremely smooth lenses. The papers from Bercovici's group demonstrate that modulation of densities can also create aspheric lenses with the Bessel function popping up in the math of the profile.

As an engineer that has done precision liquid dispensing in the past, I think this provides us a way to produce low-cost lenses for prototyping of optical systems.

Systems that need to be made include:

- Syringe pumps to dispense solutions (FUYU linear stepper stages with lead screw with a few printed parts)

- UV lights (LED strip lights wrapped around the liquid container)

- Selection and search of proper resin (currently looking into Loctite smartphone adhesives)

- Leveling system for making sure the fluid container is aligned with gravity (ball ended fine pitch screws along with kinematic mount)

- Dispensing needle movement system (FUYU) to properly dispense the resin into the fabricatable frame

- Stepper motor controllers (will likely go with Tinkerforge elements which use Trinamic drivers to coordinate movement)

Here are the concept designs for the project: