An example of a siphon recorder 1922 Image: Proceedings of the IRE

Continuous inkjet printing on cans Image: Ax130i

Jetting in the context of additive manufacturing is generally divided into two major techniques: a) material jetting where the model is built up layer by layer of additive material, and b) binder jetting where the model has a sand base and a resin is used to hold or bind the material together. There are other exotic variants of jetting based additive tools, these will be covered at the end.

Droplet based jetting techniques are generally enabled by inkjet heads. The high precision needed to display text on a printed sheet of paper lends itself well to the kind of precision you would need from a 3D printed object. Initially these techniques were referred to as Droplet on Demand or DOD, as a distinction from earlier techniques involving a continuous stream of droplets, i.e. Continuous InkJet (CIJ). The first implementation of a CIJ style printer was the Siphon (sic) Recorder 1867, used to record the dots and dashes of morse code from a telegraph. In 1965 Carl Hellmuth Hertz and Sven Simmonsson invented the CIJ which paved the way for a droplet based recording method. In 1977 the first thermal inkjet was developed at Canon, and the first piezo inkjet reached the market in 1984 the first piezo array inkjet head was developed.

An example of a siphon recorder 1922 Image: Proceedings of the IRE

Continuous inkjet printing on cans Image: Ax130i

Inkjet droplet on demand, (left) piezo displacement, (right) thermal inkjet Image: Inkjet Wikipedia

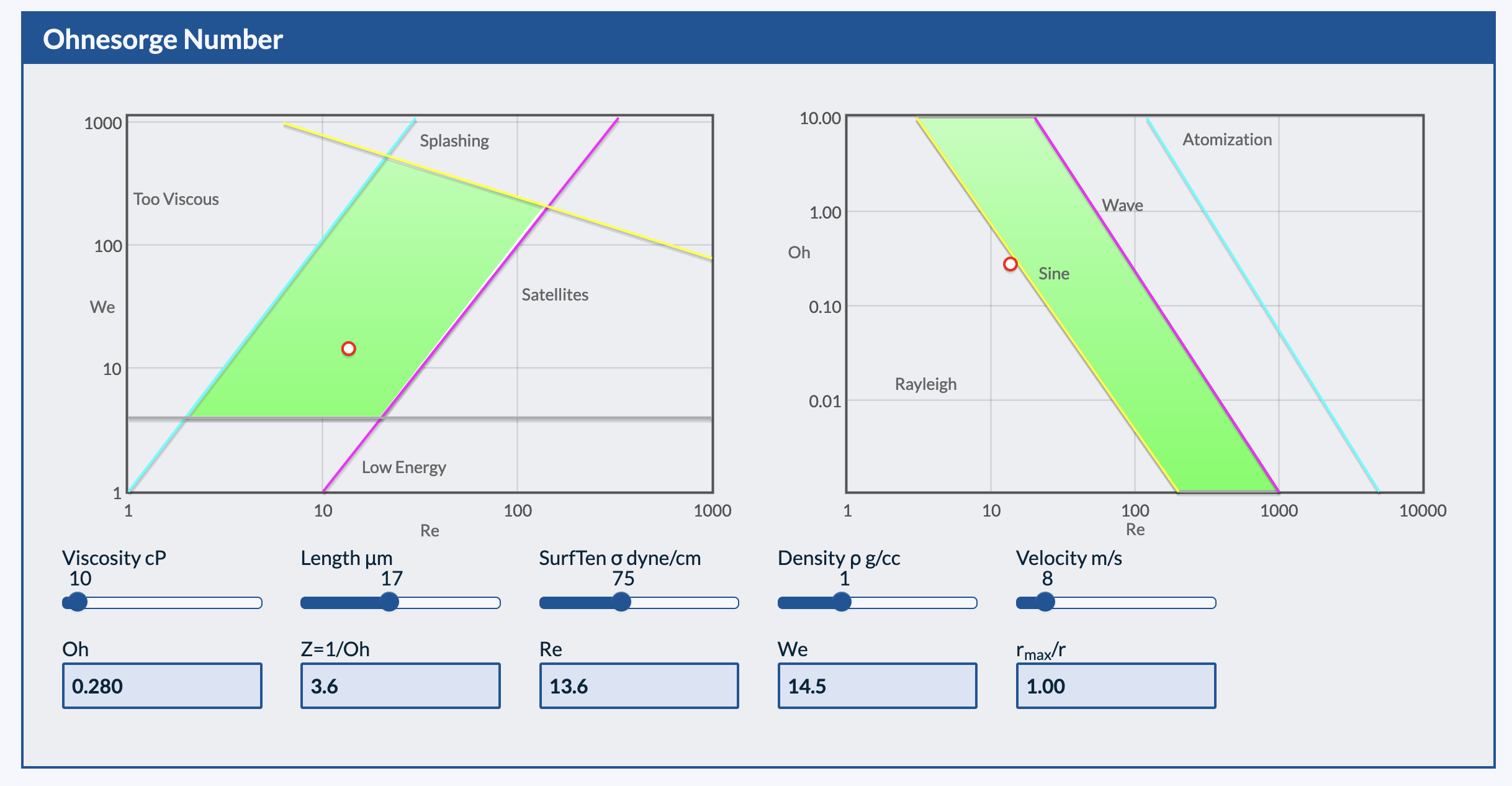

Inkjet Printing of Functional and Structural Materials: Fluid Property Requirements, Feature Stability, and Resolution, - Brian Derby

Steven Abbott's Ohnesorge Number Calculator

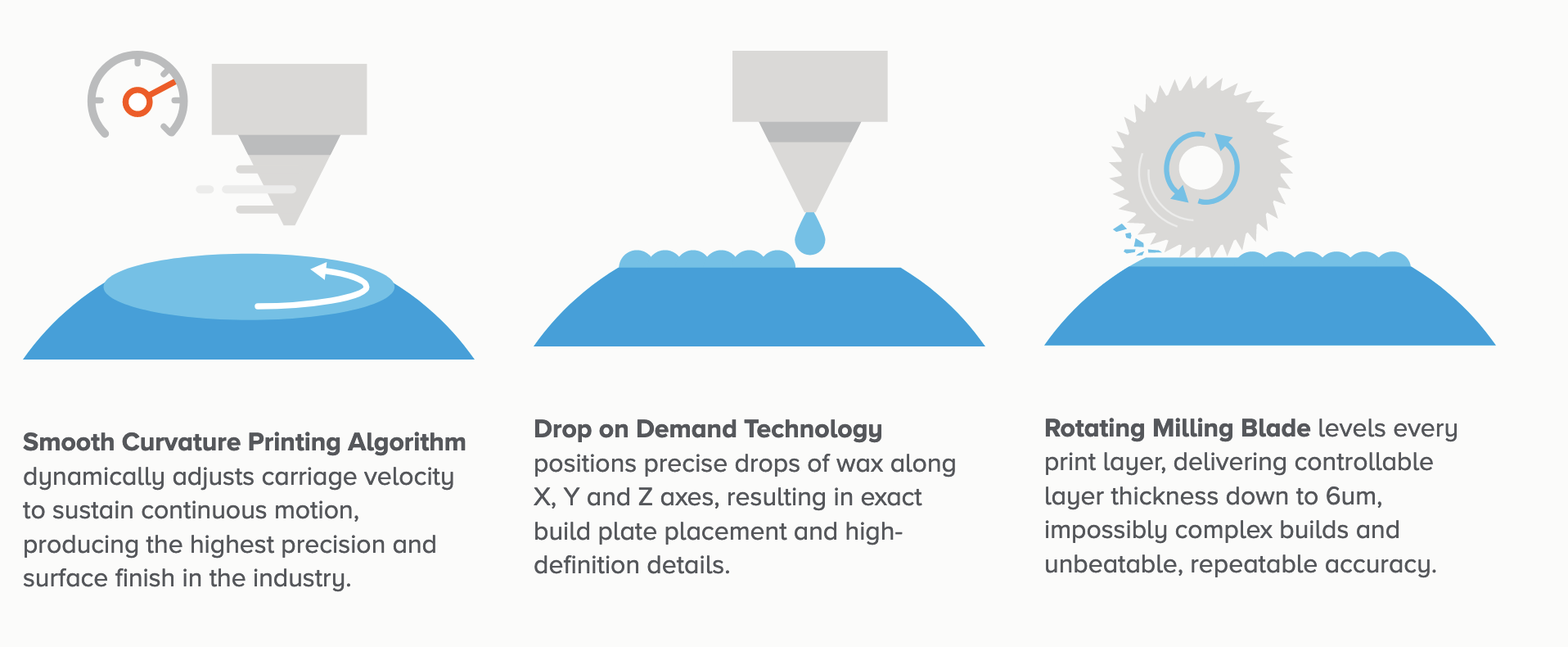

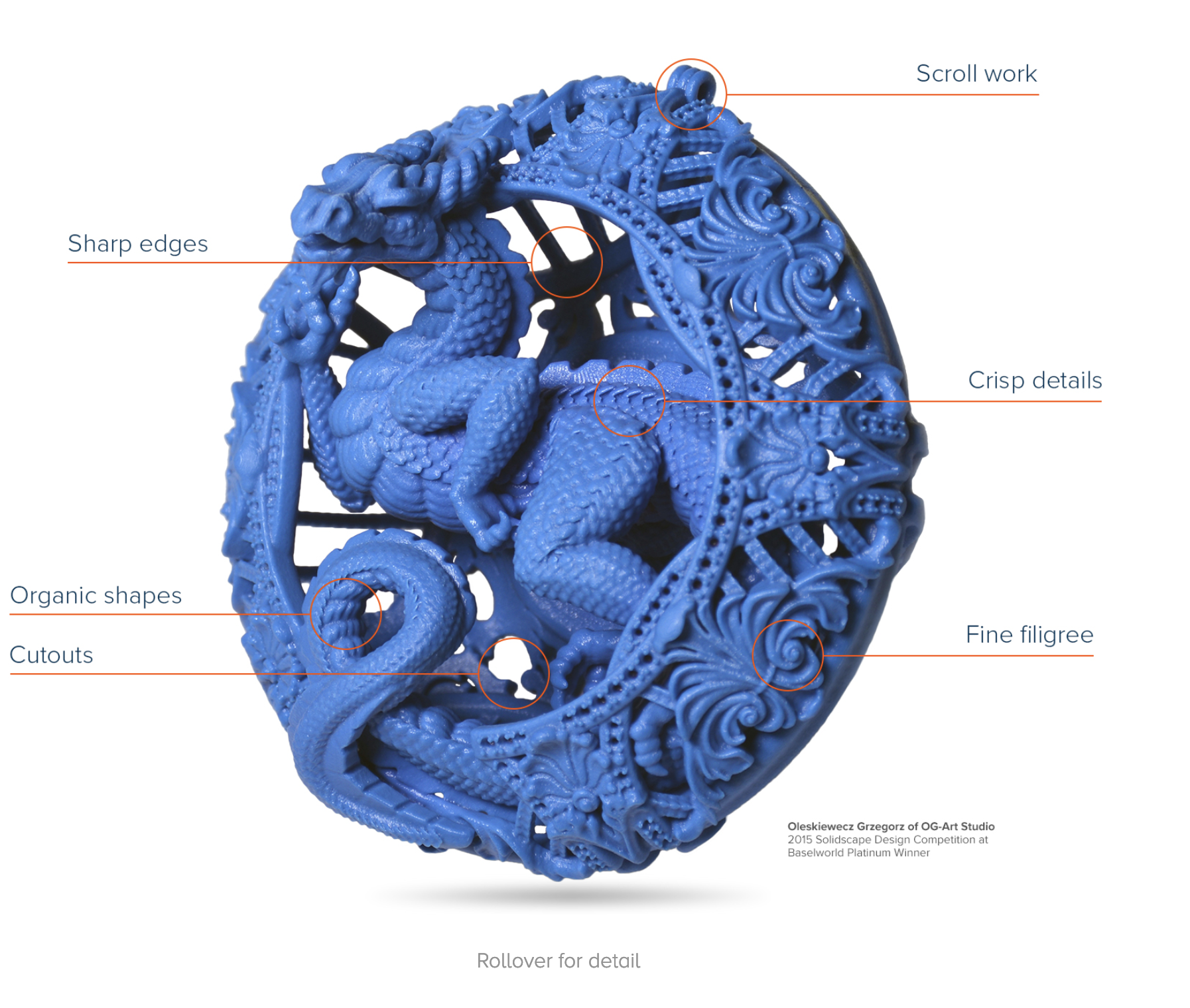

After purchasing the rights to patent US5136515A, in 1993 Sanders Prototype Inc, AKA Solidscape was founded as the first wax based inkjet 3D printer. Using

Howtek nozzles they brought wax models to market for jewelers to use in Lost Wax casting methods.

Diagram showing Solidscape technology Image: Solidscape

Solidscape wax model, Image: Solidscape

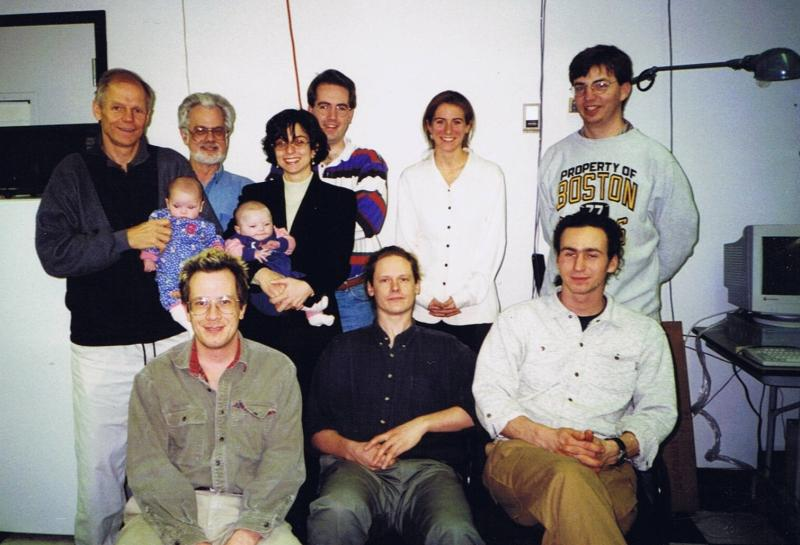

In front (left to right): Jim Bredt (Co-Founder), Tim Anderson (Co-Founder) and Martin Seymour. In back (left to right): Walter Bornhorst (Co-Founder) holding Natasha, Dave Russell, Marina Hatsopoulos (Co-Founder) holding Zoe, Darryl Spencer, Stephanie Waraksa and Mike Vogel. Image: Marina Hatsopoulos LinkedIn

Founded in 1994 by Marina Hatsopoulos, Walter Bornhorst, James Bredt and Tim Anderson, based on a technology developed at MIT by Professor Ely Sachs and his lab, Z Corp was the first 3D printer to leverage inkjet binding commercially.

Z-Corp powdered binder jet Image: CMU

The Multi Jet Fusion process relies on layer by layer addition of a powder to the work area, where a wiper pulls the powder across the bed, and subsequently an inkjet deposits a pattern in the shape of the layer slice in one continuous pass. The inkjet simultanouesly deposits an anti-binding agent on sections of the slice that are not part of the model. Finally, an IR lamp is used to fuse the polymer particles together, conferring significant strengh on the part.

The Objet Polyjet system relies on the use of piezo driven DOD inkjet heads that deposit a layer of UV-curable resin whilst simultaneously applying a UV cure light. The original patents, filed in 2001, depict a control as defined by a printer positioner, a material dispenser, an inkjet head, and a UV curing system. In later implementations a planarizer was included as well. In 2012 Stratasys merged with Objet to form a centralized corporation Stratasys Inc.

Patent 6,259,962

Stratasys J55 Image: Stratasys

Stratasys J55 in action Gif: Youtube

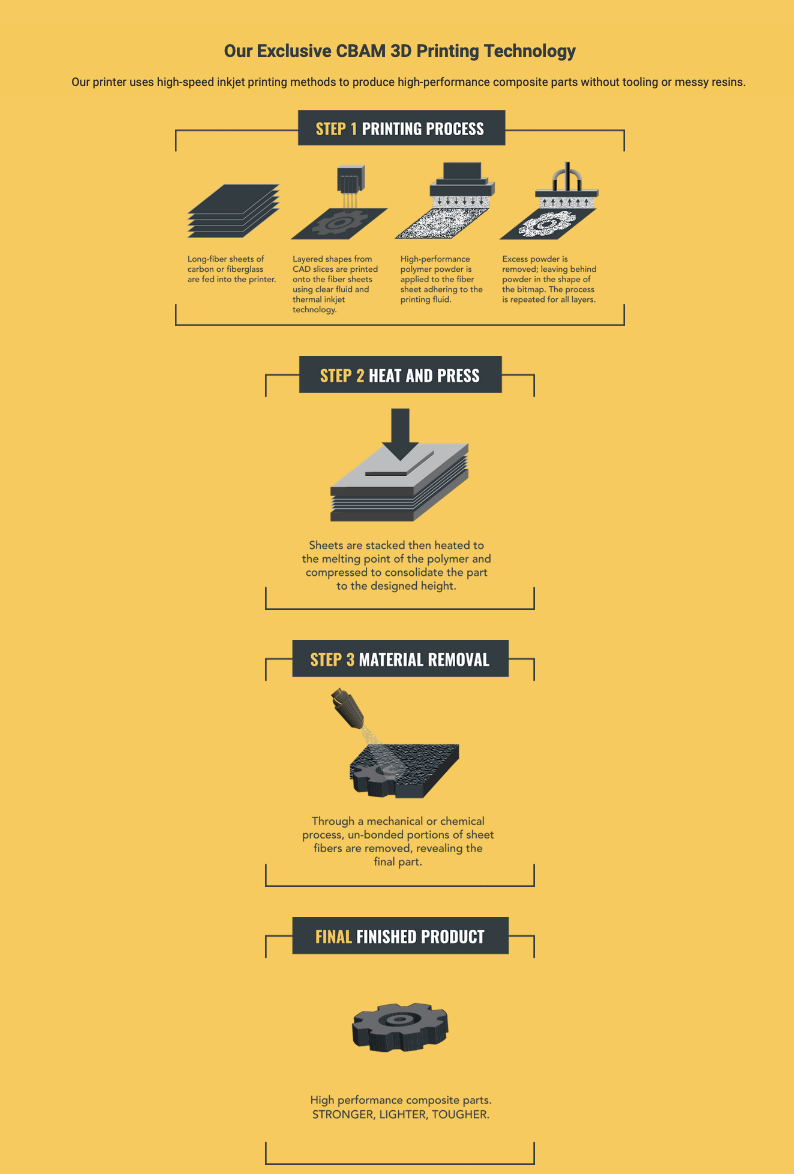

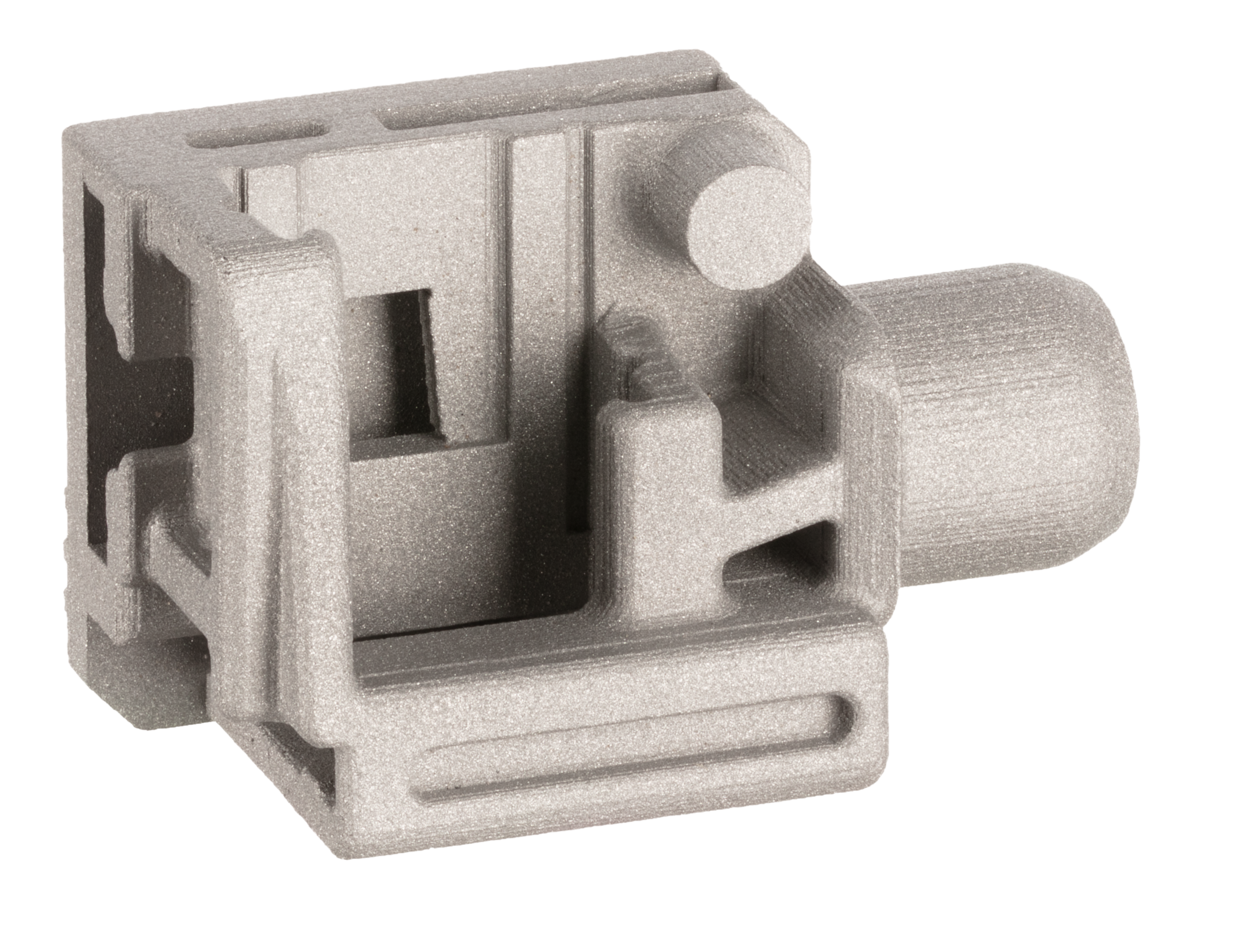

Inkjets deposit layer slices onto a continuous roll of fiberglass, or carbon fiber, sheets are singulated, stacked, and thermally bonded together.

CBAM Method Image: Impossible Objects

Spun out of Prof. Wojciech Matusik's lab at MIT, Inkbit is developing a system known as Vision-Controlled Jetting (VCJ) where a camera simultaneously scans components as the layers of resin are stacked on the build plate, and inkjet parameters are tuned on the fly to compensate for measured distortion.

Vision-Controlled Jetting (VCJ) Inkbit

Another MIT spin-out, Desktop Metal came from Prof. A. John Hart's lab, and relies on inkjets to bind powders together to make green parts. Subequently green parts are debinded, and sintered to make functional ceramic or metal components. This workflow is quite similar to typical powdered or metal injection molded components.

InnoventX Desktop Metal

A metal part from a Desktop Metal machine post-sintering Desktop Metal