The LITHOMAN Long Grain. Source: manroland Goss

| Page Rate | Example | |

|---|---|---|

| Web Offset Press | 4M/hr | LITHOMAN Long Grain |

| Sheef-Fed Offset Press | 21K/hr | Heidelberg Speedmaster XL 106 |

| Web Digital Press | 27k/hr | HP PageWide Advantage 2200 |

| Sheet-Fed Digital Press | 18K/hr | Xerox Baltoro HF |

| Typical Office Laserjet | 2.1K/hr |

Injection Molding

The Sumitomo Demag El-Exis SP - molding 216K bottle caps per hour (1.9k cycles / hour)

What's the point?

- Printing may be the world's fastest manufacturing technology (although I know somebody is going to suggest some clever counter-point:-)

- Being able to parallelize provides huge productivity gains.

- The LITHOMAN referenced above produces 4M sheets / hour, but that's at 50K cylinder revs/hour and 80 sheets per rev.

- The injection molding machine is about 10x faster than one of the world's fastest sheet-fed offset presses, but only because it makes 96 caps per cycle. Otherwise, it's slower than a typical office printer.

CBAM - Composite-Based Additive Manufacturing

Sheet lamination, in which printed sheets are laminated together, fundamentally has both speed advantages above. And indeed, Impossible Objects claims that their composite-based additive manufacturing (CBAM) technology has enabled the world's fastest industrial 3D printer.

This video explains how CBAM works, and is worth a watch.

LOM - LAMINATED OBJECT MANUFACTURING

The Mcor Iris 3D Printer prints on paper which it cuts, glues, and stacks together. Source: Rik Panganiban via Flickr

Source: Wired

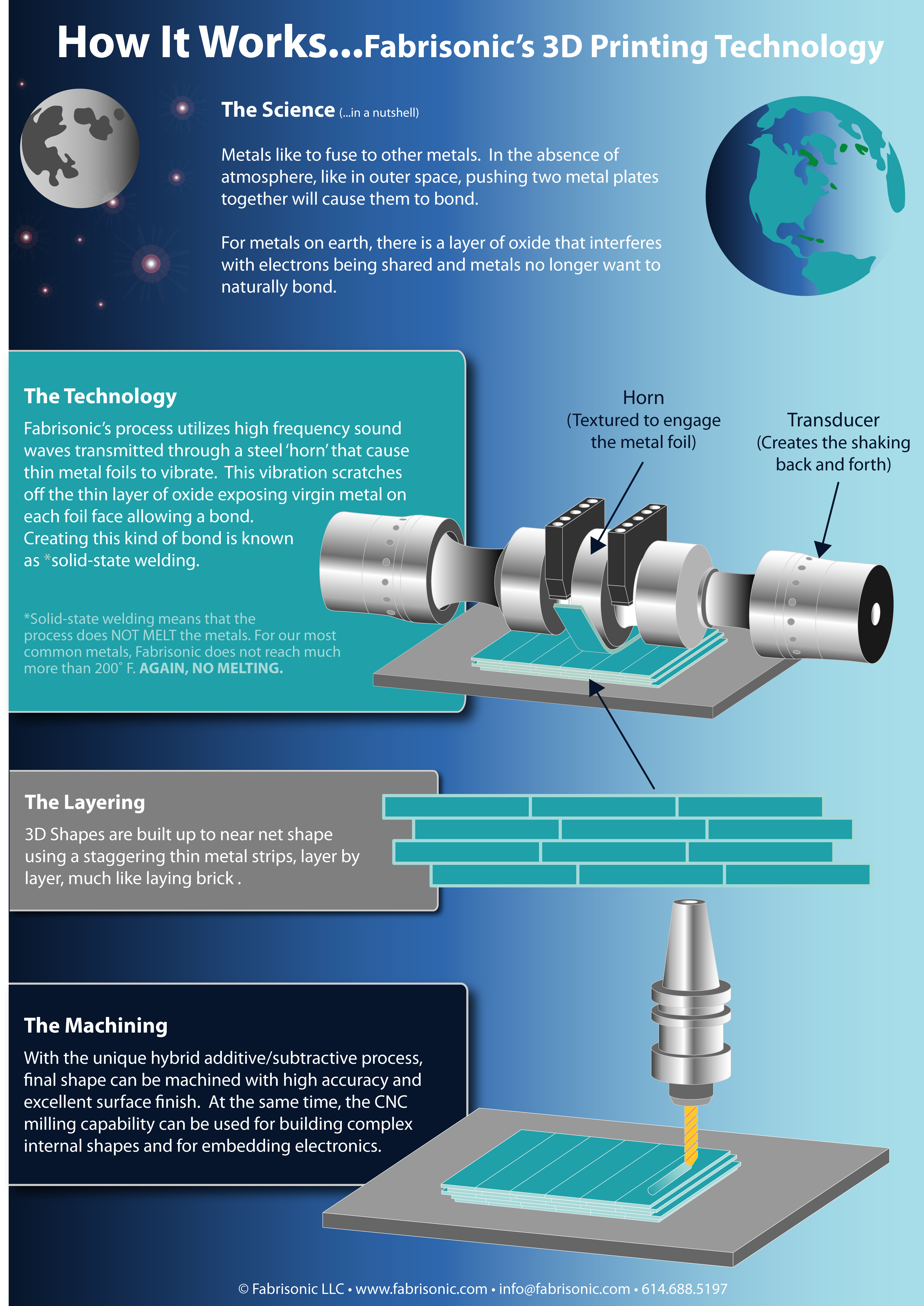

UAM - Ultrasonic Additive Manufacturing

Source: Fabrisonic

The Fabrisonic UAM system retrofitted into a Tormach 1100 CNC mill. Source: 3DPrintingIndustry.com