Vat-Photopolymerization

Aka - Vat-Polymerisation, Photoresin

Note: the author of this section was a previous employee at Formlabs. He does not hold any affiliation at the time of this publication and would like to express a deep desire to maintain neutrality when writing this page as a resource (o/a March 2024).

Definition

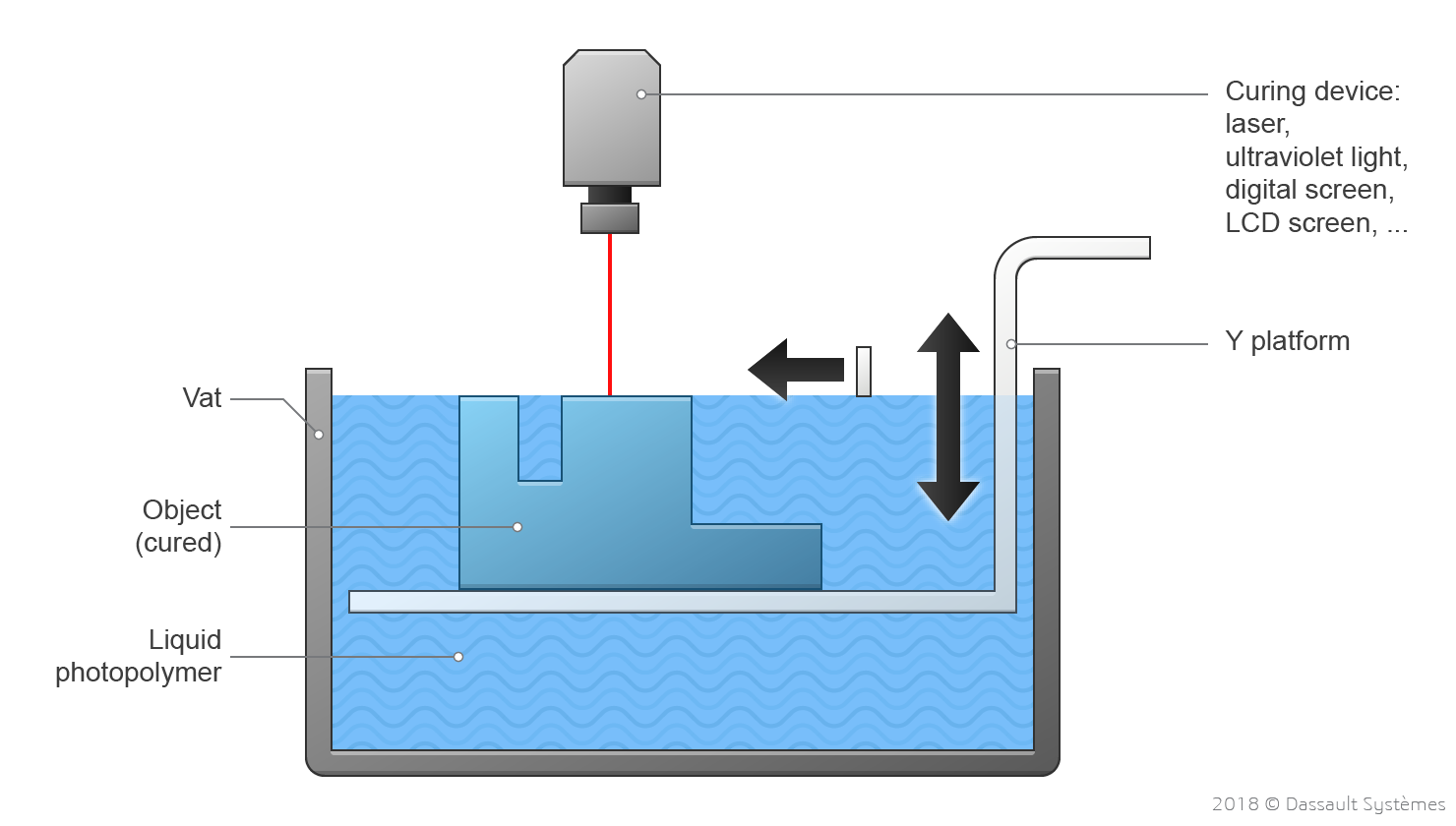

- Construction of 3-Dimensional Objects based on creating cross sectional pattern of objects by creating a cross-sectional pattern of the object to be formatted at a selected surface of a fluid medium capable of altering its physical state in response to appropriate synergistic simulation by impinging radiation, particle bombardment or chemical reaction, successive adjacent cross-sections of the objected, being automatically formed, and integrated together to provide a step-wise laminar buildup of the desired object, whereby a three-dimensional object is formed and drawn from a substantially planar surface of the fluid medium during the forming process." Charles "Chuck" W. Hull - Patent # 4,575,330

Key Concepts:

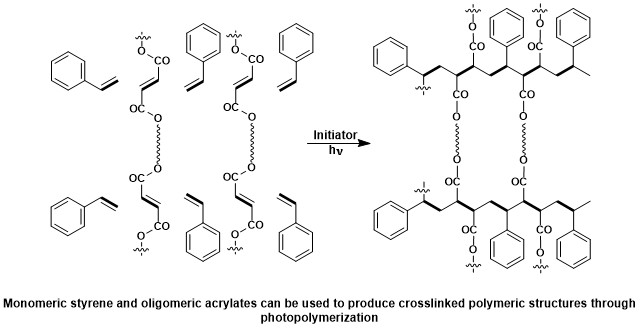

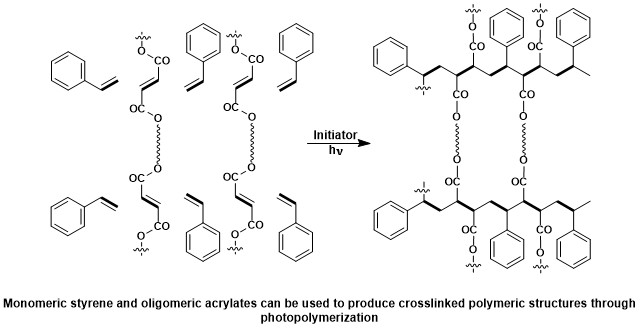

- Free Radical Photopolymerization - is when a initiator break down and attacks the pi-bond of a monomer. This initiates a chain reaction where monomers link up (propagation) until a free radical bonds on the other end (Termination).

- Photo initiators - used in resins to activate changes in structure once electromagnetic radiation (mostly light and near UV band) is introduced

- Blockers - used to limit the rate of reactiveness in order to control geometry of material. Blockers balance photoinitiators in resin compounds. Without blockers, resins would immediately harden at any introduction of the reactive band radiation.

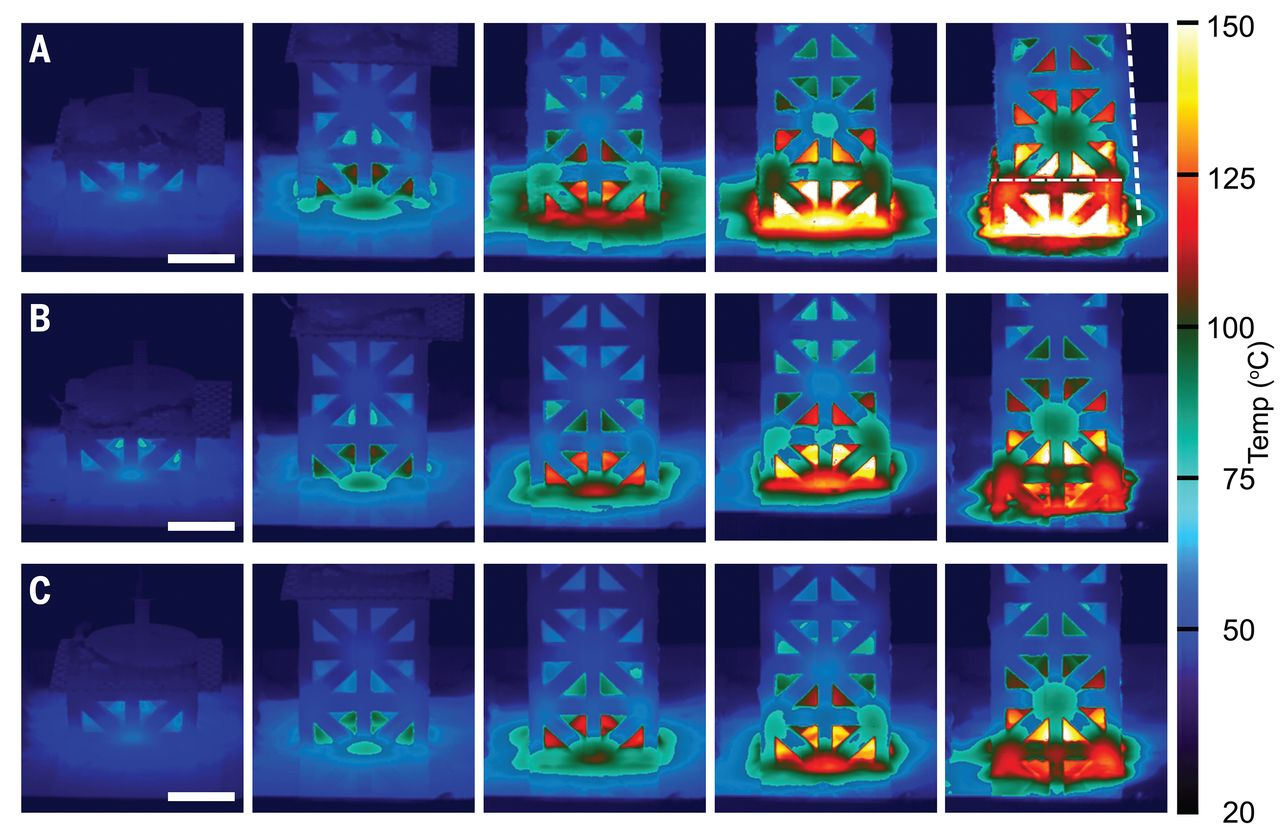

- Exothermic - reaction or process that is accompanied by the release of heat. Most of the techniques have an exothermic reaction somewhere between green and the full cure stages. Some techniques utilize different mediums in order to expedite heat transfer.

- Post Processing - generally a process that involves removal of excess material, followed by post-curing if needed. Removal of excess material may be physical (like a brush) or chemically assisted (like IPA wash). Additionally post curing may involve additional UV, light, heat or even a full kiln in order to achieve fully desired properties.

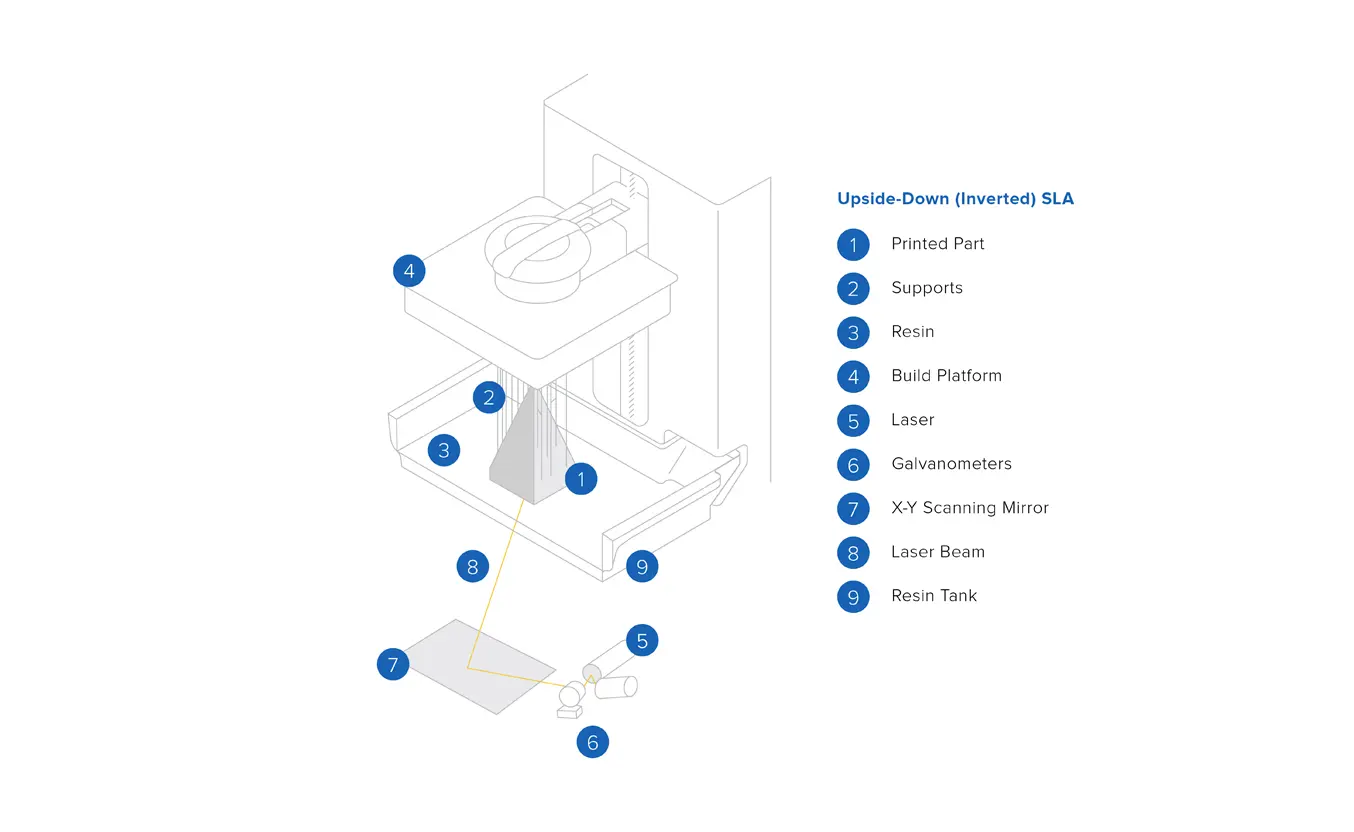

Science / Technique

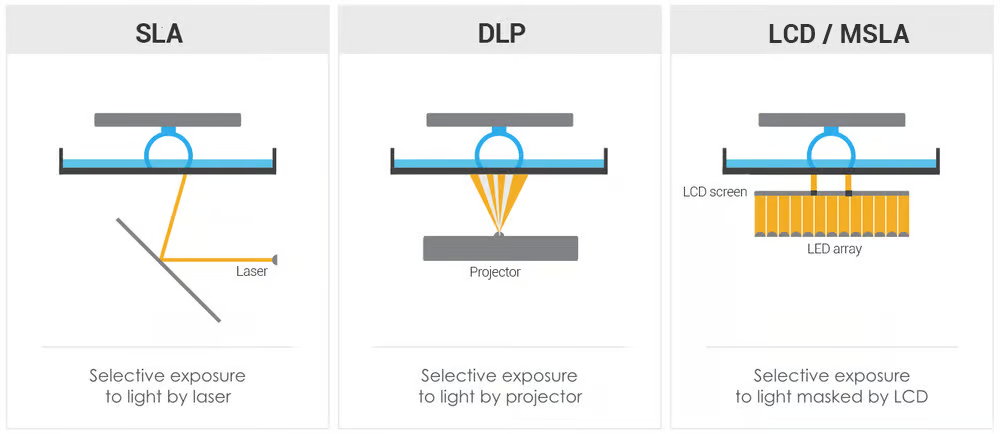

- ! -

-

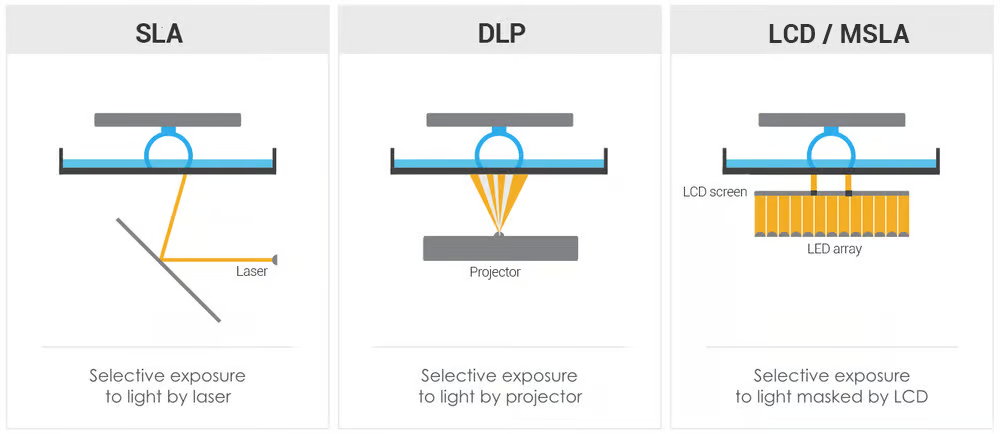

- Source: Formlabs (https://formlabs.com/blog/resin-3d-printer-comparison-sla-vs-dlp/)

- Source: Formlabs (https://formlabs.com/blog/resin-3d-printer-comparison-sla-vs-dlp/)

LCD / mSLA Printing

- Liquid-Crystal Display / masked Stereolithography

- Note: this technology works using the same methodology as the DLP system but instead of a projector uses an LCD-type display to create the electromagnetic radiation (mostly UV) to excite the particles. In order to create images, instead of limiting the projection, it instead masks the LCD array to prevent unwanted voxels to react/cure.

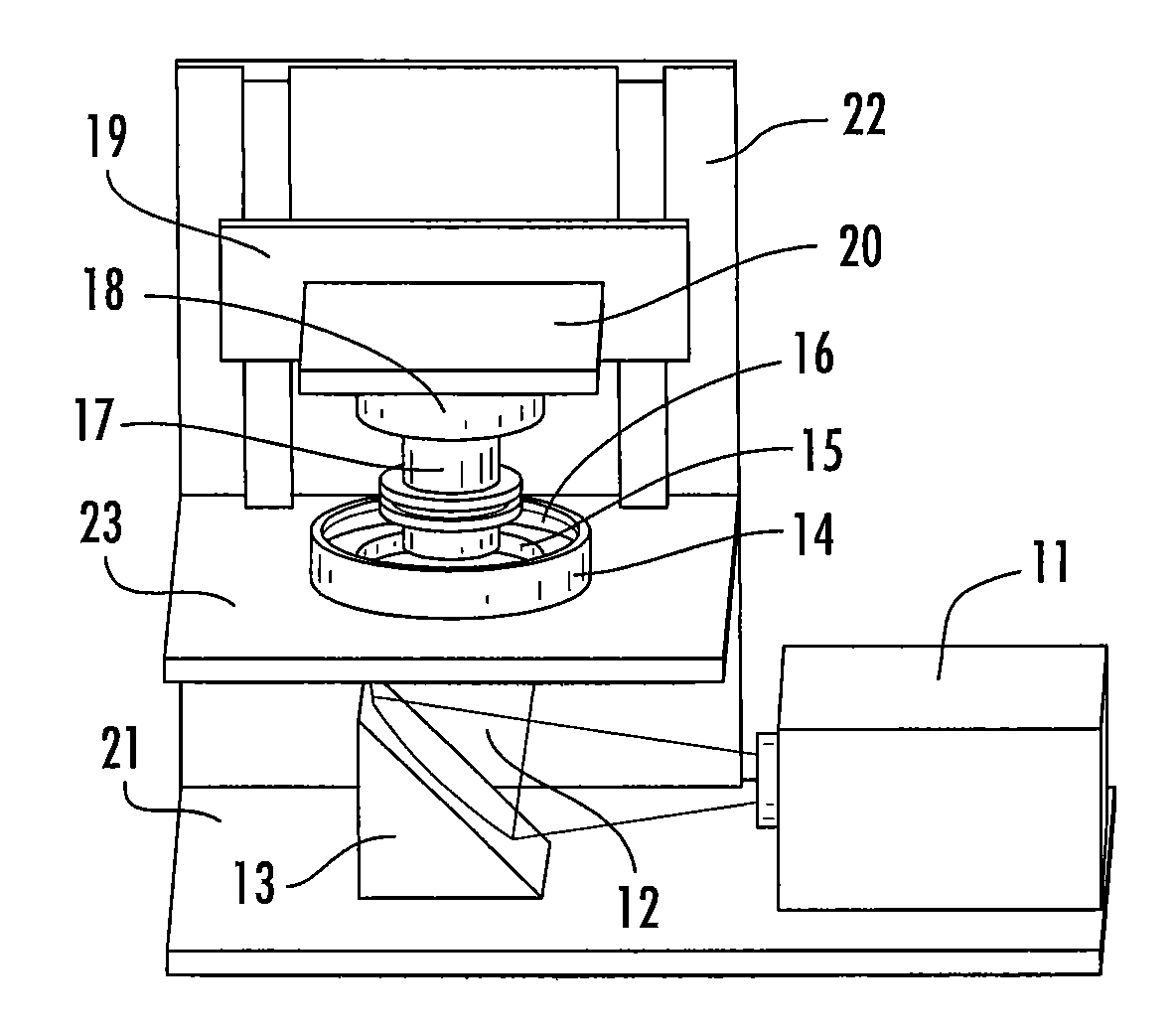

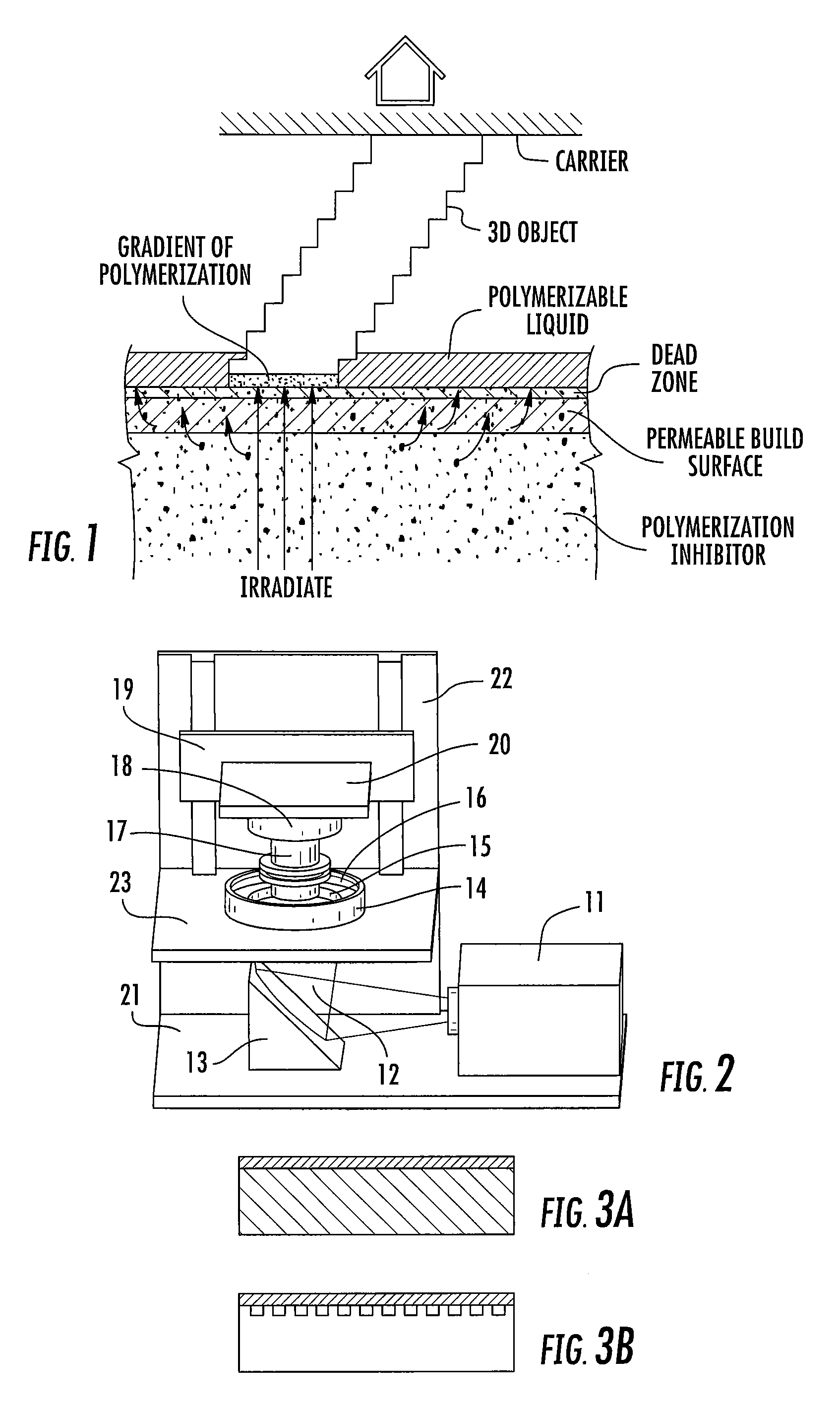

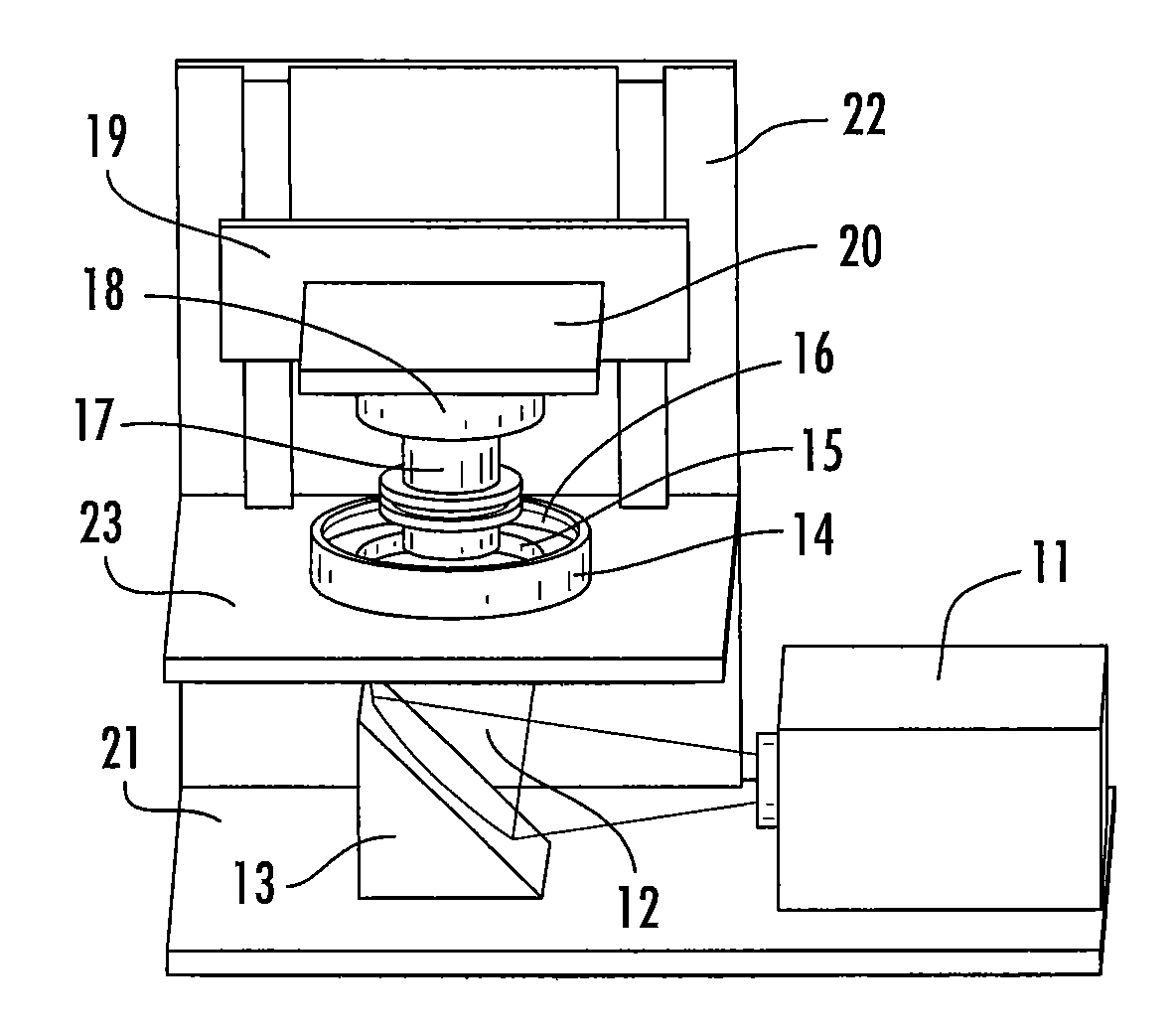

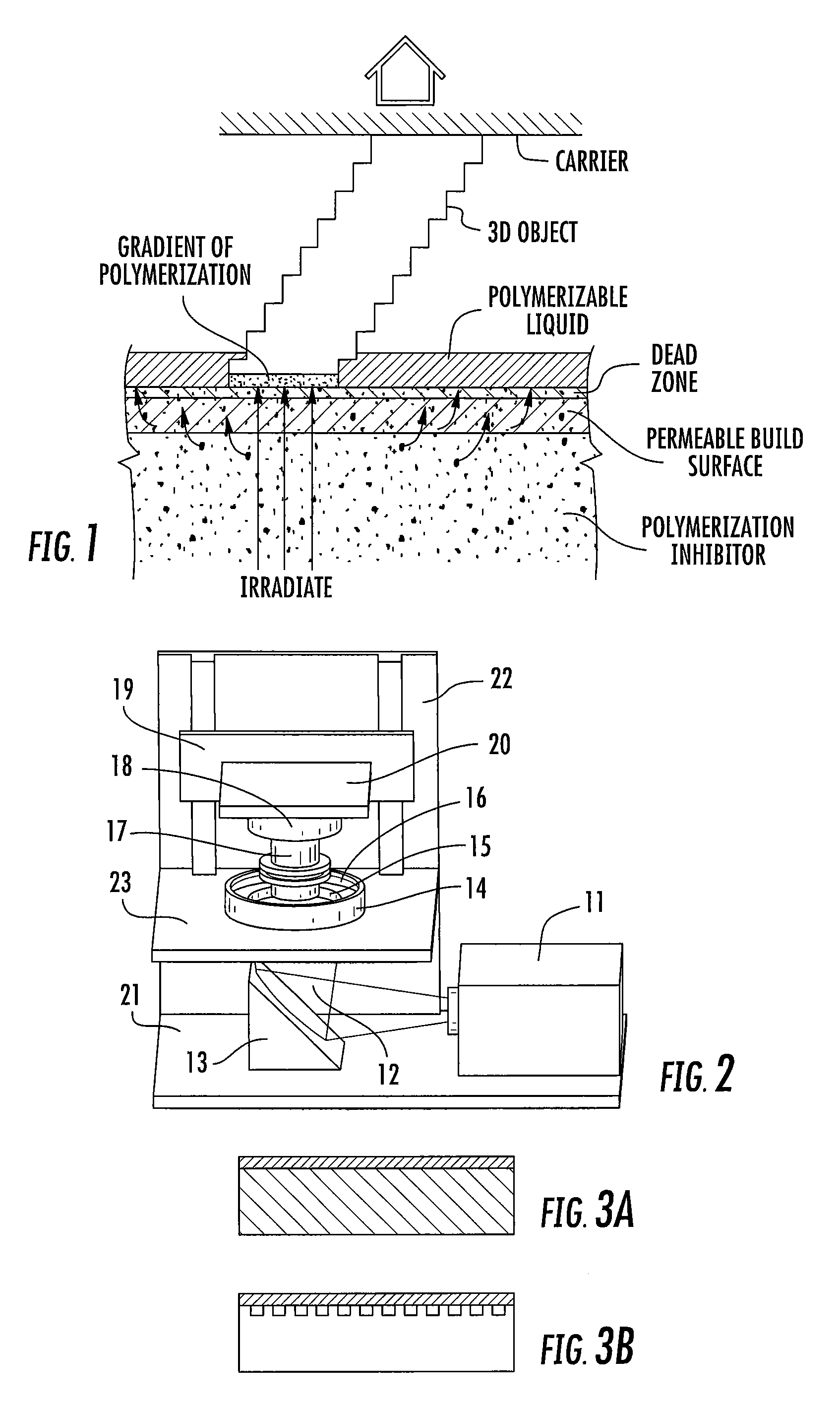

Continuous Liquid Interphase Printing (CLIP) - Carbon

- Patent Reference Numbers US9205601B2, US10016938B2, ## US20150097315A1,

- Dated: March 14, 2024

- Joseph M. DeSimone, Alexander Ermoshkin, Nikita Ermoshkin, Edward T. Samulski

- Key difference between DLP and CLIP is that in lieu of a glass window, CLIP utilizes an oxygen permeable surface between the polymerization liquid/resin.

- "3D printers require a series of steps to cure, replenish, and reposition themselves for each additive cycle. Tumbleston et al. devised a process to effectively grow solid structures out of a liquid bath. The key to the process is the creation of an oxygen-containing “dead zone” between the solid part and the liquid precursor where solidification cannot occur. The precursor liquid is then renewed by the upward movement of the growing solid part."

- Note - ETEC's CDLM (continuous digital light manufacturing) appears to have the same technique as Carbon's CLIP with its oxygen permeable window/layer.

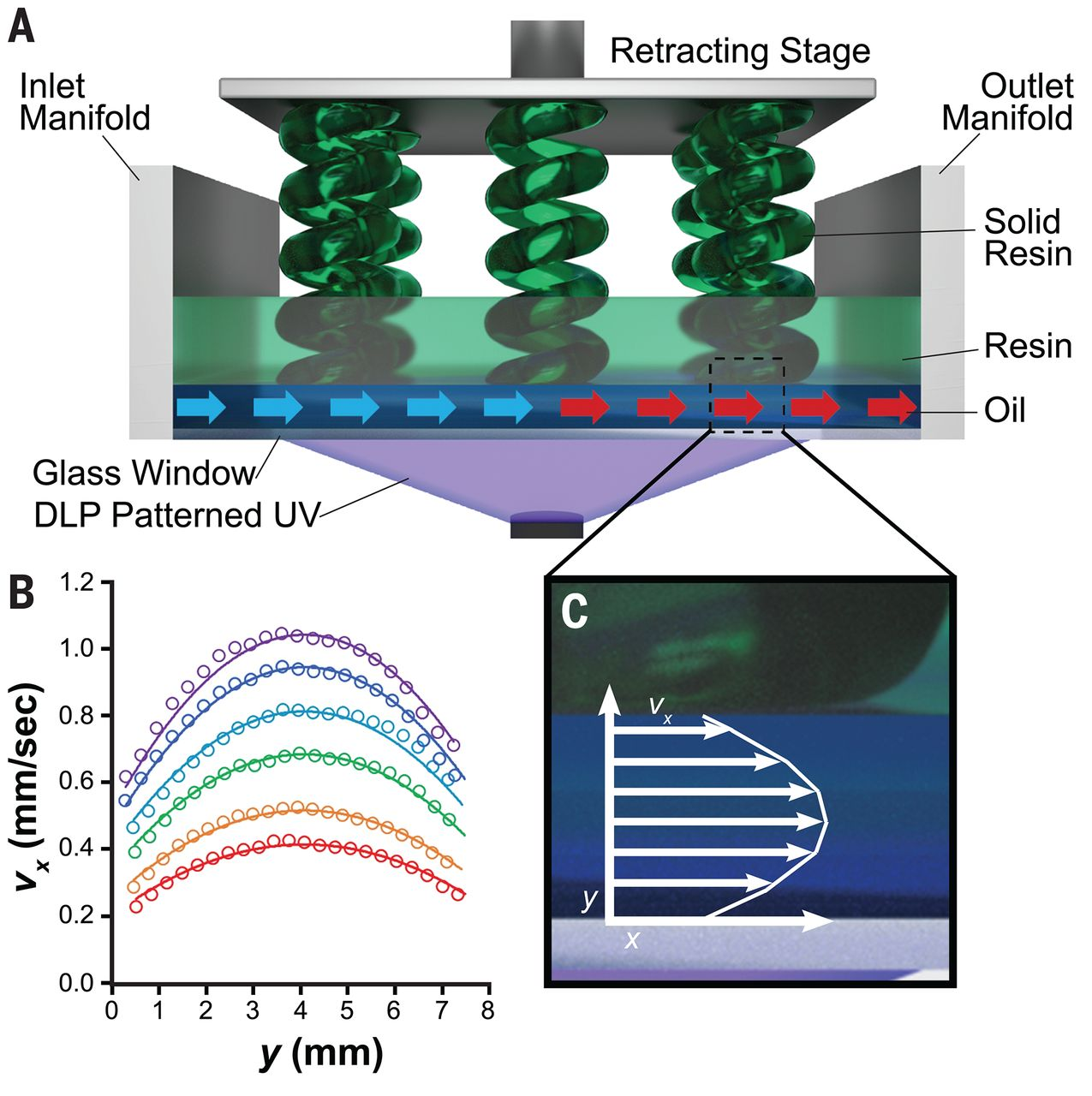

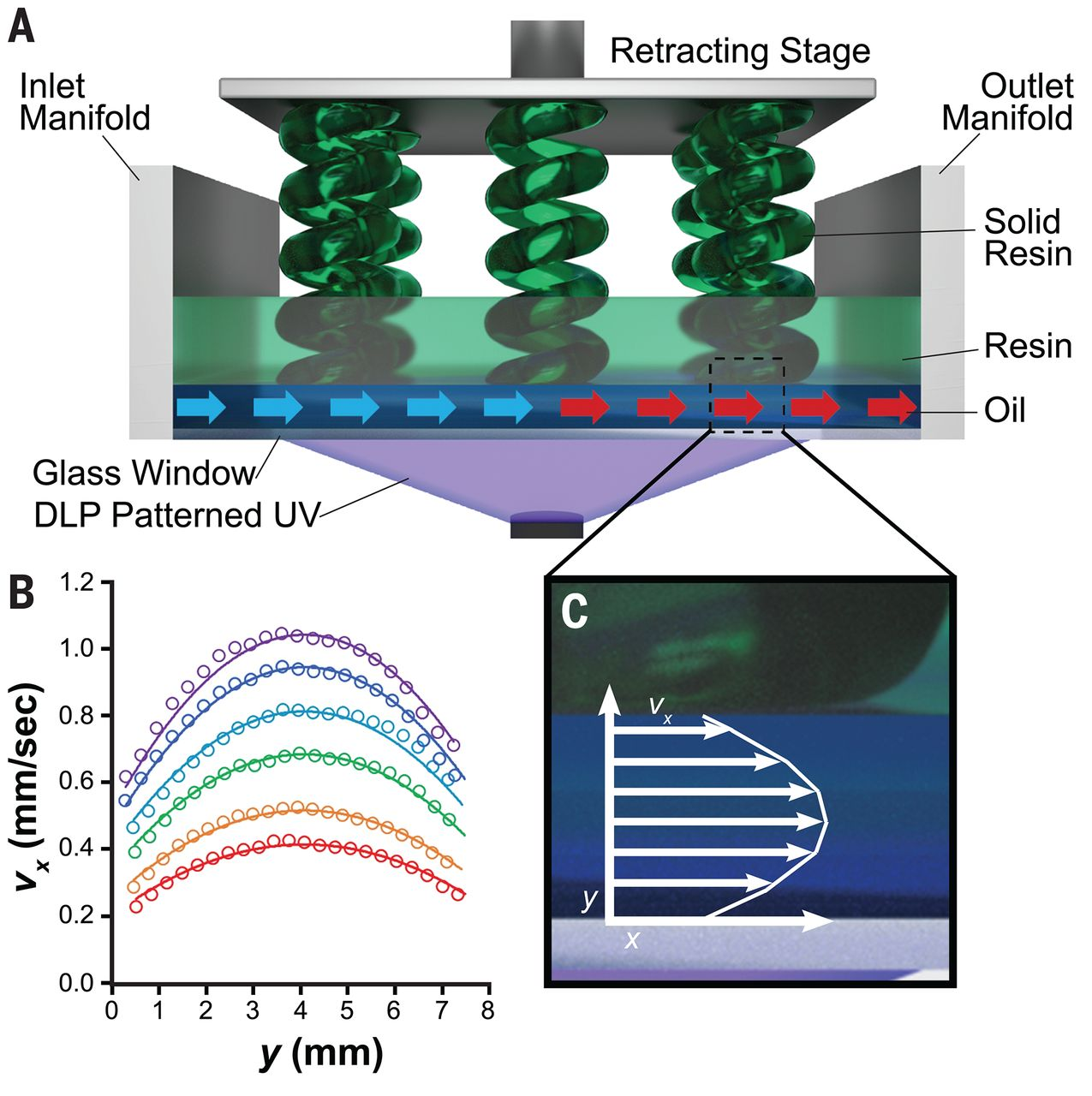

High Area Rapid Printing (HARP)

- "The printer operates on the principle of a UV-curable resin floating on a bed of flowing immiscible fluorinated oil to minimize interfacial adhesion at the build region."

- Oil operates in the same manner that the oxygen zone in CLIP does with the added benefit of a better heat transfer coefficient and increased velocity of the fluid for even better heat transfer characteristics. This prevents unwanted reactions while mitigating any exothermic characteristics during the UV exposure process.

- Printer Speed - est. 7x that of SLA, 4-5x DLP

- Removes heat and heat dissipation:

- https://www.science.org/doi/10.1126/science.aax1562

2-Photon Polymerization

Xolography

- "a dual colour technique using photoswitchable photoinitiators to induce local polymerization inside a confined monomer volume upon linear excitation by intersecting light beams of different wavelengths"

- Source: "Xolography for linear volumetric 3D printing" - Martin Regehly, Yves Garmshausen, Marcus Reuter, Niklas F. König, Eric Israel, Damien P. Kelly, Chun-Yu Chou, Klaas Koch, Baraa Asfari & Stefan Hecht

- https://www.nature.com/articles/s41586-020-3029-7

- XOLO3D

Computed Axial Lithography

- First introduced by researchers at Lawrence Livermore National Laboratory (LLNL). Instead of a layer-by-layer approach, volumetric 3D printing works by repeatedly projecting a pattern into a vat of transparent photopolymer liquid from various angles; this method is known as computed axial lithography (CAL). This method uses computed tomography (CT) scans - formerly known as computed axial tomography (CAT) scans

- UC Berkeley

Stereolithography Apparatus for Tissue Engineering (SLATE)

Material

Generally wide use - usually have a photopolymer (light-activated resin) additive that changes properties when exposed to light or other bands of the electromagnetic spectrum. Additionally, most materials have a photoinitiator compound that requires reacts with light. This is similar to those found in dental compounds for products such as synthetic teeth or dental adhesives (https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7867280/)

Additional properties from vat polymerization printers is photo-curing requirements ] through electromagnetic radiation. 3D printed photopolymers and resins are specifically designed to minimize volume shrinkage post cure.

"More recently, epoxide resins together with cationic photoinitiators are finding increasing use in 3D imaging technology. These photopolymer systems are used primarily because their volume shrinkage upon ring-opening photopolymerization is on the order of 5−10%, significantly below that of competing acrylate or methacrylate chemistries"

Source: "Photopolymer Materials and Processes for Advanced Technologies" - James V. Crivello and Elsa Reichmanis (2014)

Source: https://pubs.acs.org/doi/10.1021/cm402262g

- ProtoLabs

- Formlabs - all labeled Resin

- Black

- Clear

- Draft

- Grey

- White

- Elastice 50A

- Silicone 40A

- ESD

- Durable

- Flexible 80A

- High Temp

- Rigid 4000

- Tough 1500

- Grey Pro

- Tough 2000

- Model

- Alumina - https://formlabs.com/store/materials/ceramic-alumina-4n-resin/

- Flame Retardant

- Rigid 10K

- PU Rigid 1000

- PU Rigid 650

- Color Base

- Denture Teeth

- Denture Base

- Permanent Crown

- Temporary CB

- IBT Flex

- Dental LT Comfort

- Dental LT Clear

- Surgical Guide

- Custom Tray

- Premium Teeth

- BioMed Flex 80A

- BioMed Elastic 50A

- BioMed Durable

- BioMed Black

- BioMed White

- BioMed Amber

- BioMed Clear

- Castable Wax 40

- Castable Wax

- Stratasys - SLA (Somos branded)

- PerFORM Reflect

- Taurus

- Element

- NeXt

- WaterShed XC11122

- 9120

- GP Plus 13122

- WaterClear Ultra 10122

- WaterShed AF

Example Companies

- 3D Systems (SLA/SLS/MJP/PBF) - https://www.3dsystems.com/

- Stratasys - https://www.stratasys.com/en/

- Formlabs (SLA/SLS)

- Carbon3D (DLP/CLIP)

- Nanoscribe (SLA) - https://www.nanoscribe.com/en/products/

- Azul3D (HARP)

Limitations

- Traditional Printing (exposure is top down with the object going into the vat)

- Part size is based constricted on VAT size

- Low-Tension Based (exposure on the bottom, part is dragged vertically up)

- Limited by viscosity of the material pulling against gravitational load.

- Post Processing

- Usually requires wash, cure, and/or heat (usually all 3). Most of the processes are not automated outside of extreme industrial scale.

- Hazardous

- Resins (generally) can be toxic to humans after prolonged skin contact. PPE is required when handling (most) resin based material