Machine Week

Link to group webpage: https://gitlab.cba.mit.edu/classes/863.23/Architecture/machine.

I volunteered to be the group leader for this weeks machine production. Therefore, this post will be mostly a reflection about that kind of work that was involved in coordinating a machine like that, both forseeable and unforseeable.

The first task in getting this machine together was to decide on a machine. It turns out deciding on what to build in a week amongst 14 MIT students is a more complicated process than expected because each person had so many ideas, which was great. In the end after a couple of polls in our group chat, we decided to make a machine that plots the daily headline of the newyork times on toliet paper.

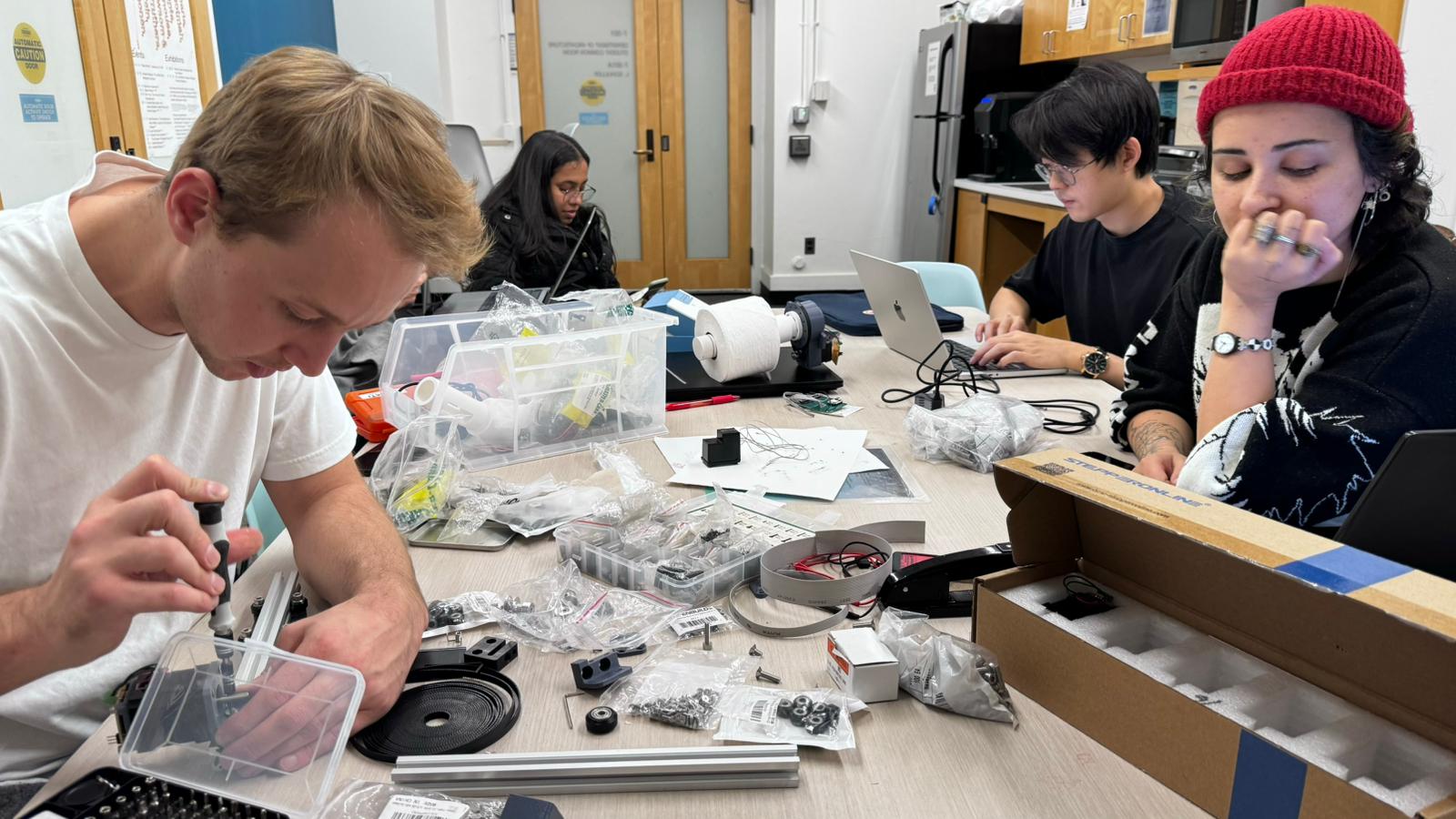

We all met up on Saturday morning to begin the project with just four days left after much deliberation on what the machine itself was going to be. My first task then became dividing the team into sections based on interest and skill and what they wanted to learn. It was a pretty democratic process despite some telling me that the best way to create an integrated project was to dictate.

Throughout the week I floated around from group to group checking in on progress and to make sure people were uploading their information to the gitlab page. I think I learned then the value of documentation that's been pushed in this class because theres no need for so many questions if all your answers are in one place.

The majority of the work came down to the last couple of days where the team and I bonded a lot in the architecture student lounge that acted as our hq. This is where Neil's 95 - 5% logic started to make sense. The number of issues we discovered when we tried to integrate everything was pretty overwhelming. To list a few: the waterjet didnt cut out every single square for the aluminum extrusion so we had to find a way to make the same whole in the same spot by hand since no one could operate the waterjet. We decided on a mortis drill which was sketchy but did the job.

Also some more forseeable problems that we knew we'd need to solve was how to get a pen to plot on such a delicate material. The answer we came up with in the beginning to start out design was to use a linear z motion to create points rather than dragging a pen to create shapes. But, when we started plotting the paper still ripped and bled through. Thankfully, I had a perfectly sized piece of aluminum from an old studio assignment that we were able to bend into a shape that could integrate into the rotary axis to provide a hard surface.

Im happy with my job in that the machine was very well integrated in the end. Likewise, I think the time spent together making this brought us together as a section which was really helpful going forward in the class.