Wildcard Week: Waterjet

This week I had a couple of unfortunate things that I had to deal with that kept me from venturnig to CBA to do a cool wildcard week assignment with a new group. I chose to do the waterjet assignment because it was something I needed for my final and was close to where I normally work in the architecture department.

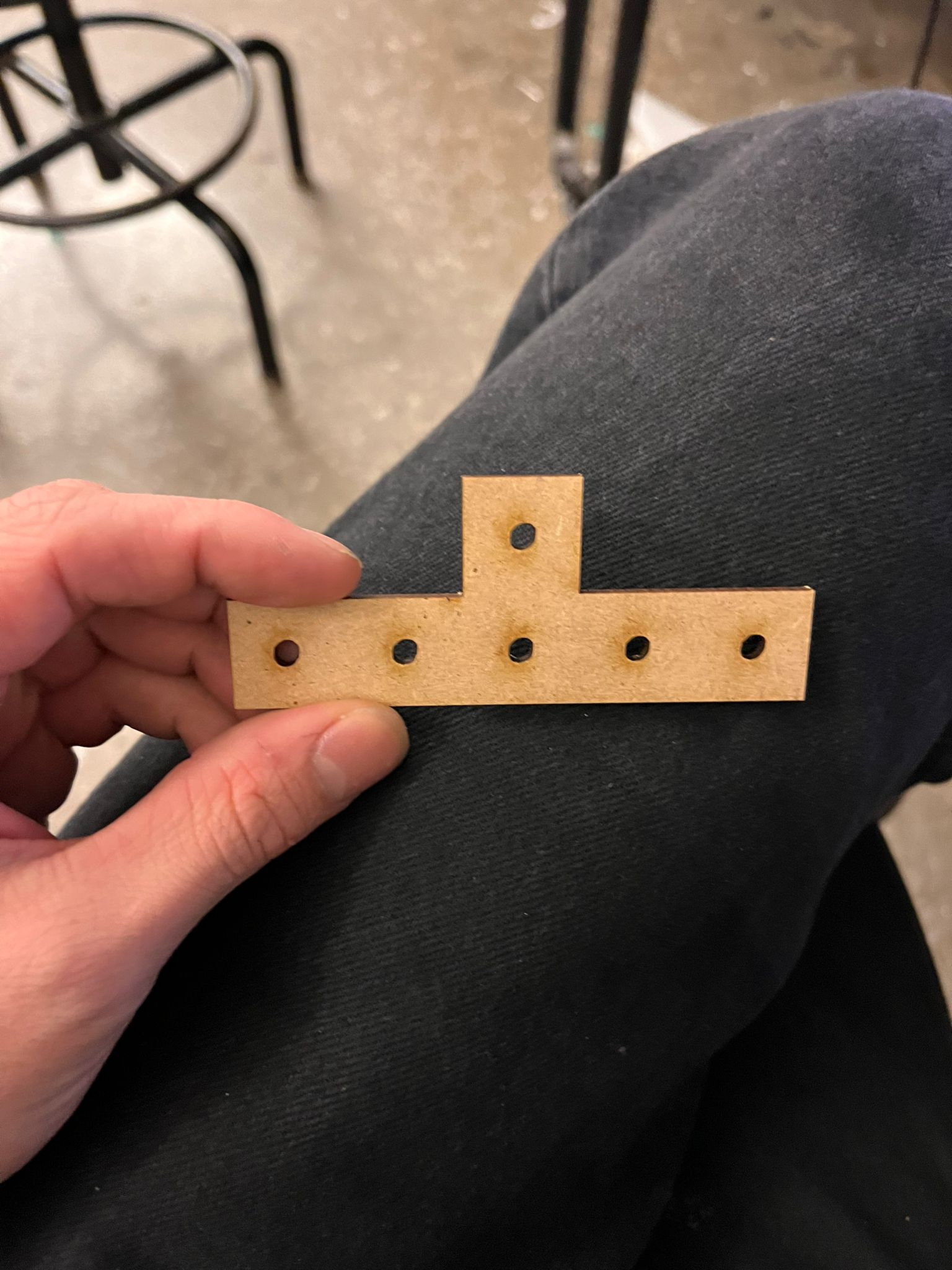

I've cut aluminum in the past, but its generally been pretty thin, around 1/32 inch, so I was able to cut it on the fab light laser cutter. This week, I wanted to make some more hefty parts for my drawing machine. Since metals pretty expensive and the omax material is also expensive I lasercut some prototypes so I could rapidly test whether my design worked and things fit together.

I was a bit worried about the kerf difference in the two machines but since I was using them mostly for screws what mattered the most was to have the center point in the right spot and to make them smaller so they wouldnt be loose and I was tapping them anyways.

The machine was a bit slow but I liked the results it produced a lot, so I'll make sure to use it for more projects in the future.

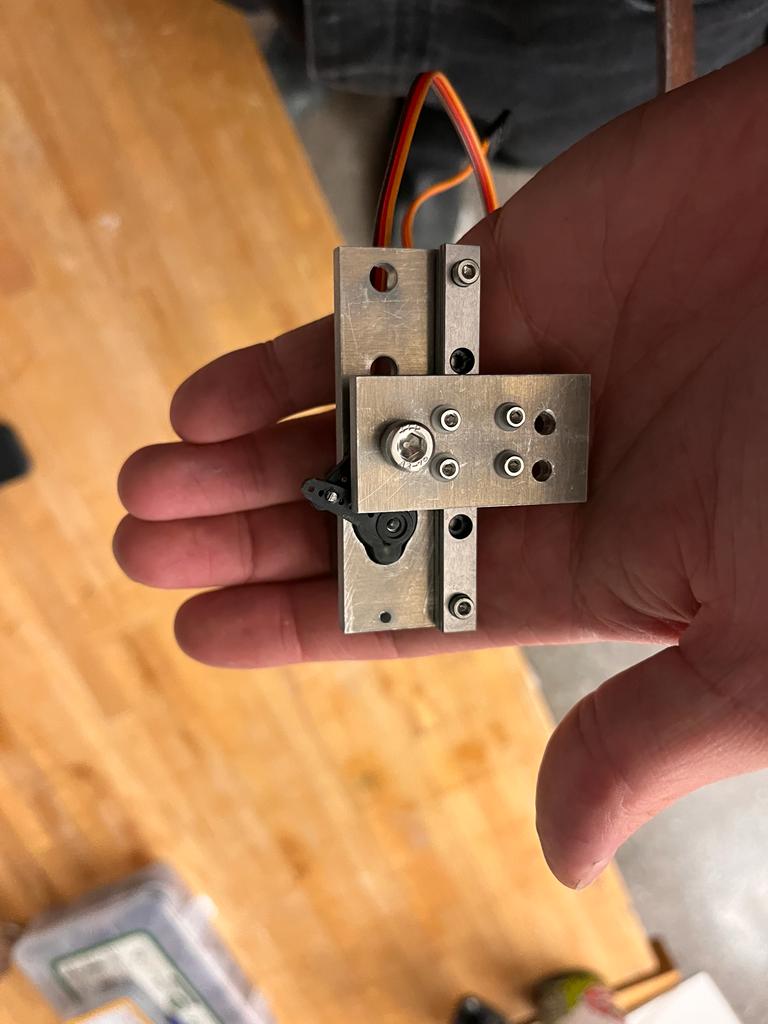

I was pretty happy with the tolerances that I calculated for, here is a servo that a hole for that fit perfectly.