Week 5

Electronics Production

This week was a significant step in my project development. I revisited my previous week's assignment and began working on my personal electronic design, with a focus on its relevance to drone production. After consulting with the teaching assistants, Miana and Alfonso, they recommended exploring the Adafruit 9-DOF Orientation IMU Fusion Breakout - BNO085.

The Adafruit 9-DOF Orientation IMU Fusion Breakout - BNO085 is a specialized sensor module that offers detailed insights into a device's orientation and motion. It boasts a 9-DOF sensor array, encompassing three fundamental sensor types:

1. Accelerometer: This sensor gauges linear acceleration, enabling the determination of changes in velocity and overall motion

2. Gyroscope: It measures angular velocity, providing information on an object's rotation and orientation changes.

3. Magnetometer: Detecting magnetic fields, it assists in determining the device's orientation relative to Earth's magnetic field.

The sensor fusion breakout serves various applications, including drones, for several reasons:

1. Precise Orientation Data: The BNO085 offers precise and stable orientation and movement data, a critical factor for maintaining stable drone flight by accurately measuring pitch, roll, and yaw angles.

2. Reduced Drift: Combining data from multiple sensors helps mitigate sensor drift, a common issue with standalone sensors, essential for maintaining long-term accuracy in drone navigation.

3. Fusion Algorithms: The sensor integrates fusion algorithms that combine data from accelerometers, gyroscopes, and magnetometers, ensuring a more reliable and accurate representation of the device's orientation.

4.Compact Form Factor: Its compact breakout board size makes it ideal for integration into small and lightweight drone designs.

5. I2C and UART Communication: The BNO085 typically communicates with a host device, like a microcontroller, using I2C or UART interfaces, making it compatible with various microcontrollers commonly used in drone projects.

6. Diverse Applications: While drones greatly benefit from this sensor, the BNO085 finds utility in a wide range of applications, including virtual reality, augmented reality, robotics, and other motion-sensing projects.

In summary, the Adafruit 9-DOF Orientation IMU Fusion Breakout - BNO085 is a valuable sensor module for drones. It delivers precise orientation and motion data, minimizes sensor drift, and integrates seamlessly into drone systems, enhancing their stability and precision during flight.

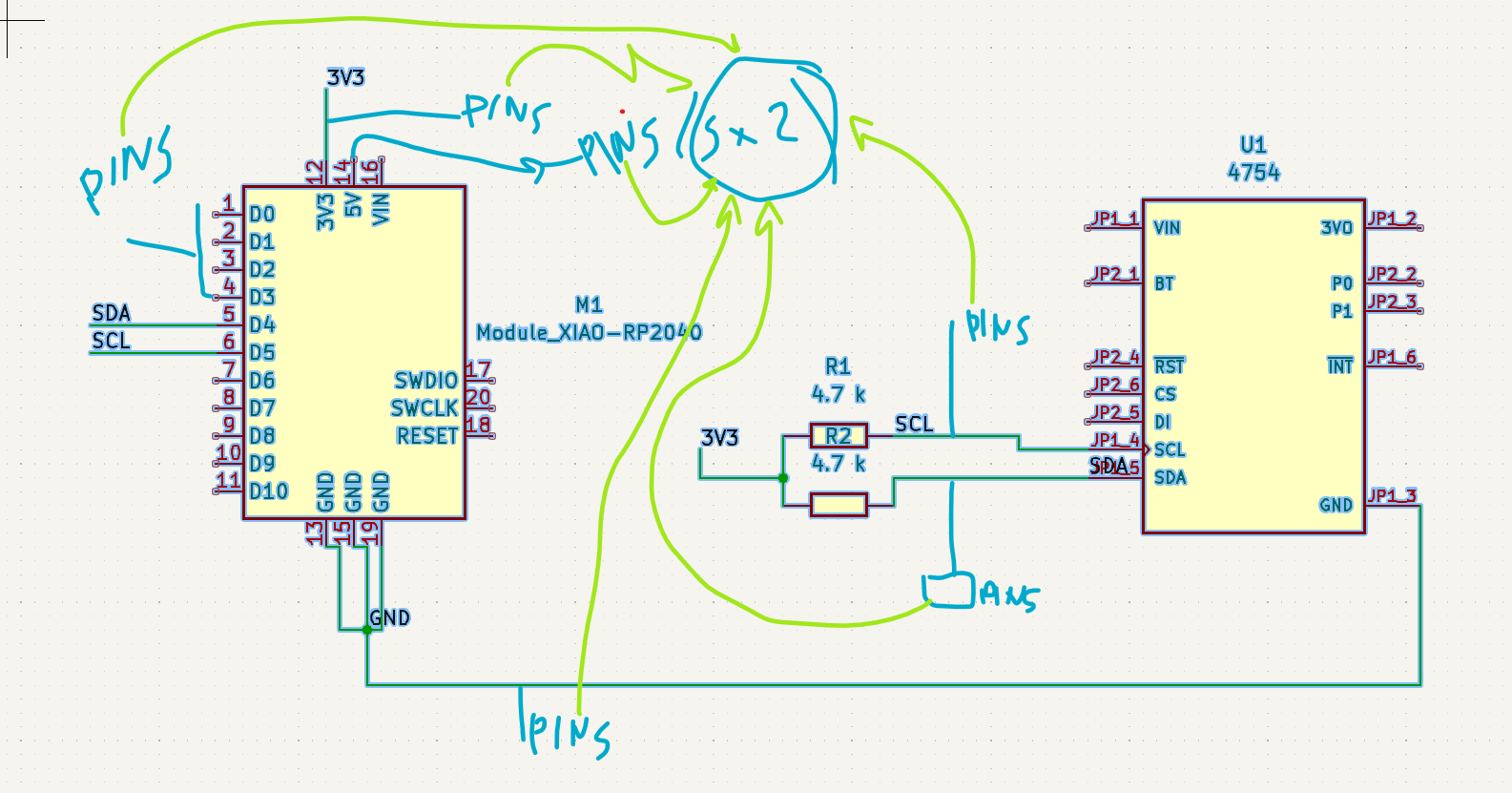

With this newfound knowledge, I proceeded to the next steps of my project. My tasks included downloading the KiCad library, which took some time. The schematic diagram for the BNO085 was created, and then the exciting part began - combining the RP2040 with the BNO085.

Miana explained to me what I2C stands for: "Inter-Integrated Circuit." It's a serial communication protocol used to connect and exchange data among various electronic components, including microcontrollers, sensors, displays, memory devices, and other integrated circuits. I2C employs a two-wire communication interface, consisting of a clock signal (SCL) and a data signal (SDA). Multiple devices can be connected to the same bus, each identified by a unique address, allowing efficient communication between different components within an electronic system. I2C is widely used in various electronic applications due to its simplification of component communication and its reduction in the number of physical wires needed for interconnection. We also have defined and covered some Design Rules.

Following our discussion, I proceeded with the setup and connection of these components. This marked a significant milestone in my project.

In parallel, Miana recommended connecting the components to their respective pins, and the final outcome showcased the successful integration.

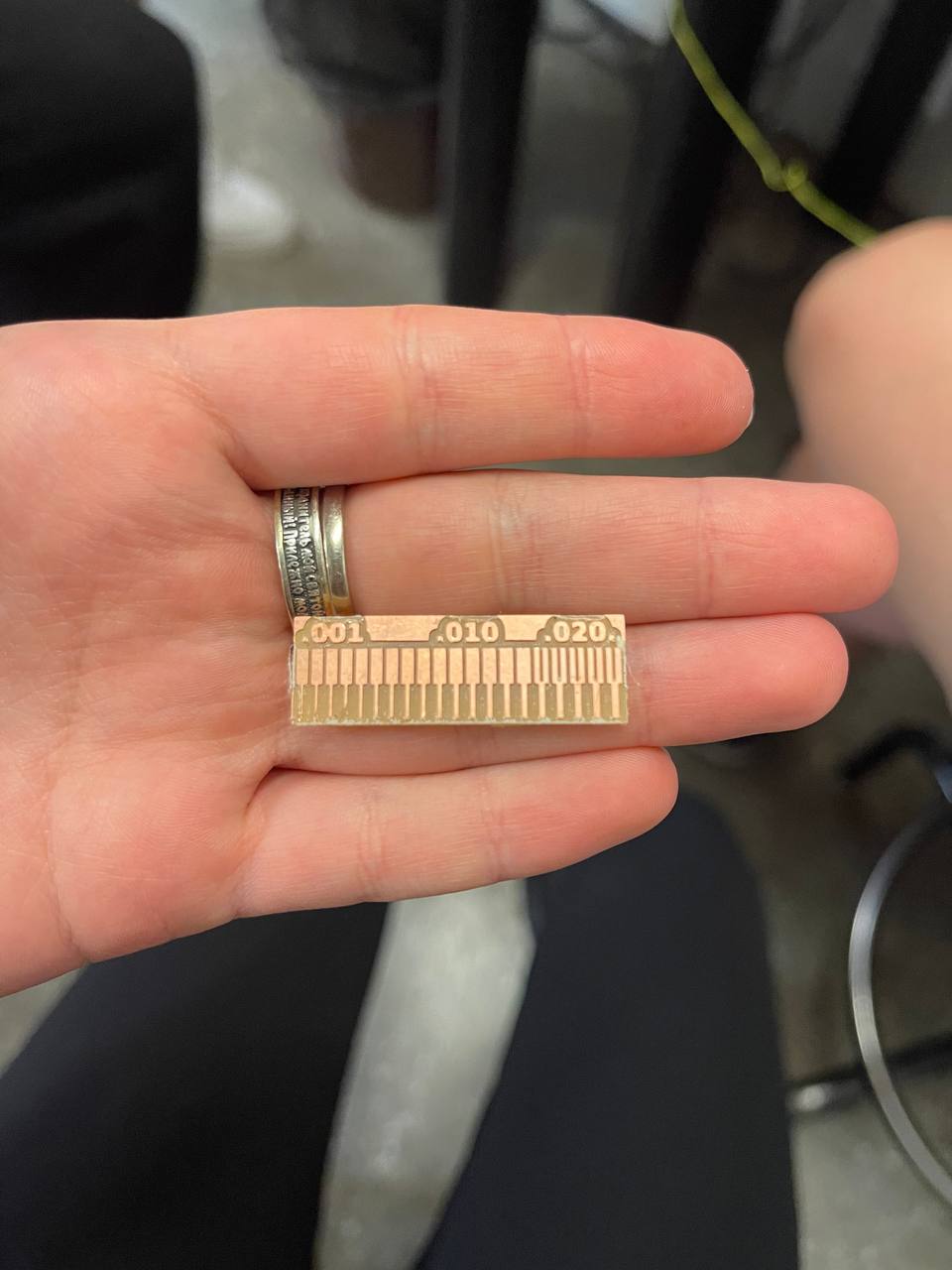

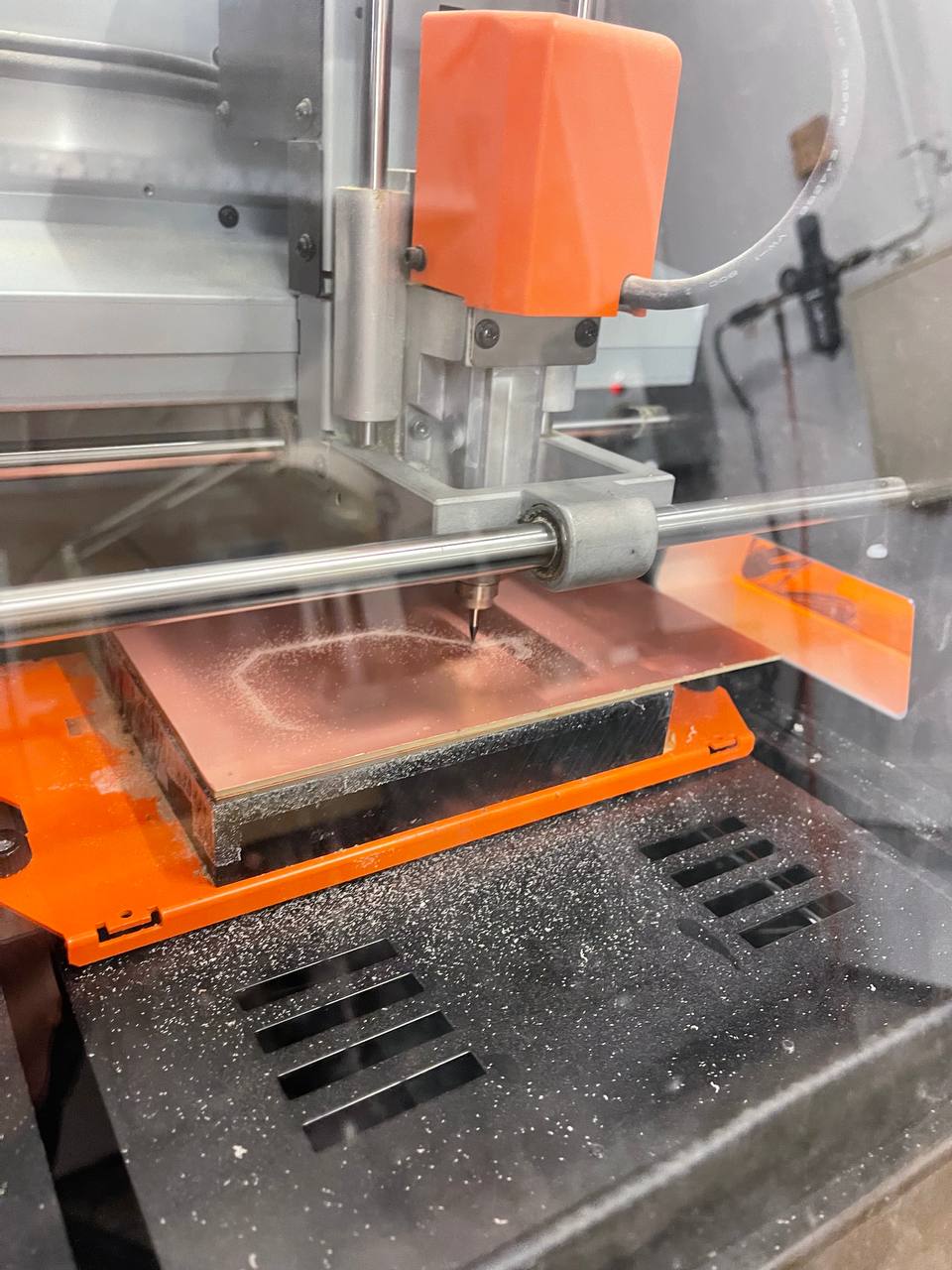

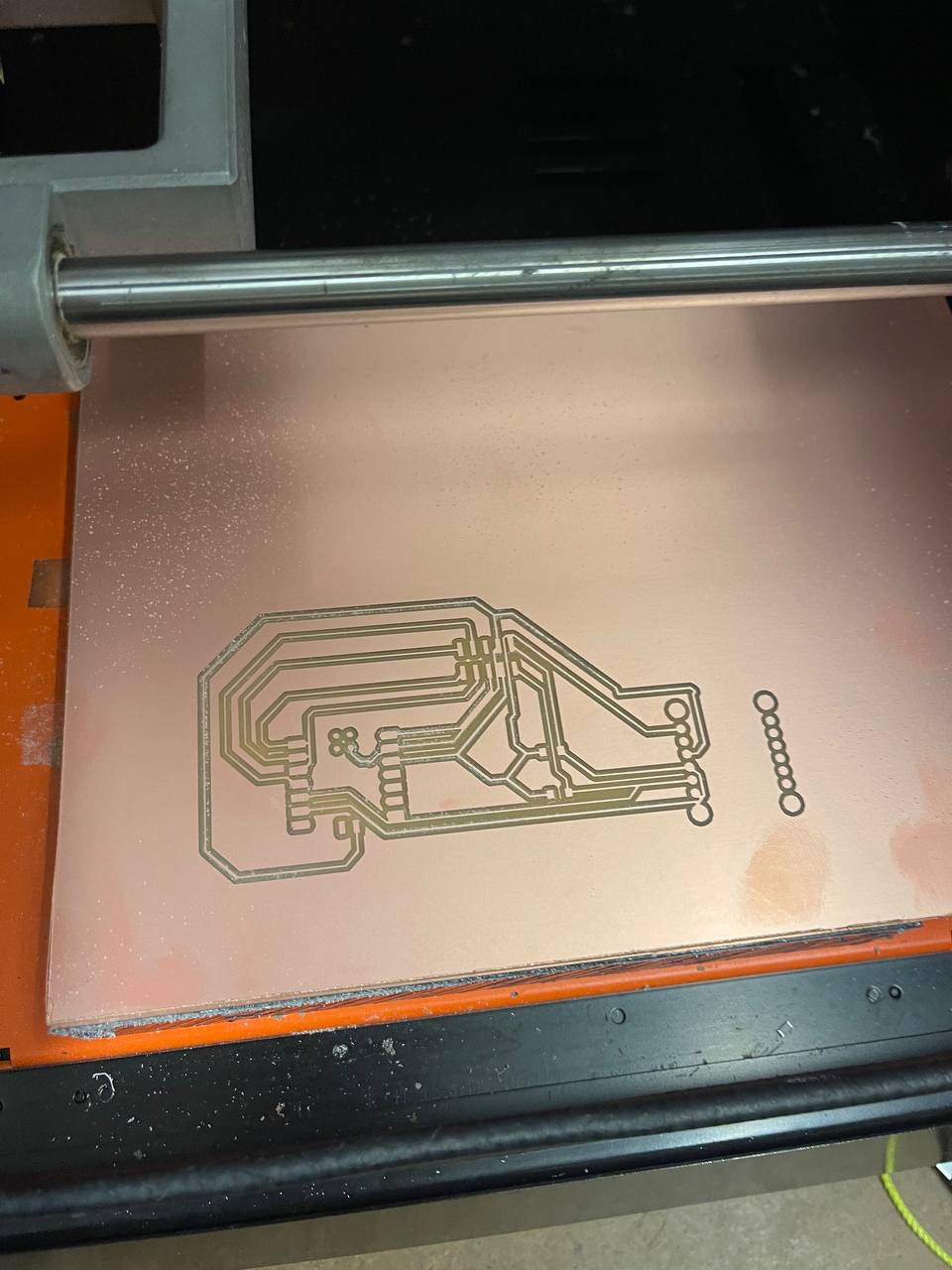

My journey this week exemplified perseverance and the valuable lessons learned from making numerous mistakes. The primary focus was on manufacturing our own PCB boards. In total, I manufactured nine PCB boards, with only three turning out successful, including one ATtiny board and two BNO085 boards. This process wasn't without challenges, as I had to go through seven 1/64 mills due to others not adhering to workshop etiquette. After these trials and errors, I mastered the mill setup and produced my successful PCBs.

This journey encompassed ups and downs, as evident in the unsuccessful batches for ATtiny and RP2040. However, through adjustments and improvements, I achieved the desired final outcome.

Once I reached the soldering phase, I came face to face with the harsh reality of my PCB design and the extent of my shortcomings:

1. My PCB is incredibly large, almost unwieldy. This presents multiple issues - it consumes a significant amount of time, and it's even larger in diameter than the drone I intend to work with. This size concern needs an immediate resolution.

2. During the assembly, I discovered at least five short circuits that had to be manually rectified using a knife.

3. Perhaps my most significant regret is not contemplating the RP2040's connection with the USB cable. This oversight stands out as a glaring failure. Due to the nonfunctional PCB with holes, I now face the challenge of soldering the microcontroller directly onto the board. As a result, I won't be able to plug it in as originally intended. This hiccup has left me quite frustrated

These experiences and efforts have enriched my project and contributed to my growth as an electronics enthusiast and developer.

So the next step is to re-design the PCB to fix the mistakes, and then write a code for the BNO085 !!

Group Project