WEEK 7 : Computer-Controlled Machining

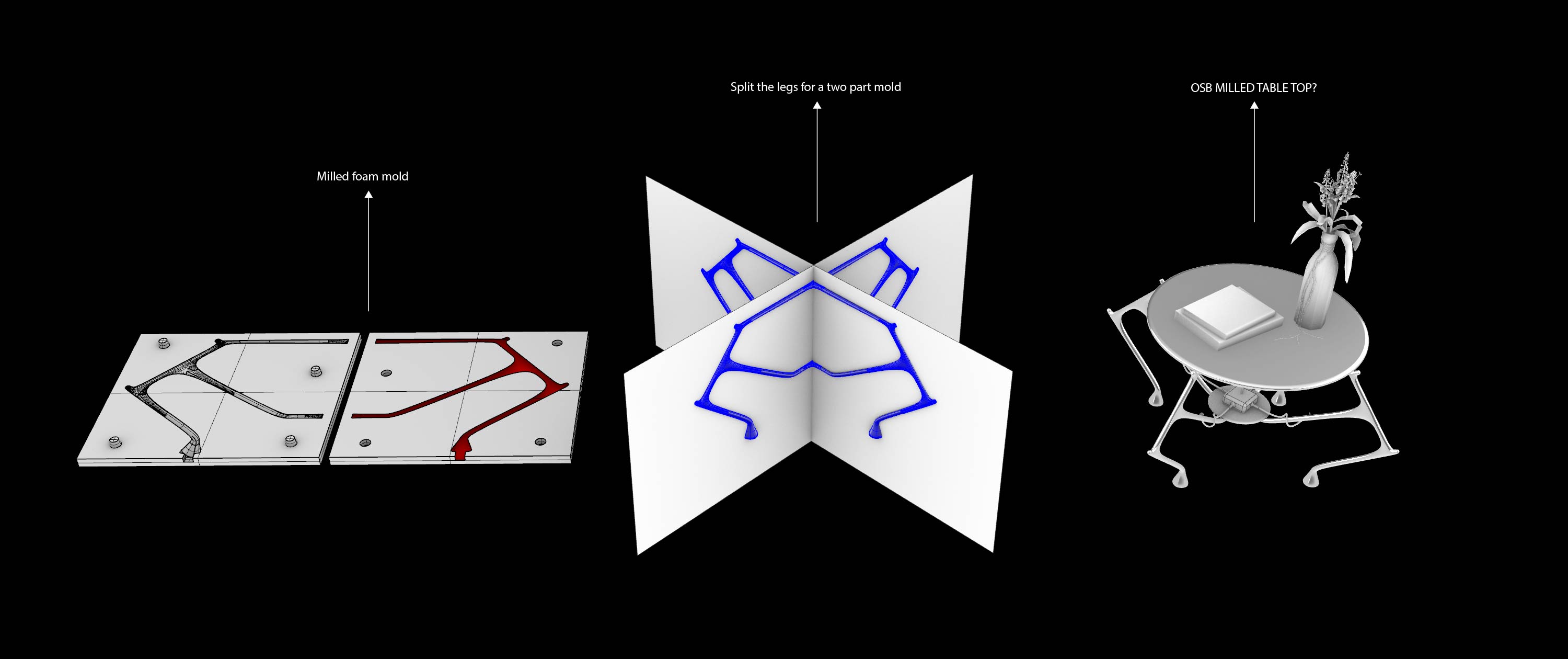

For this week I decided to start protoyping the Final project! I really liked casting and molding week so I thought I would mix and match this two weeks by using the CNC mill and OSB wood for the table top and then mill some green foam in order to create the mold to cast the legs out of clear epoxy.

I then went ahead and started preparing the mold to mill, by splitting both legs the idea would be to use the mold four times to create the four legs. I intend to use epoxy of some shor of plastic in order to create this kind of flexible motion and material properties.

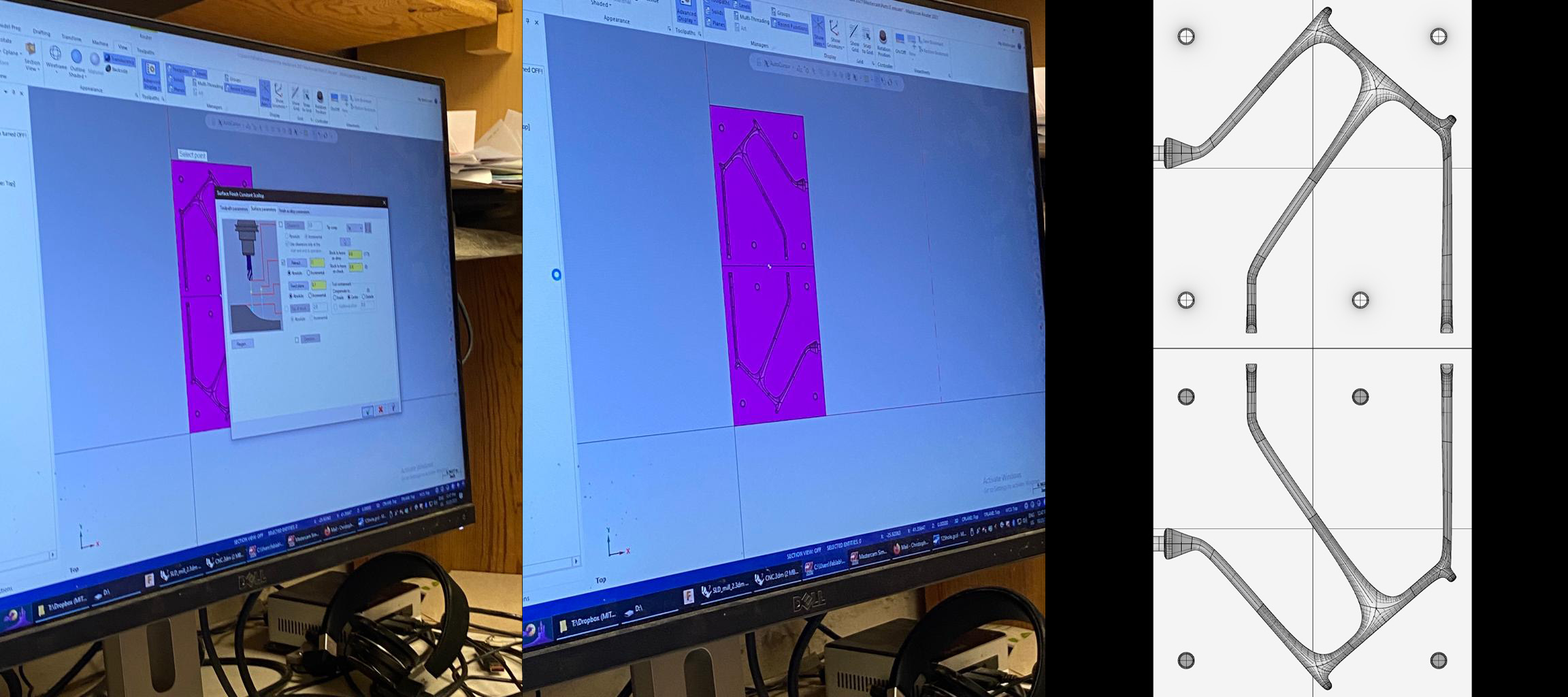

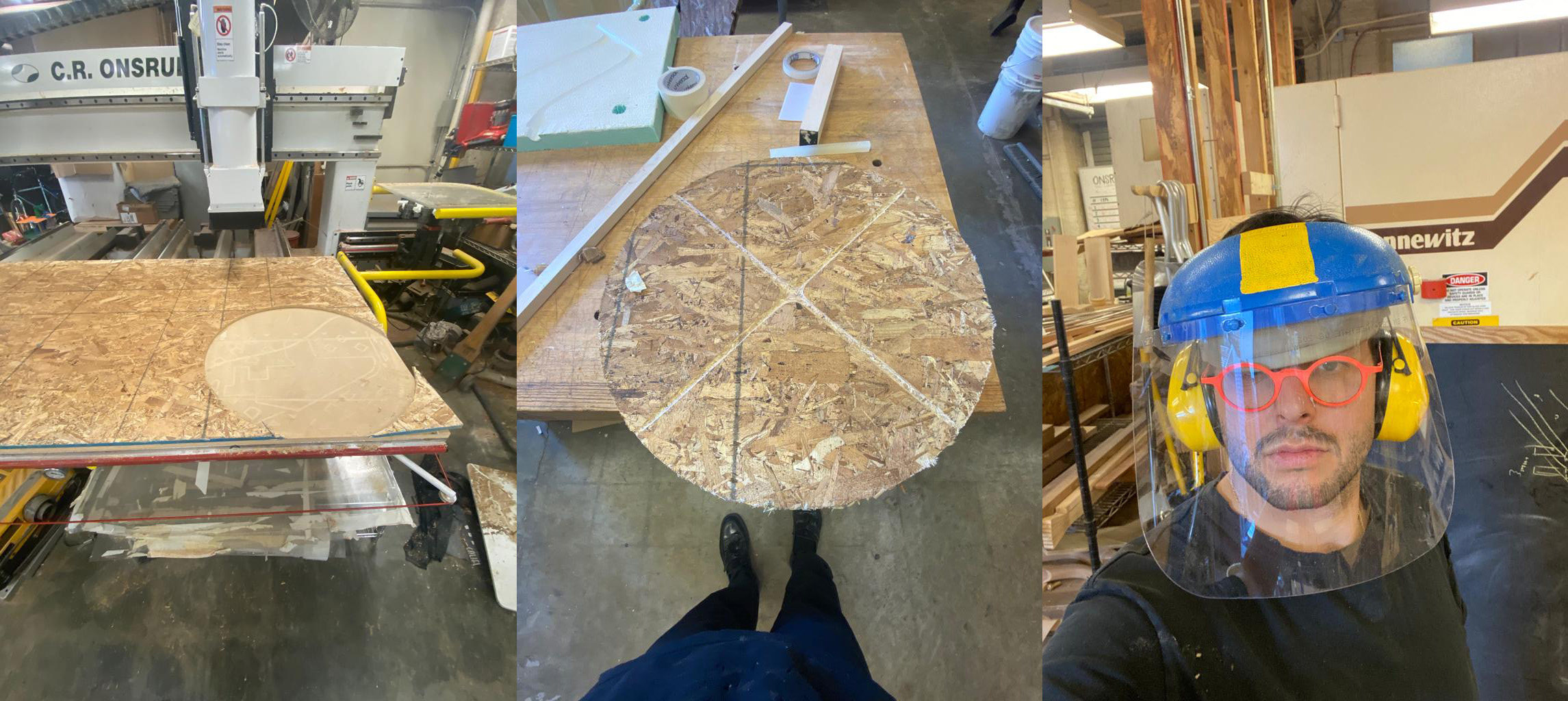

After the file was prepared I went to N51 and chris and I prepared the mastercam file in order to mill it out of green foam. The complex curvature of the object caused a little bit of inconvenience when running the simulation because it was getting the toolpath all confused, however after going back to rhino and exporting a couple of guiding lines for the toolpath to follow it was all good!

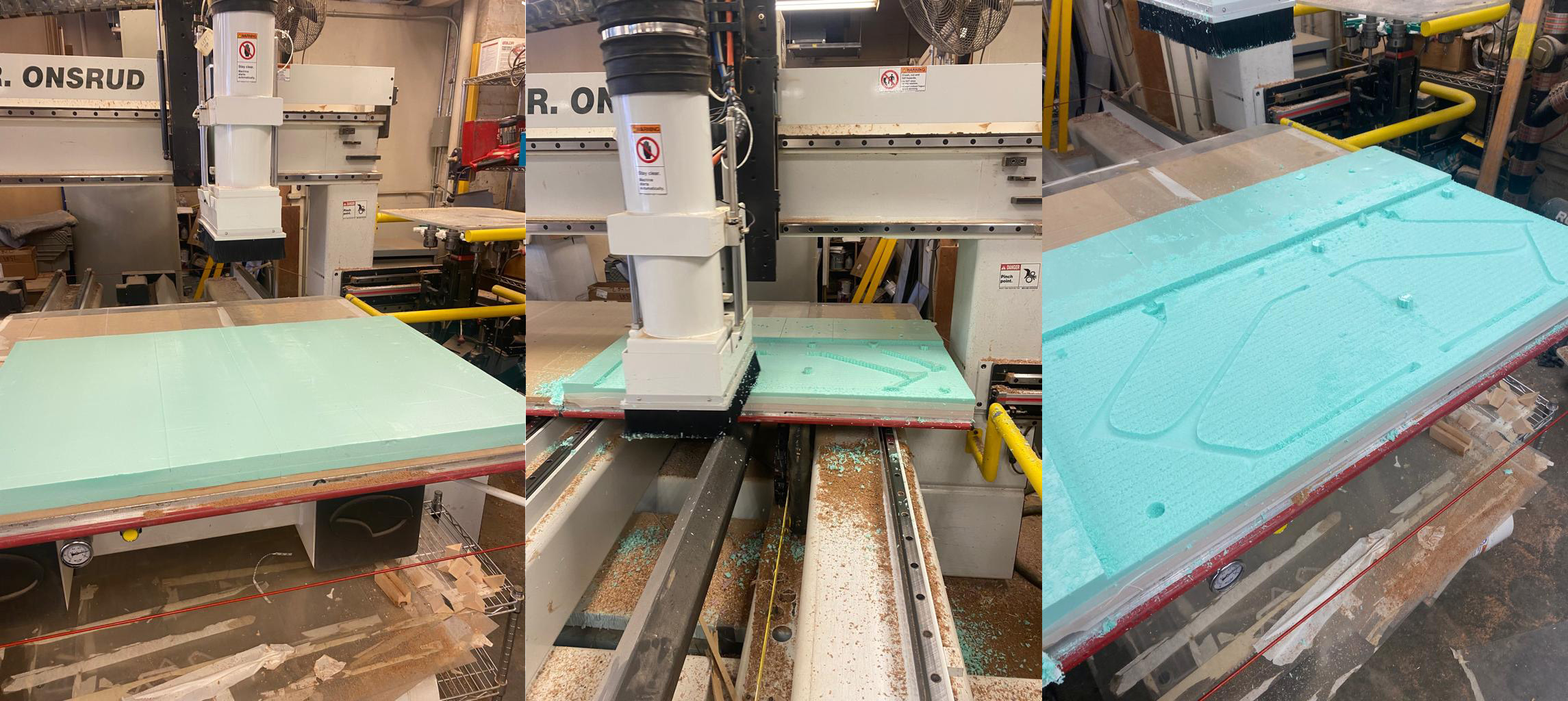

The milling process for this time was fairly straight forward it did two passes the rough cut and the final one. The job was quite smooth however we did ran into a couple of issues, the holes for the mold were not clearly perforated which means I have to hand cut them which doesnt sound like a very big deal however for the mold to be reused everything has to be done with perfection and not left to chance.

I have to maybe add this on caps so I remember PREPPING THE MATERIAL TAKES LONGER THAN YOU THINK!! so it took me about three days to get the material ready since foam is quite delicate when dealing with chemicals since chemicals would basically burn through the foam, I used Gesso to prime it and the first layer was basically just absorbed by the foam and then I had to keep giving it passes in order to get it fully coated I also did a final layer of wood finishing.

Here is basically where everything that could go wrong went absolutely terrible. First after a lengthy back and forth about epoxy with the department of architecture and with great discontend the allowed me to cast epoxy however I could only do it outside with some supervision, because of this the epoxy requires room temperature and with the cold outside it doesnt want to cure. Second I absolutely under sealed the whole mold so the epoxy started leaking EVERYWHERE. and because it was not curing it kept just leaking. I finally used hot glue to get it sealed and im still waiting to get the first leg out but after the mess I did I doubt they will let me use epoxy again. soo time to pivot!

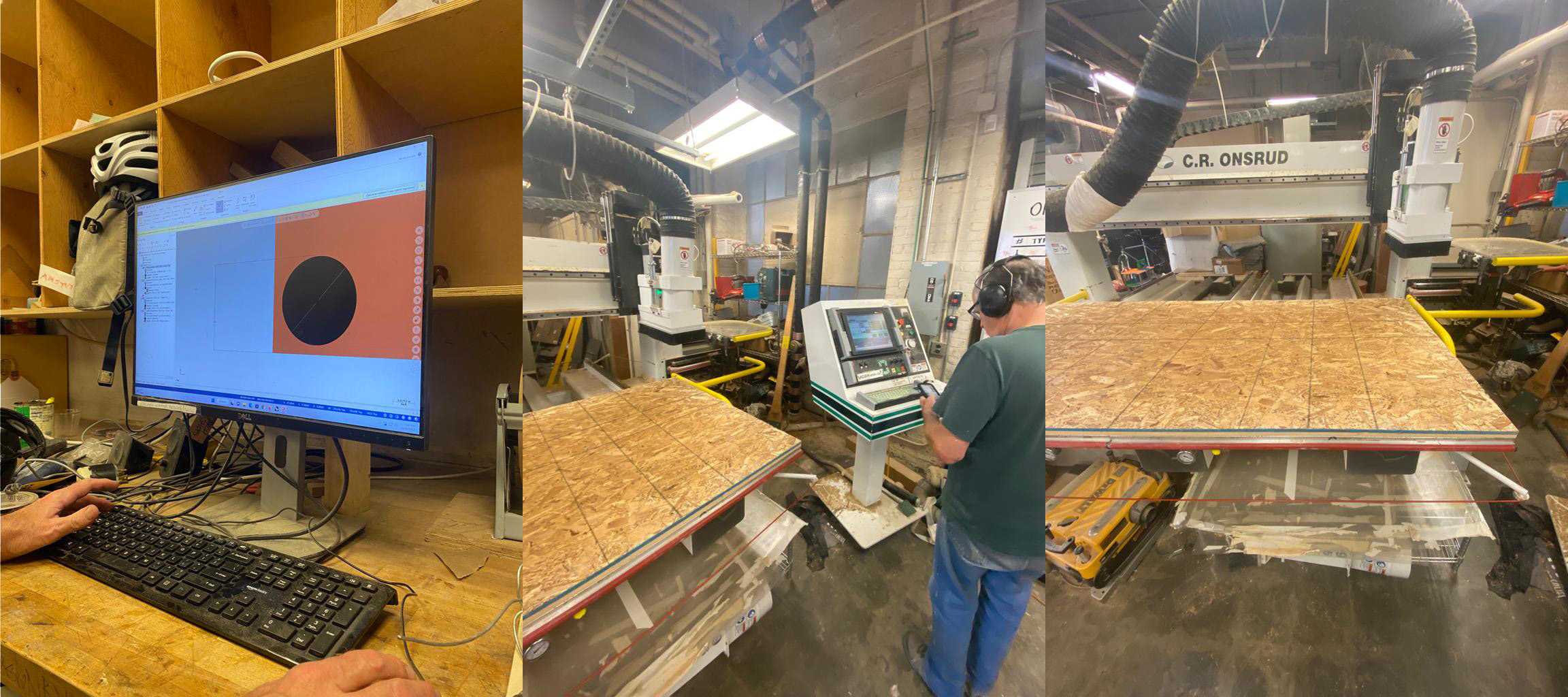

I decided to just cut the top of the table from OSB because I thought my legs might still work, which I was completley wrong about haha but at the time I did not know it and I felt quite confident on the legs working so I said oka I just mill this circle and assemble later.

Safety first!

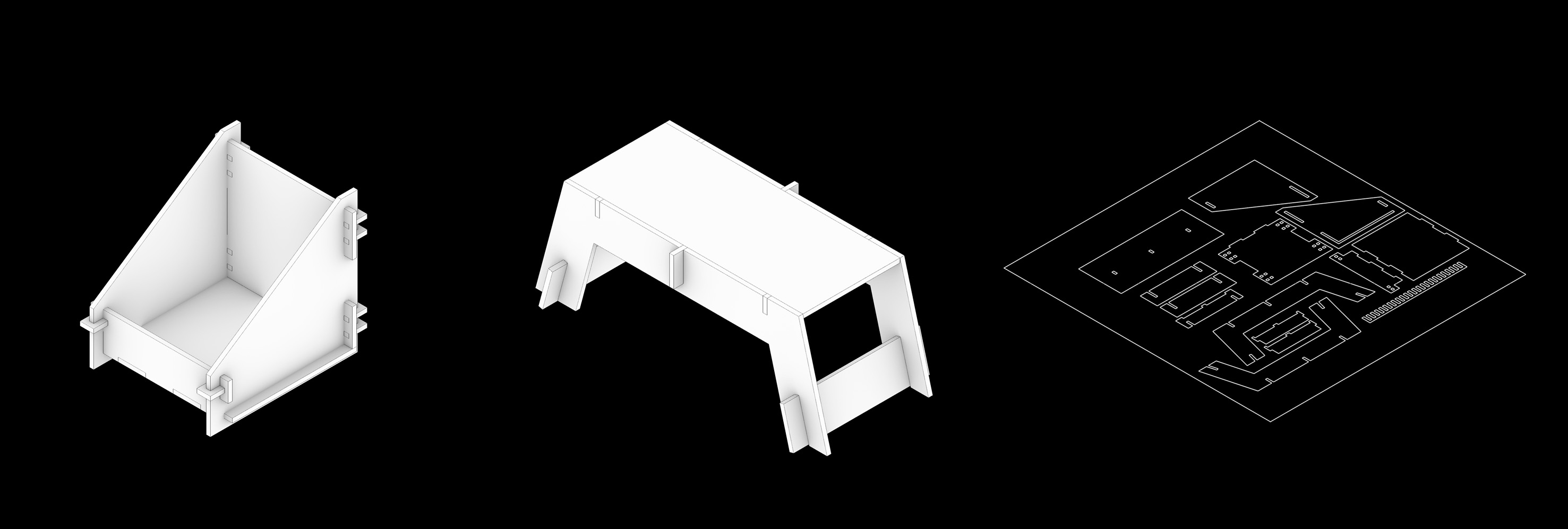

At this point in the week I realized my ambitions had not matched my skills. And I had not really fullfilled the weeks assignment because I had just been stubbornly trying to make this leg cast work. But I now finnaly accepted defeat, casting got the best of me and might won this battle but it shall not win the war! anyway time to pivot. My good friend Simon had some extra wood aaand since we were both tackling ambitious ideas me with the cast and him with his chair pants! we decided to partner up to fullfill the assignment and do a couple of BIG objects. a record player and a tiny stool!

And just like that! it was time to mill again

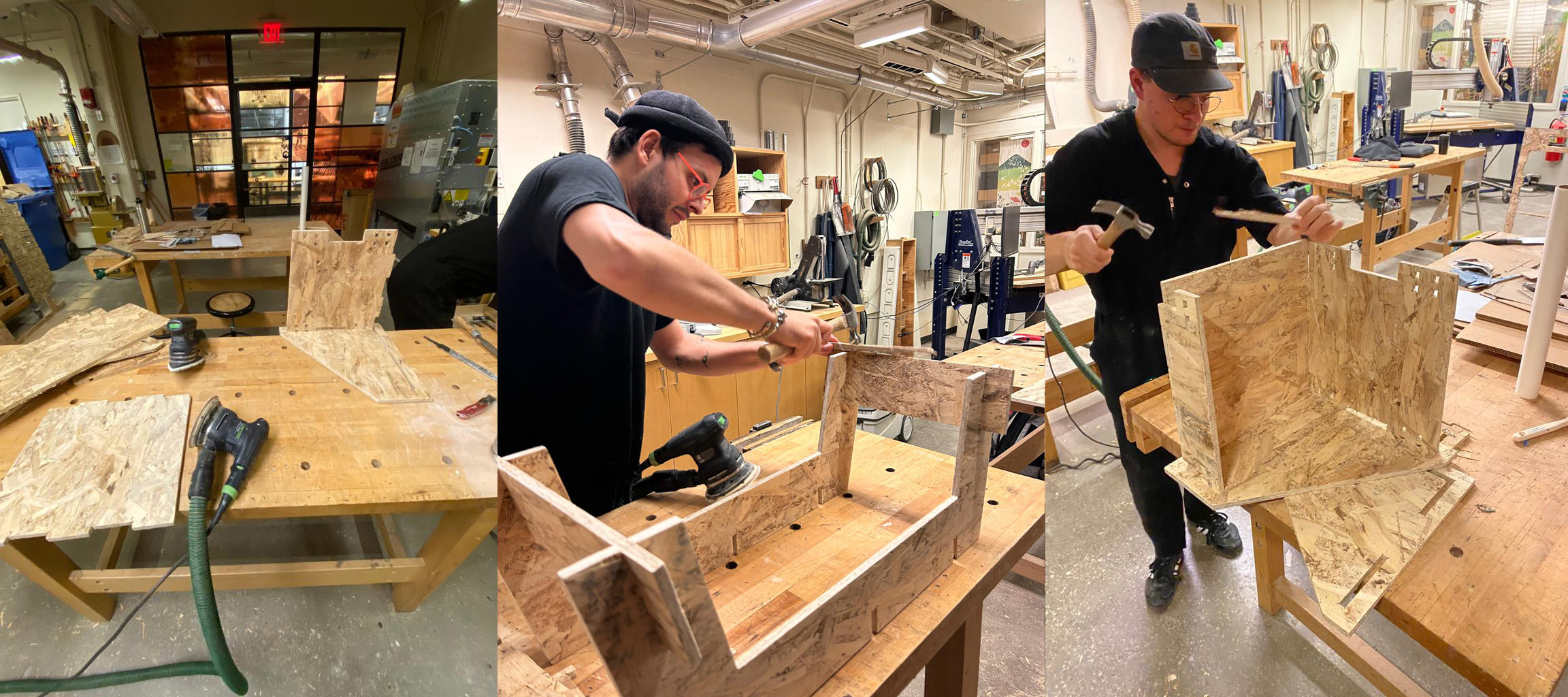

Unfortunately no pictures were taken but Simon and I had to carry the massive 8 x 4 sheet of OSB from N51 to the architecture department through the stairs because it would fit on the elevators. Then we used some japanese saws to cut all the parts and we got sanding!

After we got all the pieces pieces sanded down we started assemling them and press fitting them.

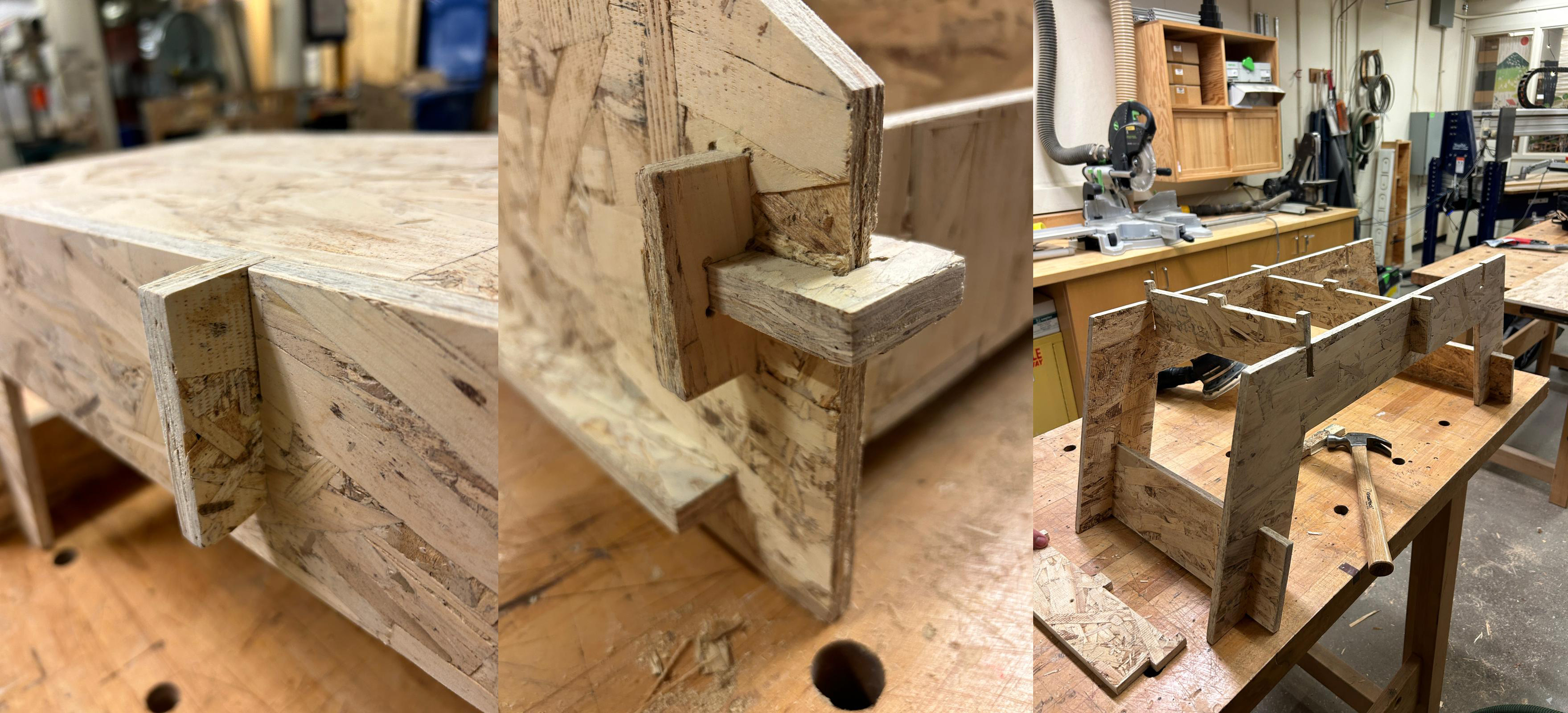

Here are some detail images of the construction, whats cool about the design is all the pieces are press fitted and no glue is needed. The pieces fitted quite well with just a small level of sanding!

Final objects!

.jpeg)

It works!