Week 1

Introduction and Computer-Aided Design.

Engineering Files

Ideation and Fusion 360

For the first week of HTMAA, we were responsible for ideating some potential final project ideas and becoming familiar with CAD. With conference deadlines, I wasn't able to dedicate as much time as I would have liked to fleshing out possible ideas, but fortunately I already had quite a bit of experience with CAD from undergrad.

Unfortunately, most of my prior experience was with Solidworks and Creo Parametric - Fusion 360 had a number of unique quirks that made it difficult to easily transition. I spent a lot of time trying to figure out shortcuts for simple commands, and defining parameters for the models is surprisingly inconvenient, with no shortcut to immediately add parameters when defining lengths or sketch constraints.

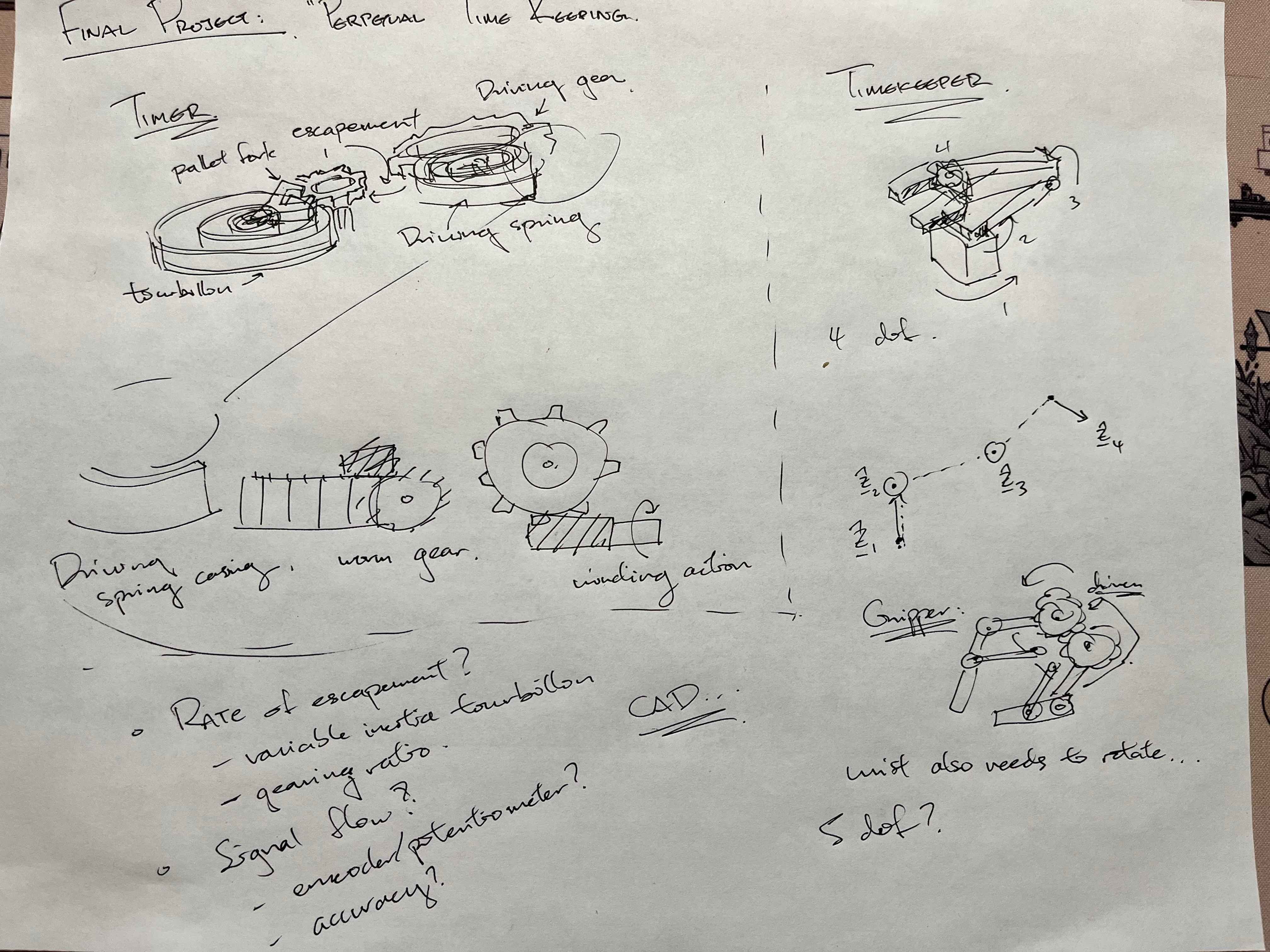

The two main ideas I would be interested in exploring are 1: a large, mechanical watch, with a functioning tourbillion and gears, and 2: a mechanical numpad, possibly a full keyboard.

I wanted to focus on the clock: even though my undergrad was in mechanical engineering, the past few years I've mainly focused on controls, math, and coding, and had little to work on with my hands. I've always been fascinated by the inner workings of watches, and I thought it would be a fun project to try and build a large, mechanical watch.

While I've had a lot of experience with higher-level programming and controls from my research background, my undergrad didn't have many chances to really get hands-on with complicated mechanical machinery. The workings of automatic watches have always been fascinating to me, and I would love to get the chance to build one myself. Hopefully, at a larger scale, it would be easier to build and source the inner workings of a watch.

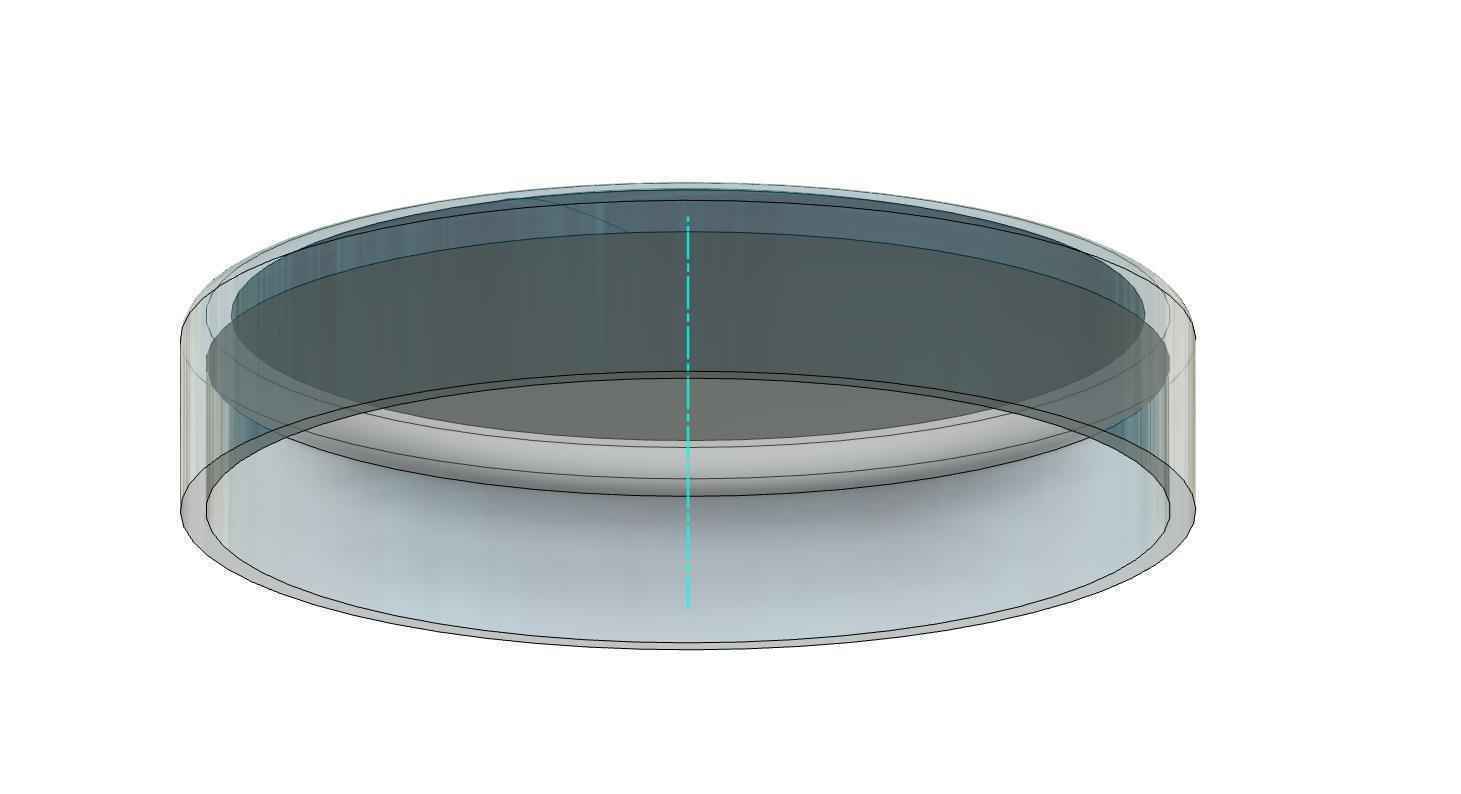

I made a very quick mock-up of what the watch face would look like. As my first CAD model in Fusion, I struggled more that I expected to do simple tasks like revolves and extrusions. Many of the way Fusion treats its components and parts feel very unintuitive, and I felt like I was fighting more against the UI than my understanding of how to model something. Here, I only modeled the face and casing of the watch - ideally, most components of the shell could be transparent so that all the inner workings could be visualized. I would have to do much more research to understand deeply how the mechanisms of a watch works, and how they are all integrated into such a compact space.

My second idea is to build my own mechanical keyboard, or at least a functional numpad.

Recently, I've learned about how customizable mechanical keyboards can be - enthusiasts fixate on the feel, sound, aesthetic, speed, and compactness of their keyboards, and I've seen so many interesting and unique designs on the internet. I think a mechaincal keyboard project would nicely tie together a lot of the concept we would learn in class, like PCB design, 3D printing, electronics, and programming.

I similarly threw up a quick mock-up of what a numpad would look like in CAD. I was thinking I could 3D print the individual keycaps and case, design and program the PCB, and buy the individual switches to assemble the keyboard. This feels like a relatively "safe" projects, with the number of DIY kits and tutorials out there.