CADing

I attended the Society of Women Engineer conference over the course of this week, so I lost Thursday-Sunday to the conference. I got an early training from Anthony did not do much else until Tuesday.

I first started with installing an add-in to do dogbone in Fusion, following this tutorial.

I went back and forth between the table design, taking inspirations from the one that was shown on the website.

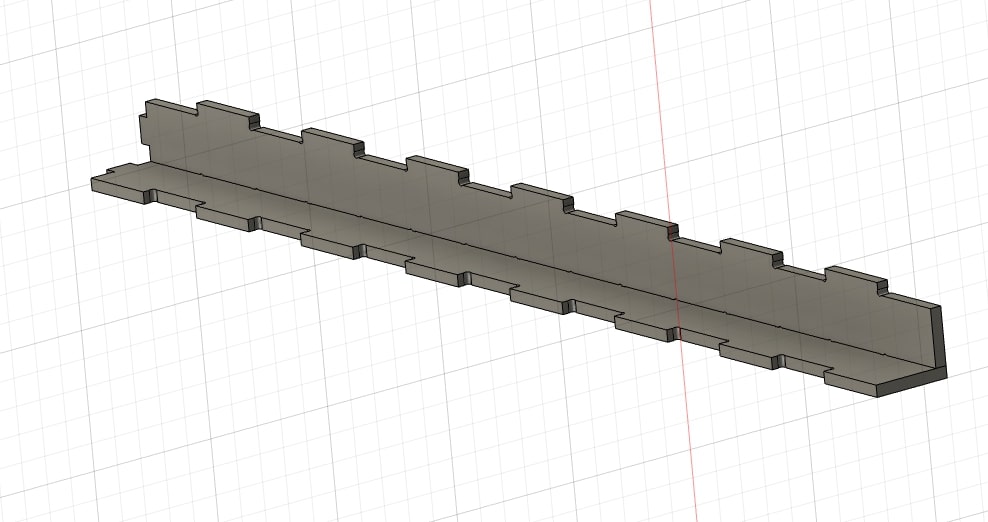

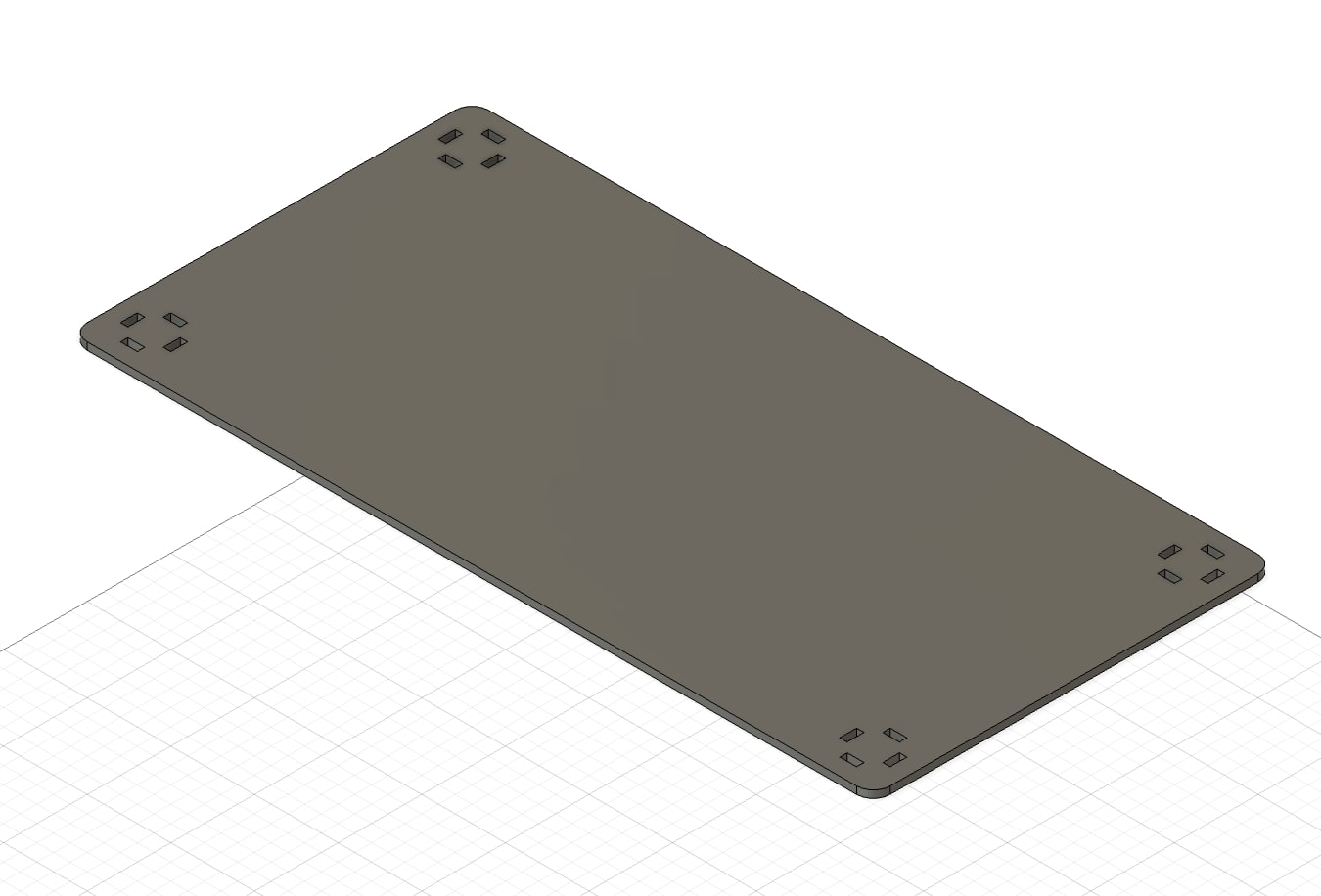

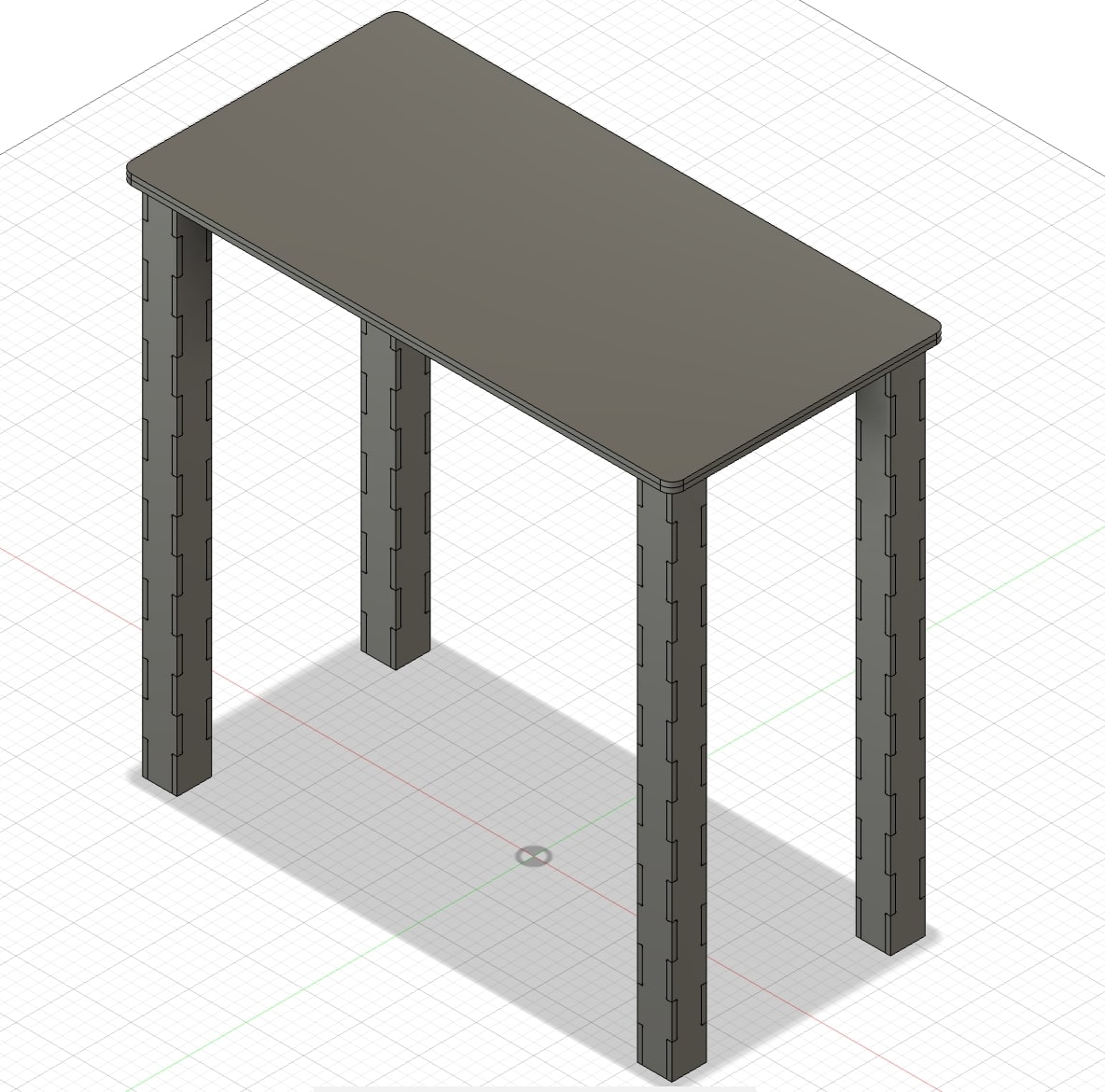

I settled a design that has four legs made of four pieces each jointed by dogboned fingers. I joint the tabletop and the leg with pegs. See the design below.

CAMing

I layed my parts down flat with the Arrange function. I used three different arranges because I have too many parts. I learned that the different arranges need to be made on different planes or else they will be merged together. (I calculated so that my parts fit just right on two 4x4 board, but I forgot to account for the buffer zones on the sides).

Then, I jumped into the manufacture space to create my setups. I create three of them for the three arranges that I have. I selected the appropirate orientation, stock, created a toolpath using the 2D option. I generated tabs with Fusion, but I manually added more to make sure that no wood would learn how to fly--and then I got to milling after generating the G-code on Anthony's laptop.

Sadly, my computer lost the file, and it's not recoverable as far as I can tell. I think Anthony may have a copy on his laptop, but since I'm not making another table anytime soon, I'll just let this file live in a Schrodinger state of possibly existing somewhere.

Assembling

After milling, I broke the wood apart by hand and feet. I used the band saw to cut of most of the tabs that are not tucked into a corner and hand file the rest of them. A lot of the dog bone was not cut well by the CNC machine (I suspect it was the OSB's fault), so I also hand file those. I gave my hand a few cut in the process.

After filing for hours, I assemble my table together using a lot of brute force and a rubber hammer (and definitely not a regular hammer...). I join the leg together via hammer and join the table top pieces together via the nail gun because it was just the right height.

The table came together but the joint between the legs and the table top was quite weak because the tab connecting them was only the height of the wood thickness. I attempt to glue it together (twice), but atlas, the table did not survive transportation :(

Below are some pictures of the table before its eventual death. I tried sanding the table down, but I inhaled a whole lot of wood dust that made me cough for many days. Maybe I'll make another table with nicer wood and nicer joint later.

You can find my CAD file here. Sadly, the CAM file lives in Anthony computer (due to my Mac slacking more so than I do). I can retrieve it if needed.