Laser Cutting

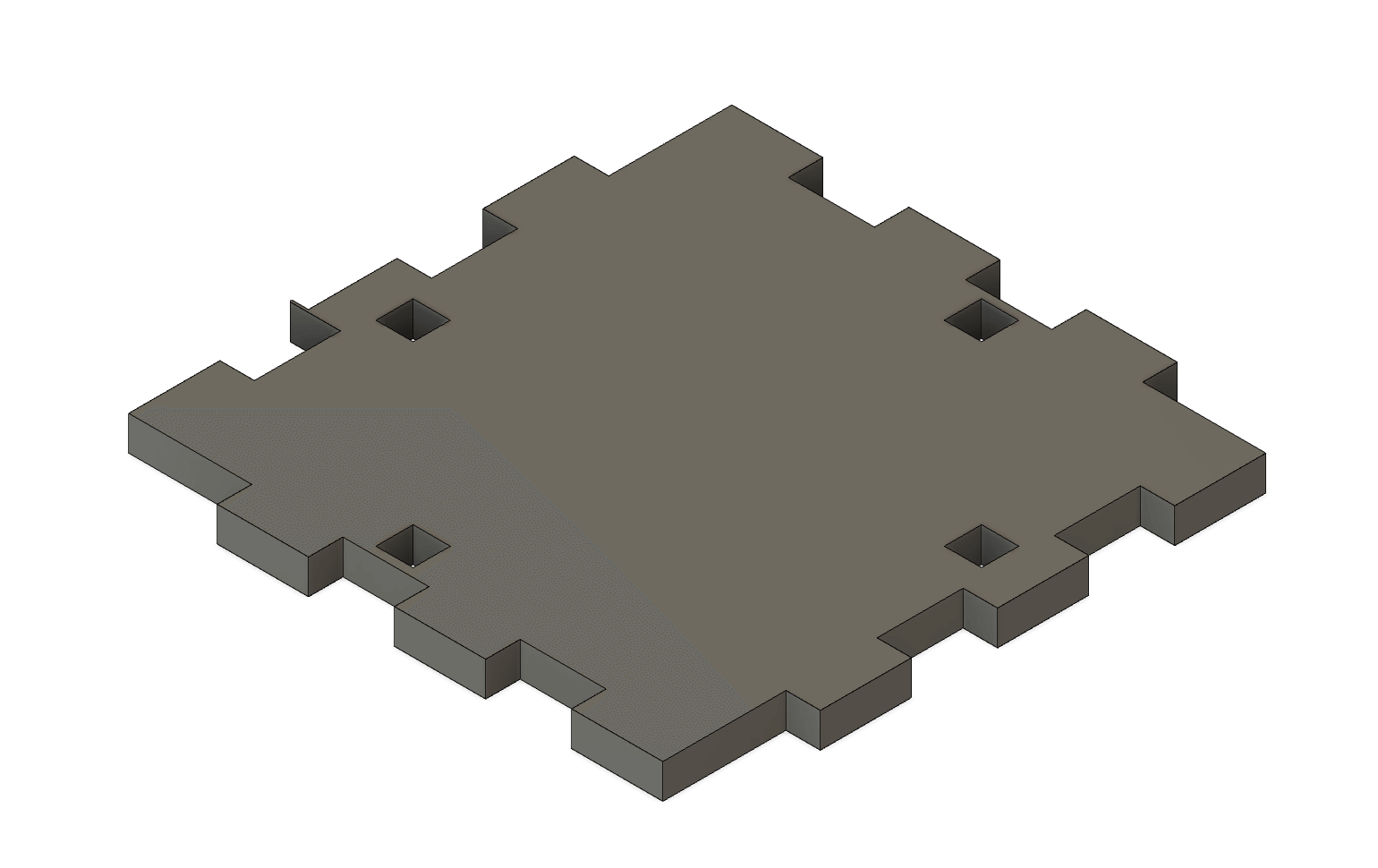

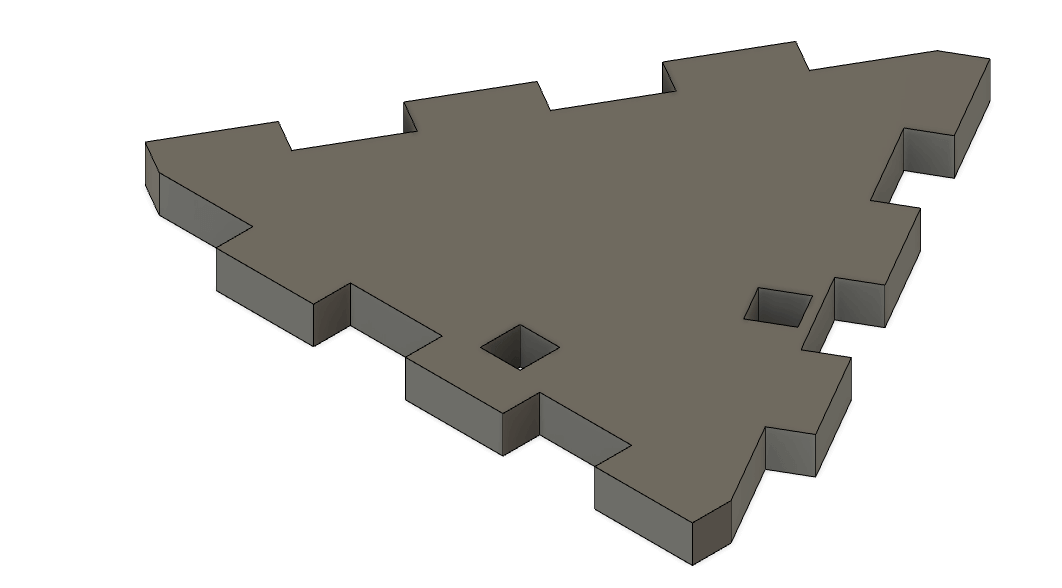

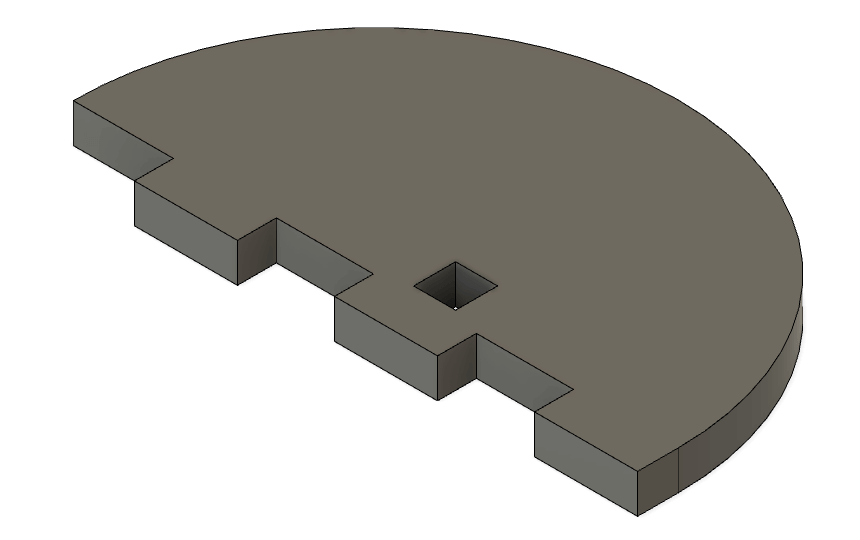

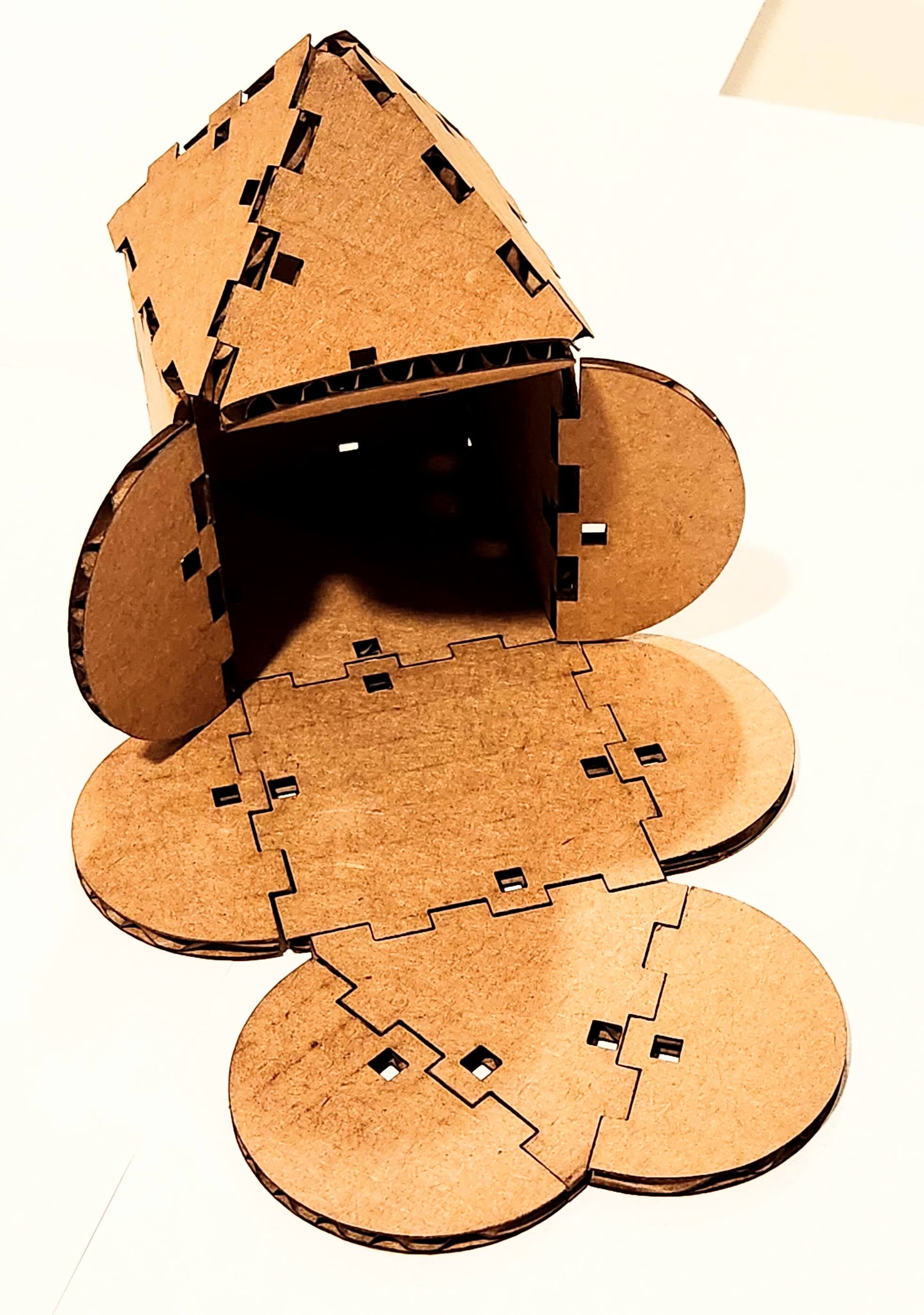

Idea: House Blocks

The idea emerged from the fact that all homeless impromptu "tents" are made of cardboard. I wanted to build a CAD design where you can adjust dimensions and fingers number and it will automatically generate building blocks. I was not sure about the ethical perspective and implications of this idea. I ended up designing the building blocks for any purpose, as a toy as a doll house or kids house, designing random shapes from elementary blacks.

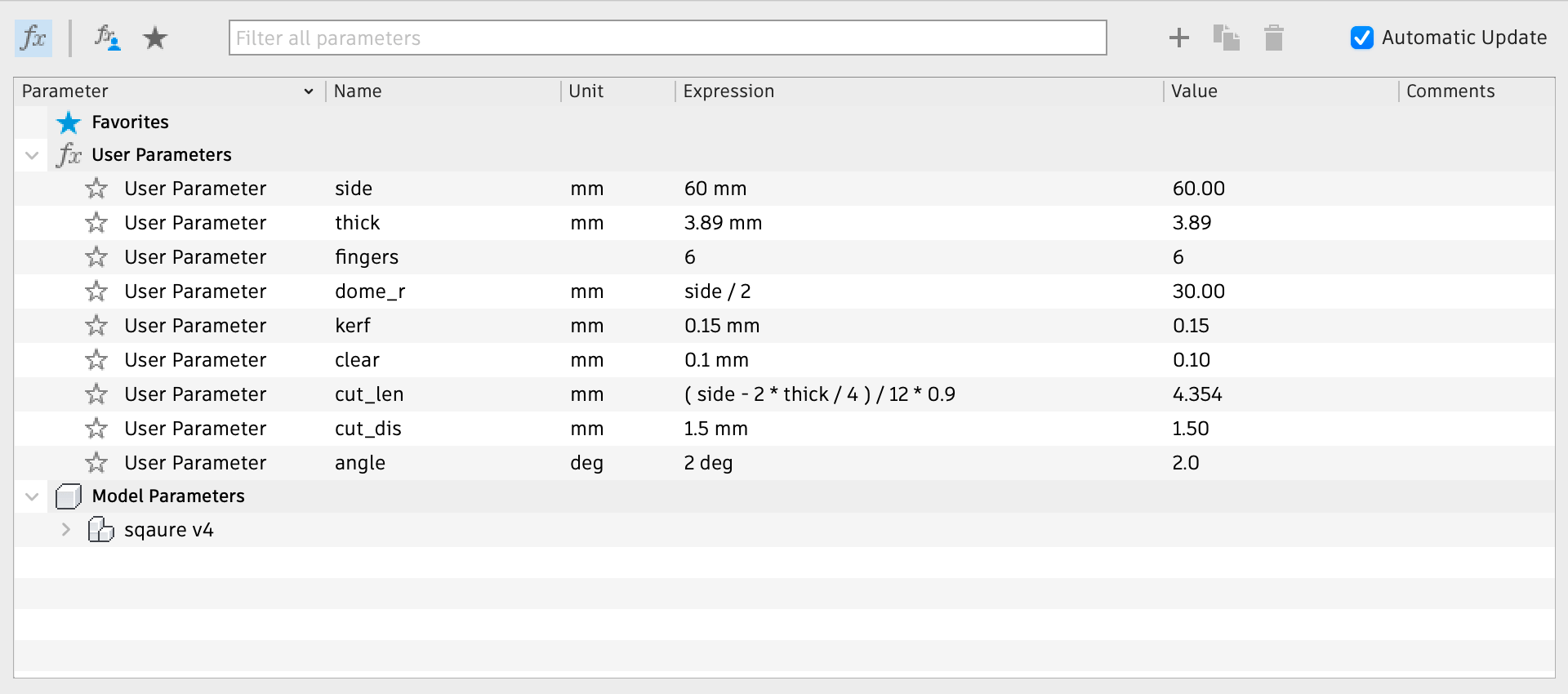

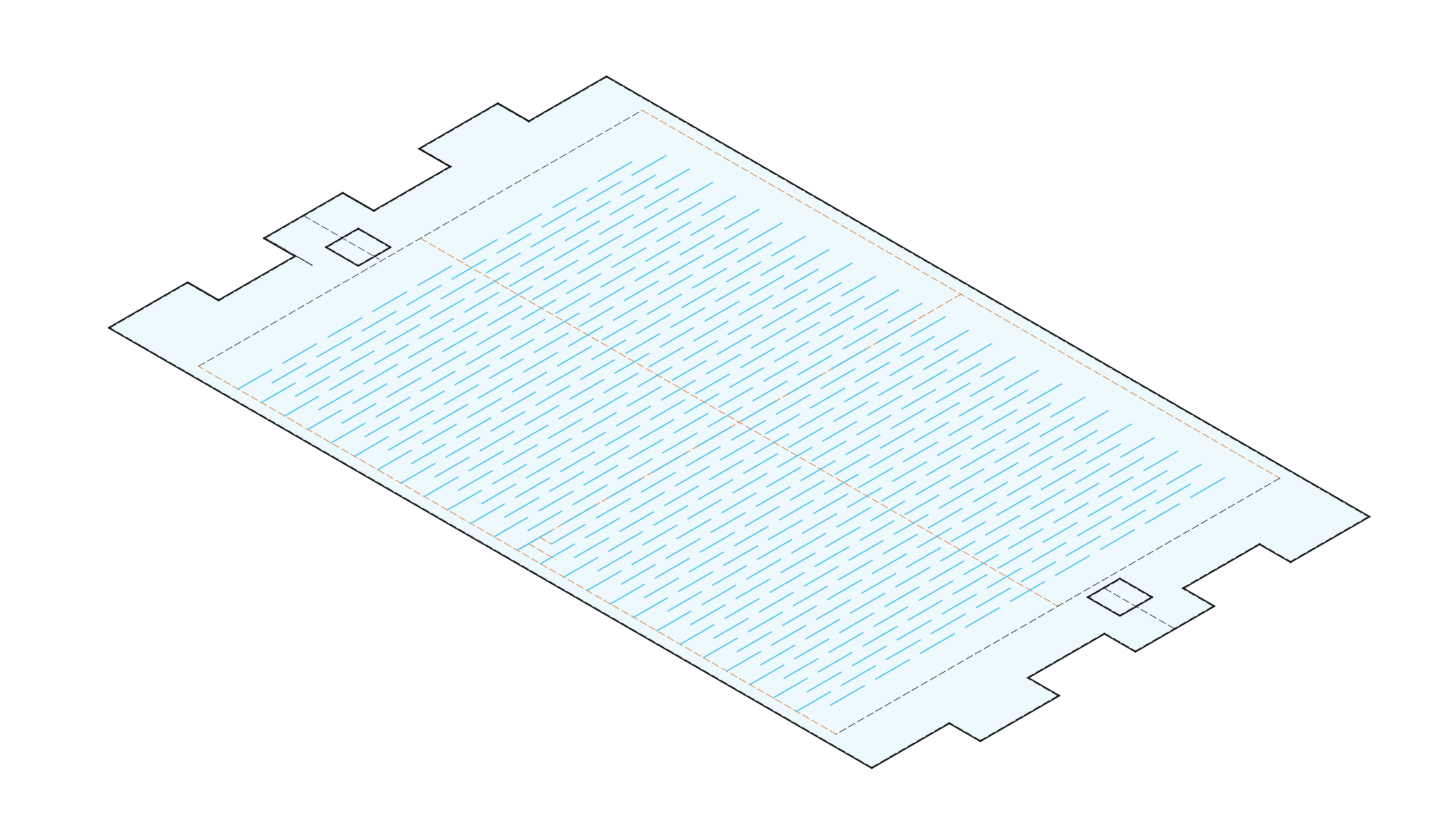

Designing: CAD

In the CAD, I tried to parametrize the design in term of dimension and finger numbers. I also incorporated the kerf and clearance to be adjusted easily through the parameters.

Cutting

Steps to Laser cut: 1. Turn on device and pump 2. Put the surface in bed and adjust the bed z-axis. 3. Import design, adjust to desired functionality (red:cutting, black:engraving). 4. Print to laser cutter app and choose the right material and setting. 5. Make sure with the laser pointer that the location is empty and enough for the piece. 6. Cut Cut Cut

Final Product

Vinyl Cutting

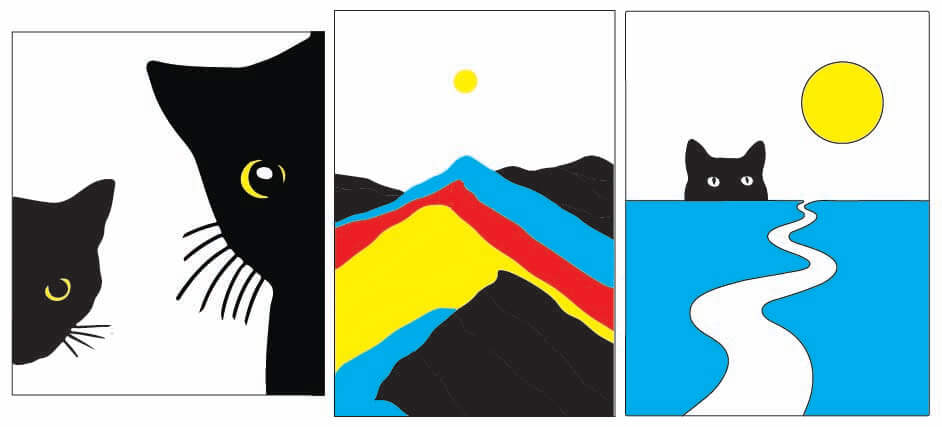

Idea: Layered Art

As I was working on the laser-cutter project, I found a transparent piece of acrylic in the scrap material drawer. It had the perfect size of a desk painting, which inspired me to make a painting.

Designing: Illustrator

1. I put the color pallete in Illustrator.

2. Pulled some minimalist art from Pinterest and used Image Trace to simply them.

3. Chose a picture and divide them to layers to prepare for cutting.

4. Using the VinylCutter to cut the layers

Assignment Description

Individual Assignments:

- work through a git tutorial

- build a personal site in the class archive describing you and your final project

- cut something on the vinylcutter

- design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways, and for extra credit include elements that aren't flat

Group Assignment:

- characterize your lasercutter's focus, power, speed, rate, kerf, joint clearance and types