Idea

Make the designed board from last week and solder the components.

PCB Fabrication

1. Export

From Fusion 360, we can export the PCB board as either PNG or .GRB file, depending on what machine we are using. For the machine I

used, Othermill which takes .BRD files. Check what the machine requires.

For PNG, use the ULP file. Check the

following documentation

to get the ULP file and use it.

Link to Board File

Follow this tutorial to reference

how to use the Othermill. I will mention some tips in each step, but my explanation is not comprehensive.

2. Prepare for the Milling

1. Turn on the machine and open the software.

2. Change the mill. When changing the tool, always place a finger on the tool to prevent it from dropping and breaking the tip.

3. Measure the thickness of the board+tape and add it to the board dimension.

4. Placing the board, press it well to avoid moving it while cutting.

3. Software and Run

1. The software is user friendly and will prompt you to take some steps.

2. Choose the correct tools. In EDS, we are using the 1/64" standard mill and 1/32" PCB conservative mill. The second is

will making milling slower but it will prevent ripping out the traces.

3. Start with the smaller tool, since the bigger tool will cut the outline which will make the board moveable.

4. Make sure the settings are correct. Press start milling and follow prompt to change the tool. You don't need to monitor the milling

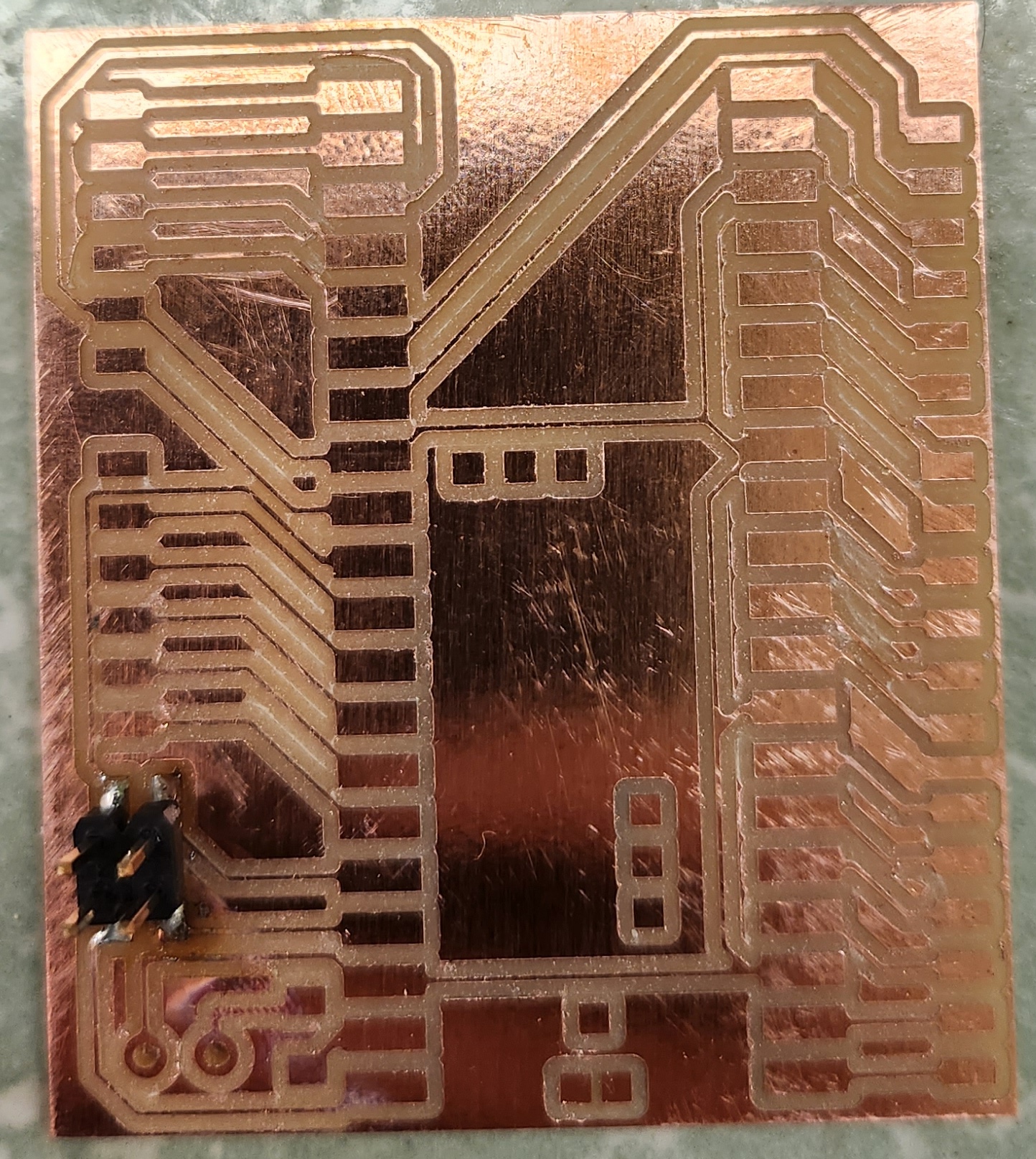

4. Pulling and Cleaning the Board

1. Open the window, bring the board closer (I forgot how). Use vacuum machine to remove the copper dust.

2. Use the putty knife to scrap the dust away from the board to clean it.

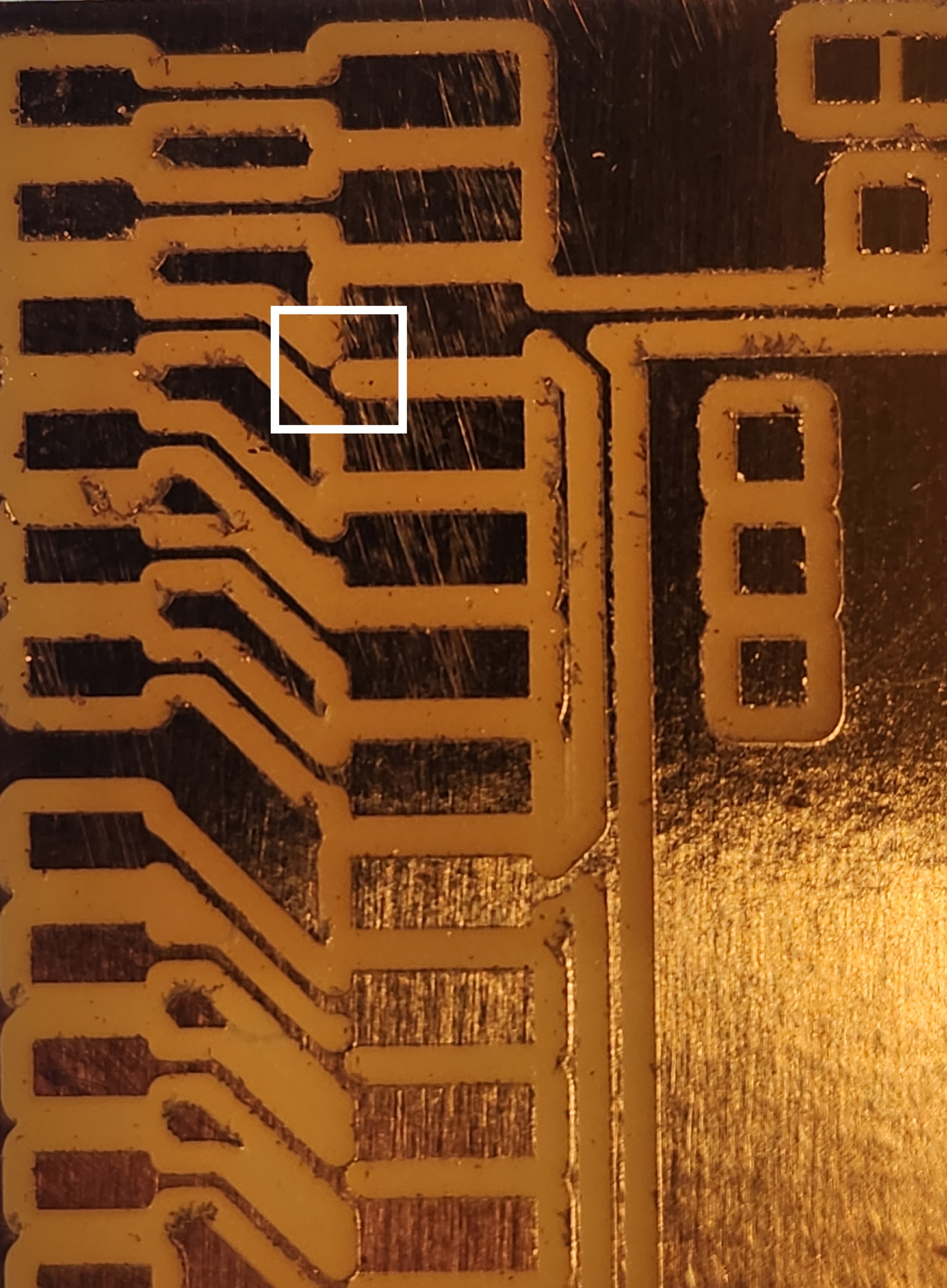

3. Put a flashlight underneath the board to see clearly see any bugs. Use an exacto knife to remove any unwanted copper the mill couldn't remove.

In the image, there is a trace that needs to be cut.

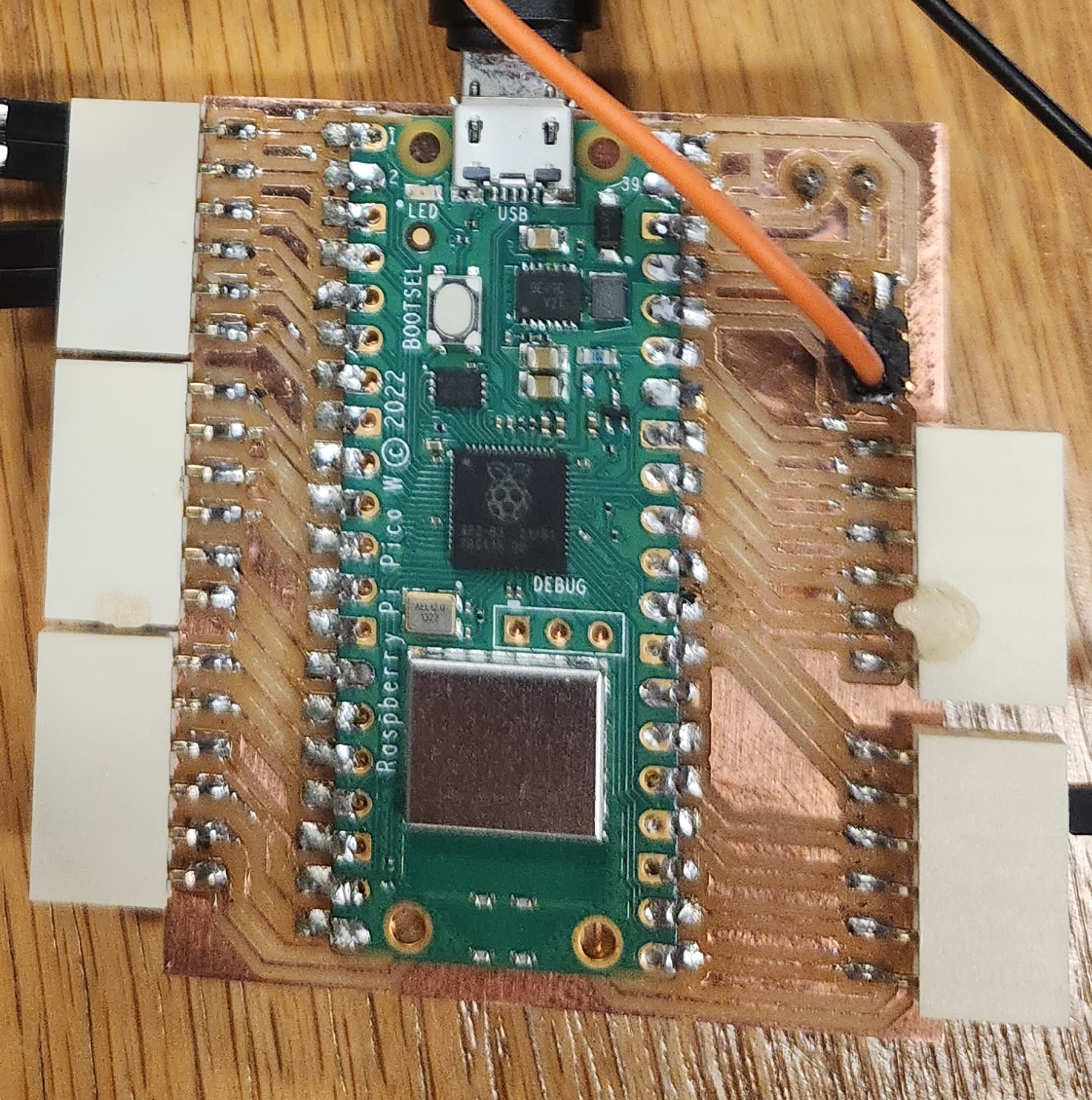

5. Solder components

1. Gather all component. Based on their size, choose to either use reflow or soldering iron. 2. Start with smaller components from the center of the board. 3. You can use the tweezer to remove any solder bridges or use copper wick. 4. Finally, use a multimeter to check connections.

Notes

PCB Fabrication

PCB Materials:

MDF, FR1(safe for machining), FR4 (itch, not machine because it's glass fiber and hazardous to enhale)

Methods:

1. Etching: Very toxic chemicals, but good feature size with hight resolution.

2. Machining: Not hazardous, good but lower resolution compared to etching.

Other notes

Can have various mill bits with different resolutions and shapes. V-bits: more robust, cheaper, but height sensitive.

Holding stock down: stick tape. You can use clamps, but it can bend the board which results in uneven cutting. Make sure that

the clamps are distributing the force. Make sure that the underlay is good. If it is uneven your board will move around.

Don't over tighten the set-screws. It will damage the threads.

Clean the board from hand oil.

If the mill just create overflowed material, you can use a ruler to remove that. When the features

are not accurate, it is time to change the mill. New mills tends to leave hairy traces too.

Solder: an alloy where the percentage is chosen for the lowest melting point.

Soldering joints should be shiny and smooth. Cold joints work but break immediately if you ben the board.

Methods of Soldering: manual, wave, and drag, hot air reflow (must be done from above with FR1, FR4 is a good heat conductor so it can be heated from the bottom).

Solder from small to big part, center to edge located parts tp avoid blocking.

CAM: gerber files for boardshouses. PNG image (uncompressed) for in-house fabrication.

Future Work

- Try layering techniques for PCB and how I can use vias and holes to connect them.

- Try Connecting various board with a flushed connection

Assignment Description

Individual Assignments:

- make and test the development board that you designed to interact and communicate with an embedded microcontroller

- extra credit: make it with another process