HAOHENG TANG'S PROJECT

HTMAA23

Week 14: Wildcard-Composite

Ideas & Design

I'd like to make a longboard for my final project and the main challenge this week is to make a longboard deck with wood veneers. Fortunately, Alfonso can help me with this work!

Preparation

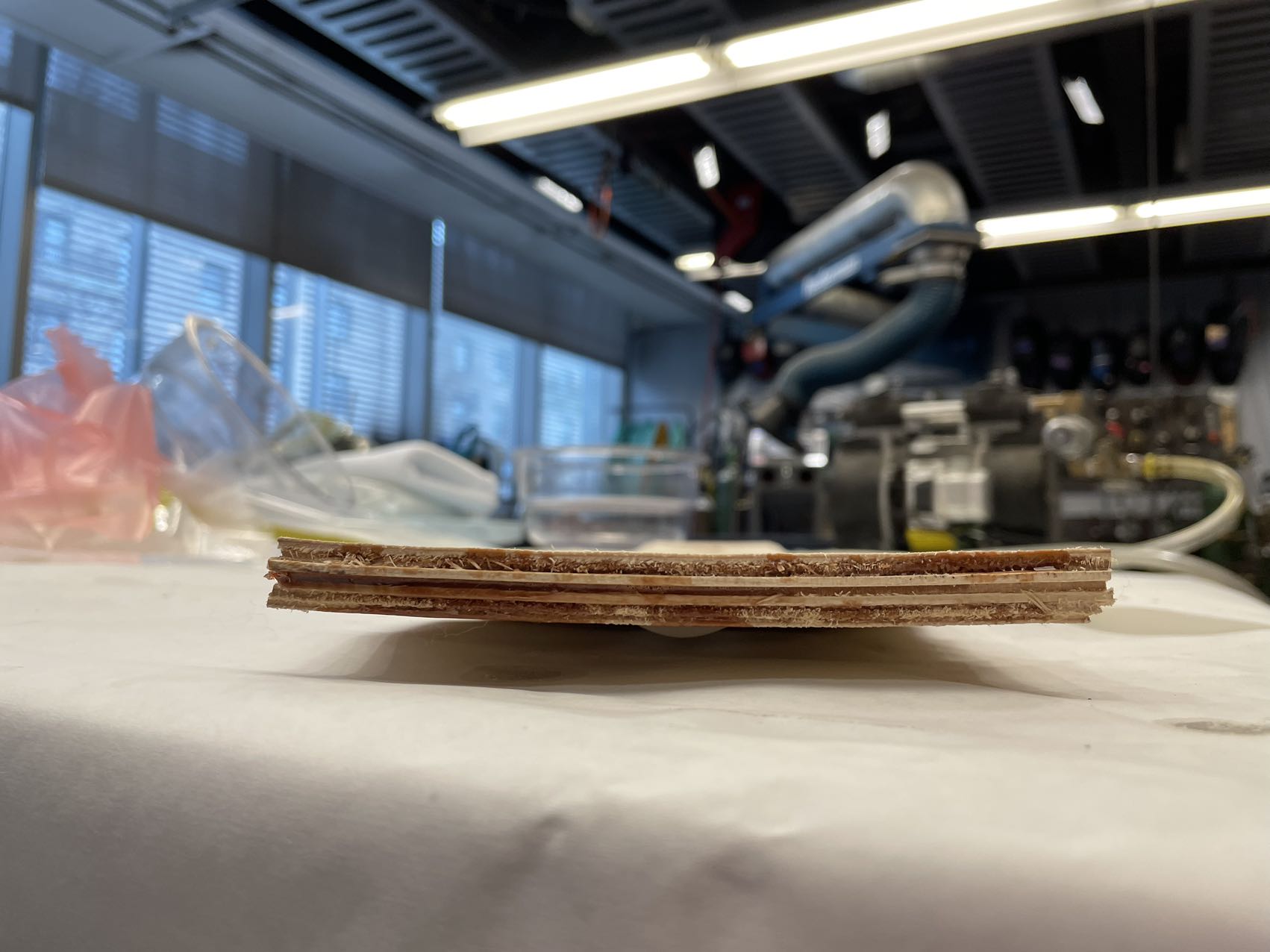

Though it looks like a single piece of wood, the longboard deck is actually made by 7 layers (in my case) of wood veneers.

High-quality rock maple wood veneers can be purchased on Woodcraft.

This skateboard veneer pack contains 7 plys or layers that measure 12" × 48" including:

Face Grade: Layers 1 and 7

Core Grade: Layers 2, 4, and 6, same grain

direction as Face Grade for flexibility

Crossband Grade:

Layers 3 and 5, grain goes across direction of the other two layers for dimensional stability.

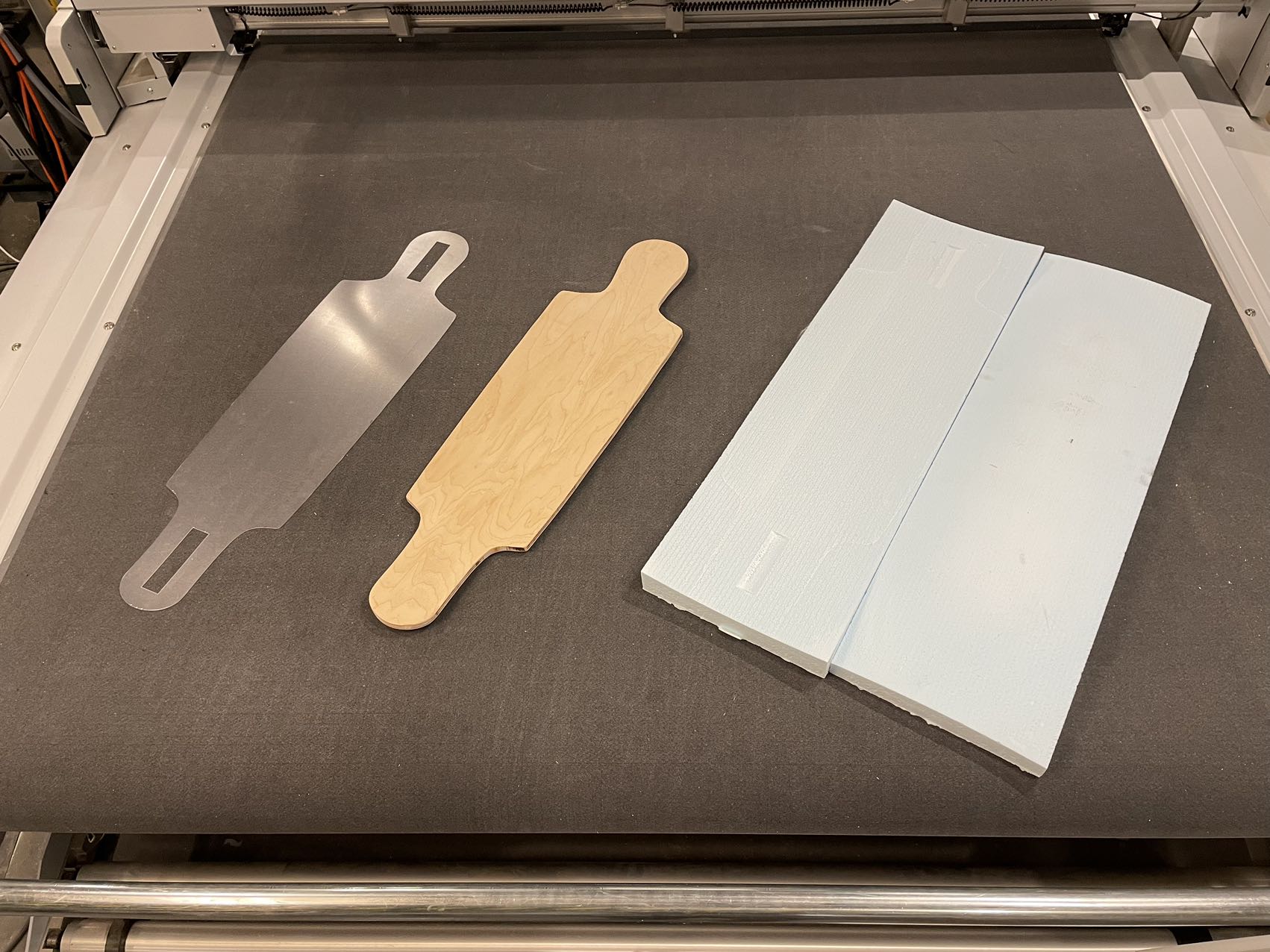

The wood veneer is too big so I need to trim it to a proper size and a shape close to my longboard deck.

Laminating & Vacuuming

The wood veneers are soft and easy to bend. Alfonso helped me laminate the 7 layers of wood veneers.

Then, we vacuumed the mold and the wood to make the use of atmosphere pressure to press on the wood and form the shape we want.

...

...

24 hours later...

We got this nice piece of longboard deck with a subtle but smooth curvature surface.

Trimming

The longboard deck is a bit larger than the shape I want so I have to trim it to get the perfect shape.

However, the shape of the longboard deck is so complicated that it cannot be perfectly trimed with the machine. I ended up cutting it with a saw by myself... It took me three and a half hours.

Sanding

The contour of the longboard deck is not cut perfectly and the surface is still rough, so I have to sand it.

I first use coarse sandpaper (180) to sand the contour to make it exactly the shape that I want

Then I use finer sandpaper to create fillet on the edges and remove some stains on the board.

Finally, I used a piece of fine sandpaer with a sponge in-between to polish the wood surface.

Assembly

Finally, the longboard is done! I really like it and can't waiting skateboarding on the road!

Last but not least, I wanna give a big thanks to Alfonso!!!! He helped so much during this process of making.