HAOHENG TANG'S PROJECT

HTMAA23

Week 7: Molding and Casting

Ideas

Molding and casting is a traditional way of making stuffs. Compared to 3D printing, it allows more possibilities on combinations of materials and textures but usually has some unexpected flaws, too. Therefore, instead of making something geometrical and accurate, I want to make something texturalized, irregular. I intentionally want some imperfect details to show that it belongs to handcrafts rather than mass-produced products. Finally, I chose fossils as my project's concept.

Though I did want to create a large fossil, I had to compromise due to the limit of scale of our CNC machine. I cropped the image and decided to make a fossil of a claw.

CAD

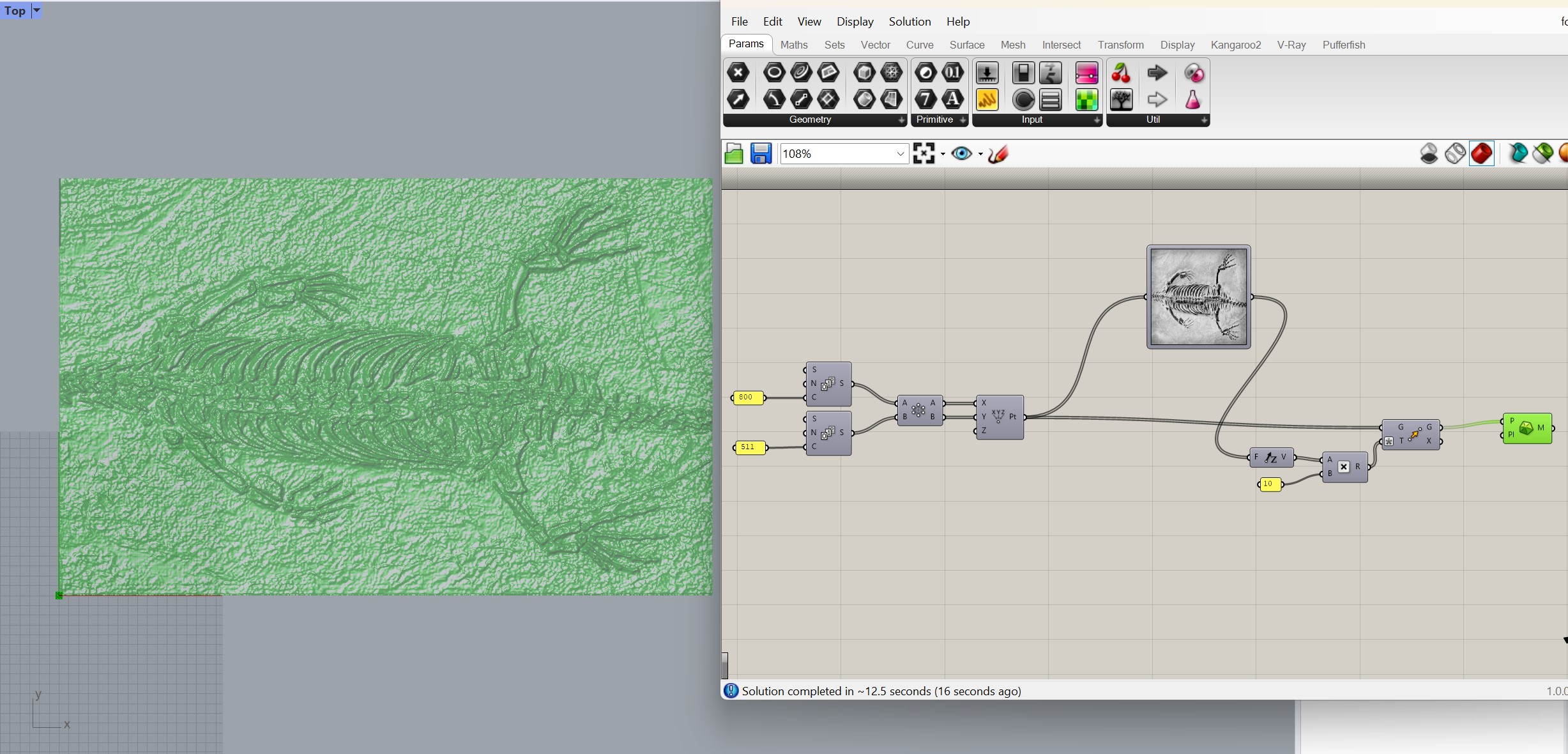

I read the image in grasshopper, transferred it into greyscale and get the "brightness" value for each pixel.

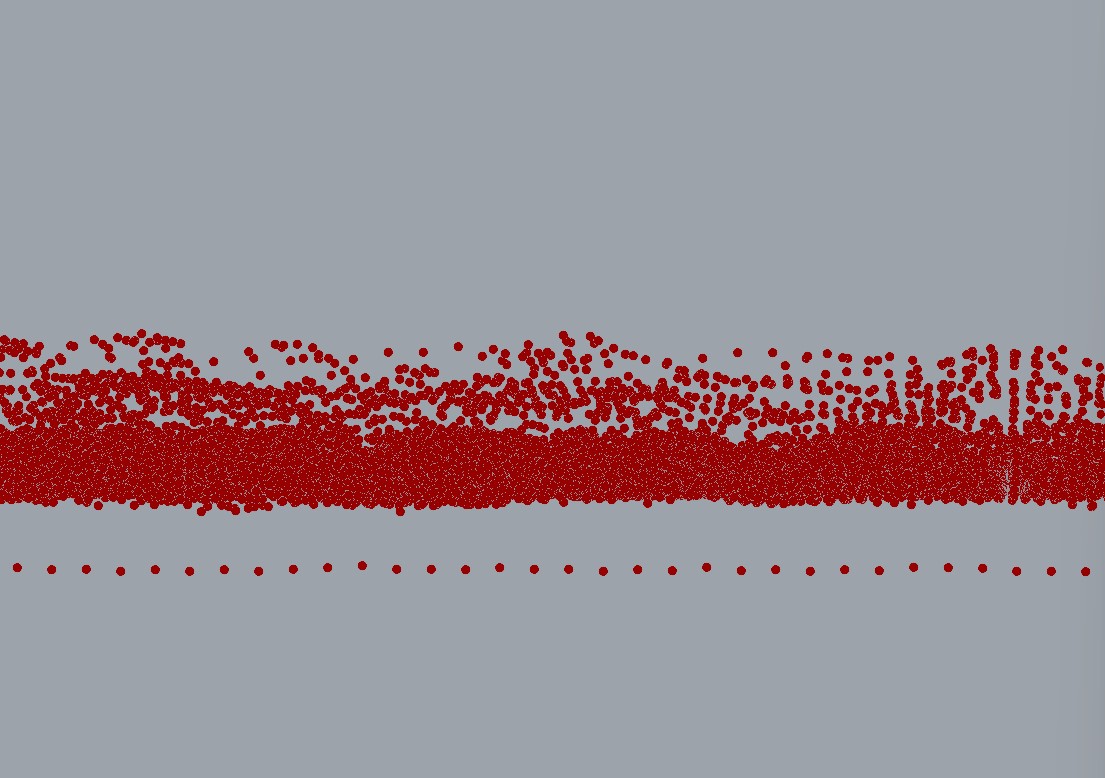

Then I moved each point (representing the corresponding pixel) upward in a distance accroding to its "brightness".

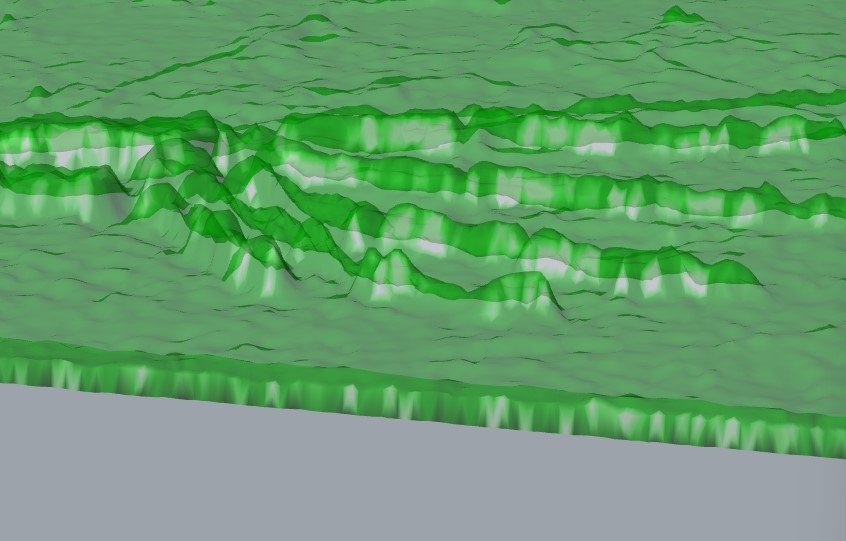

I created a mesh surface using these points

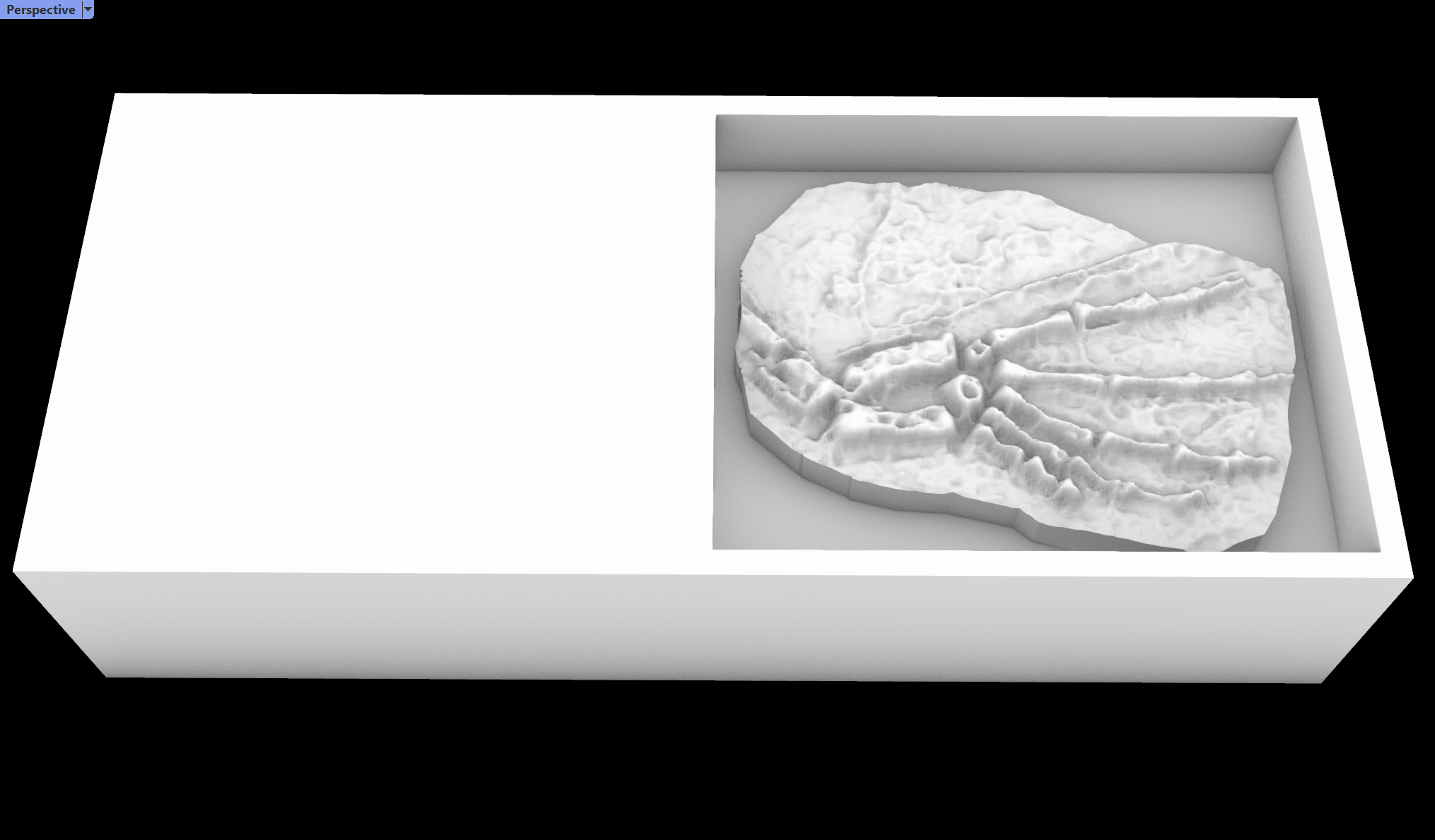

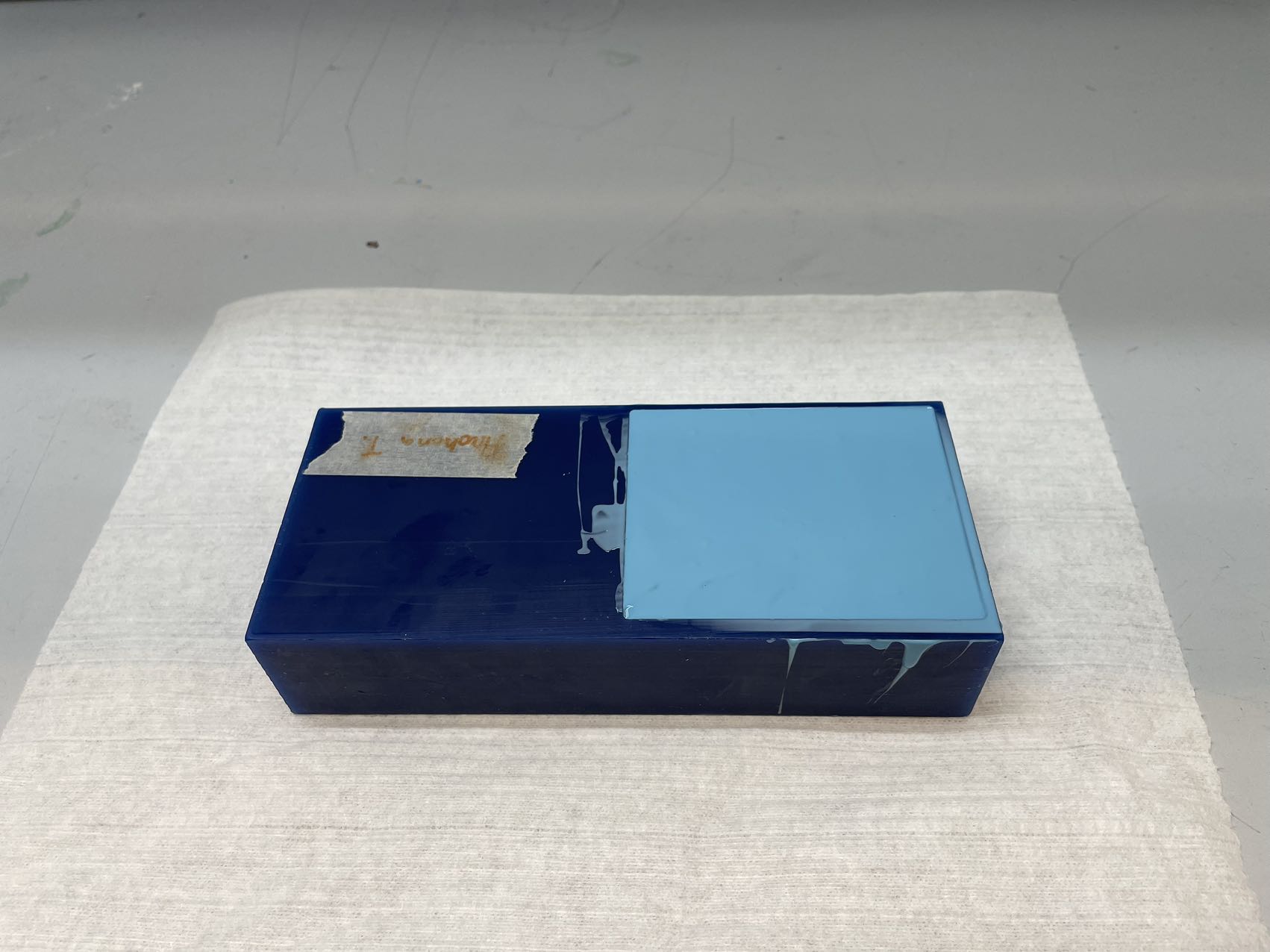

I baked the fossil model from grasshopper to rhino and CAD the wax for cut.

CNC

It took 4 hours in total to CNC this mold.

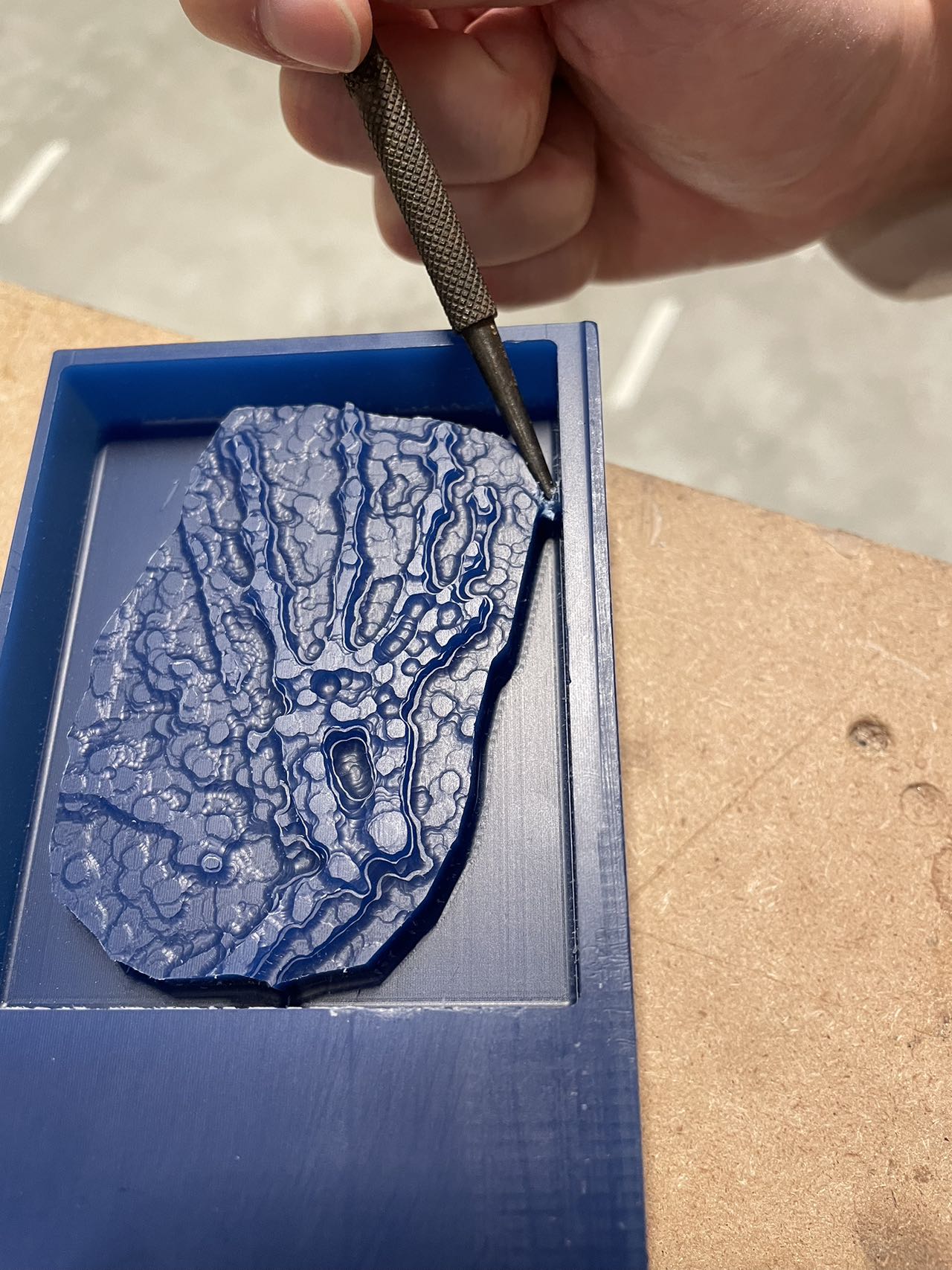

Bug1: The "fossil" inside the "container" is so close to the wall that the CNC machine failed to detach it from the wall. This would result in problems in casting, so I got rid of this uncut part using a knife.

OOMOO!

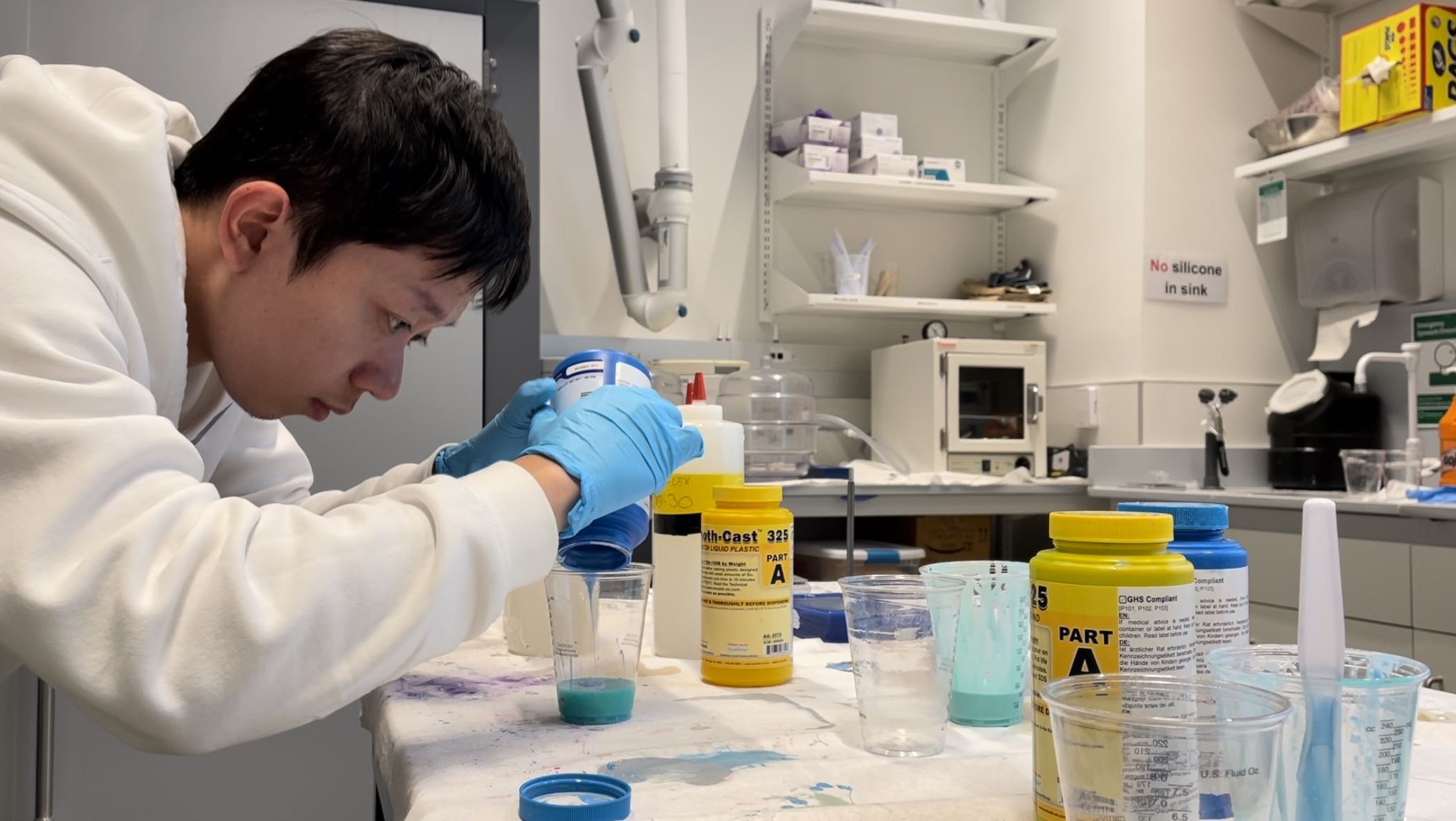

Pouring out OOMOO 25 out to the container. For some reason, the part B is really dense.

Mixing OOMOO 25 part A and part B, 1:1.

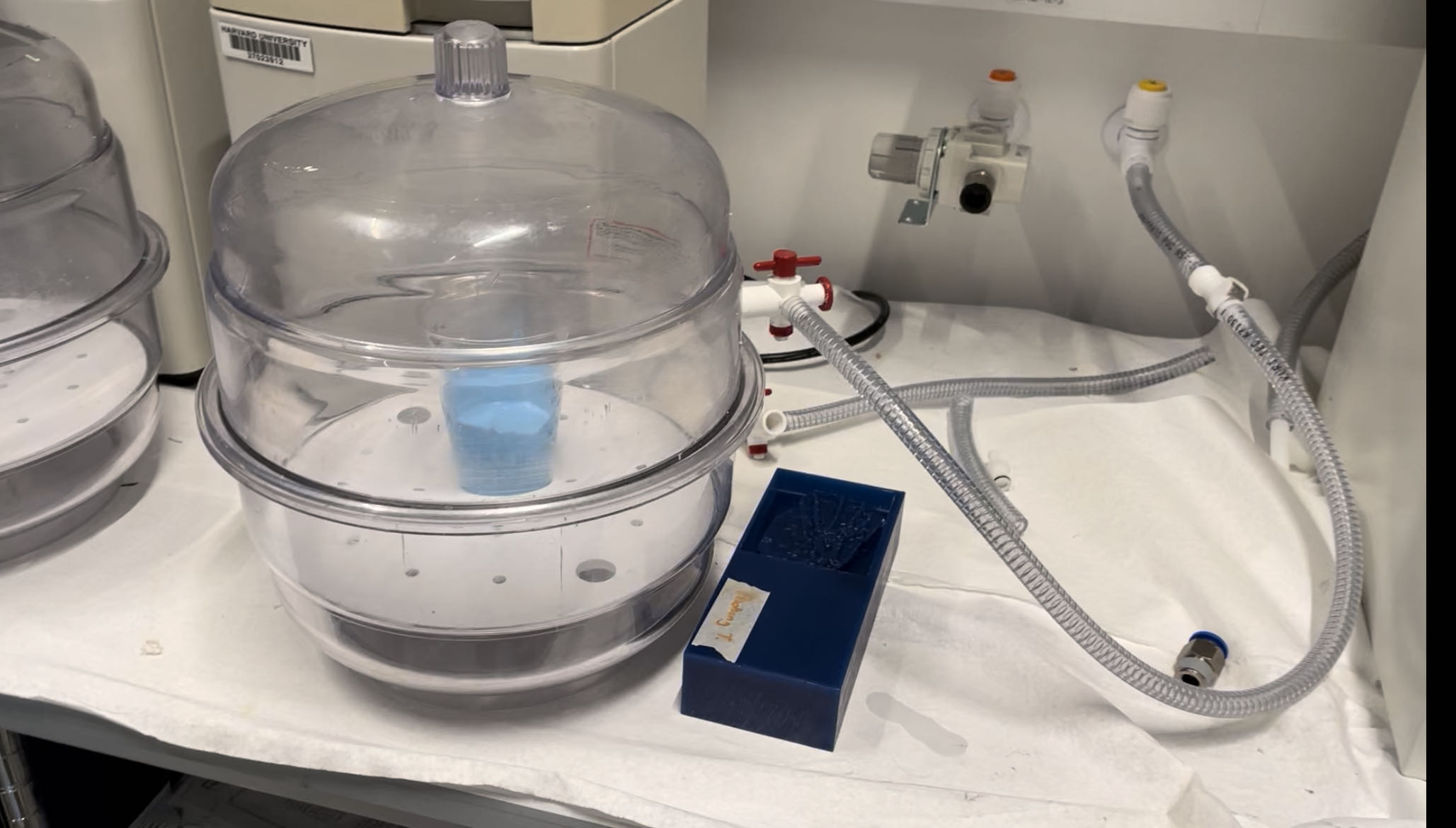

Vacuuming to get rid of the bubbles

My first OOMOO casting failed because I spent so much time on the above steps that it exceeded the pod time for OOMOO25, which is 25min.

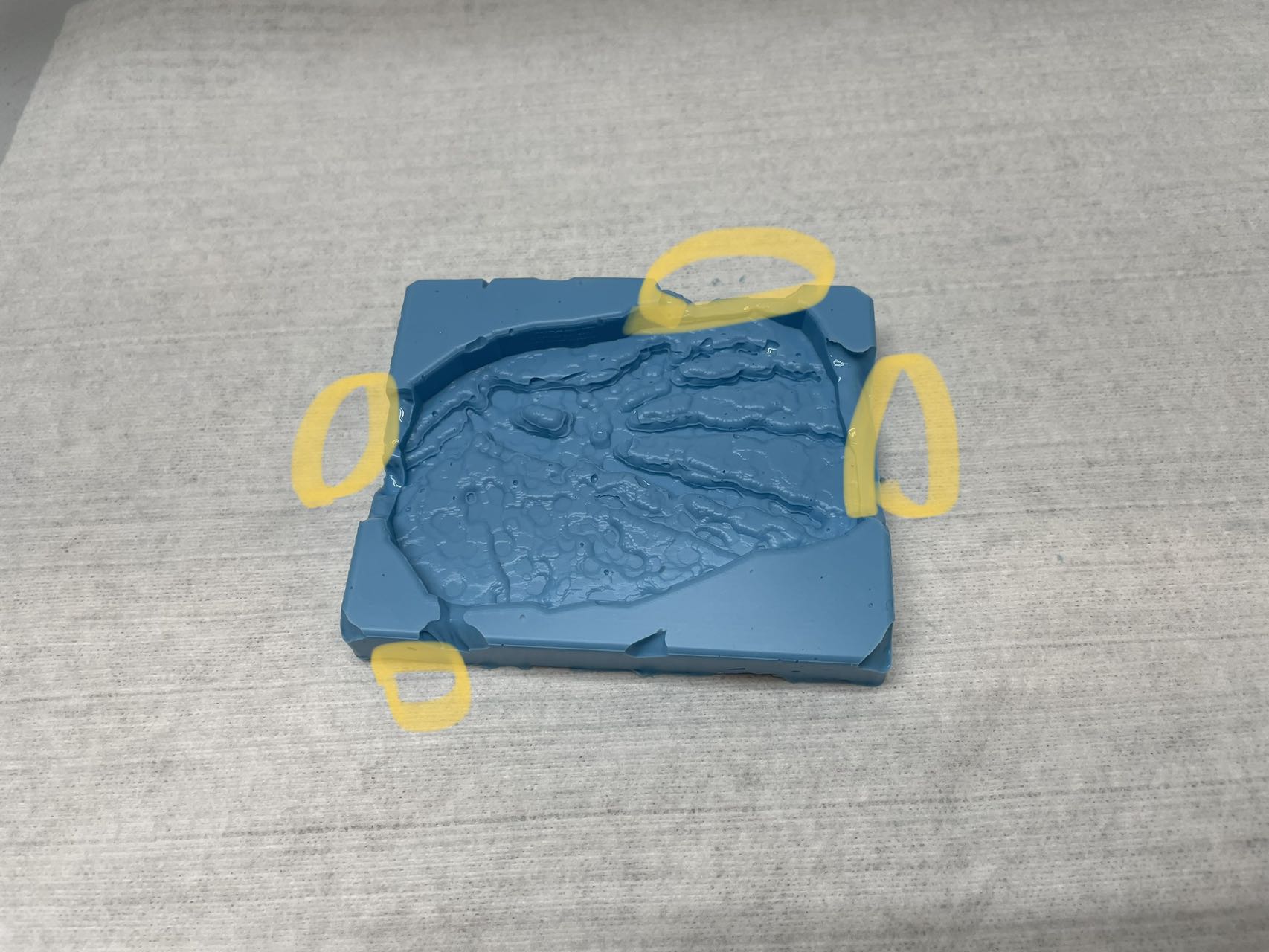

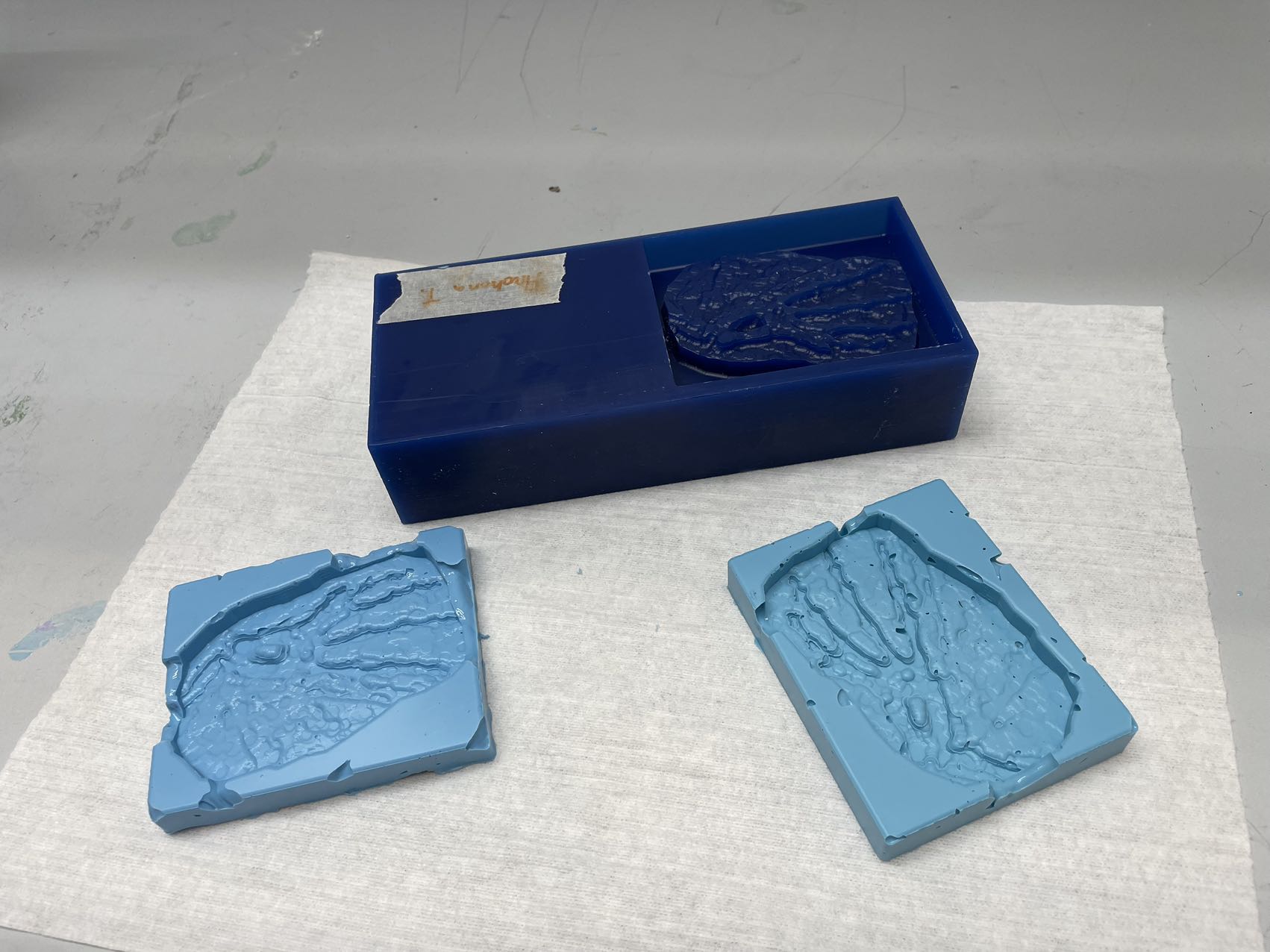

The OOMOO mold is not satisfying as you can see the missing part on the edge, which is caused by the loss of OOMOO's liquidity after its pod time.

So, I did it a second time.

The second try (on the rightside) seemed to be improved but still had some missing part. I guess I need to leave more space between the fossil and the wall when I do CNC next time.

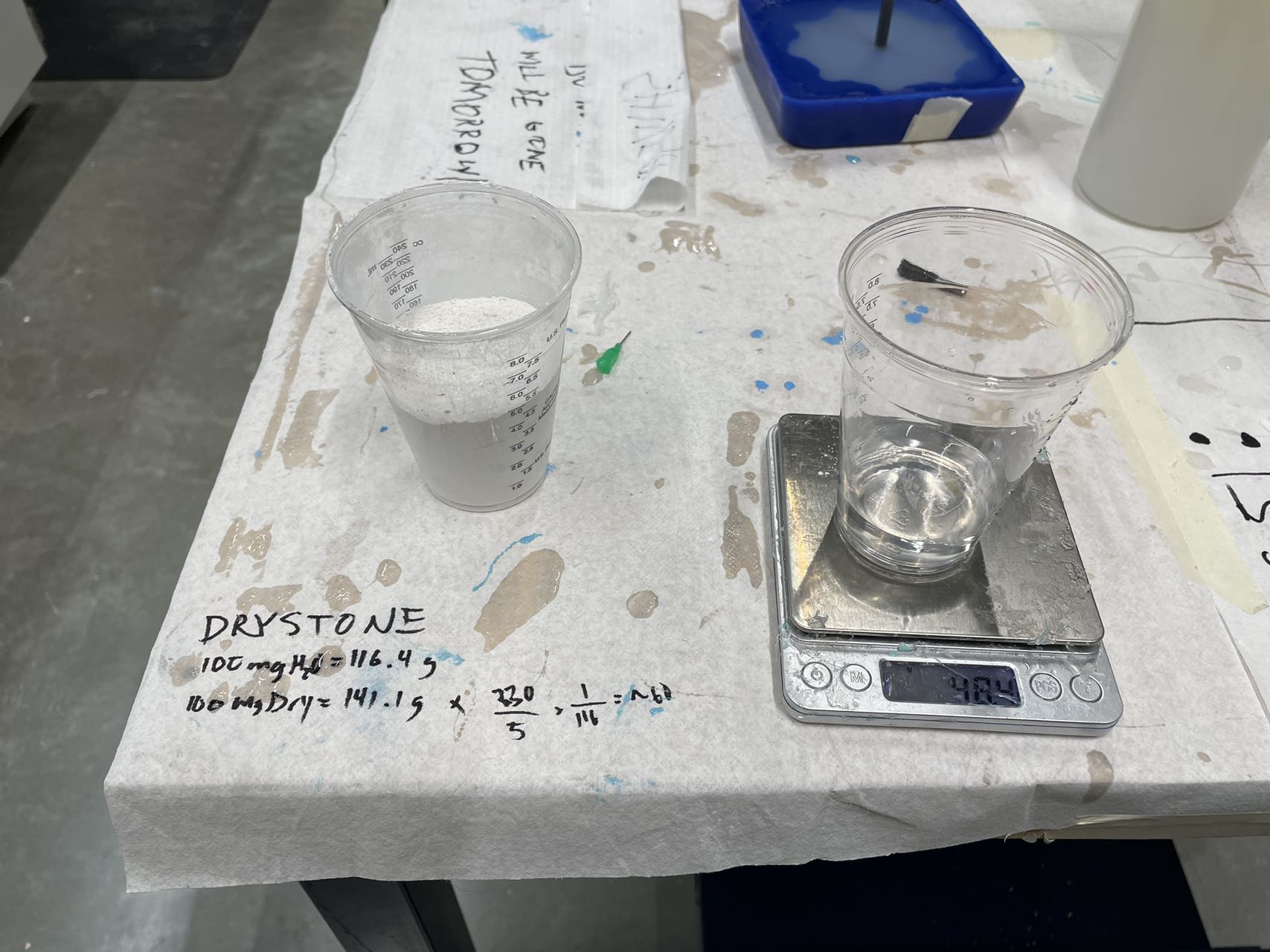

Drystone!

To create the effect of fossil, I decided to use drystone for casting.

I mixed drystone powder with cold water, 5:1 in weight.

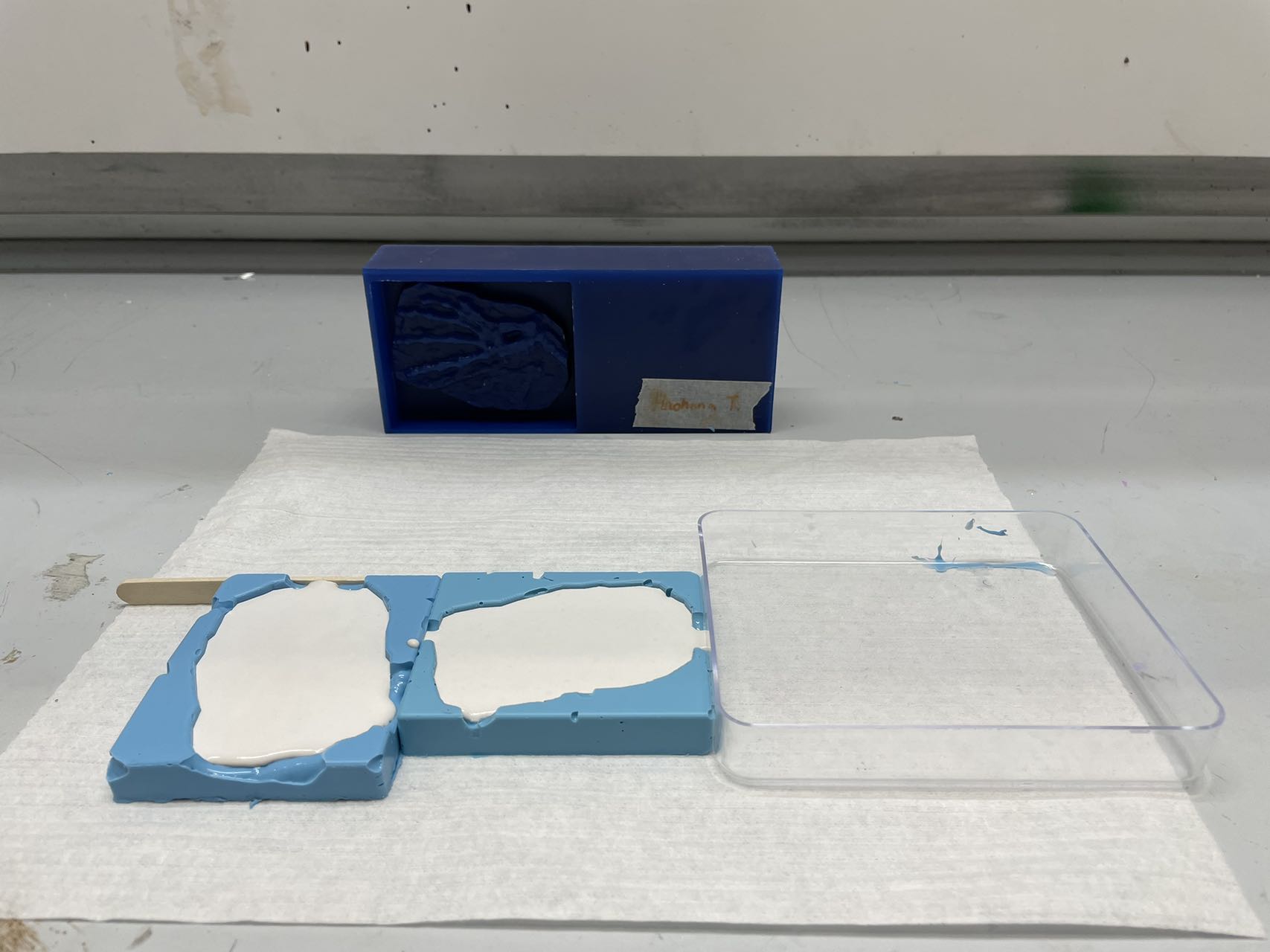

Casting. Since there were some missing part of my OOMOO mold, I used some other stuffs to support the drystone.

Final products

The final products captured all the details and textures of the fossil and I am pretty satisfied with these two fossils!

If I had time, I would do two-layer or multi-layer casting to create different colors on the fossil. e.g. the claw would darker and the stone would remain white. I would also like to try two-part molding next time.