To create a work exploring the first animation machines.

Total time spent: Approx 35-40hrs

Research and Thought 30%

Design 40%

Fabrication 30%

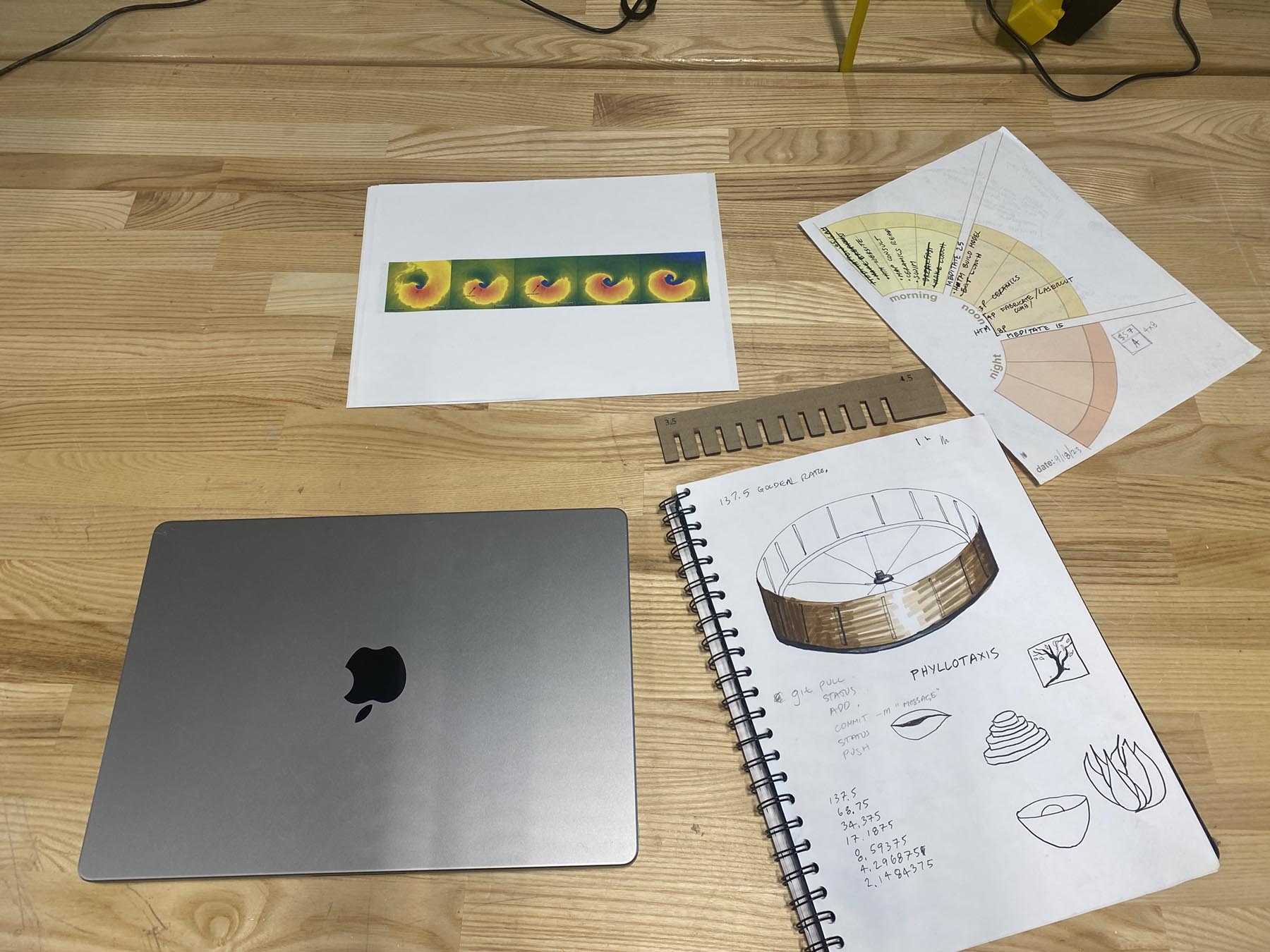

Wanted to make something fun to play with while thinking about the relationship of time. The Zoetrope spins at 78 RPM - the speed of a traditional record player. And the images are of 2 billion years of history in a distant galaxy. With 19 total frames you go back and forth through time.

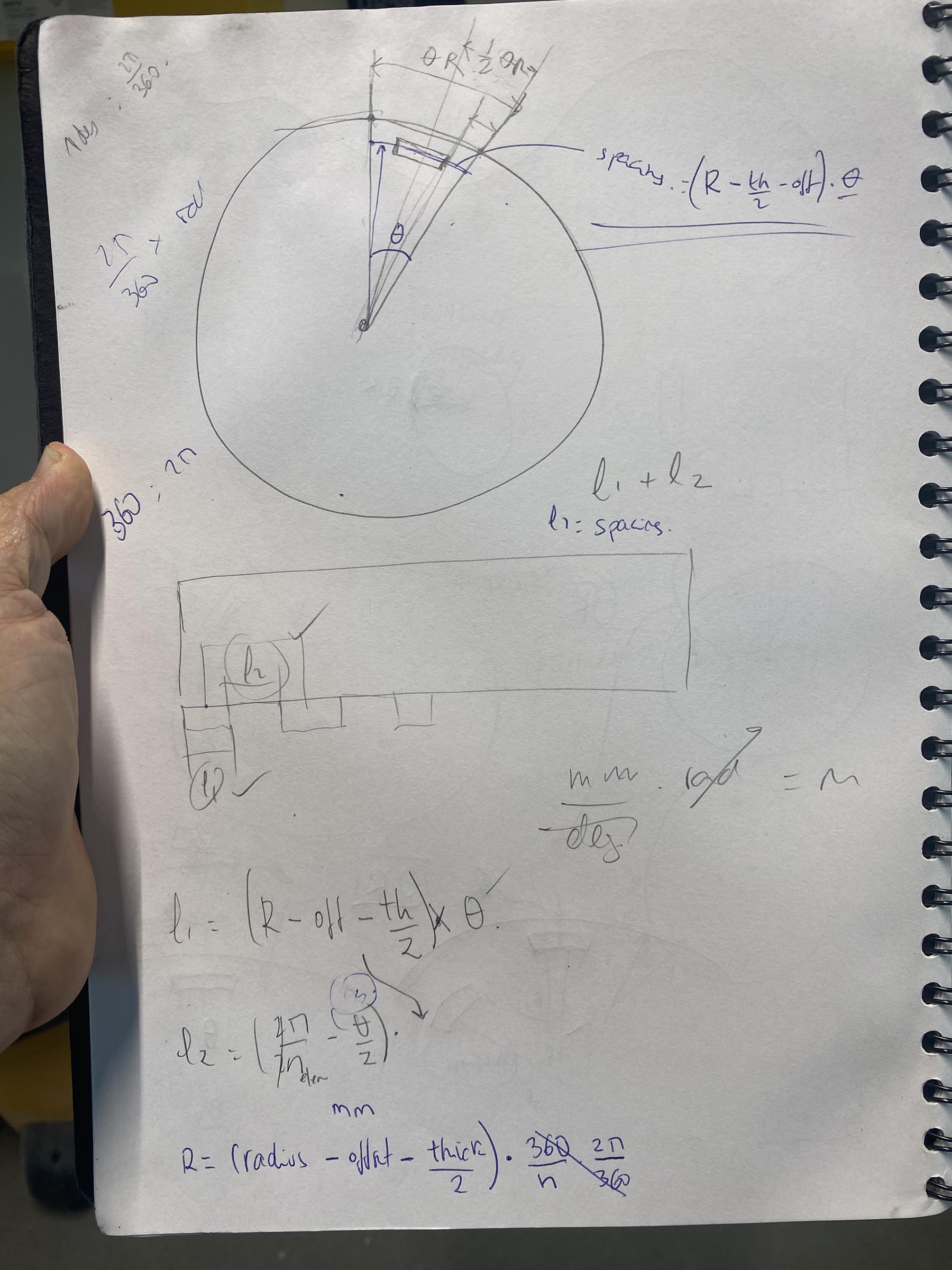

First step was to set the parametric parameters for the Fusion 360 model. The most difficult part being to create the shape for the slots in the bottom circular disk, of the Zoetrope

Need to brush up on my geometry skills for sure. In the meantime Alfonzo, the TA, helped me with some calcs...

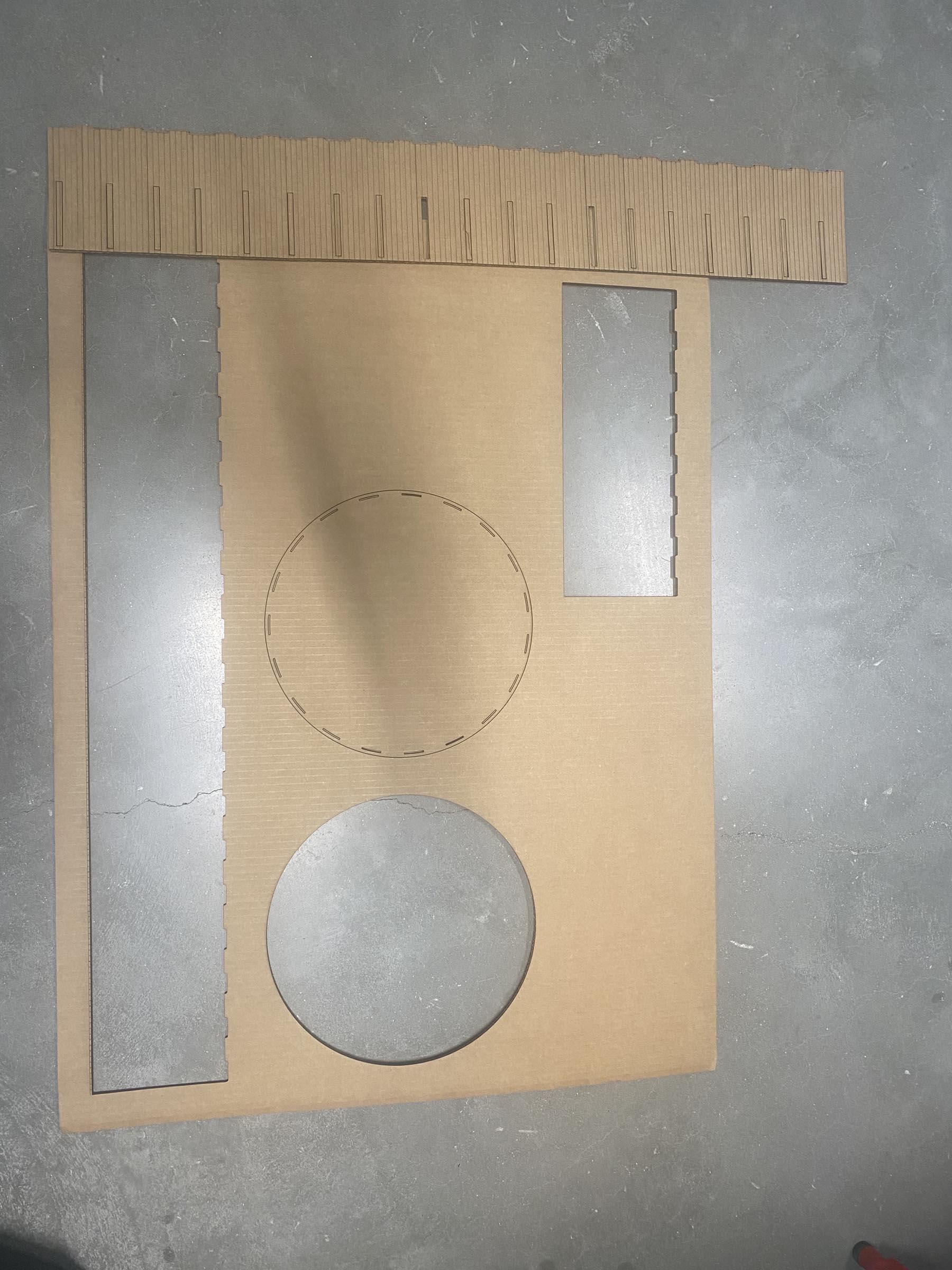

I had to measure the thickness of the cardboard while cutting a comb test in order to establish data points for preparing the cut file for the laser.

I wanted to animate an event that took place over a very long period of time. A gigantic and resilient "cold front" hurtling through the Perseus galaxy cluster has been studied using data from NASA's Chandra X-ray Observatory. This cosmic weather system spans about two million light years and has been traveling for over 5 billion years, longer than the existence of our Solar System.* https://chandra.harvard.edu/photo/2018/perseus/

10 Frames were extracted from the animation and were sized in photoshop to fit the model. Care was taken to make sure all of the frames would fit the circumference evenly.

My first attempt at cutting the file failed. I forgot to change the parametric thickness settings in fusion for the larger cardboard sheet, which was needed to accomodate the length of the zoetrope wall.

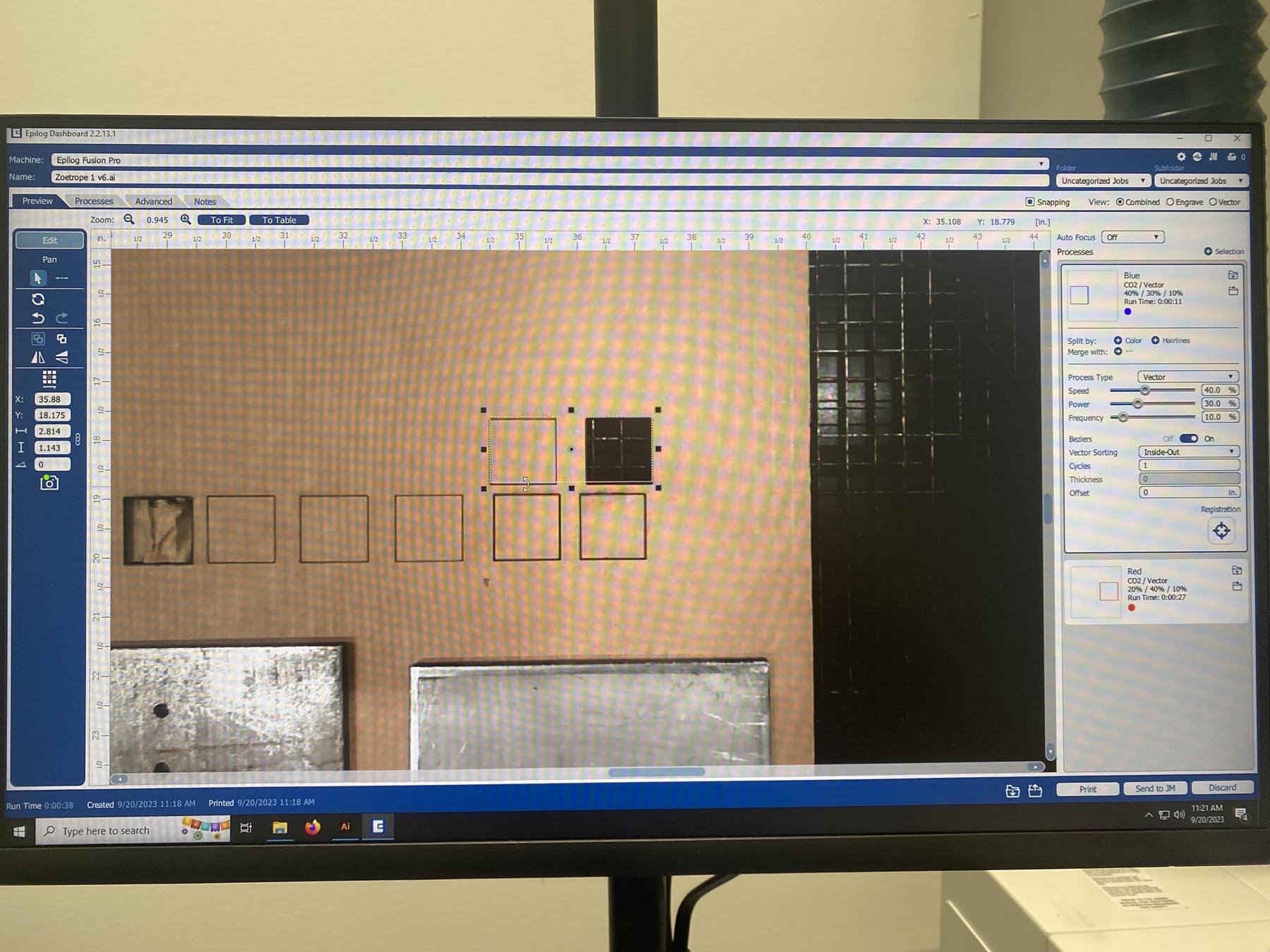

The cut depth also did not work well so on my next run I changed the parametrics to accomodate the new cardboard and I created a series of test boxes for the two kinds of cuts - scoring (in red) and full cut through (in blue). These were separated in illustrator by RGB color in order for the laser cutter to recognize them as different cutting types but cut them at the same time for registration purposes. (Flat metal weights were used to flatten the bowing cardboard).

If you run them as separate files you have to register manually by eye (using the overhead camera) in the larger laser unit. See the dotted line in the image below lining up the cut through file over top of the already scored cardboard on the bed.

What would be better than ending with lesson learned. Never put your laptop on or near the laser cutter when opening the top my laptop whent flop!