How to Make (Almost) Anything

Week 14

Task: Design and produce something with a digital fabrication process

(incorporating computer-aided design and manufacturing) not covered

in another assignment, documenting the requirements that your

assignment meets, and including everything necessary to reproduce

it.

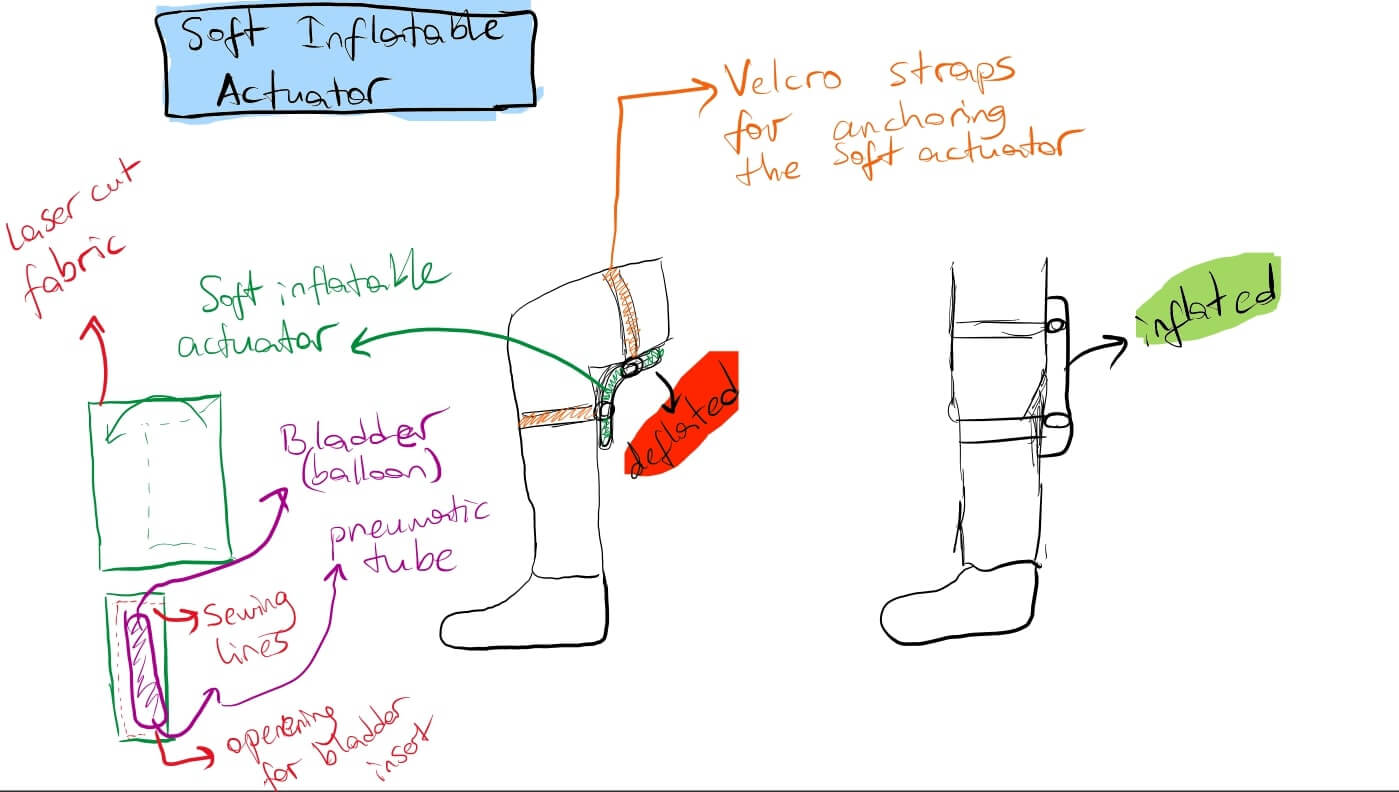

For this week's assignment, I decided to make a inflatable soft wearable knee assistive device based on textile actuators. I started with

sketching my idea, I plan to use textiles and sewing machines to put together the actuator shell (based on textile), and TPU based bladders (balloon) for pneumatic

actuation. Below figure illustrates the conceptual idea:

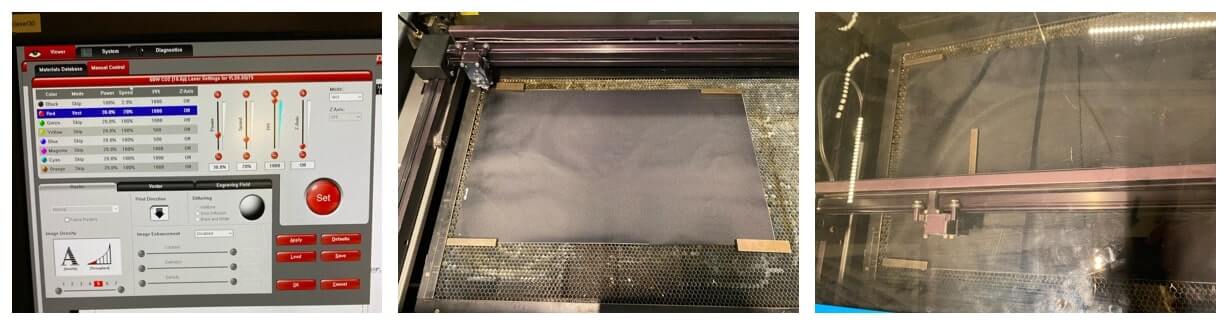

I designed the actuator patterns in SolidWorks [1] which is 12*13 inches rectangles and laser cut them with below cutting settings:

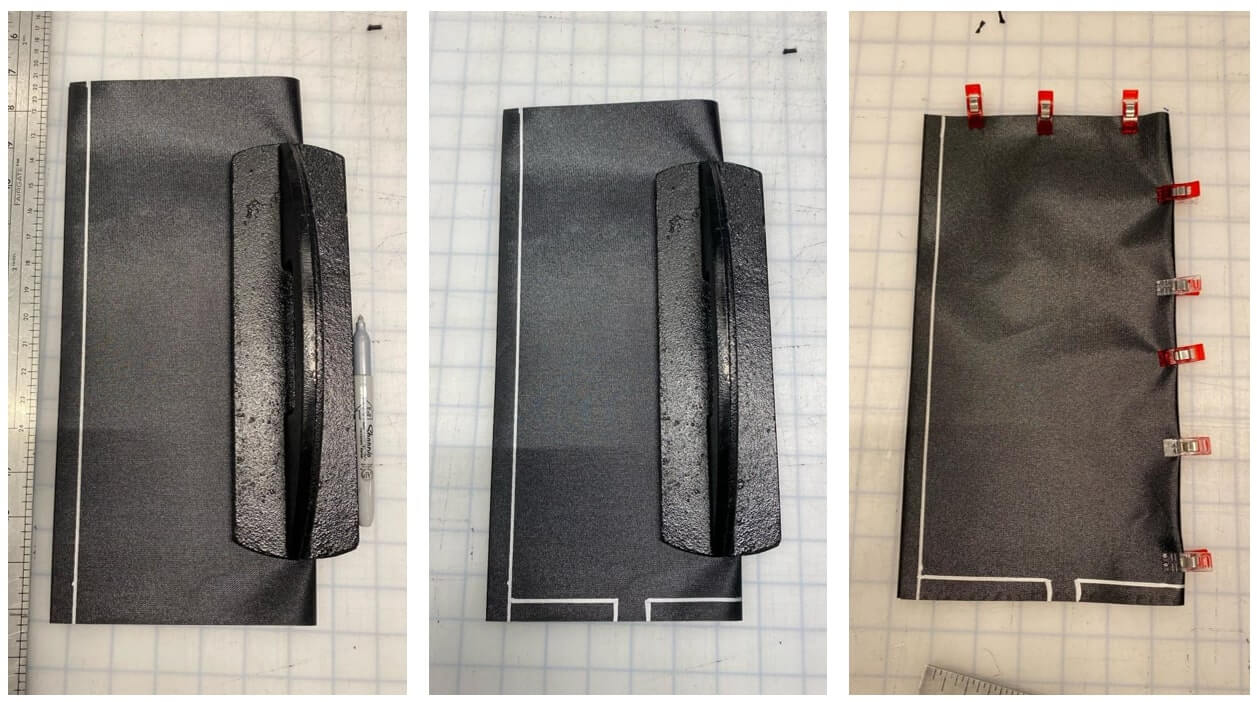

After that I marked the sewing outline on the textile (0.5 inches offset from the edge) to make it easier to sew on the machine:

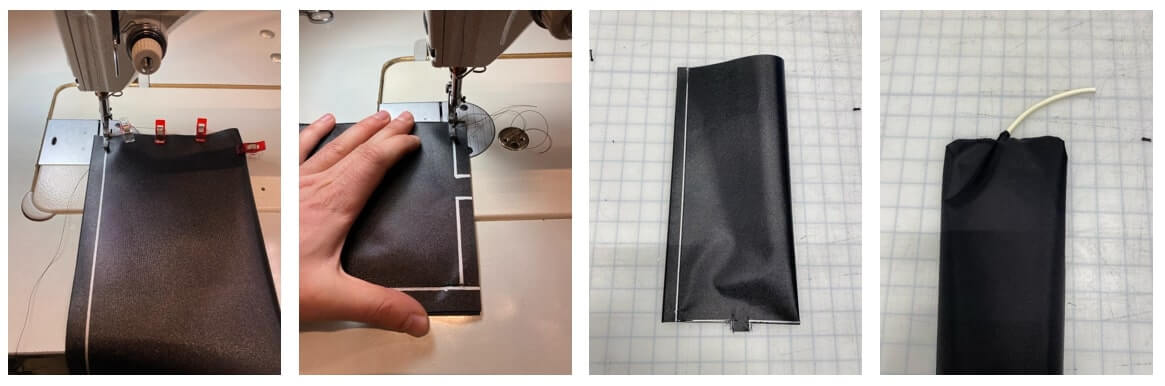

Then I started to sew the textile as shown below, one important thing after I finish sewing I flipped the textile so that sewing lines will be left inside and it will look good.

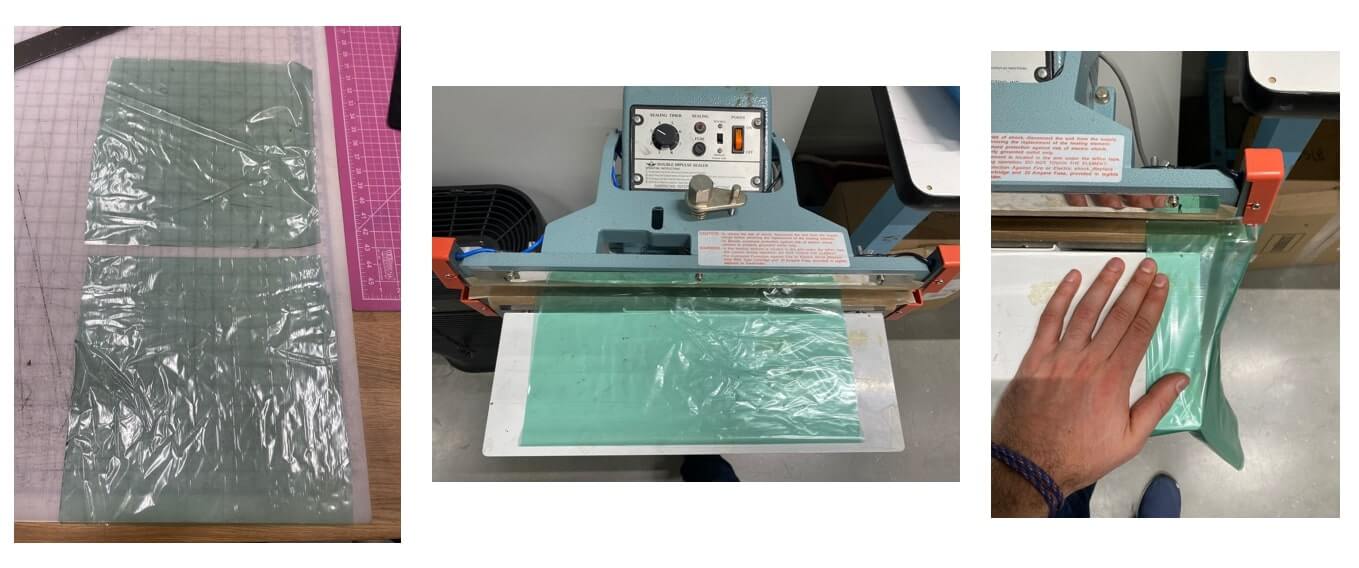

In order to inflate the actuators with high pressure to support human joints and limbs, TPU (shown as green below) is heat sealed and has a bigger size (15*15 inches) than the textile shell so once it is inflated thin TPU will not hold the pressure and stress on it but textile and sewing lines can hold the high pressure (max 15 psi).

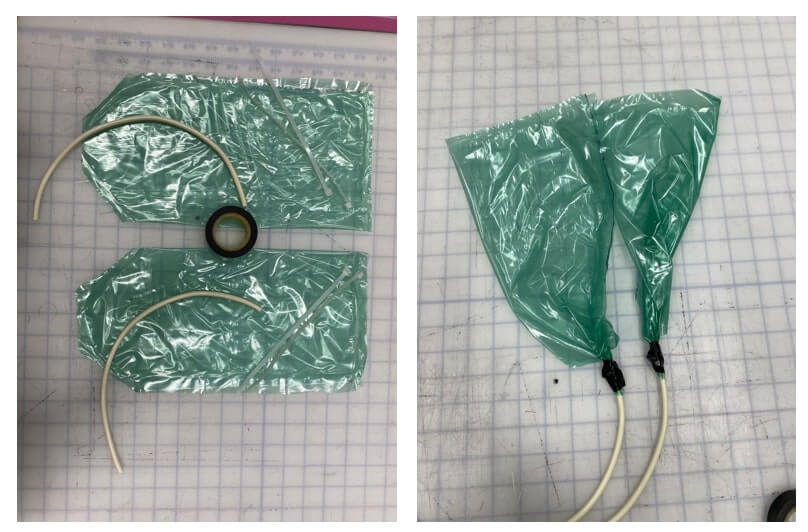

After inserting the pnuematic tube I used zip ties to seal the air inlet and black electrical tape to cover the sharp edges on zip tie, as shown below.

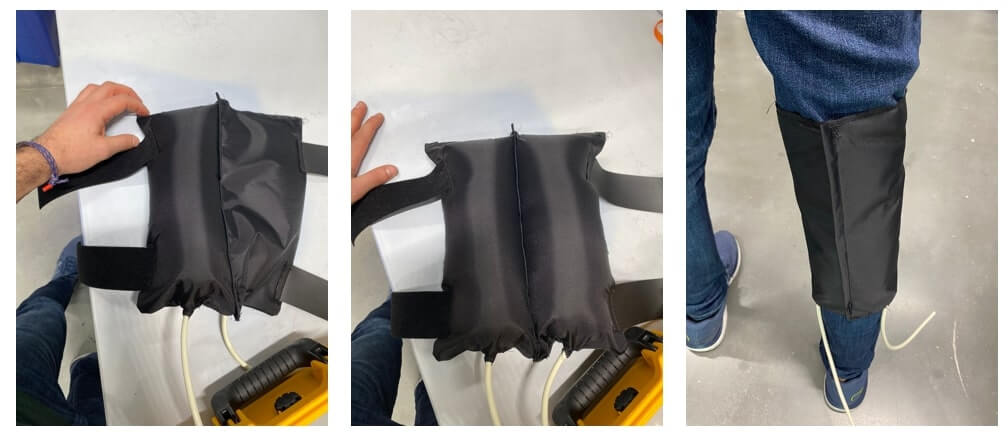

Since this design involves 2 seperate actuators to support the knee, I sewed them together to make the structure more stable, and add velcro straps for soft anchoring on the knee, after that I trimmed the unnecessary velcro pieces.

Now it is time to insert the bladders, I started with the end of tube to push through the outlet on the textile and then pull the tube until it stopped by the zip ties, after that I sewed the top part of the actuator so that it is completly enclosed.

I passively tested the actuators with 3 psi on bench to understand if there is any leak or any problem before tested on the knee.

Below is the video that shows the soft actuator while it is inflated with 3 psi.

Below is the video that shows the soft actuator while it is tested actively on knee.

Below is the video that shows the soft actuator while it is tested actively on knee.

CAD files for textile actuator: https://drive.google.com/drive/folders/1FAC5Opyq8a73X5xFIHMn33HSVuHPQMfa?usp=sharing

References:

[1] https://www.solidworks.com/