Please use the links, research configurations, and design your own flexures!

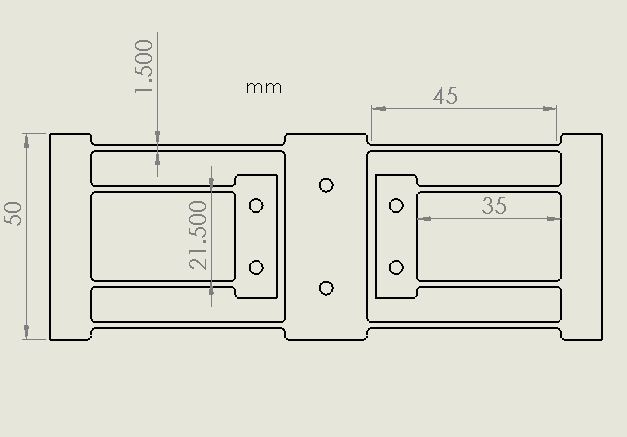

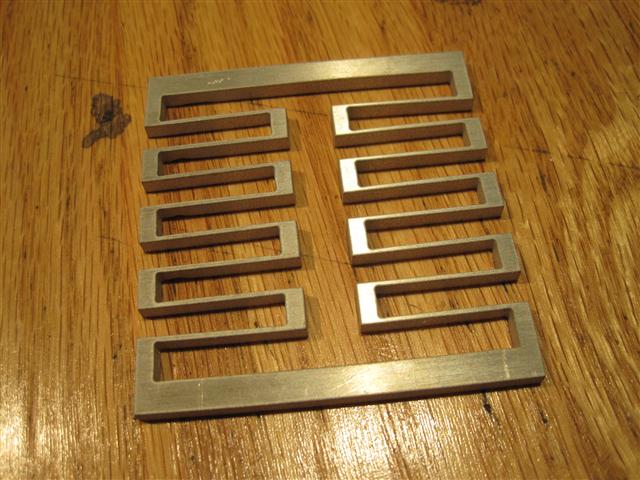

Flexures are nice because they allow controlled relative movement without bearings. Creating them on the waterjet is easy, but care must be taken to use appropriate designs and aspect ratios. Some uses for flexures include springs, precise linear motion, preventing bearing shaft over-constraint, and precise small rotary motion. The best materials to use for flexures are homogeneous. Stiff metals like aluminum are most commonly used. Here are a couple examples. The configuration on the left has a travel of about 8mm. The spring on the right is not a very good design because each of the flexure beams add their error to the whole configuration, yielding poor performance. Also, using some thicker stock would prevent the material from failing due to stress fracture.

page started by Daniel Fourie, MAS.863 Fall '10