Vinyl Cutter

For Tricks and Tips after learning the basics try Here.

Loading your Material

- Cut off a large piece of material from the roll. This works better than feeding directly from the roll.

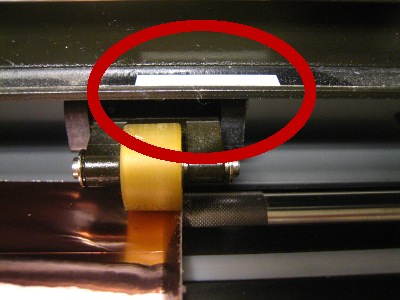

- Lift the rollers using the lever to the back left of the machine.

- Notice the white markings along the cutting area of the machine. Move the rollers by hand to where you will place the edges of your piece. If the blade is in the way move it to the right. Make sure the rollers coinside with the white markings so that they can catch the moving ridges.

- Then put your piece under the rollers and use the lever to put the rollers down, holding the piece in place.

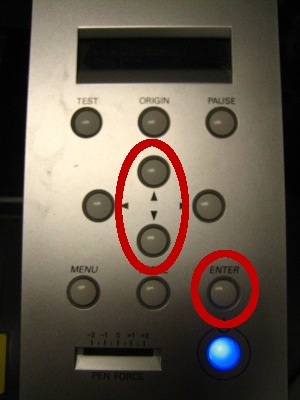

- Now there will probably be a message about sheet unloaded. Select "piece". The machine will measure the width and length of your piece.

- Use the arrow keys to get to where you want your origin to be (the origin will be the bottom left corner of the cam.py window). Press and hold the origin button until the message appears in the display that origin is set.

- It might be necessary to prop up the cutter, if your copper piece is longer than 12" as it needs to remain bent (it does not flatten out completely when taken of the rool) otherwise it will crumple.

Sending the File

Method One - cad.py file

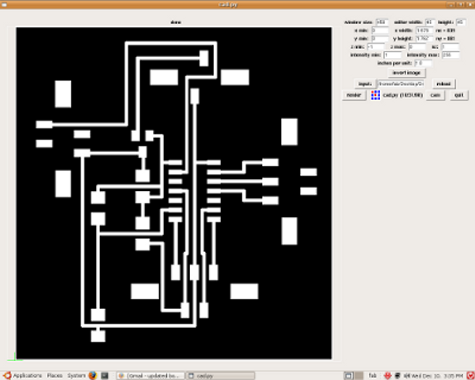

- Open a shell and type "cad". You can make any shape in cad.py you want to cut out.

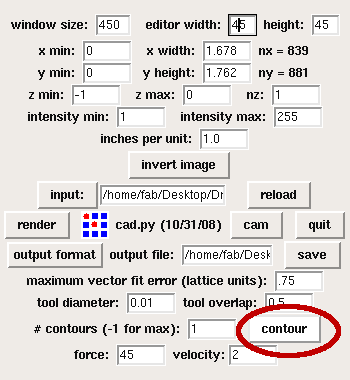

- Next, select the right output device and do 1 contour. Set the desired force and velocity.

Method Two - png file

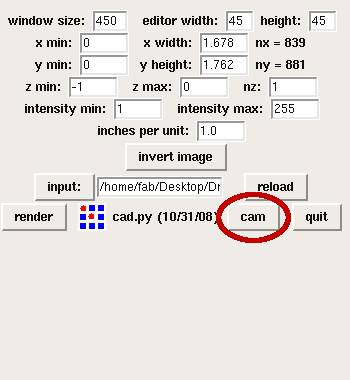

- Open cad.py - Open a shell and type "cad" or open it from the desktop icon. Your first screen will look something like this. Click the "camm" button.

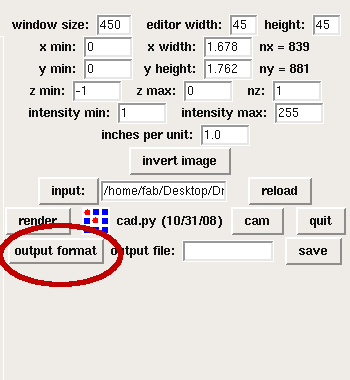

- Click on "output format" and select "camm" from the drop down menu.

Next, click "contour". Set the desired force and velocity - most likely you will use the settings preselected by cad.py (force = 45, velocity = 2).

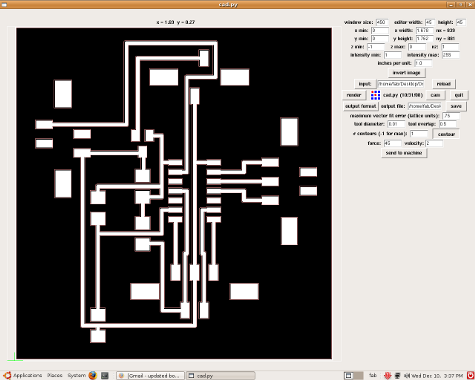

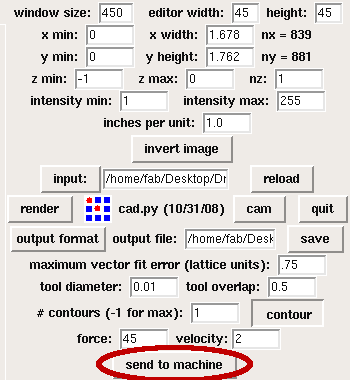

Wait a moment for cad.py to contour your png image. When it's done, you will see a "send to machine" button. Click there, and the vinyl cutter will begin on your cutting job.

Force and Velocity

- When you begin to use the vinyl cutter, the source of greatest potential frustration will probably be finding the proper settings for the force and velocity of the blade. Don't worry, you can do it, but take your time - note that most likely you will use the settings preselected by cad.py (force = 45, velocity = 2).

- I have found that the far more important of these two variables is force. The hardware force slider and force settings in cad.py need to be adjusted togteher.

- If you cannot separate your material from its backing, then your force is too low. If your piece is mangled, then your force is probably too high (or the blade might be dull). What you want to see is slight lifting of the material around corners.

- I have found that the force value must be within about 2 or 3 units. Fortunately, you can tell when the force is too high or too low, so the narrowing process is straightforward. If anyone finds good values for new materials, please leave a note on the Desktop.

- If it turns out that the blade is in fact dull, you can get another one from John or Professor Gershenfeld.

If you want to cut a circuitboard with the vinylcutter, see the tutorial in the processes section