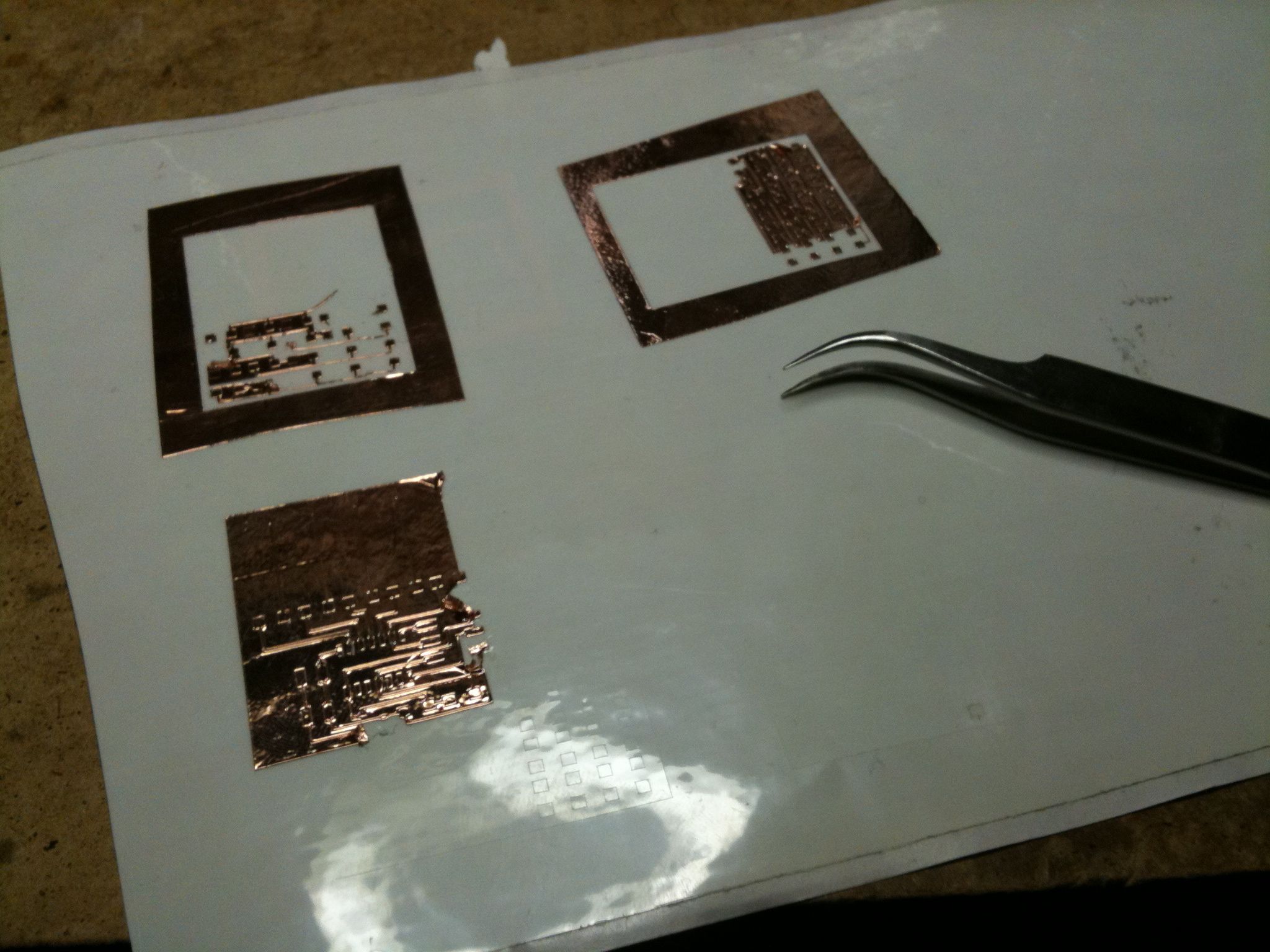

I worked on a few things this week. I finally got the hang of making vinyl-cut circuits. The trick for me was playing with the manual force settings and cutting the same path over two or three times to get a nice clean final cut.

Then weeding was tricky, but easier. The first step is to use the masking tape to remove the entire rectangle of copper containing your circuit and all the copper you want to remove. Then, laying down the copper rectangle, it is important to press it very hard onto your new surface. Use a ruler or some flat edge to really scrape it into place. This helps set the copper tape in place. Then, peel back the masking tape, pulling it 180 degrees back so it comes off without pulling up any copper traces.

Next is the hard part. Using tweezers you have to slowly and painstakingly remove the unwanted copper. The thicker your traces are, the easier time you will have. Anything smaller than 16mils will be a nightmare. Remember not to give us if you do accidentally tear up a wanted trace. You can patch and repair with a quick solder job using extra copper traces. Don't be afraid to print out several copies of the same circuit so you can transplant working parts from one copy onto another.

Good luck. You might want to scream and pull your hair out while doing this, but rest assured that it's worth it. Multi-layered vinyl circuits are awesome. They can make your life much easier when designing complex circuits, and you can pack way more stuff into a smaller space. Aw-some.

Here's my charlie-plexed circuit (Almost) working:

I also started work on a telepresence video conferencing robot. The idea with this project is to provide a stand for laptops that people can control over a Skype extension. I'm basing this project on a design on Instructables for Sparky, but my version will be cheaper by a factor of 10 and much easier to build.

And here is the circuit I'm going to use to run the two motors: