Molding and Casting

Acknowledgements

The TAs for helping us out off hours. The person that went before me on the Modela: your config file almost worked perfectly. DM Solutions Research for the DEM files. First result in Google for "DEM" and it was just what I needed.

Related Links

“Casting is a 6000 year old process.”

- Wikipedia

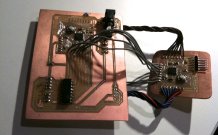

Playing around with molding and casting is a cheap alternative to 5-axis milling. You can mold complex shapes and with a little post-processing can get a similar finish. I decided to mill a watershed from a digital elevation model (DEM). See the purple wax mold. From that, I poured in a rubber mix and let it set in an over for a few hours. Once hardened, I pulled it out and cast another blue rubber mold in that. This was due to an error in the config file I used to mill the board. The milling came out inverted, so I needed to create a final rubber mold to cast the concrete in.

Problems

One of the biggest problems I had was using a 1/8 inch bit for the original wax mold. It was far too big to get the definition I wanted. Next time I’ll use a smaller bit, maybe 1/64th. The downside is that I have no idea how long this will take to mill. The 1/8 inch took over 3 hours. This will be impossibly long. Rough math suggests this will take over 24 hours. Maybe I’ll do another over the holidays when nobody is here.