About Saturday, I started feeling better, but a little dopey.

What Actually Happened:

Saturday:

I started looking at the

output from previous runs and started

debugging. The following improved the results:

- Split the scan and the data plotting into two separate

programs. One reads the log from the other.

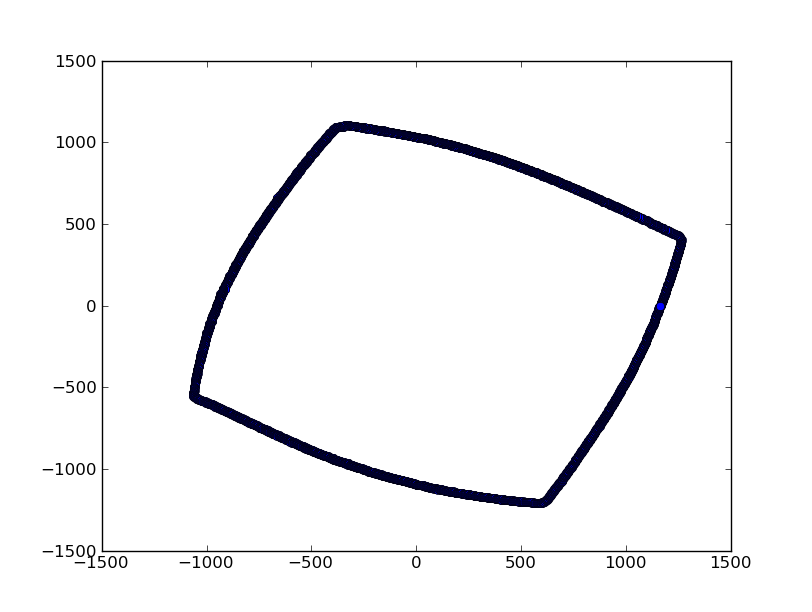

- Calibrate the machine -- It is 4000 counts per revolution, and

about 500 counts per inch of the analog sensor

- Verified the linearity of the sensor (1%).

Looked at repeated scans to confirm no drift. None found,

highly repeatable. Read error typically 5-15 counts

per 1000 units.

- Play with step speed -- found bugs in the stepping routines that

were interfering with the command parser. Higher speed

seemed like smoother output, but may be electrical noise issue.

The 5+ from the USB appeared to be wandering a bit.

- Change scale of input, and use internal reference.

- Verified graphs against raw data.

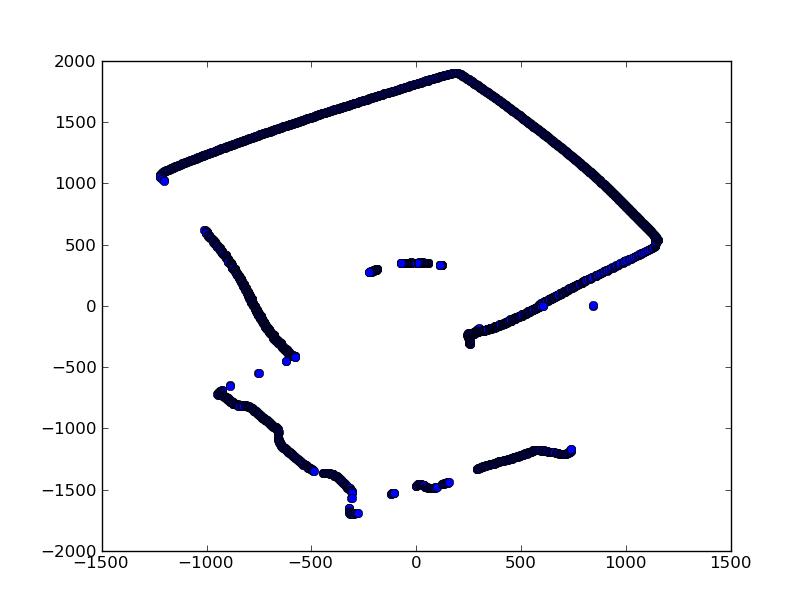

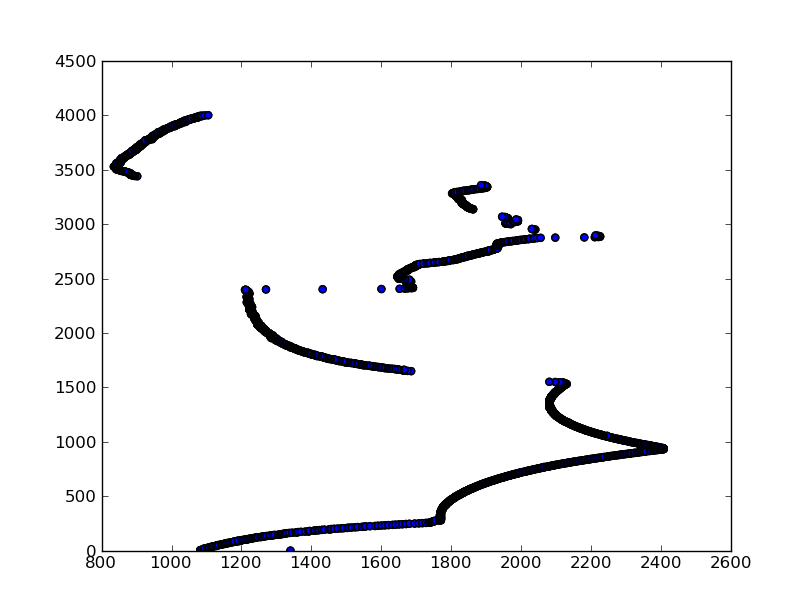

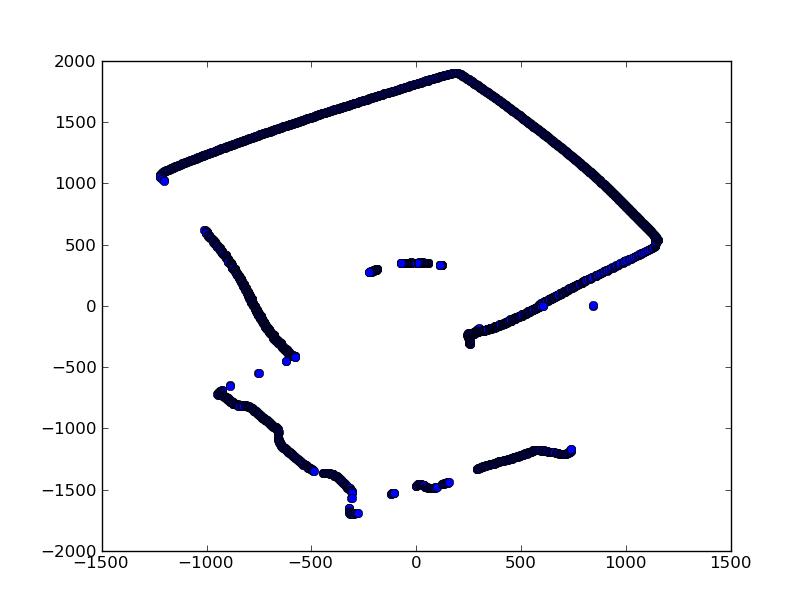

- Still wasn't quite satisfied that the output was useful -- stuff

looked a little too wrong, but measurements from the graph seemed

surprisingly accurate.

Sunday:

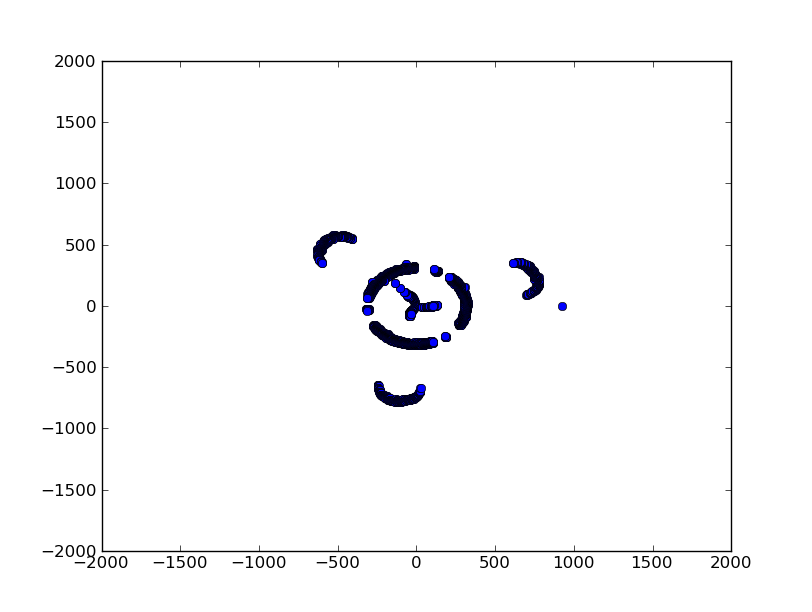

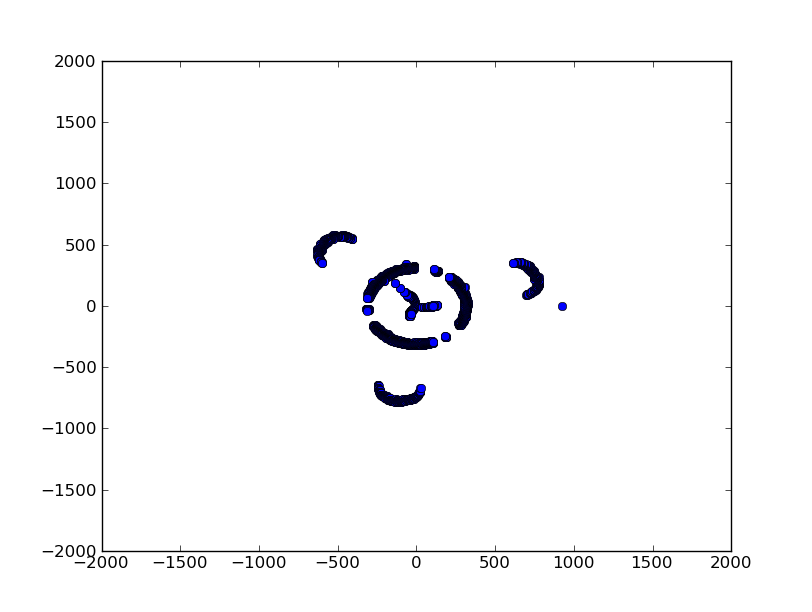

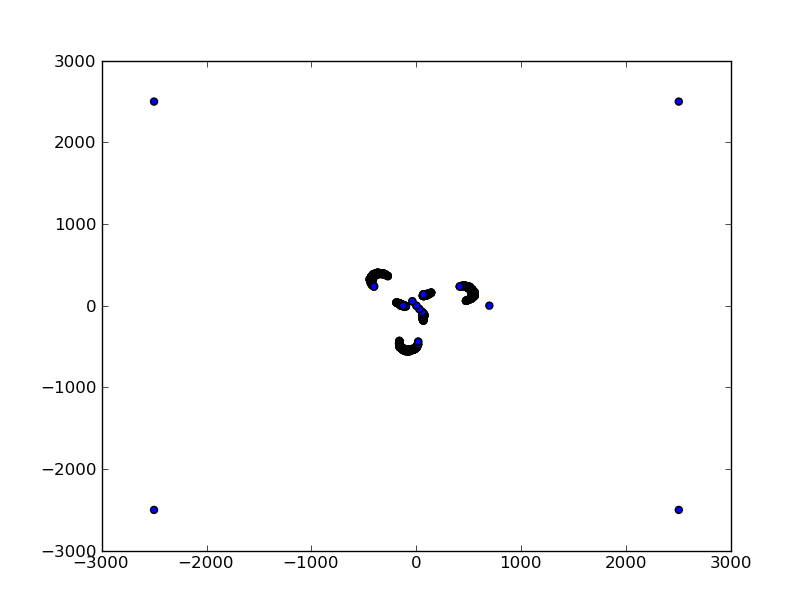

- Realized that the graph tool was auto-scaling.

This made any errors and distortions look worse than they otherwise

might be.

- Removed bad data, and understand limits.

- Decided to go with 3D and see how far I could get.

- Stripped Z slide from old semiconductor wafer robot.

- Researched servos, encoders and realized I would need to make

another board, or swap to steppers.

- Swapped the drive to a stepper.

- Mounted Z on the Theta table.

- Put a foot on it. Feet on the feet save on

crushed fingers.

- Packaged the electronics on it.

- Broke a driver, milled into package and reattached the connector.

- Orientation of the sensor matters.

- Blew all of the stepper drivers at about 2:00 am.

- Figured out that there is something wrong with the driver board I

built -- short?

- Debugged low torque, and programmed up the 8-fet board from

before to act as a unipolar step/direction interface.

- Tested, found low torque problem was the test motor I was using,

not the algorithm.

- Integrated to USB driver i/f board, remounted.

- Passed out.

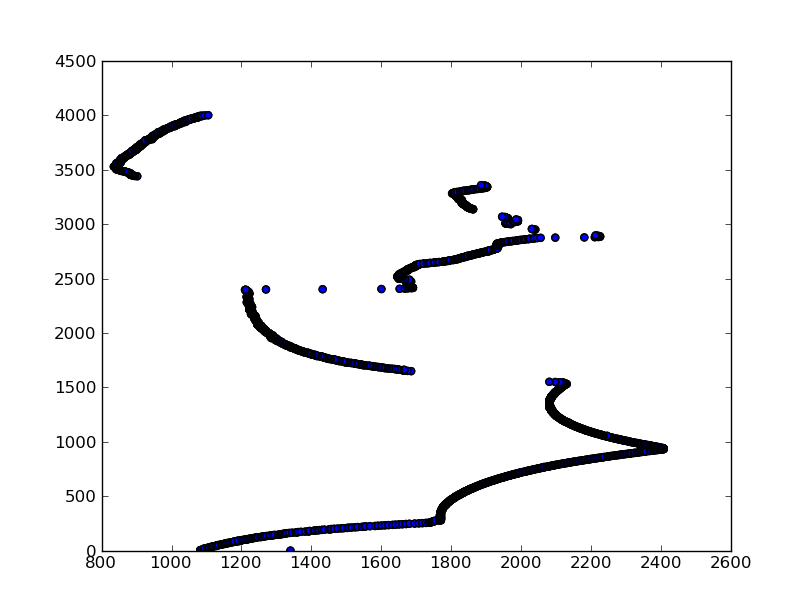

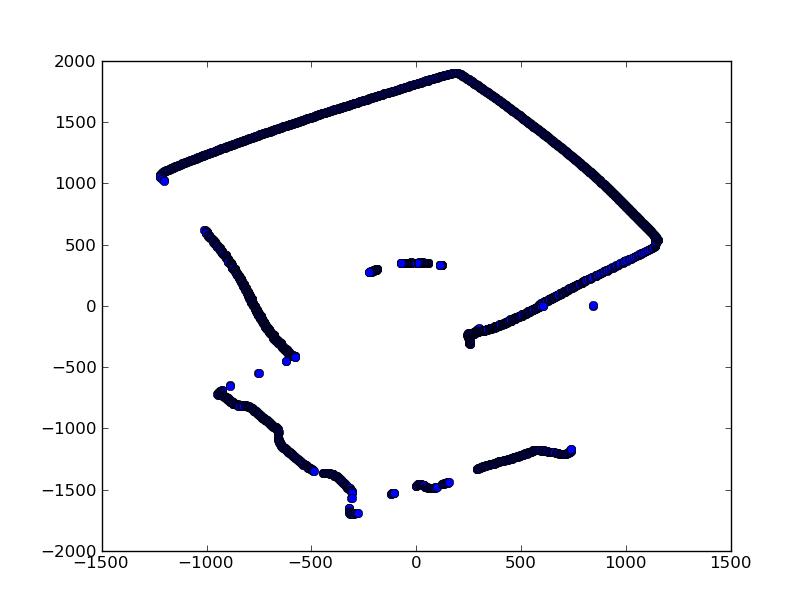

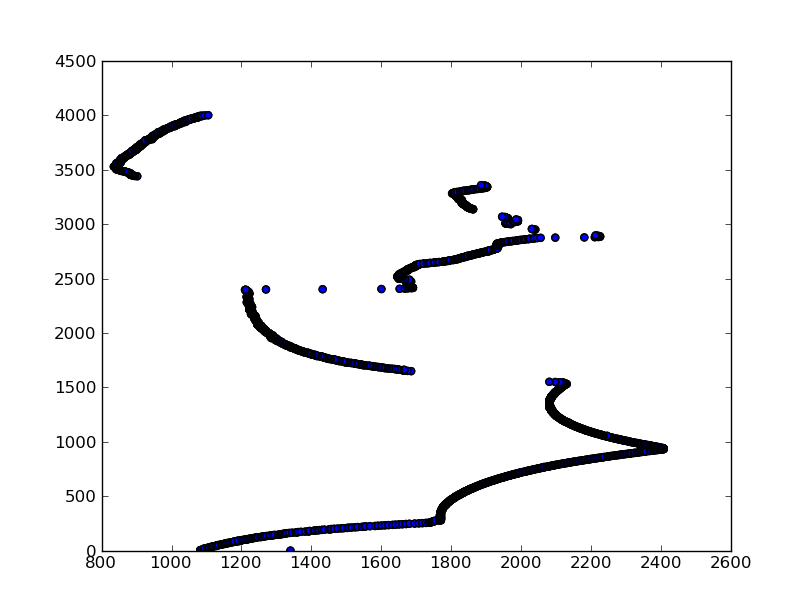

Results thus far:

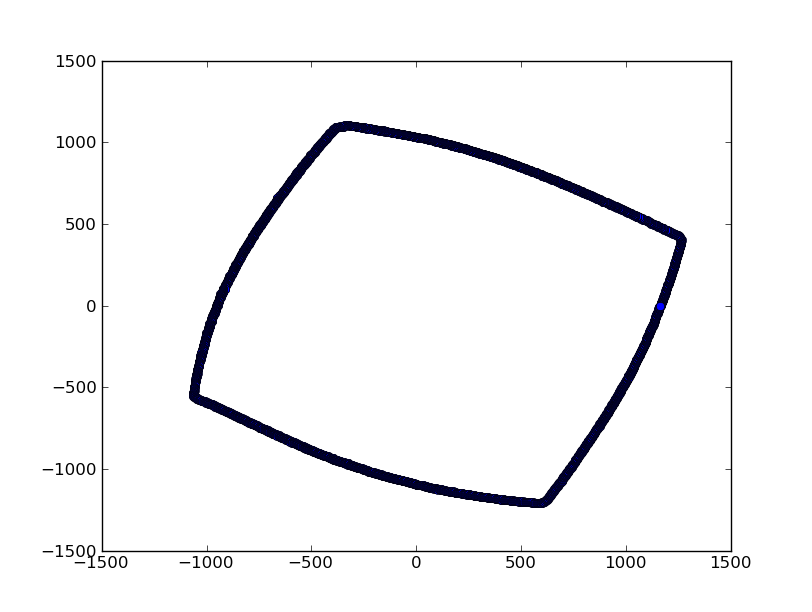

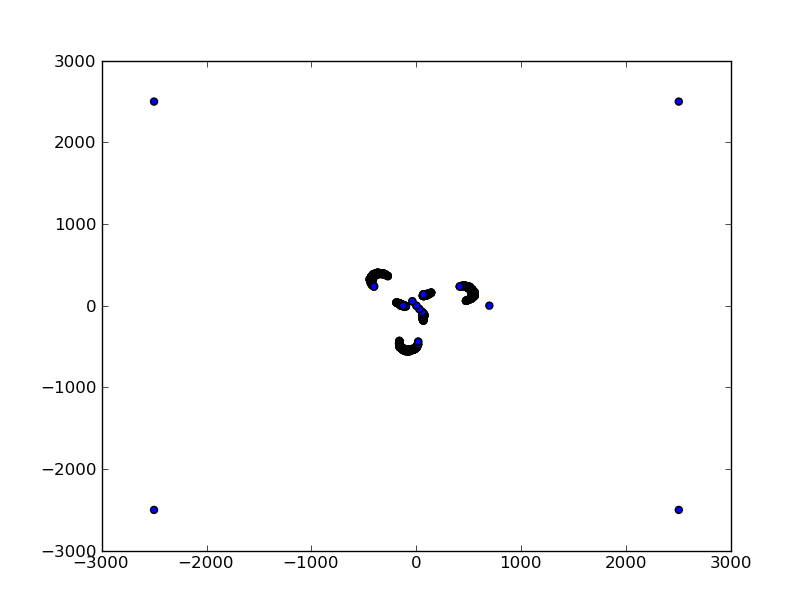

- The sensor and table are accurate and repeatable.

- The sensor does not like black and/or reflective things.

- Currently, point mapping beyond the center is not correct.

- There may be some linearity problems with straight

lines.

Will it ever be 3D.... let's see how much code gets written between

9:30 and this presentation! (Probably not

much) Update: None, just this report!