contact // irina chernyakova

1

[0912]

FINAL

PROJECT PROPOSAL

2

[0919]

COMPUTER

CONTROLLED CUTTING

3

[0926] ELECTRONICS

PRODUCTION

4

[1003]

COMPUTER

CONTROLLED MACHINING

5

[1010]

FINAL

PROJECT UPDATE

6

[1017]

MOLDING

/ CASTING / COMPOSITES

7

[1024]

EMBEDDED

PROGRAMMING

8

[1031]

3D

SCANNING + PRINTING

9

[1107]

INPUT

DEVICES 10[1114]

INTERFACE

+ APPLICATION PROGRAMMING 11[1121]

OUTPUT

DEVICES 12[1128]

MECHANICAL

+ MACHINE DESIGN 13[1205]

NETWORKING

+ COMMUNICATIONS 14[1212]

FINAL

PROJECT DEVELOPMENT 15[1219]

FINAL

PRESENTATIONS

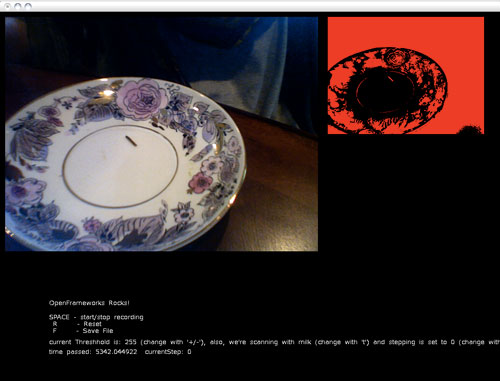

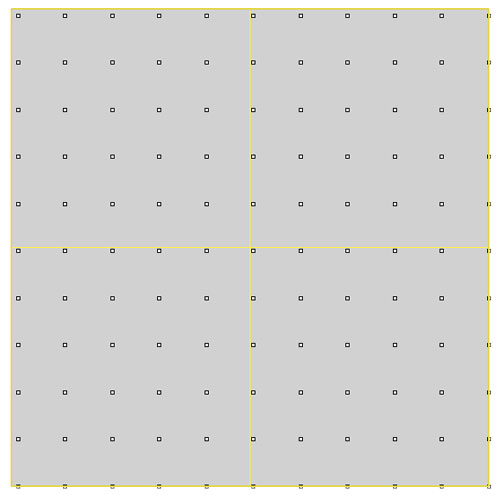

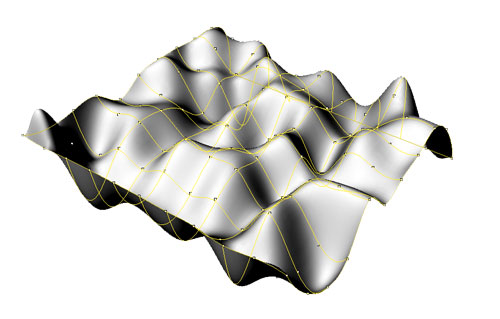

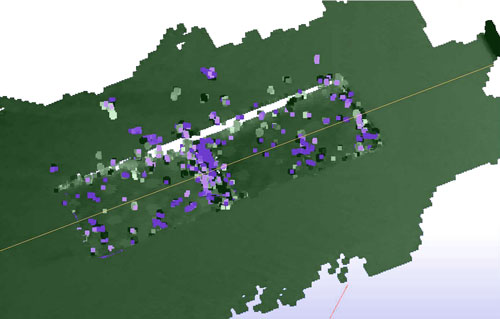

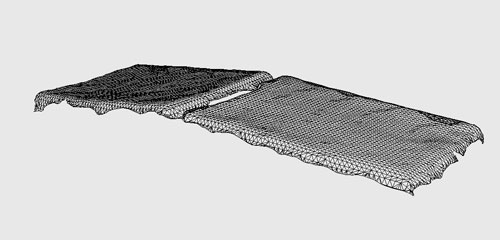

1 printing

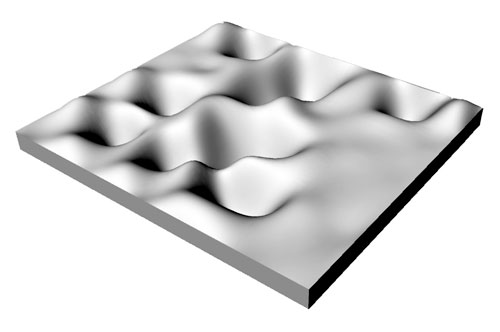

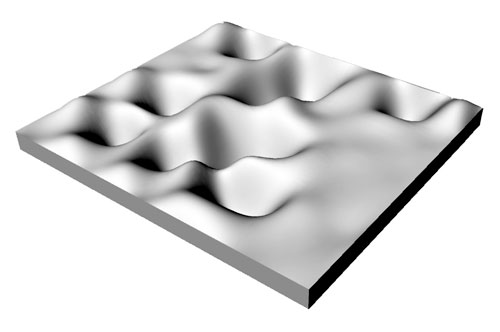

This

week, we're using the 3D printer and 3D scanner. Neil explained all

the various 3D printers in class, and I was fascinated by the recent

proliferation of 3D printing kits. Companies like Makerbot are

reducing the cost of a 3D printer to several thousand dollars.

Unfortunately, I was not able to prepare a file in time to print on

the ABS printer, which is a high-resolution printer that allows

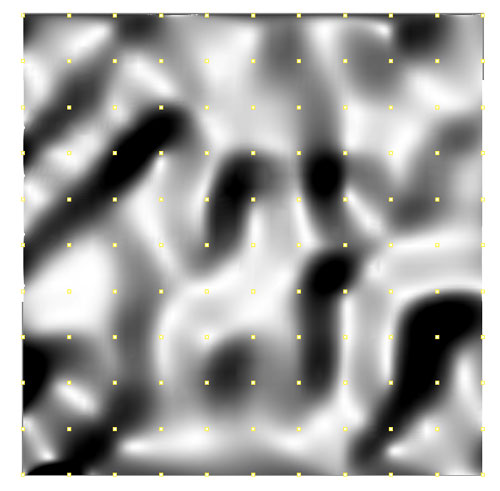

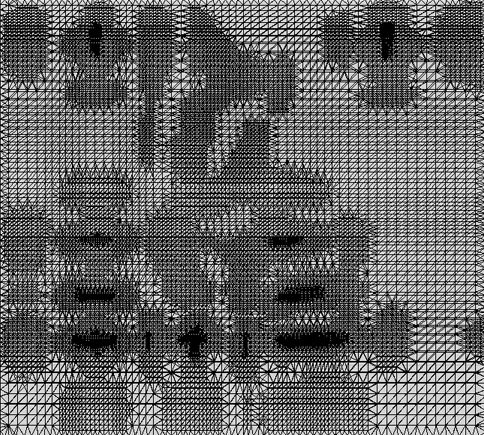

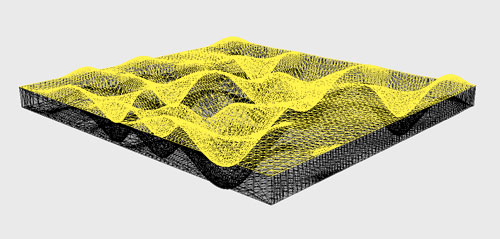

material to taper to ~1 mm. I prepared this file for the Zcorp

printer, in which I started to use the Paneling Tools plug-in for

Rhino. I used last week's QR code to manipulate a basic grid by

heightfield, then extruded the surface. The depressions are the

result of greyscale tone differentiation.

Notes

for preparing files: When

the object is ready to print, use the Show

Edges

command, and select Naked

Edges.

This tool will highlight naked edges in pink, meaning that two edges

are not actually connected. Use either the Join

command, or Boolean

Union

command to connect various edges/faces. Once there are no more

highlighted edges, export

as an .STL.

An .STL,

or stereolithography file,

creates a Mesh. You can open this file in Rhino, but won't be able to

edit. Use 3DS Max or a program like MeshLab to edit mesh objects. The

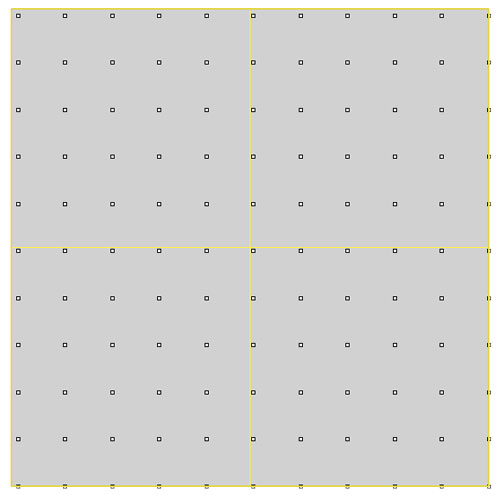

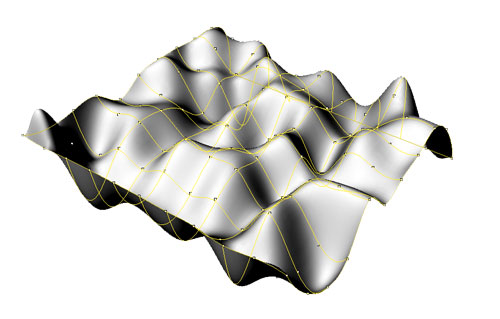

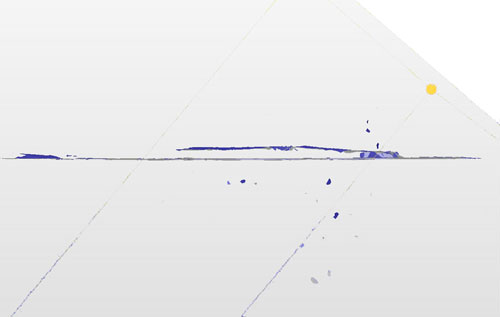

image below is the top view of the surface.

render

/ stl

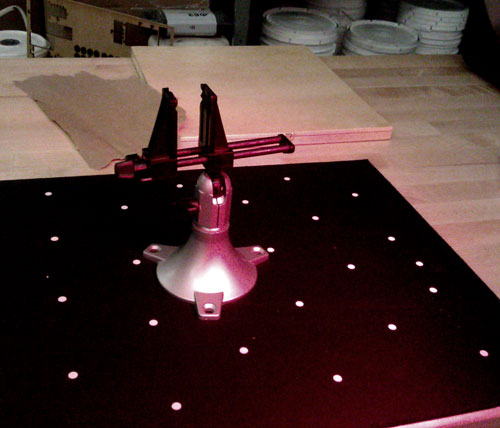

2 scanning

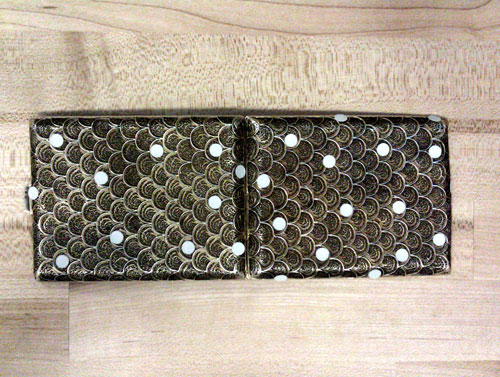

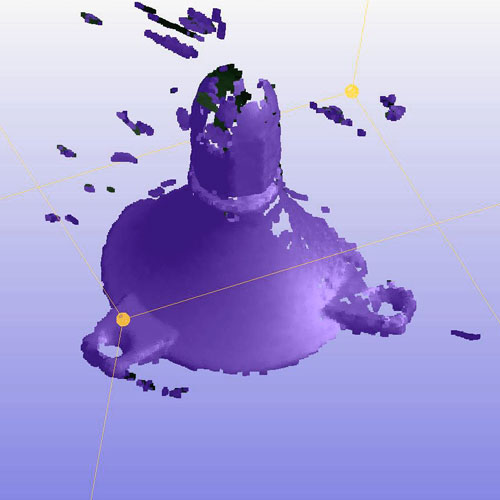

Scanning was simpler than expected. The alien kit-of-parts is packaged in an equally suspicious black suitcase. The process is relatively simple, and outlined below. I tried to scan my metal wallet, which is actually a cigarette-holder. It has a scalloped pattern, and almost lace-like detail within each scallop. I did not expect the scanner to be able to detect the actual pattern, but thought I would see how much it would capture. As visible below, the detail is completely lost by the scanner – it is best use for more simple curves and objects. I think the shine of the metal may also have reduced the quality of the scan.

1

/ object

instructions:

1/

Set-up the the scanner. Plug in the computer, plug in the

scanner into the computer, then turn on the computer and open the

Zcorp scanning software.

2/ Configure the scanner. Open

the wooden box, and first Configure. The Y-axis should reach

as close to the top of the bar as possible, while the X axis should

be within the middle brackets. Auto-adjust to match the size,

and then Apply. Then in the same column of options, Calibrate

the scanner. While holding down the button and pointing the laser at

the white X, move it closer and farther away. The program runs

several iterations and calibrates the scanner for each use. This

should be done every time.

3/ Place the positioning dots onto

your object. They should be approximately 20mm – 50 mm apart

from one another, and not symmetrically placed. Intense curves should

have less positioning dots.

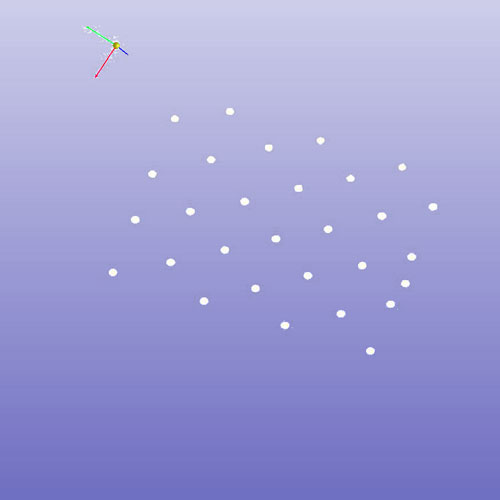

4/ Scan the positioning dots.

If these are places on your object, the scanner detects all of the

dots in order to produce a coordination system. It seems to then know

the location of each dot based on its location, and neighboring

relationships.You can find this in the top toolbar, Scan >

Positioning Dots. Press Record, and start scanning.

5

/ Once all of the dots are scanned, you can proceed to scanning the

object. You can find this in the top toolbar as well, Scan >

Surface. Watch for the crosshairs, and move slowly. You can watch

the file gather material on the computer screen as you move the

scanner around the object!

6 / One you've scanned, you can Stop

Recording. From there, you can adjust the resolution, re-size the

bounding box, or, if you're satisfied, save the file as an

.STL.

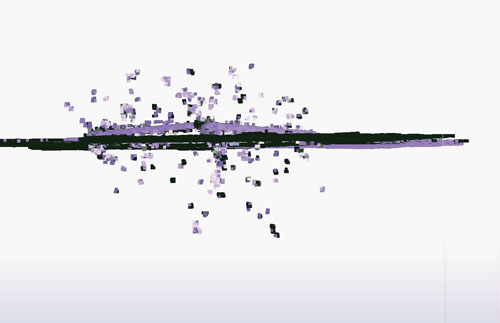

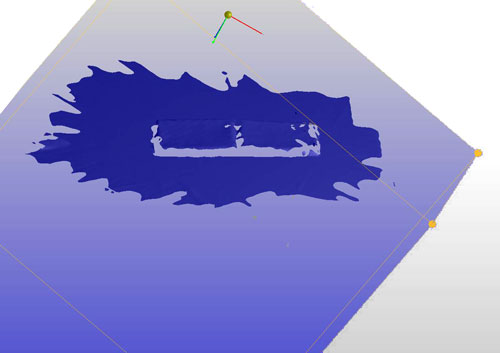

Results & Notes on

Scanning:

The metal object was too detailed. The scanner

understood the general shape, but did not catch any of the pattern.

The first time I scanned the laser seems to have moved through the

tiny holes in the material, and produced this explosion.

I

inserted a piece of brown paper into the interior to prevent this

from happening. Still not a great scan, much less chaos this time.

.

STL

2

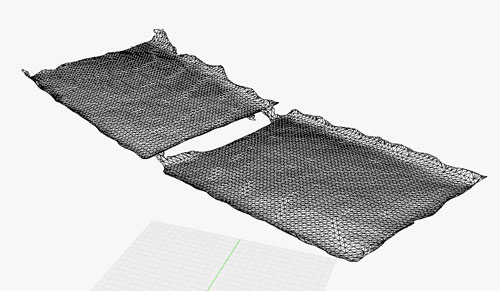

/ object on field

Since

the other object was too shiny and too detailed, I attempted to scan

this vice from the shop. In this case, I used the flat positioning

plane, and placed the object onto it. When using this method, you

can't move the object at all, or the scanner will get confused! You

can rotate the whole board, or move yourself – but not the object.

The bottom surface scan relatively well, as you can see below. I

don't the scanner was able to detect the top, black portions against

the black foamcore. Next time, remember contrast,

matte, simple. Since I

did not plan on printing these objects, I skipped post-processing and

tried out the milk scanner ..

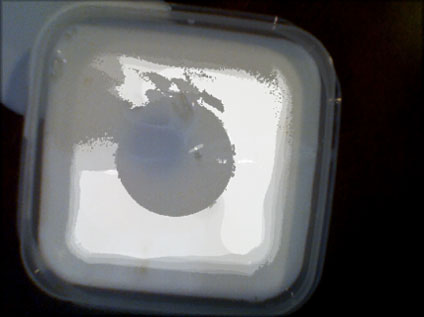

3 milk scanner

I

looked at Hannah's

page from last year for all of the information for milk-scanning,

downloaded the Milkscan

Software, and tried to scan a small bowl. The milkscanner

captures silhouettes of an object as it is being submerged into a

high-contrast liquid – milk for dark objects, soda for light

objects. I used a white bowl and a clear tupperware container, and

placed a small steel bowl in the center. Unfortunately, I don't have

a webcam, so a slightly-rigged 90 degree computer had to do. The

software is supposed to capture single sectional slices and then

compile them into a single greyscale image that can be interpreted as

3D data in a Mesh-friendly program. I did not have time to process

the data, but using the program was interesting in itself. Given the

rigged-computer and moving milk, the results were not very precise. A

more precise scanning method would be to take single exact

photographs, then using a image compiling program to produce a 3D

object.