how to make (almost) anything

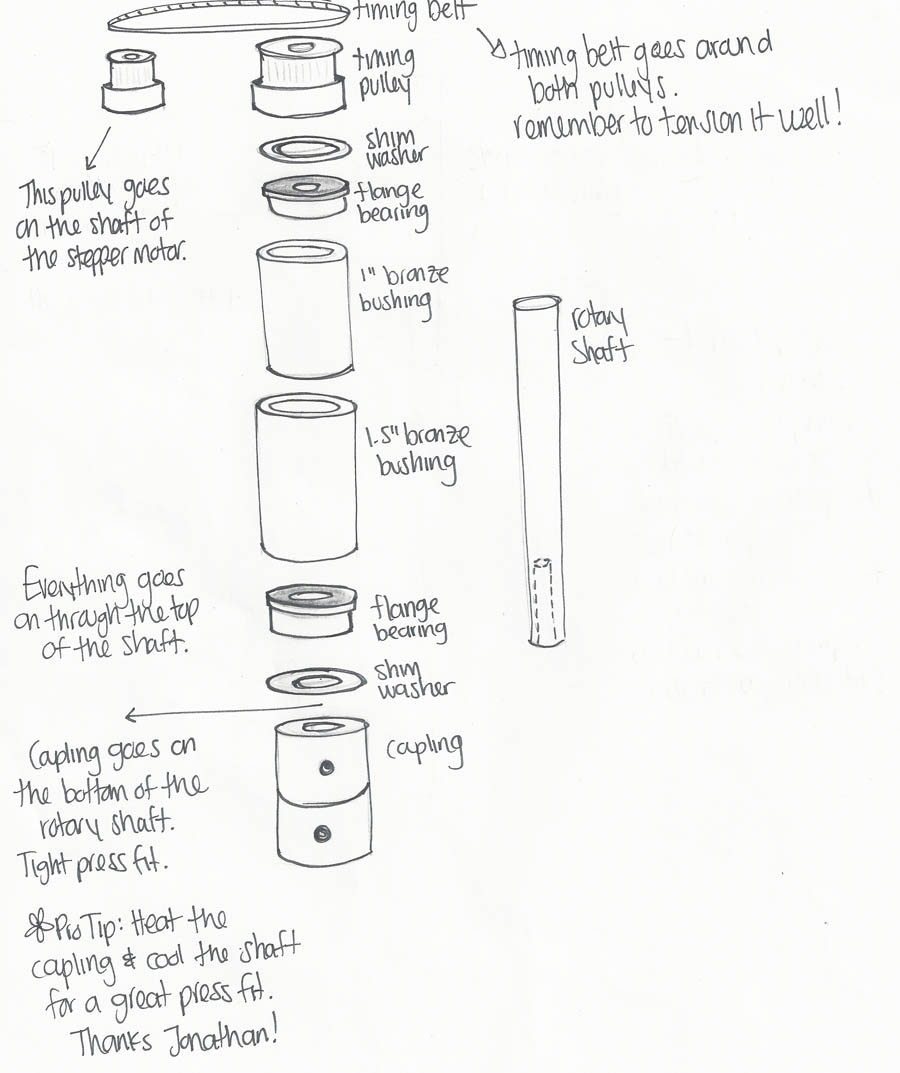

how to assemble MTM spindle:

So this is one of the trickiest parts. I spent some time with Jonathan today going over the spindle and how to assemble it, since much of it is hidden. Here are some tips.

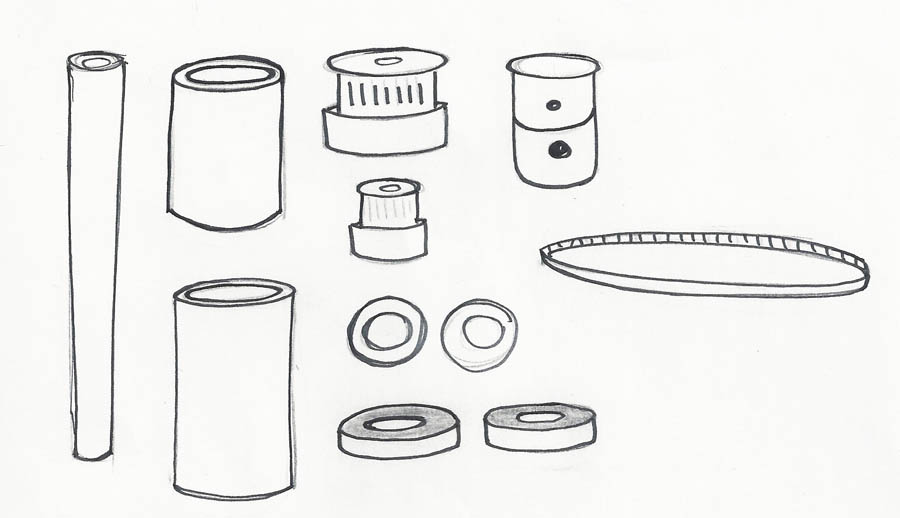

parts:

- Rotary Motion Shaft 1/4" OD length 3"

- bronze bushing 1/2" ID length 1.5"

- bronze bushing 1/2" ID length 1"

- timing belt pulley 0.25” ID

- timing belt pulley 0.09” ID

- shim washer X 2

- Roller Bearing Open for 1/4" Shaft Diameter X 2

- rigid shaft coupling (.25" to .125")

- timing belt

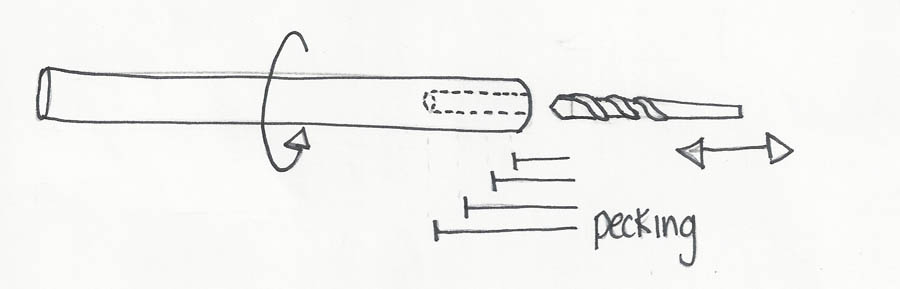

preparing the shaft

The shaft requires a bit of machining before assembly takes place. You need to turn it to bore out a 1 inch deep hole. To do this, you need to but the shaft on a lathe. Use a drill bit that's just larger than a 1/8" bit. You might also want to first make a small hole with a center drill to make sure the your tool doesn't drift. Because stainless steel is strong, you need to "peck." This means that you drill a little bit at a time, pulling the bit out completely before drilling agian. Do this until the hole is about an inch deep.

the assembly:

Here is a diagram of how the assembly happens. The parts are in order. All the parts in the long column go around the shaft. Shaft does not go through the coupling, but they do press fit together. The smaller timing belt goes on the shaft of the spindle stepper motor, and the timing belt goes around both pulleys. The entire shaft assembly is press fit into the plastic snap parts.