![]()

![]()

- 1. project description

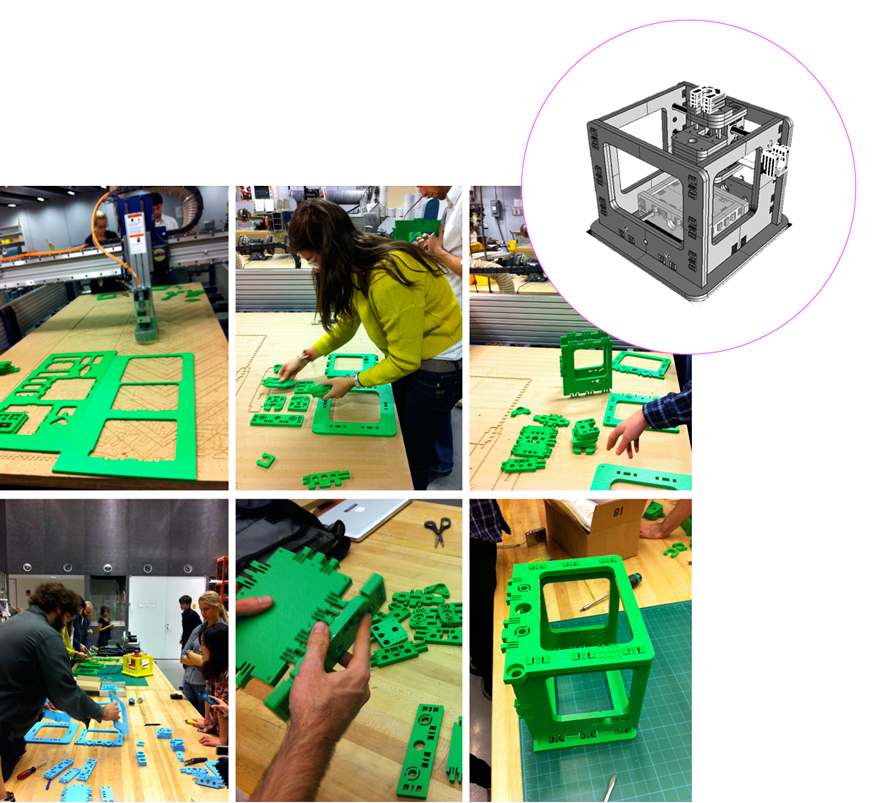

1.1. Making the MTM Snap-Together Desktop CNC Milling Machine:

This week we collectively made the MTM Snap Machine, based on the building instructions provided in the Snap MTM webpage. The purpose was to replace the Roland Modela milling machines that we currently have in the CBA and Architecture lab. On Tueasday, we went through the set up of the dxf files in Partworks which were cut by volunteers from both the CBA and the Arch Section on Wednesday morning. I attended the assembly session on Wednesday afternoon, when we cleaned the tabs from the Shopbot-cut files and put together the Snap casing. It was very interesting to see the performance of the flexure joints. We also started assembling the mechanical parts but ran out of time. The group decided to continue on Thursday morning, but I unfortunately had class and was not able to attend so I did not have the satisfaction of seeing the (victorious) finish of the CBA section.

I spent most of my time preparing for the final project. Click on the icon below to view my action plan.

> Controll Array through Button C Code: LED array is off when BUTTON is not pushed; the program keeps track of how many times the user has pressed the BUTTON since its launch and bases the delay of the LED array flashing on that

On Wednesday morning John and Tom gave us a tutorial on how to use the laser cutter. Here is a transcript of the notes that I kept along with some tips from personal experience.

3.1. Safety first:

It is quite usual to see a small flame when the laser is cutting the material. If a small flame worries you then you can open the lid and cover the flame with a piece of acrylic. If the flame is big or the material catches on fire then you open the lid, close the air valve and call 100.3.2. How to put the material on the laser bed:

The origin point is the top left corner. Make sure your material is the right size; in the Universal Laser Cutter at the CBA shop the bed is 32*18". You might need to use some tape to attach the material to the edges of the bed if it is not completely flat (this is for example very usual with cardboard)3.3. How to adjust the height of the laser bed:

Use the marked metal rod to measure the height between the cutting tool and the material you have placed on the laser cutter board. Press Z and use the Up and Down arrows to bring the cutting material to the edge of the metal rod. You will know that the height is right when the pin does not let the board to go any further up.

The check button moves to smaller digit precision for height refinements with the up and down arrows. Once you have found the right height press Z again to exit.3.4. How to send your files:

3.4.1. If you are using Inkscape:

1. Prepare your file and export it in 300dpi. Keep in mind that the white part is the one cut with precision so your offsets are "eating" off the black part.

2. Go to fab > run in terminal

3. Select the Universal laser cutter and define power and speed. Make sure that you set the pulses per inch (ppi) to be less than 500 if you are cutting cardboard. If you are cutting acrylic you can do almost 300.

4. Specify xmin and ymin. This is how far from the top left corner (origin) the machine will start cutting the file.

Hit make .uni

6. Send!3.4.2. If you are using CorelDraw (Windows):

1. Import your file

2. Make sure all your lines are Hairline (No thickness)

3. Optional step: You might want to offset your lines for precision. Go to Effects>Contour and do an Outside offset of 0.005 (or around that) Then do Arrange and break contour group apart.

4. Go to File>Print>Properties and set Power and Speed per color

Press Set to register your changes

6. Print!3.4.3. If you are using Rhino or AutoCAD (Windows) you can set the speed and power per layer through the print menu. Make sure you SKIP all the layers you do not want to cut and that you select the area you want to cut with a print window and that all your lines are 0 thickness or hairlines. In Rhino you can set the size of the print window and then Move it in the correct spot in the screen. You send your file by hitting print.

3.5 How to cut your files:

Find the right file! If you send multiple files you can navigate through them with the >> and << buttons.

2. Do a test run. It is recommended that you do a test run to confirm that the path is right. Just press the green button <|> while the lid is open.

3. Cut! If all looks fine close the lid and press <|> to cut.