Why is this so ^#(#*D(@~! difficult?

Electronics Design & Flexible Circuits

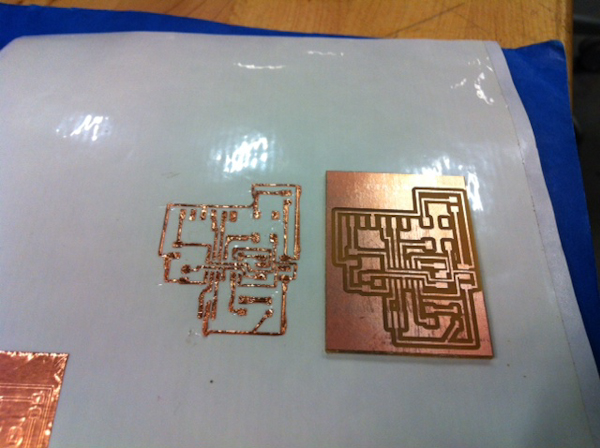

This week we focused on electronics design and production. I thought it would be a good opportunity to try making a flexible circuit. My main takeaway from the week is that flexible circuits should be designed MUCH MUCH bigger with bigger traces and bigger components so that you don't spend three hours weeding things you can barely see with tweezers.

Images

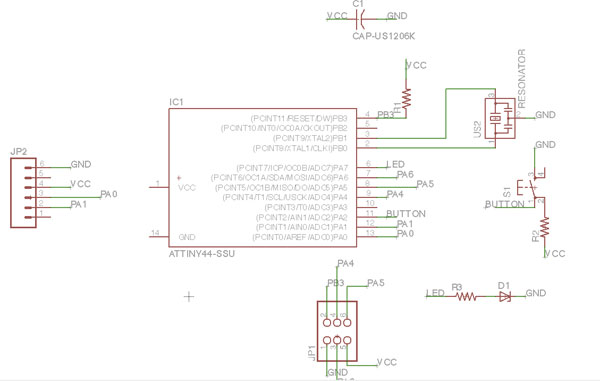

With the help of numerous TAs, Valentin's Eagle tutorial and generous copying of the images posted and others' circuits I was able to get my circuit designed in Eagle.

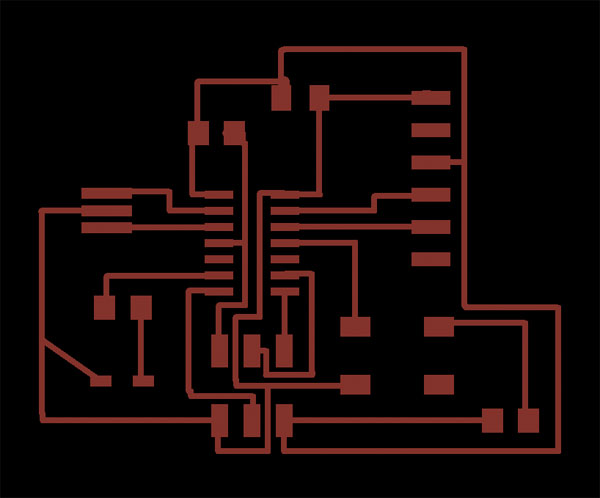

Routing the traces was pretty tricky. I changed the trace width to 0.016 so that I would actually be able to get a couple things routed under the ATTTiny. It took about an hour to get this right.

Here and here are links to the final exported files that I used for printing

I have always wanted to make a flexible circuit so I went to Tiffany's excellent vinylcutter workshop and started with this process. Little did I know...

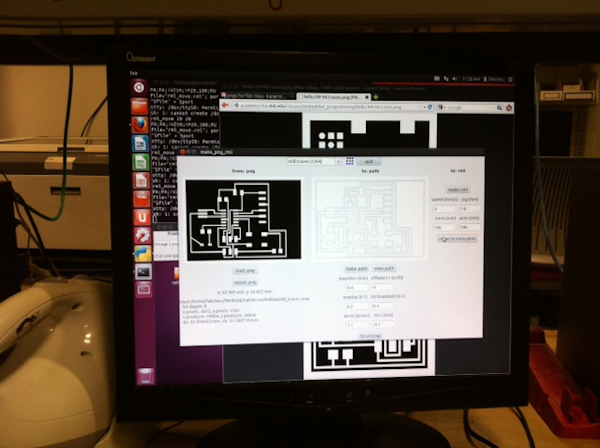

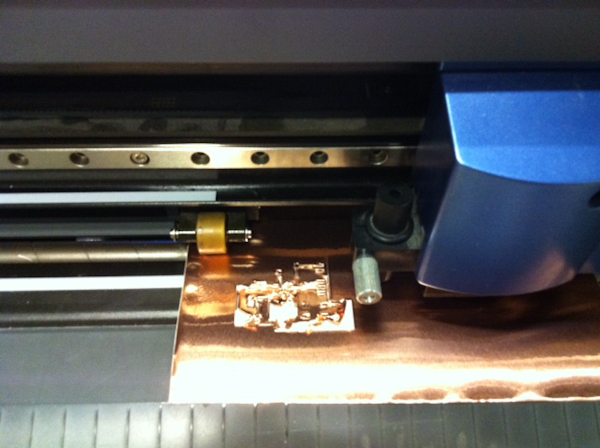

The vinylcutter was way more tricky than it seemed in the workshop. There is a very fine line between getting the traces all the way cut through and not tearing up the copper. The force setting was what I adjusted to try to get it right. At first, I used 60g/f and 2.5mm/s speed as we had in the workshop. However this resulted in traces that were not all the way cut through - in fact they were barely embossed. I went all the way up to 100g/f which seemed to yield the best result without tearing up the paper during the printing. However, when I tried to do another at this setting it tore up the paper. Huh? This machine is picky...

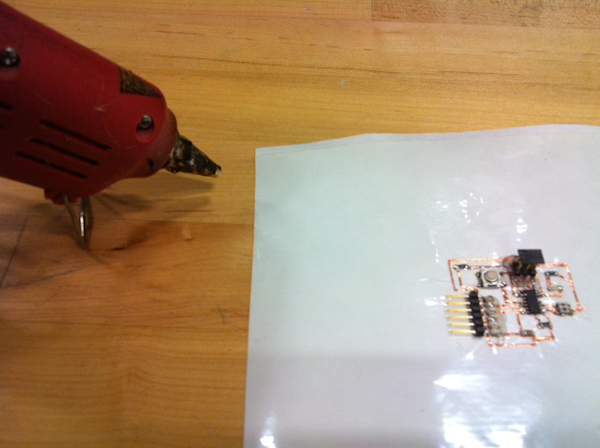

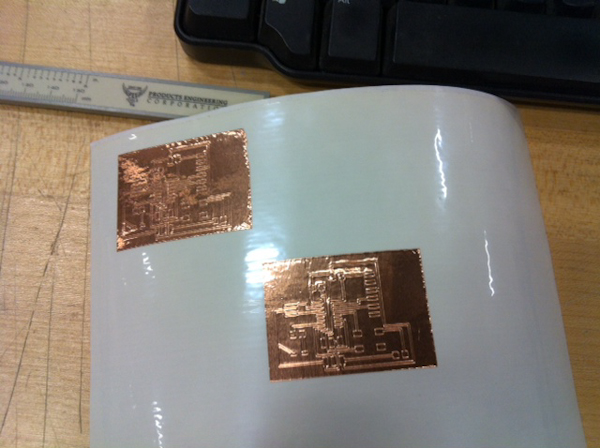

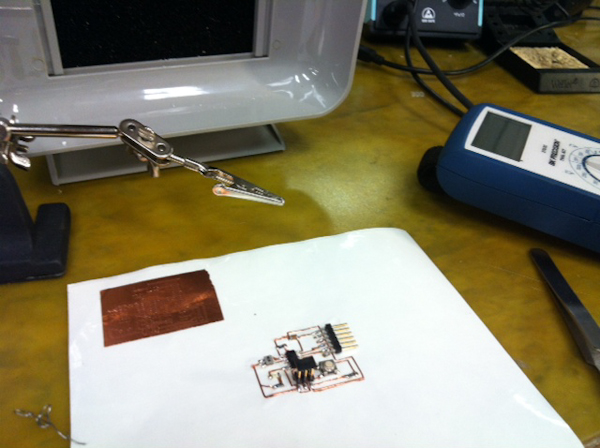

After lots of fiddling I got two results that seemed like I could live with. I transferred them with tape to heat-resistant paper.

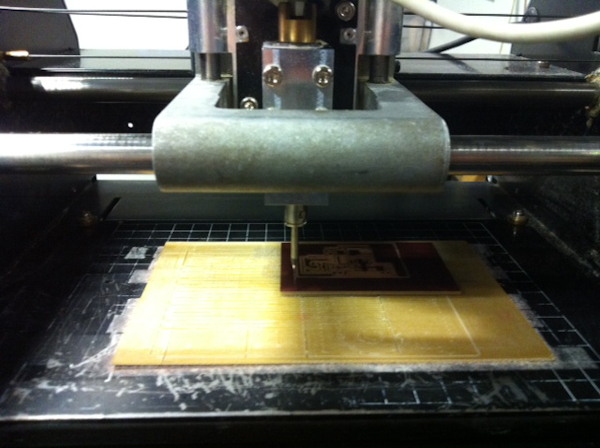

And, because I was doubtful about this whole flexible circuit thing working, I milled a board just in case.

This image makes it look like it was super easy to weed the flexible circuit.

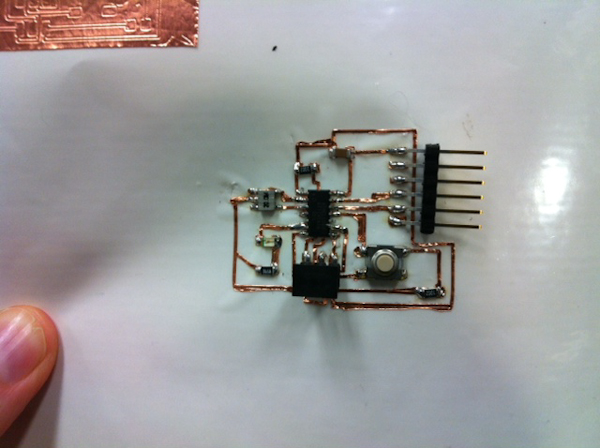

THAT IS A LIE!!!! IT WAS ONE OF THE BIGGEST HEADACHES EVER!!!! Three hours of painstaking tweezing later, I did manage to weed the whole thing. However, I am doubtful that it will work. The copper traces move around a lot and they were so close in certain places that I'm not sure if they start touching and make a bridge.

Soldering was a breeze this time. Especially in comparison to weeding.

Pretty board! Pretty board!