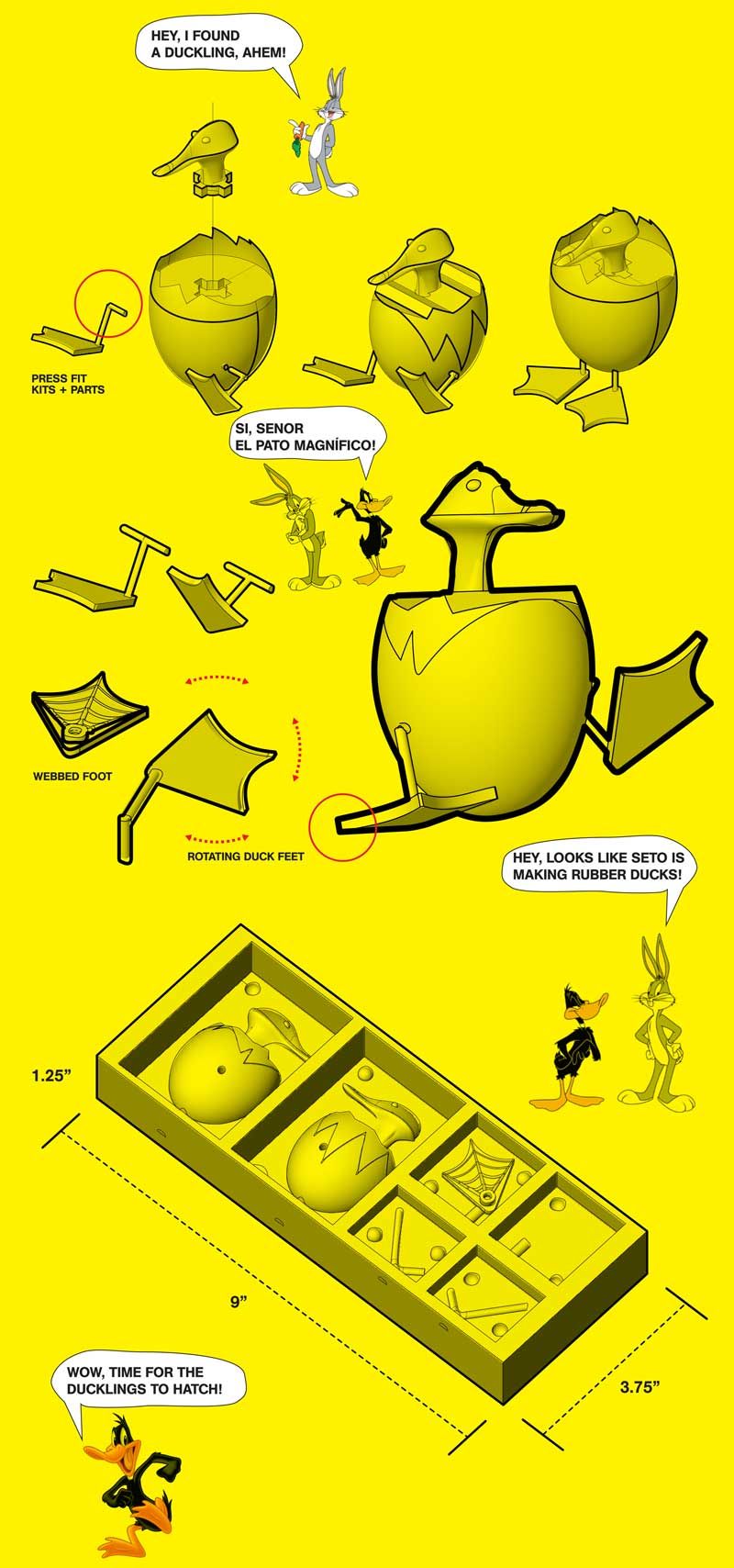

How To Make Hatching Ducklings!

It's our sixth week in this class, and it's time for some ducklings to hatch out. Mama Duck is going to be so happy to have a few little ones around her.

Milling with ShopBot

With huge help from the real Fabrication Master, Andrew Manto , on the MasterCam , I was able to mill the machinable wax on the ShopBot Buddy at the Archi Fab-Lab. The Machineable Wax is capable to produce positive or negative moulds with high resolution.

In my case, I was happy to see the duckling's foot and body details I modeled in Rhino popped up comfortably. I managed to mill everything in 90 minutes time. A huge -- probably 5-7 hours -- time saving compared to milling these forms using the Modela.

The setup I used was:

0.25" flat endmill for roughing pass

0.125" ballnose for finishing pass

0.125" flat endmill for drilling and cutting pass

150 Speed

30 Plunge Rate

6000 RPM

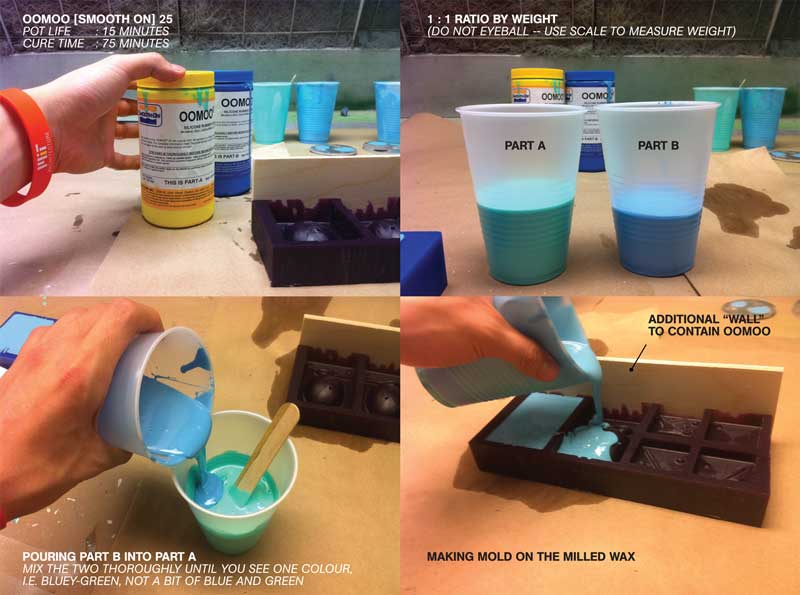

Making Cast Out of Oomoo

The Oomoo or Rubber moulds picks the details on the surface, i.e. tool paths, texture, and bumps, from the wax pretty well. Since I milled too close to the edge of the material, I had to construct, using the glue-gun, an enclosure to block the Oomoo from running away. It works nicely, no problemo!

Machinable Wax + Oomoo Cast Result

Over the last few semesters, I've learnt that casting works well when the nature of the moulds is the opposite to that of the materials cast, i.e. Hard mould will be great for Soft cast and vice a versa. In this case, the Wax (HARD) is perfect for making the Rubber (SOFT) moulds, into which the Drystone (HARD) will be eventually cast.

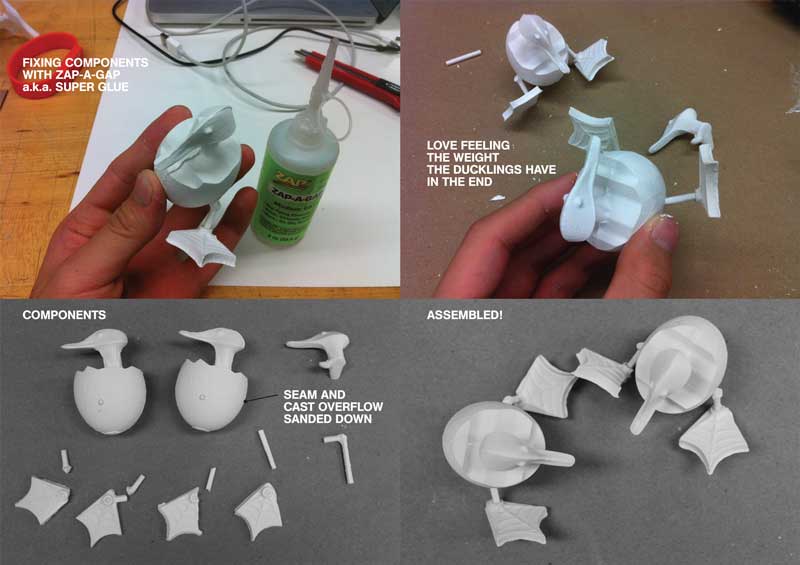

Casting the Positive using Drystone

I found the Drystone to be a great material to work with. The only thing was it tends to break easily; this is certainly not helping me to cast components that would be able to move and reconfigured many times.

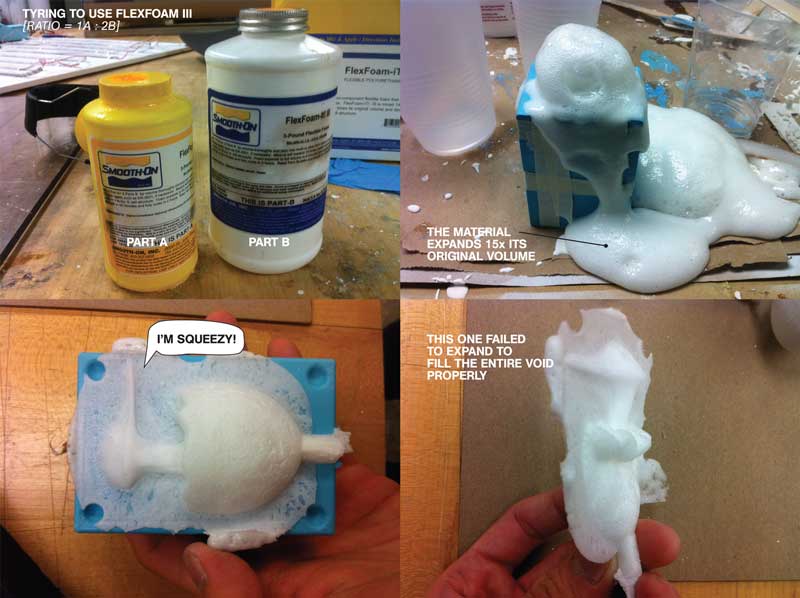

Experimenting with FlexFloam III

I tried experimenting casting with the FlexFoam III, which expands 15 times its initial volume. The pot life of this is only 35 seconds, so you got to stir fast and well. The cure time is approximately 2 hours.

I was a bit disappointed to find my cast failed. My guess is that I stirred way to long and the material had started to expand, so when I was pouring it into the hole, it already wanted to escape through the vent hole without trying to fill in all the gaps within the void of the moulds.

Assembling Pieces

Despite the imperfect Drystone casts, I decided to keep on going until I was able to make two ducklings. Since the Oomoo didn't fill the negative holes, that I wanted as the duck leg plug-ins, I had to "simulate" this by gluing the components together. They're fixed and not moving, but I feel really satisfied with it!

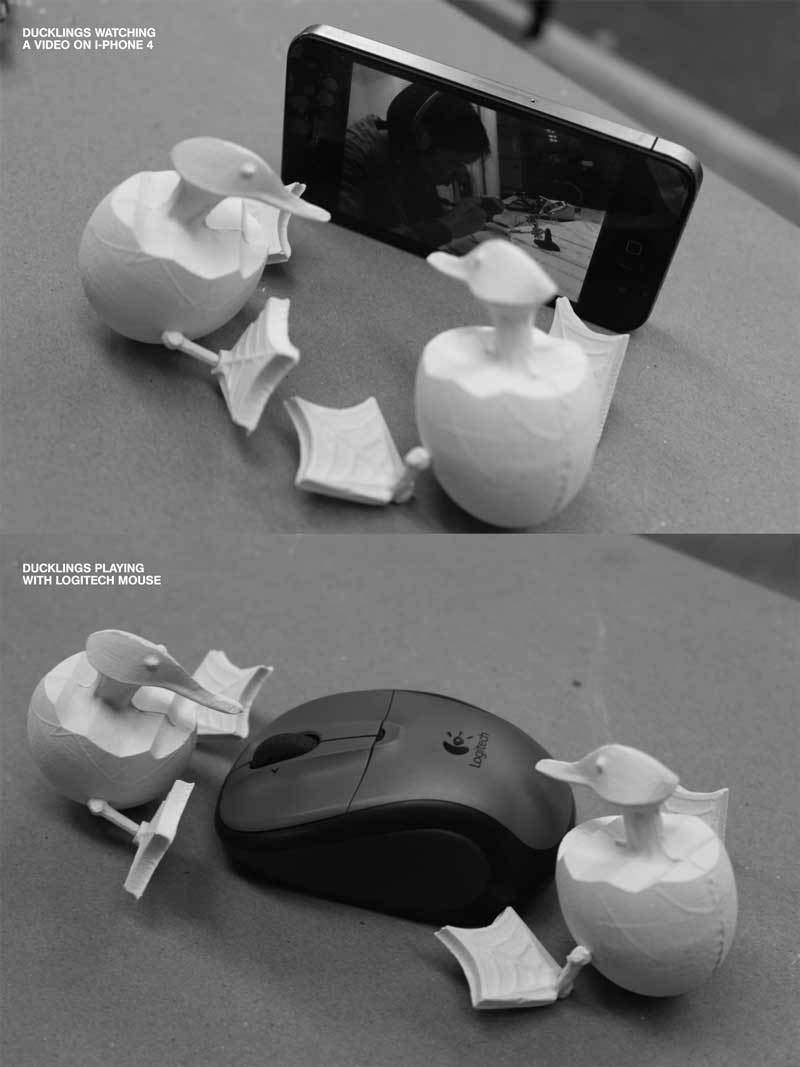

The Ducklings Having Fun!