Additive manufacturing or 3D printing is a process of making three dimensional solid objects from a digital model; it is achieved using additive processes, where an object is created by laying down successive layers of material.

3D printing an object... In my case, a spring with variable pitch, curved axe and variable section. The goal is for it to have a balanced behaviour between flexibility and stiffness, but not be too wobbly and weak. The goal is to build a fun mockup of a spring, not a structural piece.

|

|

|

Out of the photo-curing resin printer... |

Heat needs to be applied to remove the wax. |

Half melted. |

|

|

|

Right out of the oven, the spring is very flexible! |

Too much! |

|

|

|

A second wave of heat...holding while heating shapes it. |

Stiffer and more elegant result. |

|

|

|

Smaller version with special head and foot. |

After the wax melting. |

Better stiffness. |

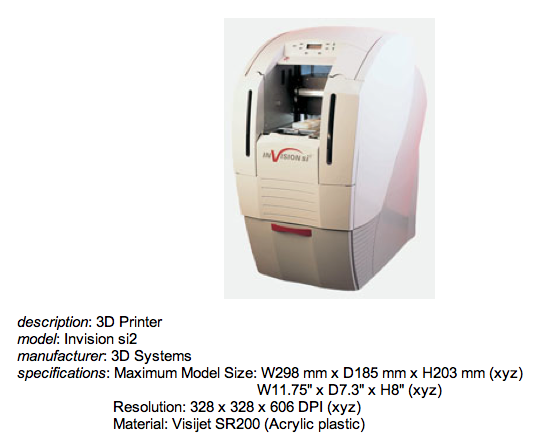

An ABS printer would not have worked for printing wire-like elements at this scale. It builds by extruding a bead of plastic, a layer at a time, in a zig-zag pattern on each layer. Small linear elements tend to have gaps in them where the plastic turns around a corner, and end up being quite fragile. A printer using a photo-curing resin can handle this geometry and scale of work much more easily.

More info: (SITE)