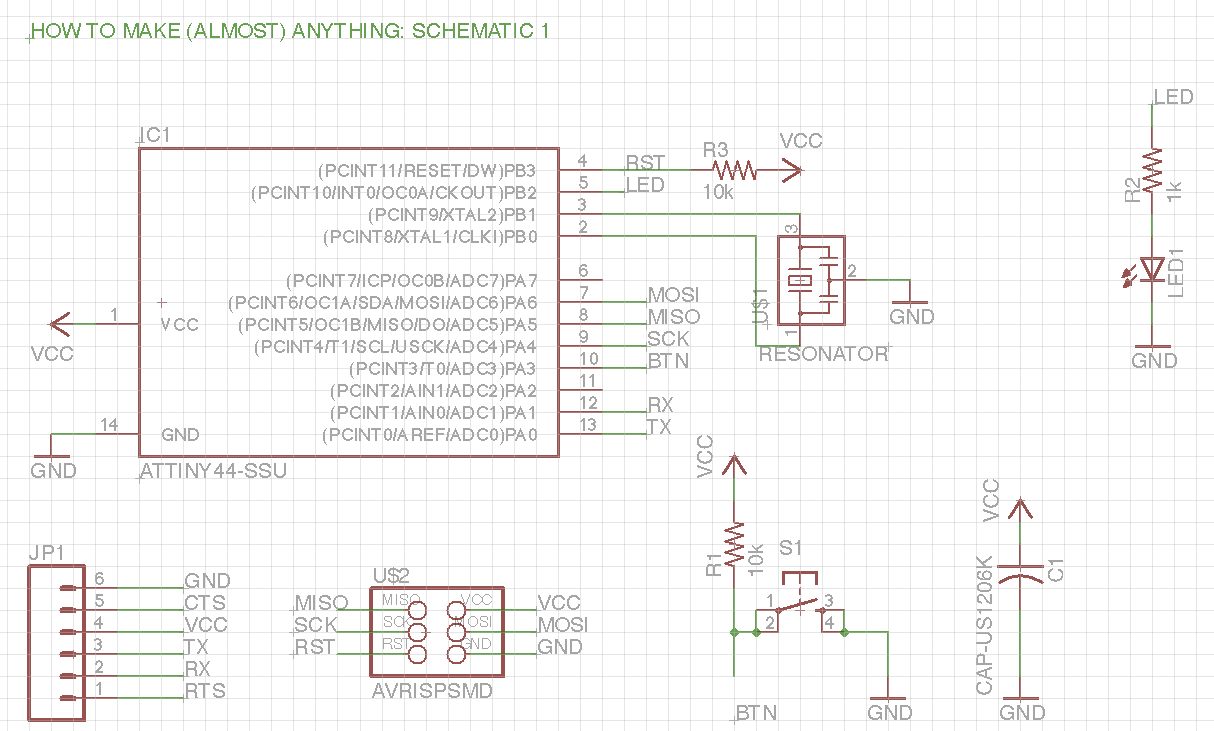

Electronic design automation (EDA or ECAD) is a category of software tools for designing electronic systems such as printed circuit boards and integrated circuits. The tools work together in a design flow that chip designers use to design and analyze entire semiconductor chips.

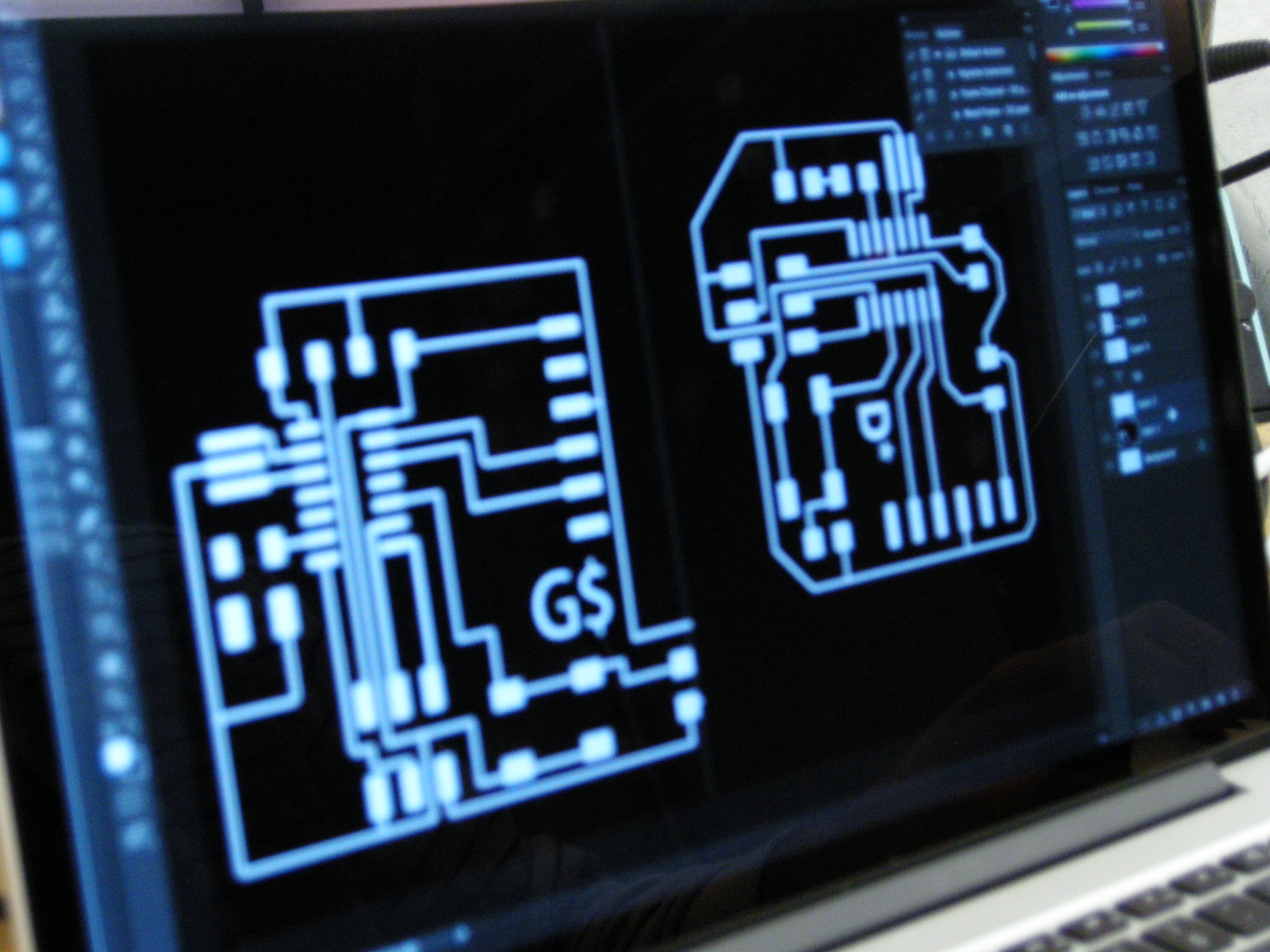

The goal for this project was to learn how to use Eagle to design electronic circuits, and to fabricate and stuff the output.

|

|

|

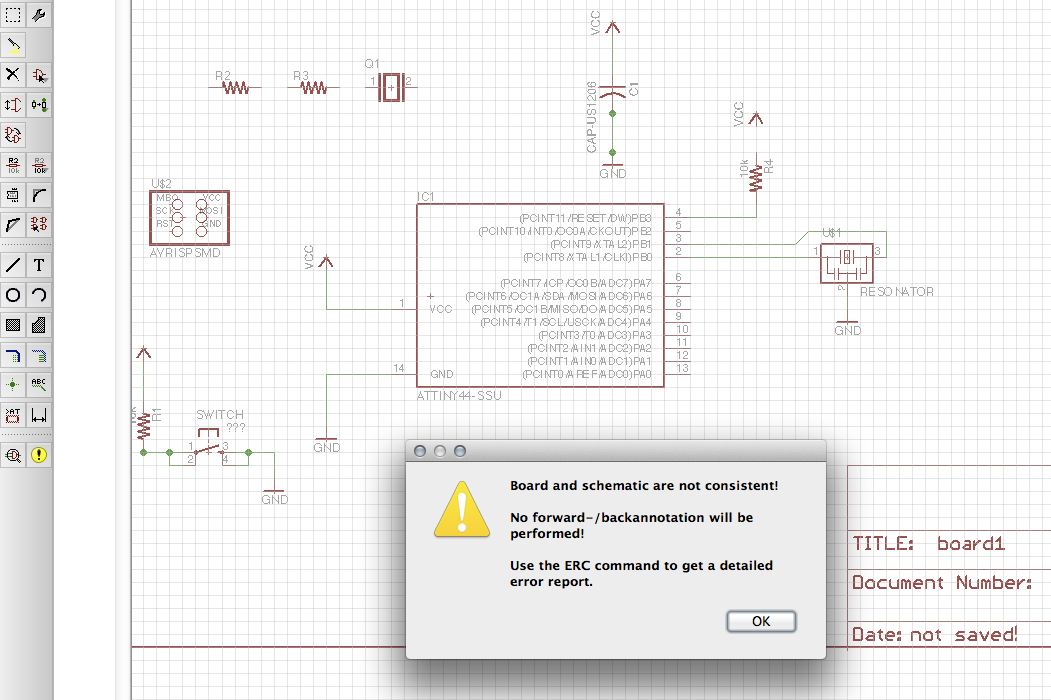

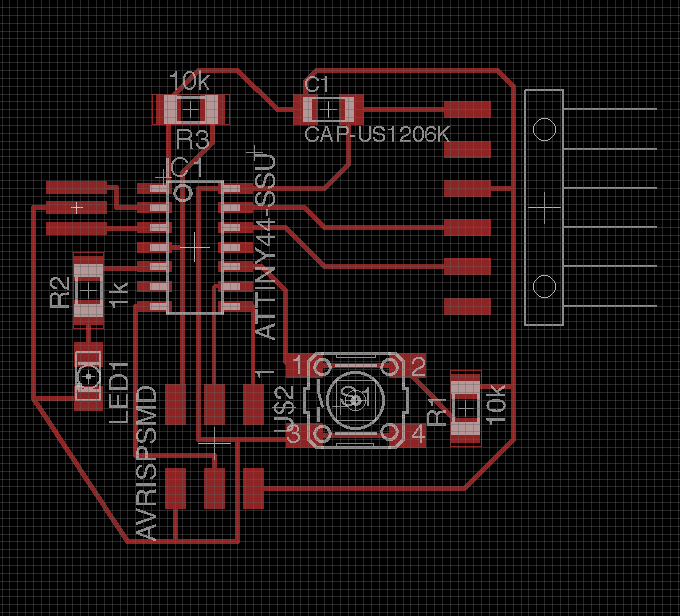

Always remember to fire up schema and board view! |

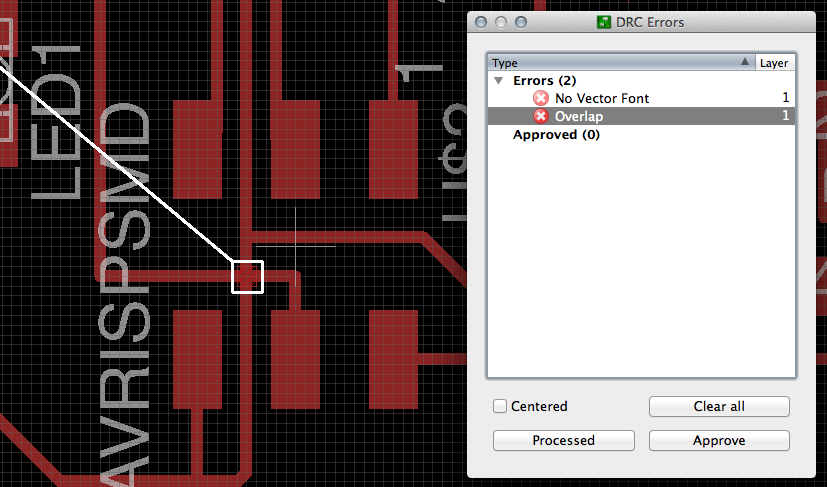

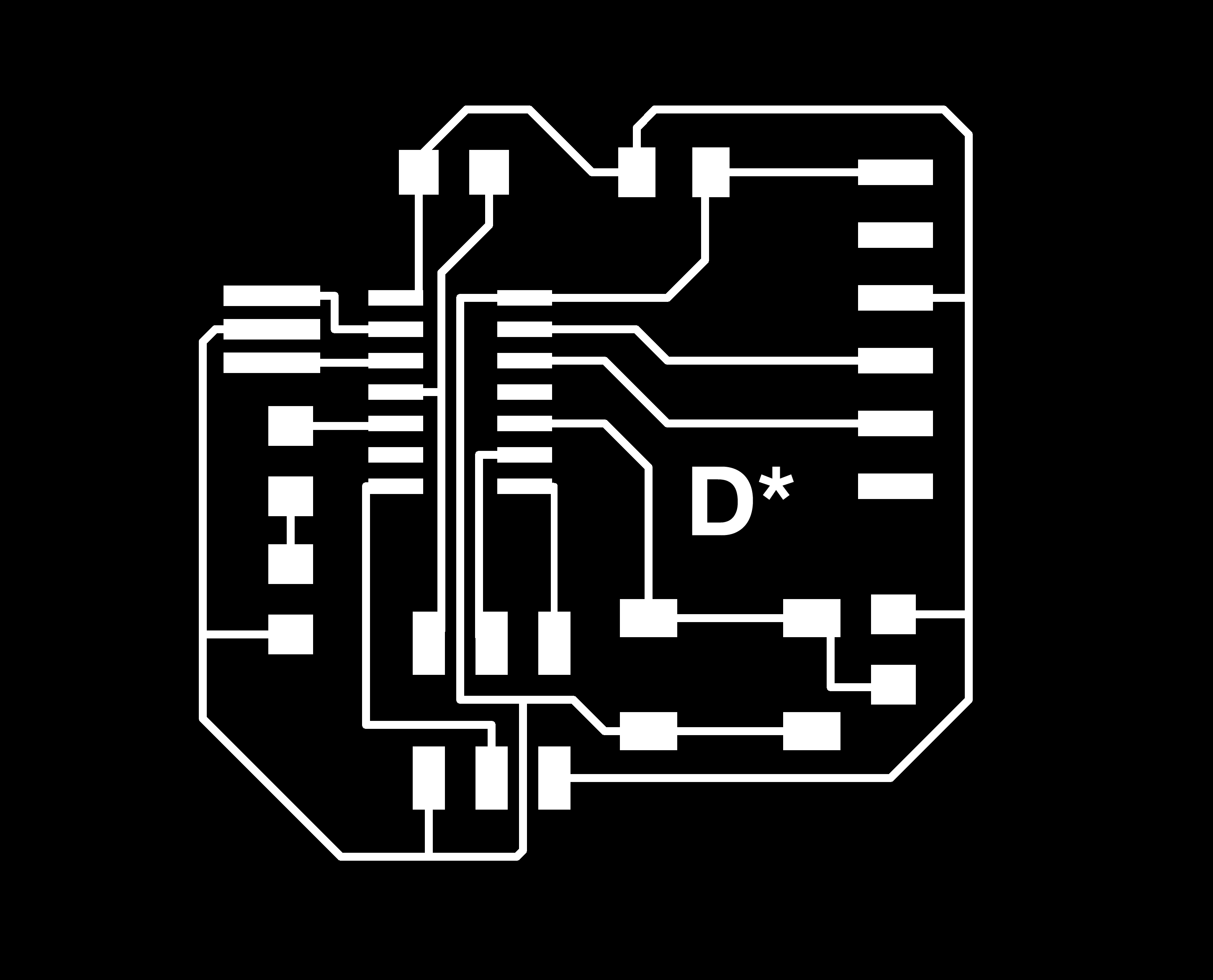

'Sign' your board with another software :) |

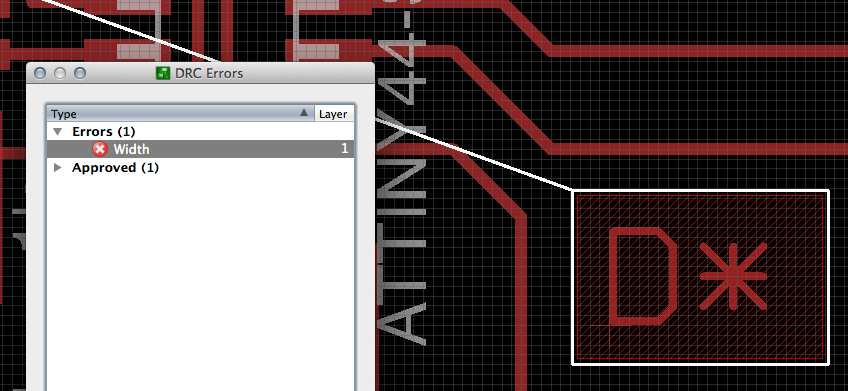

Use the 'ERROR CHECK' tool to prevent nonsense! |

|

|

|

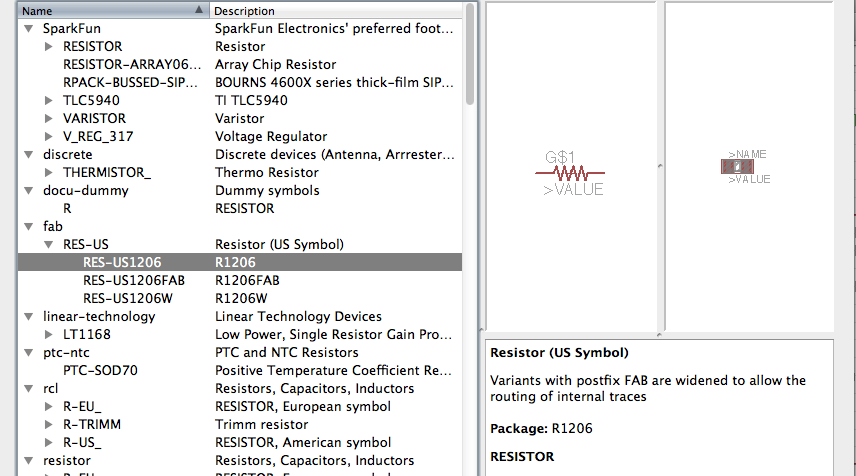

Find the right component through 'ADD' command. |

Avoid long wires with the 'NAME' command. |

In board mode: use 'AUTOROUTE' and then cleanup. |

|

|

|

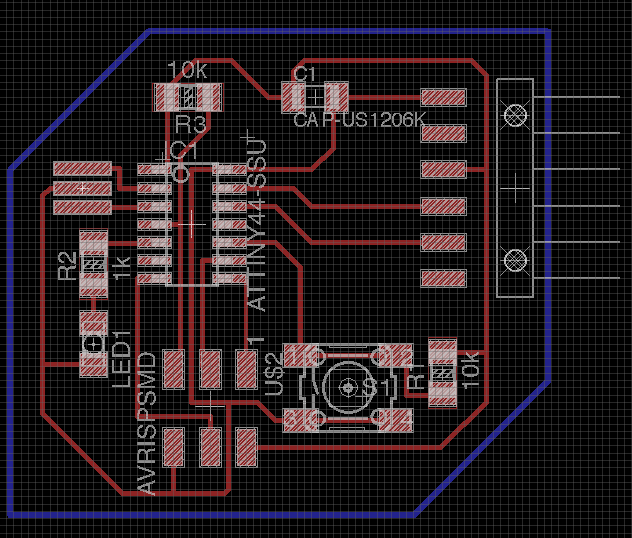

Use 2 layers: one for for CUT, and one for TRACES. |

Get image with Monochrome and Cippboard options! |

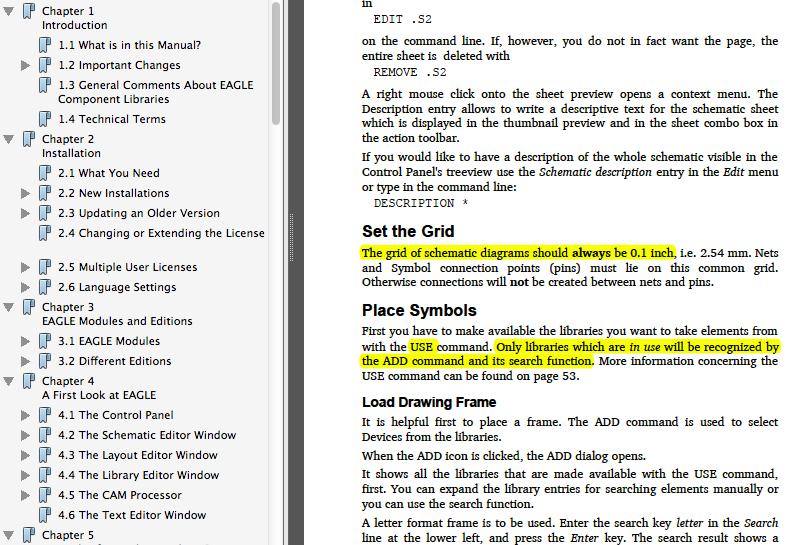

Read the Eagle manual when you feel lost...(link below) |

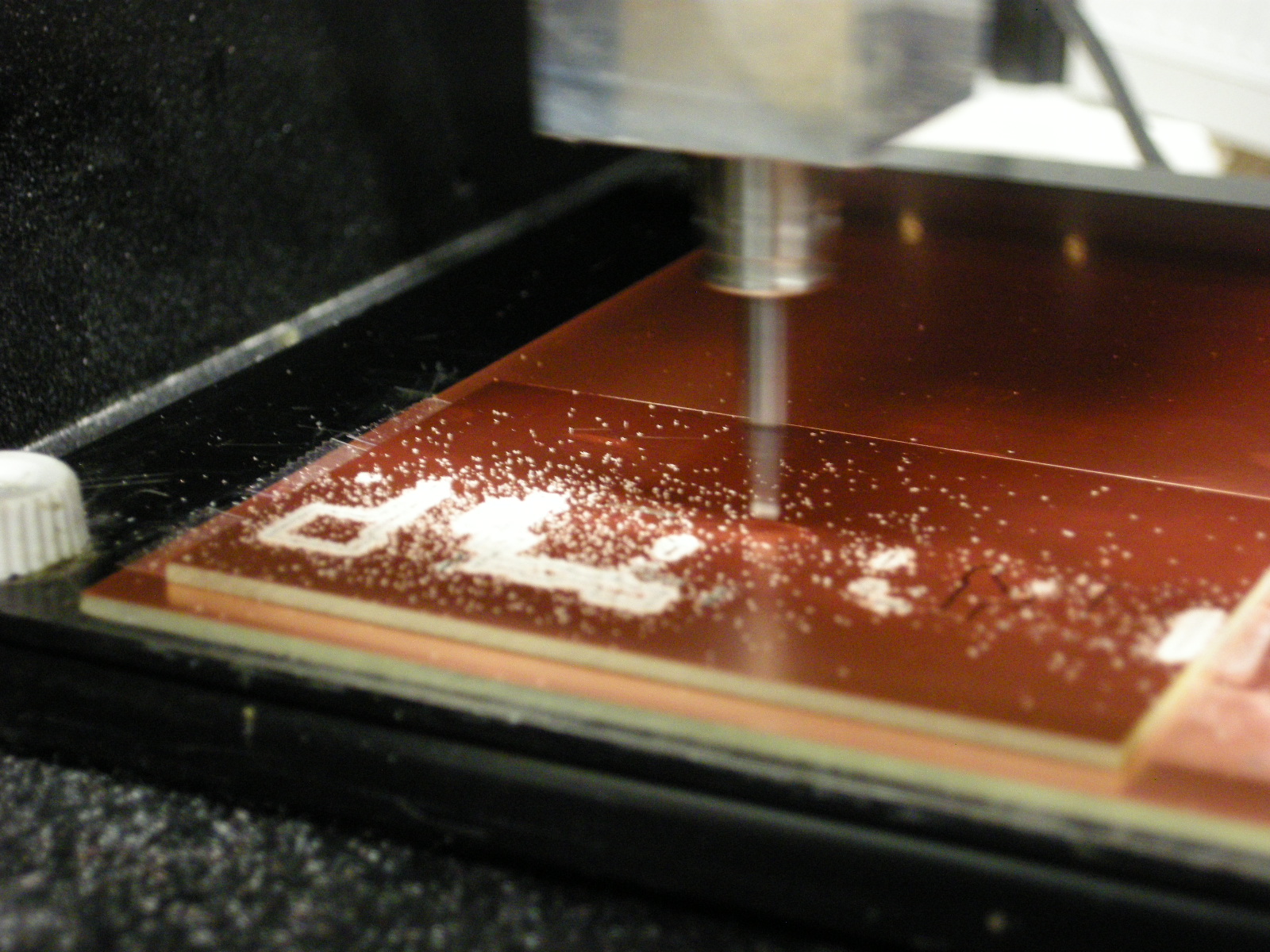

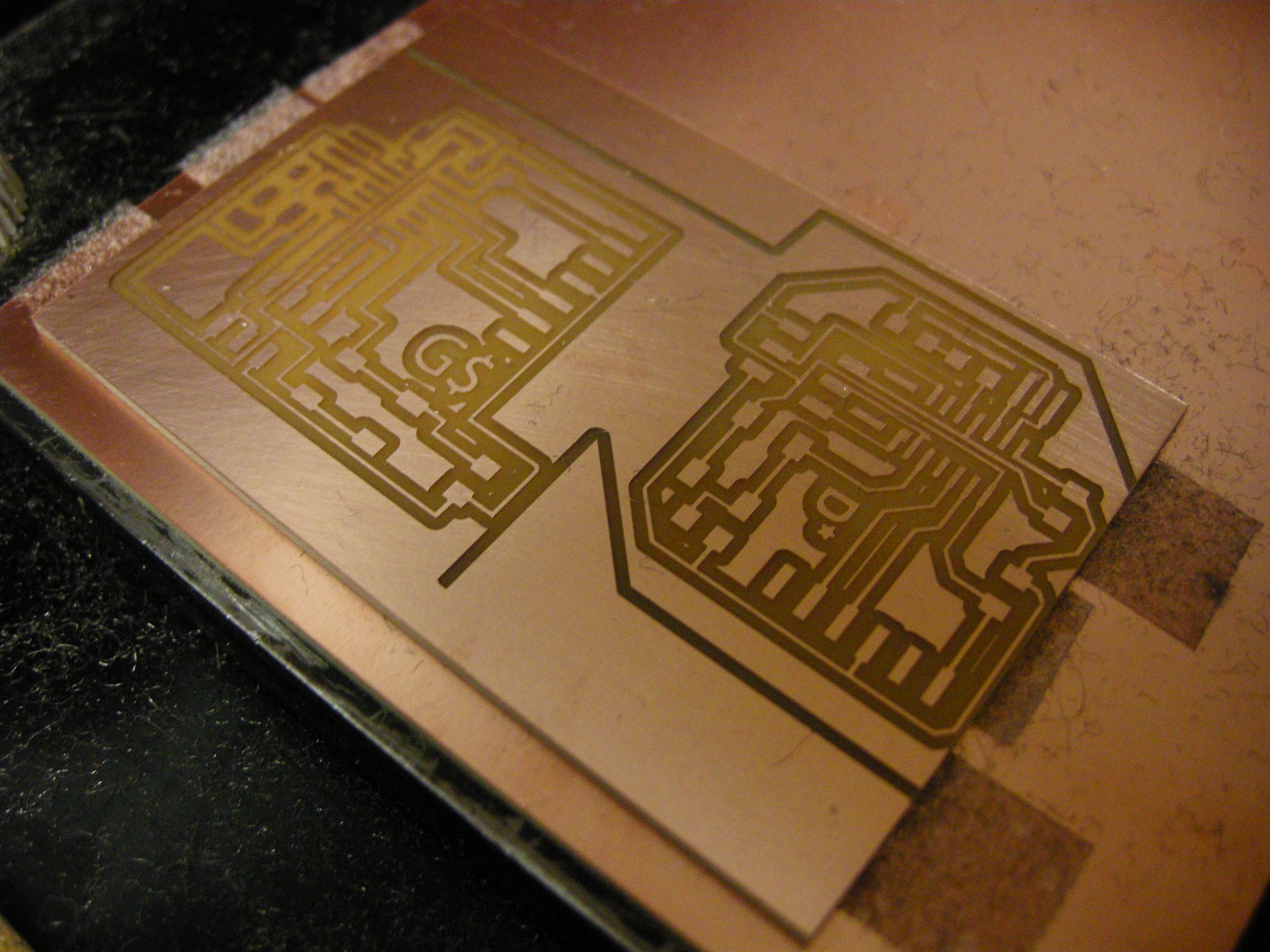

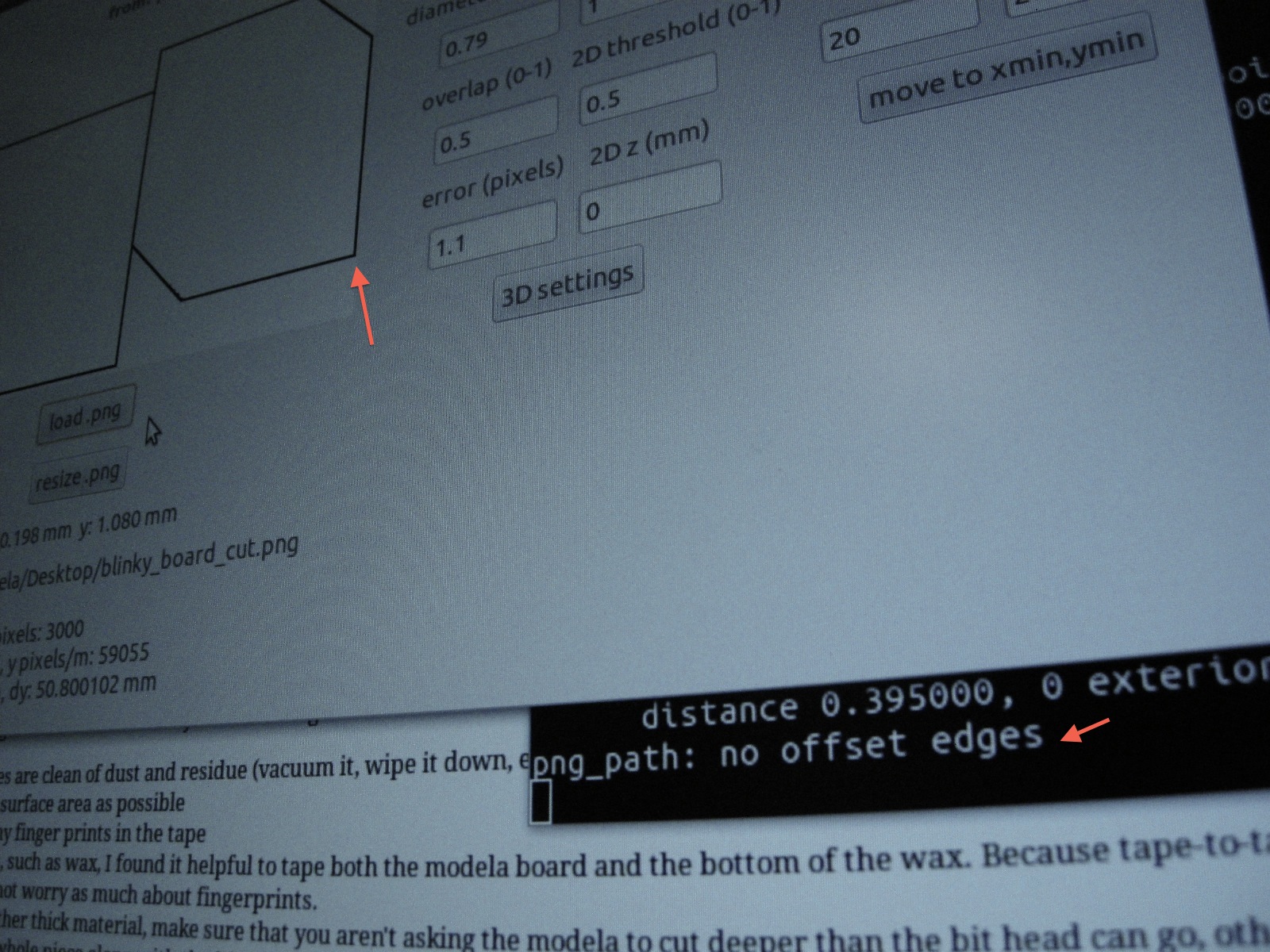

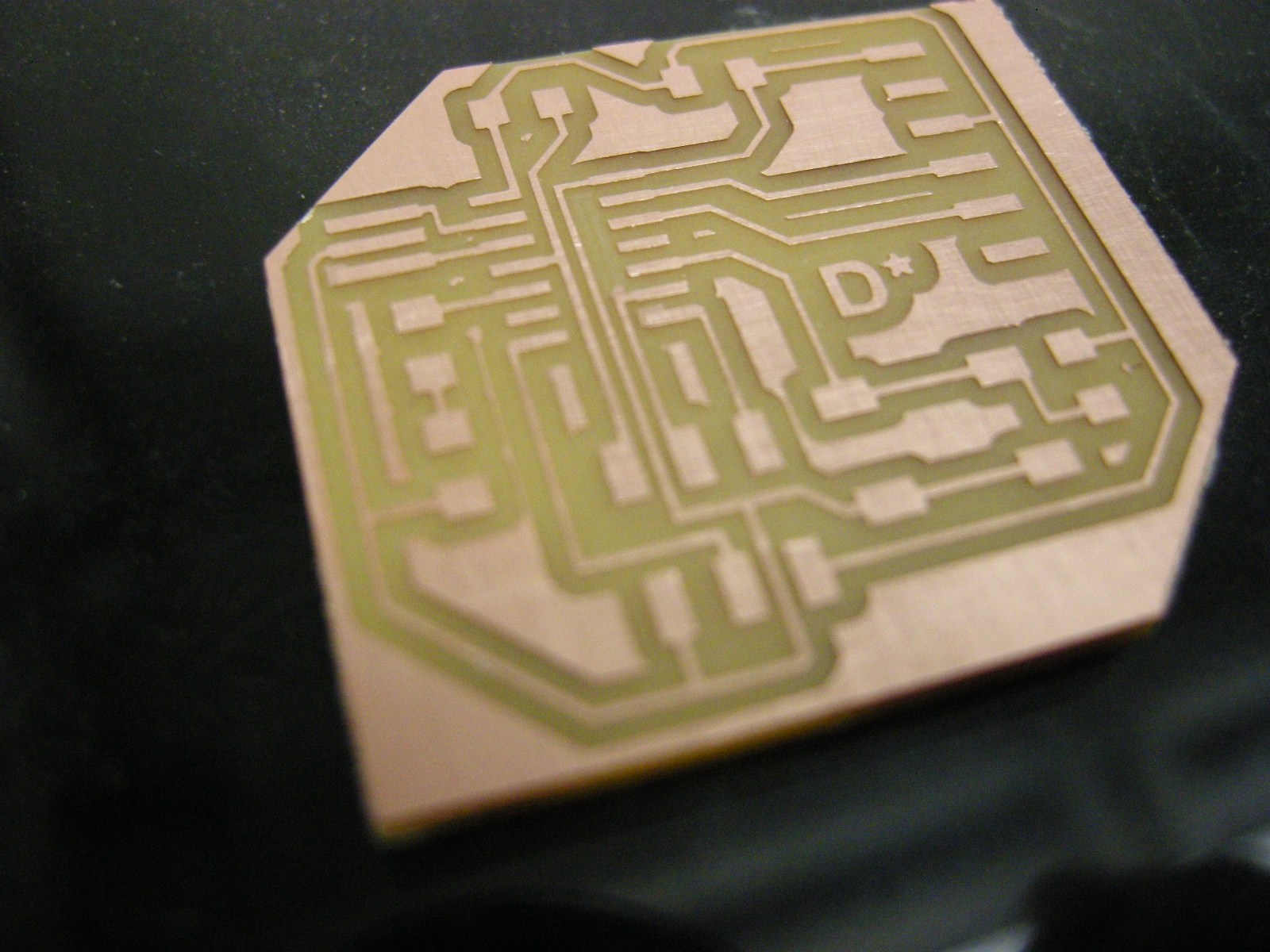

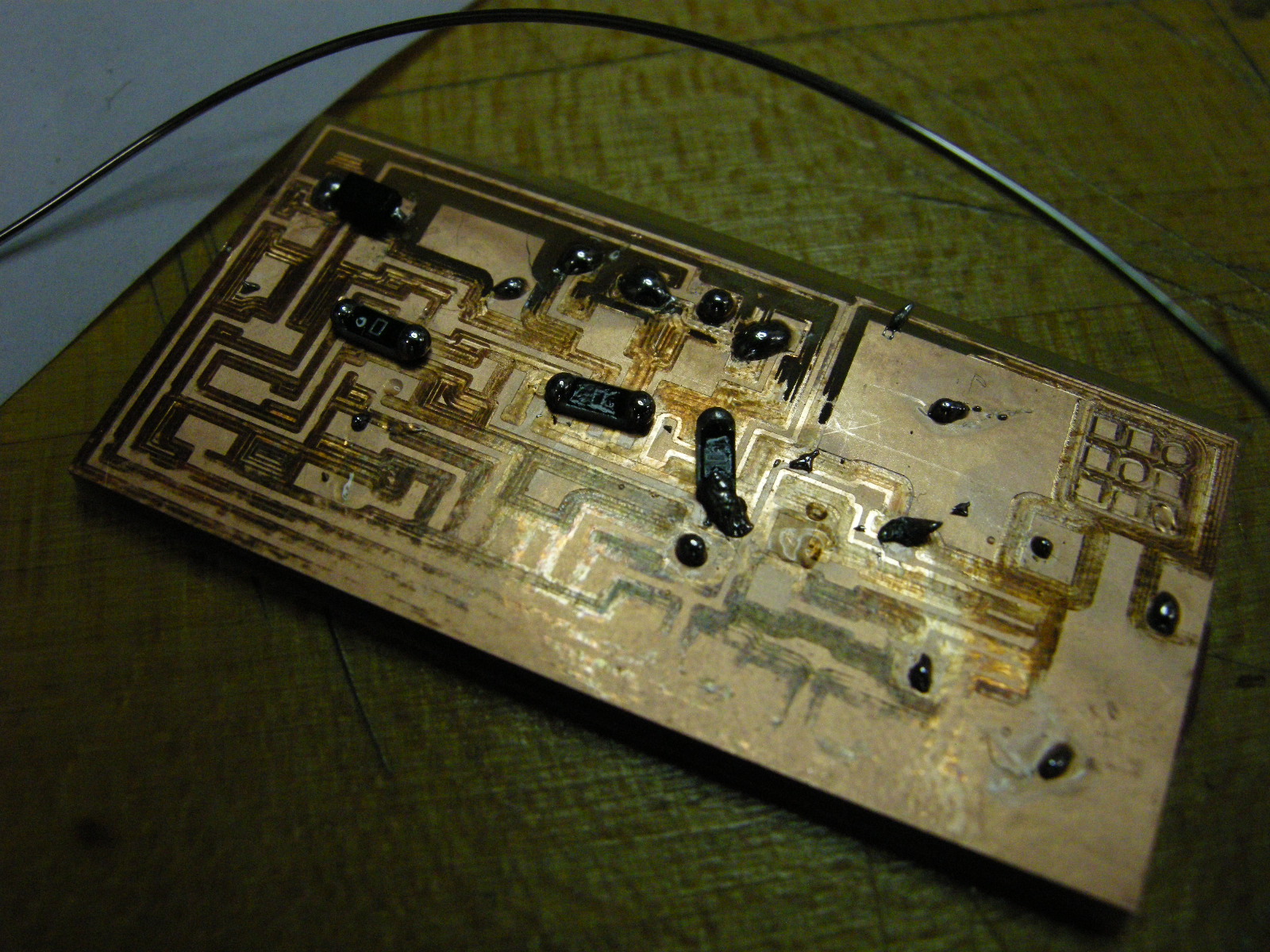

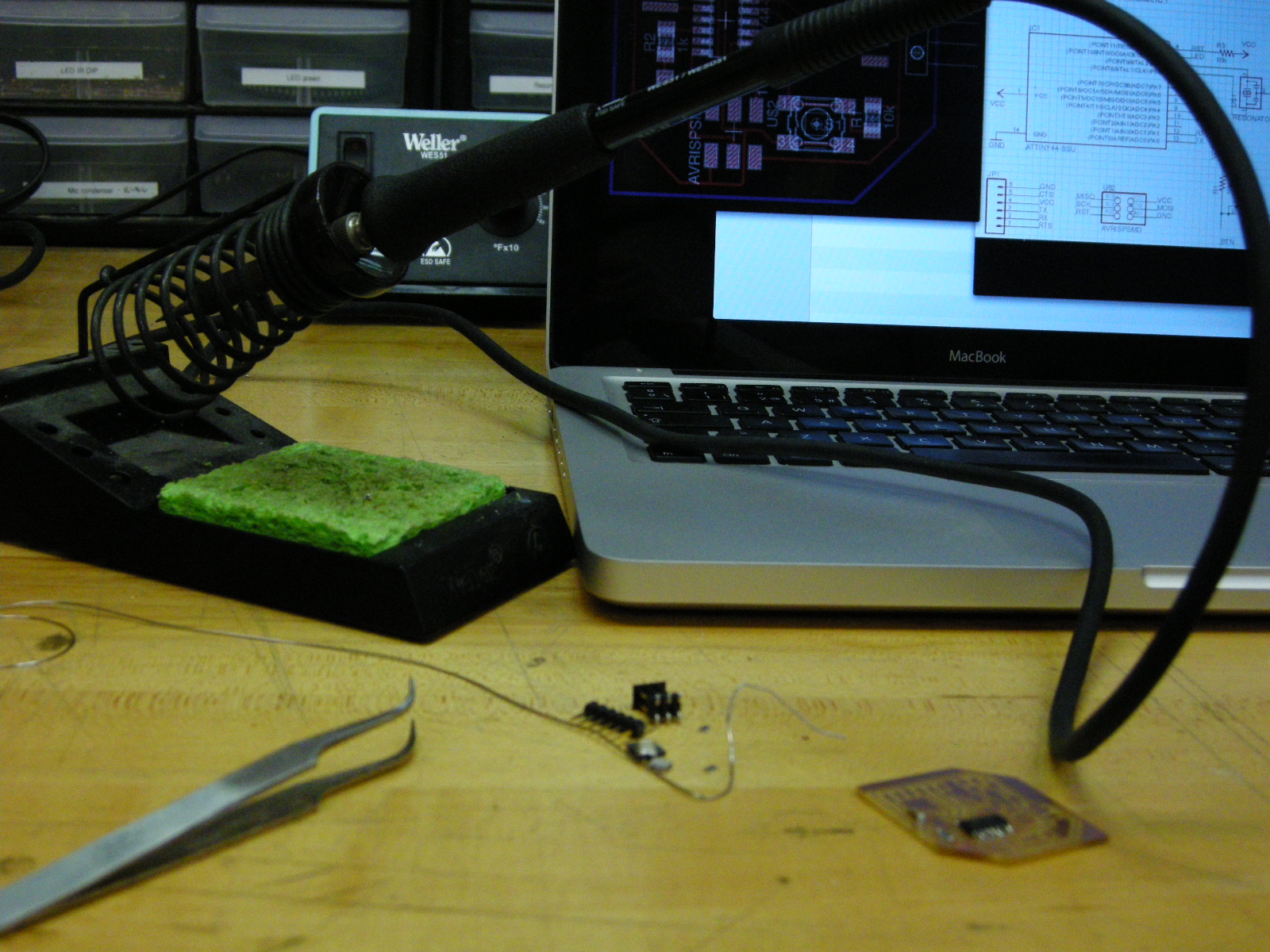

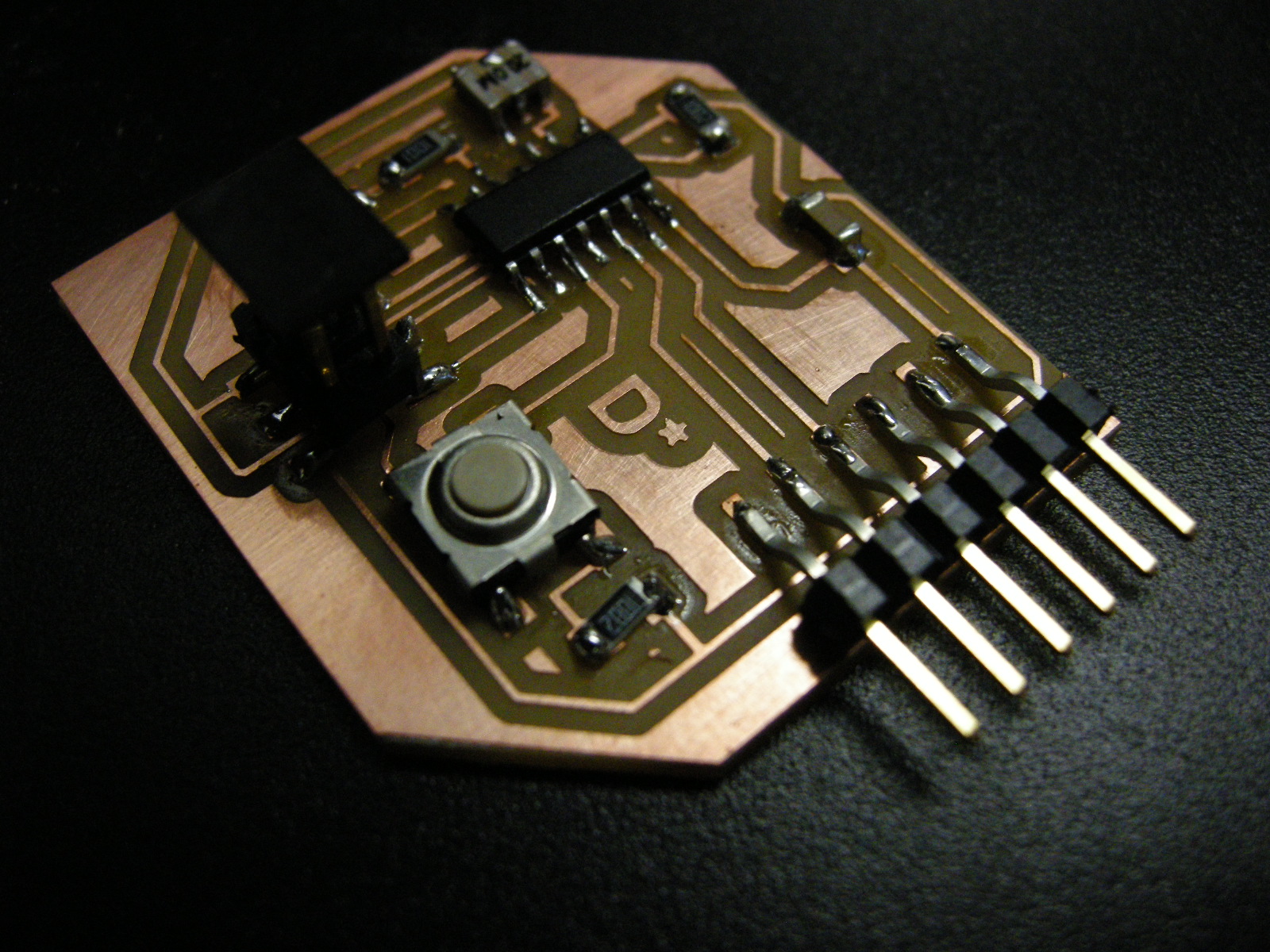

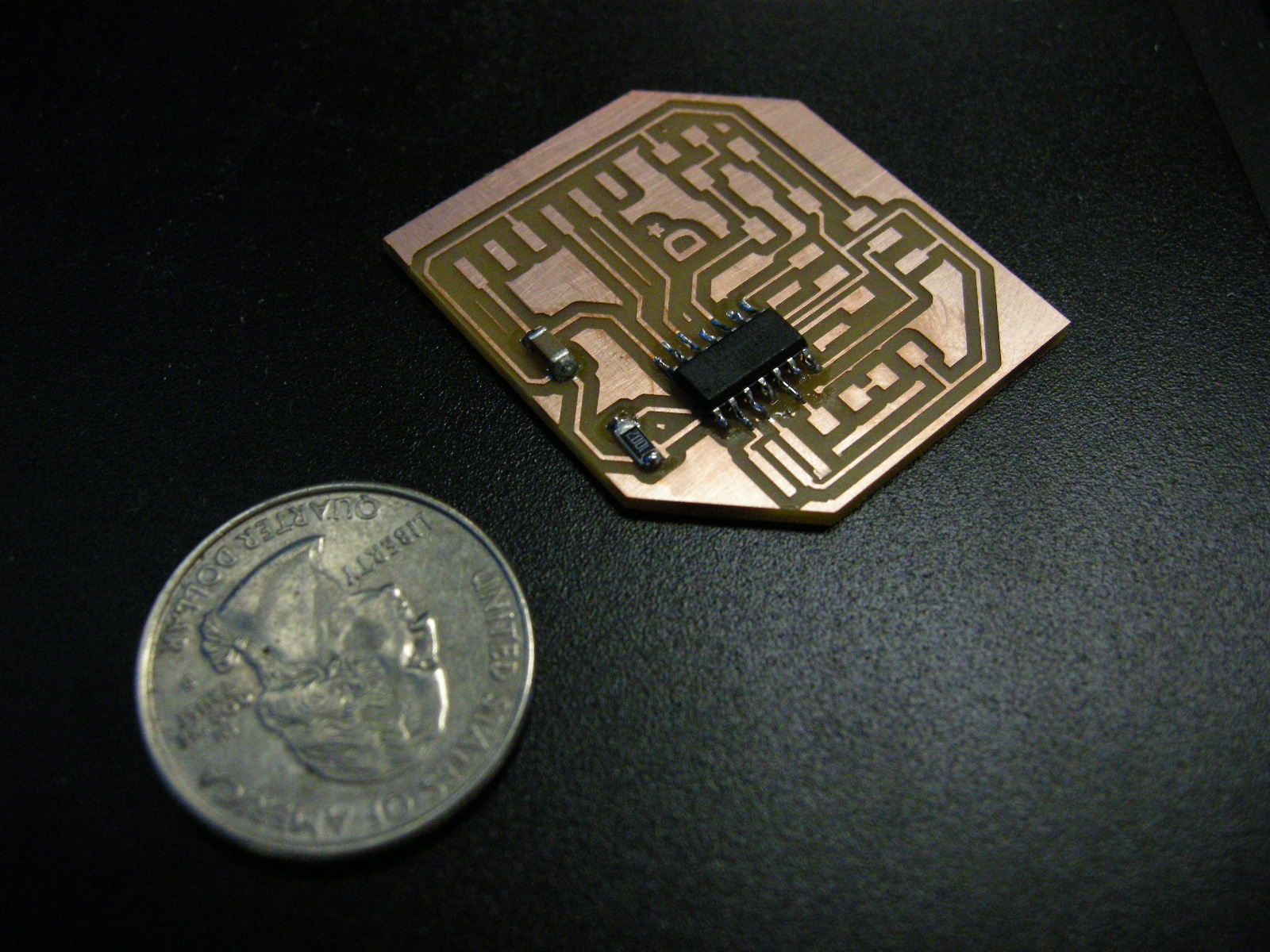

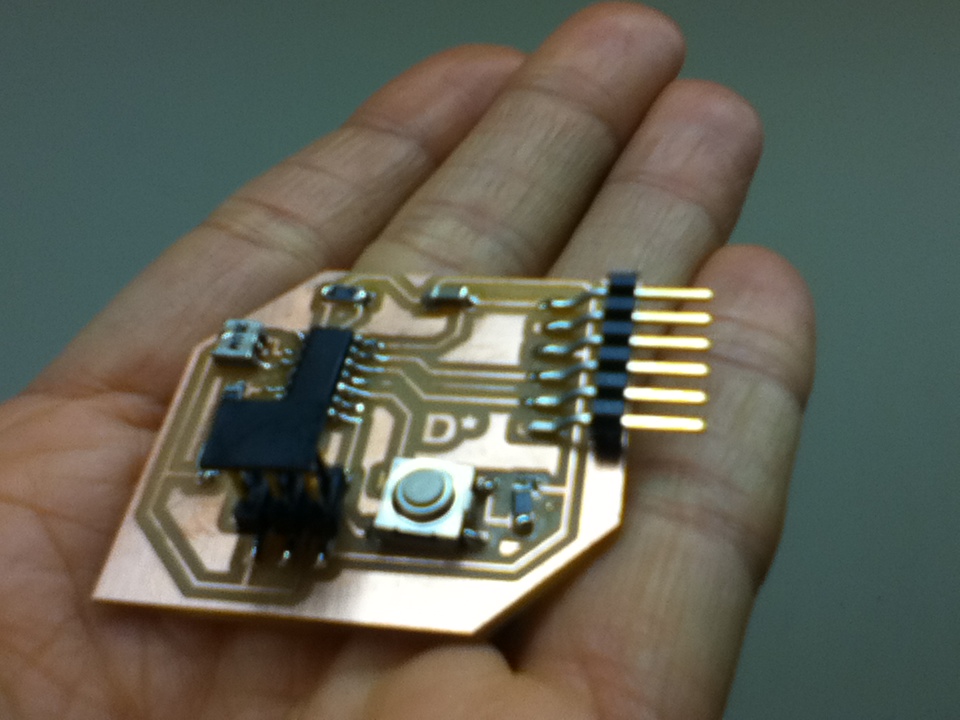

To fabricate this board we used the Roland Modela milling machine. Some of the main issues is the negotiation between the zero of the tool and the leveling of the bed. After milling, the board needs to be stuffed with the electronic components by soldering them very carefully.

|

|

|

Replace the sacrificial board it's not flat and clean. |

Nest your boards in order to save material. |

Place the trace drill (1/64) and find your zero. |

|

|

|

After milling traces, change te drill to 1/32 to cut out. |

Make sure you leave enough offset cut!!! |

Cut out the board. |

|

|

|

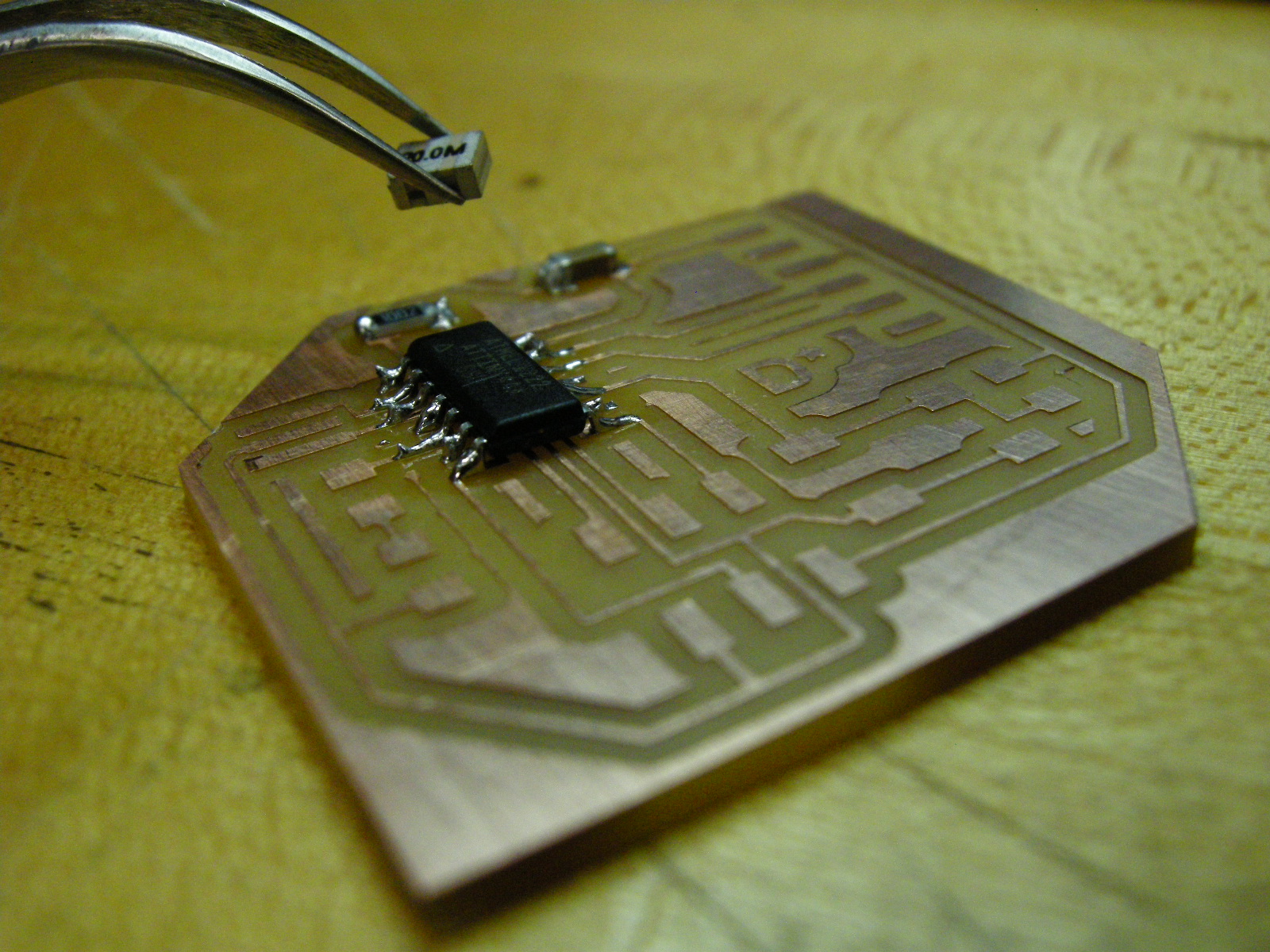

Soldering: always practice on a bad board... |

Double check your design for component orientation! |

The components are tiny, so use the tweezers. |

|

|

|

Make sure that, in Eagle, you are working with board and schematic at the same time. Also make use of the GRID resolution to better pack your traces. But think about the capabilities of drill size you will be using! Remember that Eagle is only a CAD software for electronics design, so dig up your High School knowledge to understand what you are doing...

For fabrication, always check if the Modela is milling deep enough. If it is not, you should zero it there where the traces are more shallow. If the bed is dirty, very damaged and not flat, change it! Replace the sacrificial board by a new one and you will save lots of time. Nest your boards in the material, but always give some offset margin for the drill around the cut traces. Finally, practice soldering somwhere else before attacking the final board.

Eagle Learning: v6.0 Manual LINK!

|

|

|