Casting is a manufacturing process by which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process.

Carve a block of wax to make a negative mold with the Roland Modela milling machine, use it to make a positive flexible mold with the Oomoo silicone rubber, and finally cast the piece with a dry stone solution.

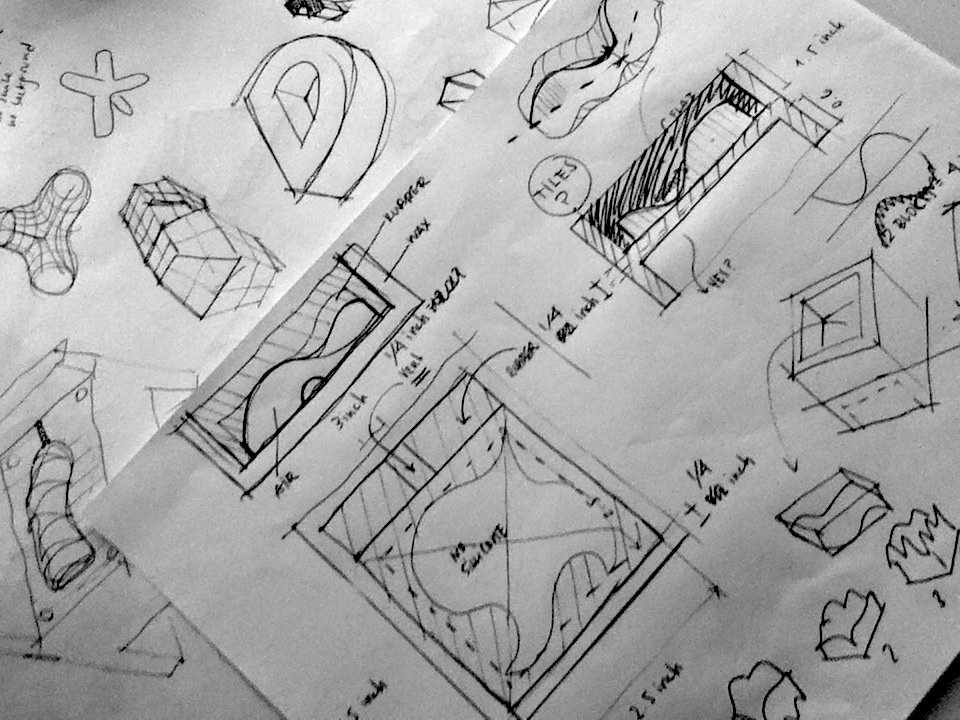

The wax is tiny... so plan ahead the geometry you want to mill. In my opinion, as the process is long, it is always better to build a mold for a repeatable unit, so it can proliferate into a system. For this case, I chose a 3d tiling system with 2 different complex surfaces sides.

|

|

|

Drafting a (TINY) 3d tile system. |

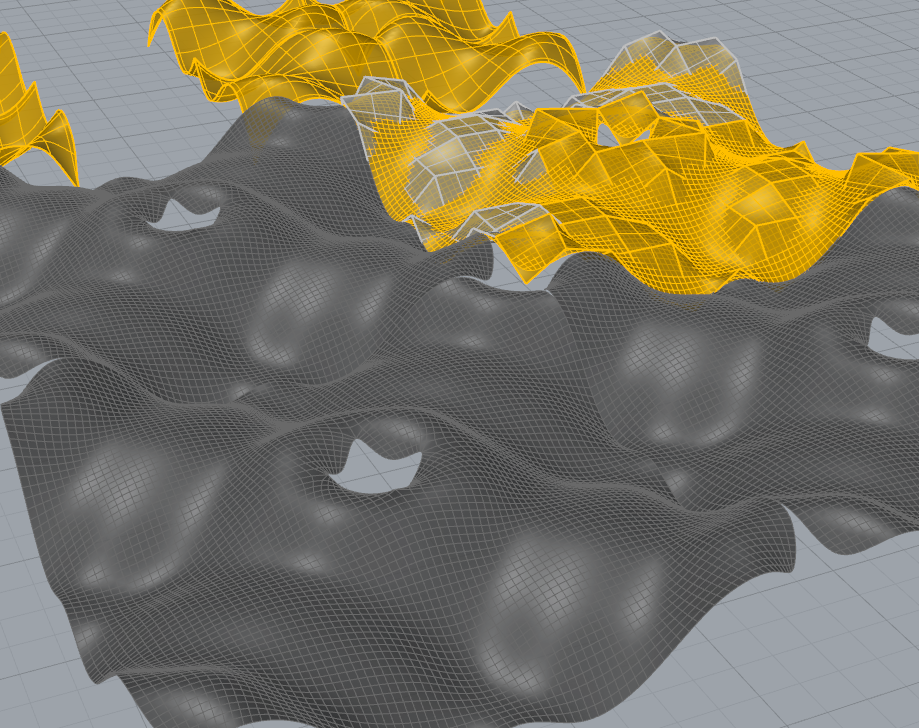

Proliferation (surface quads to smooth meshes). |

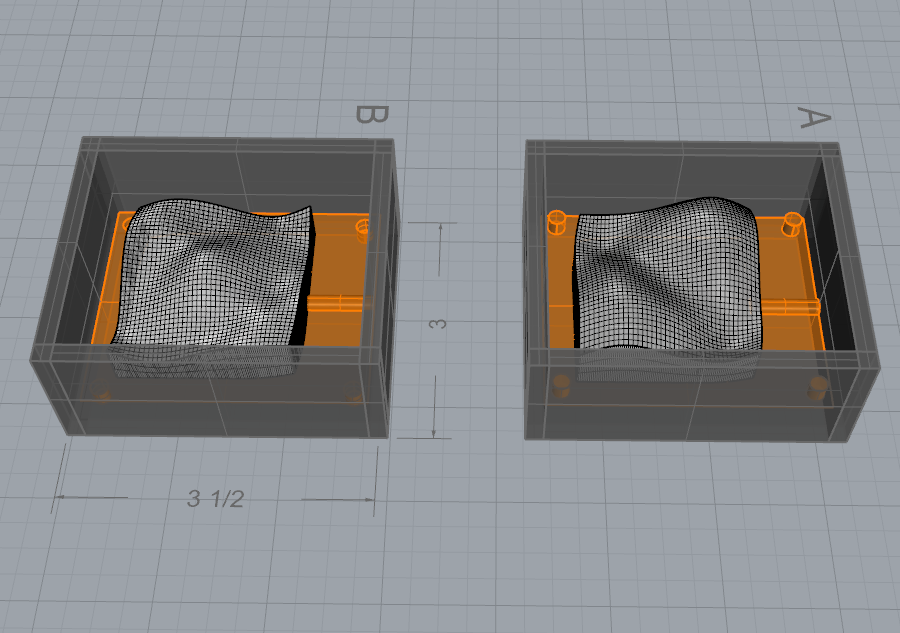

Final tiling geometry A & B. |

|

|

|

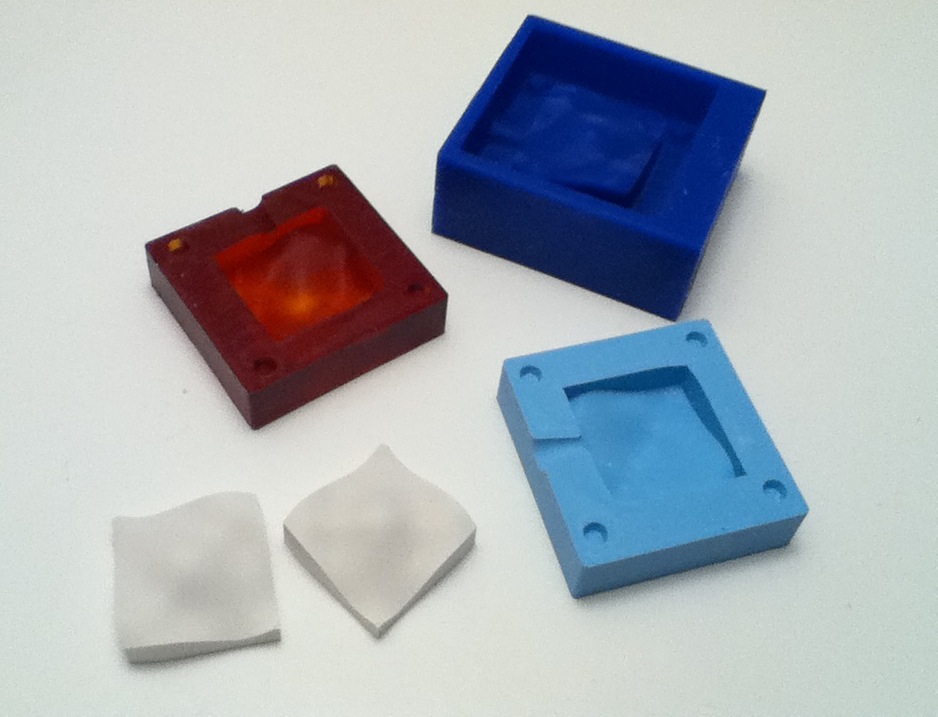

WAX > SLICONE > PLASTER |

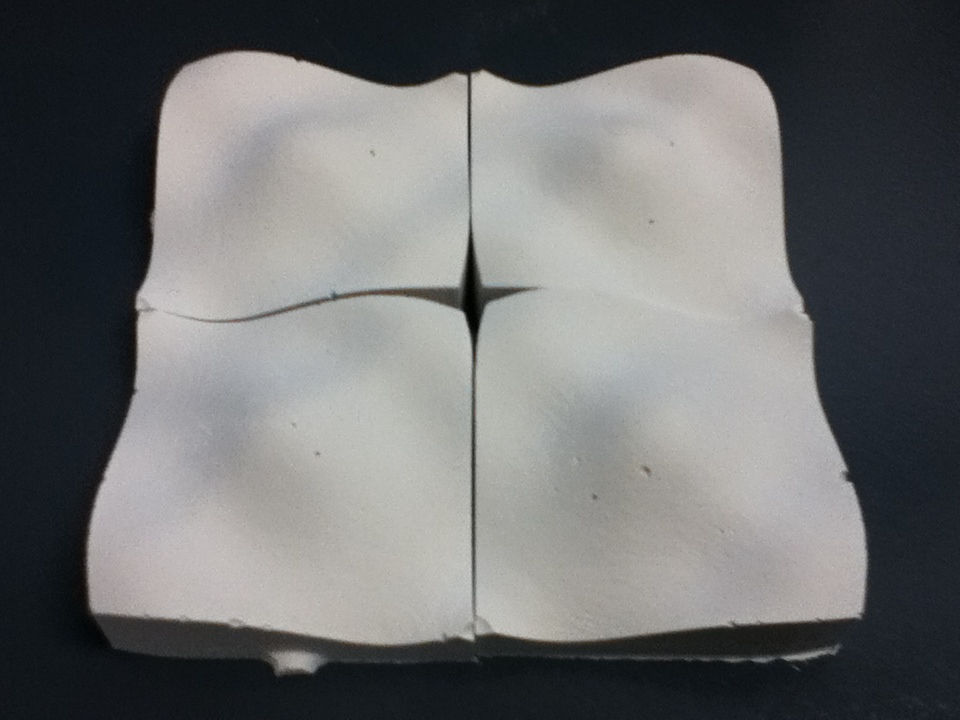

Sides A - free joint. |

Sides B - solid joint. |

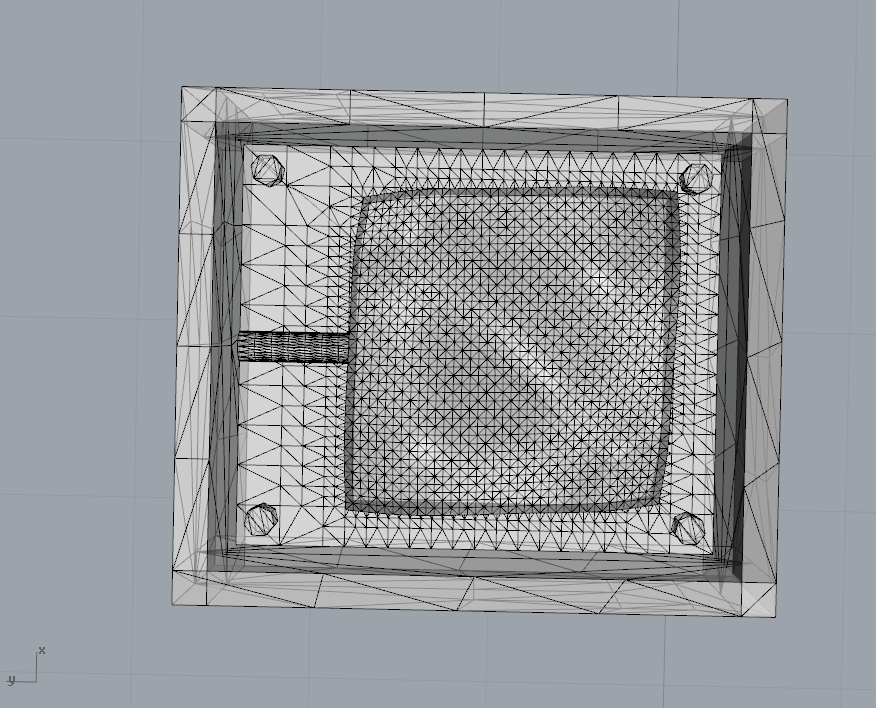

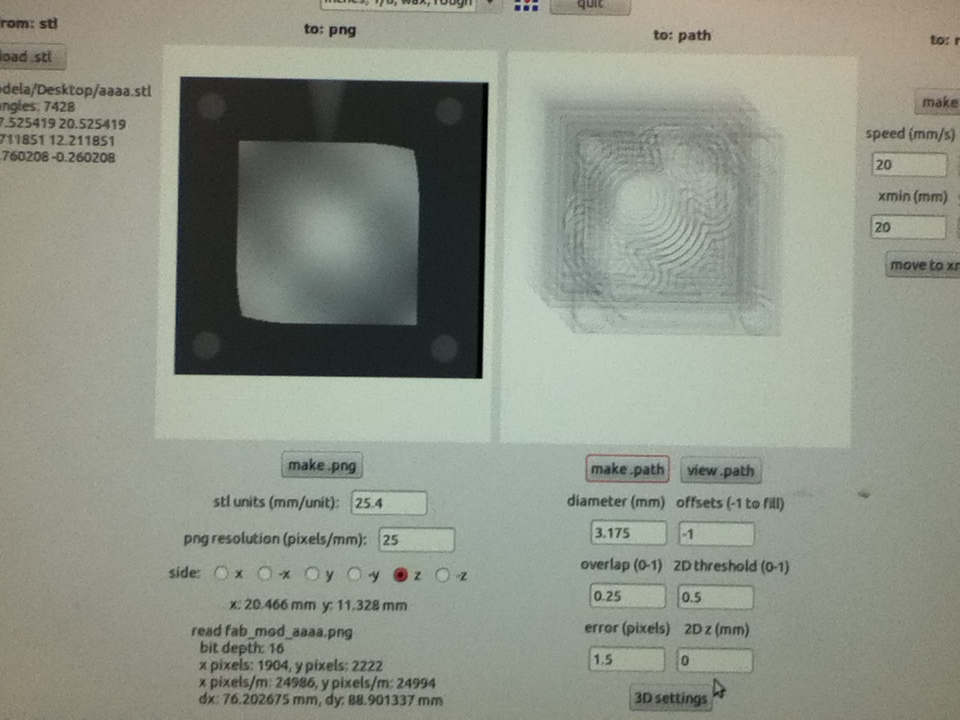

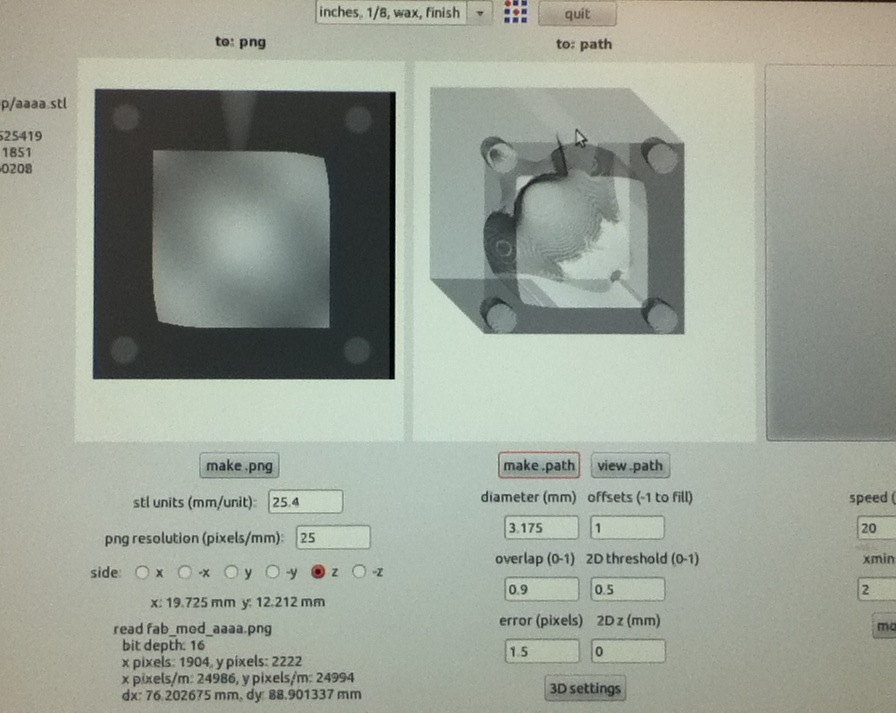

If your piece is not squared, make sure that your PNG and your WAX BLOCK are alighed the same way: the Modela will start milling from the bottom left corner up. It has a short tool, so do not create deep and narrow pockets because it will not reach or it will destroy your mold walls! Also make sure that your STL is a mesh block and test it back and forth on the fab modules png maker before jumping into the milling.

|

|

|

STL file. |

Map from STL to PNG (ROUGHING path). |

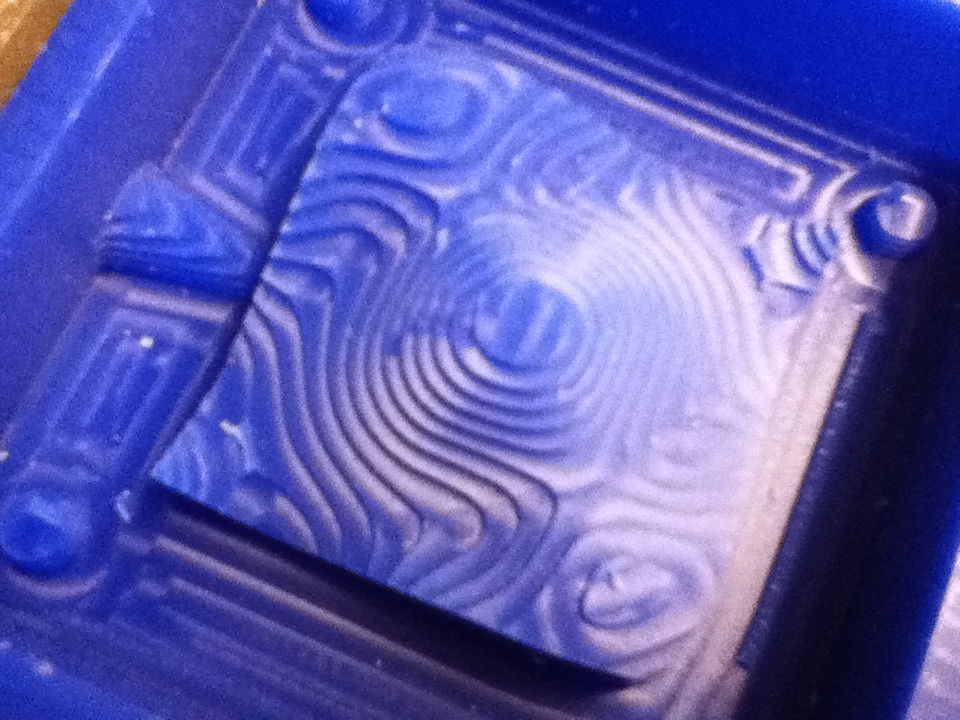

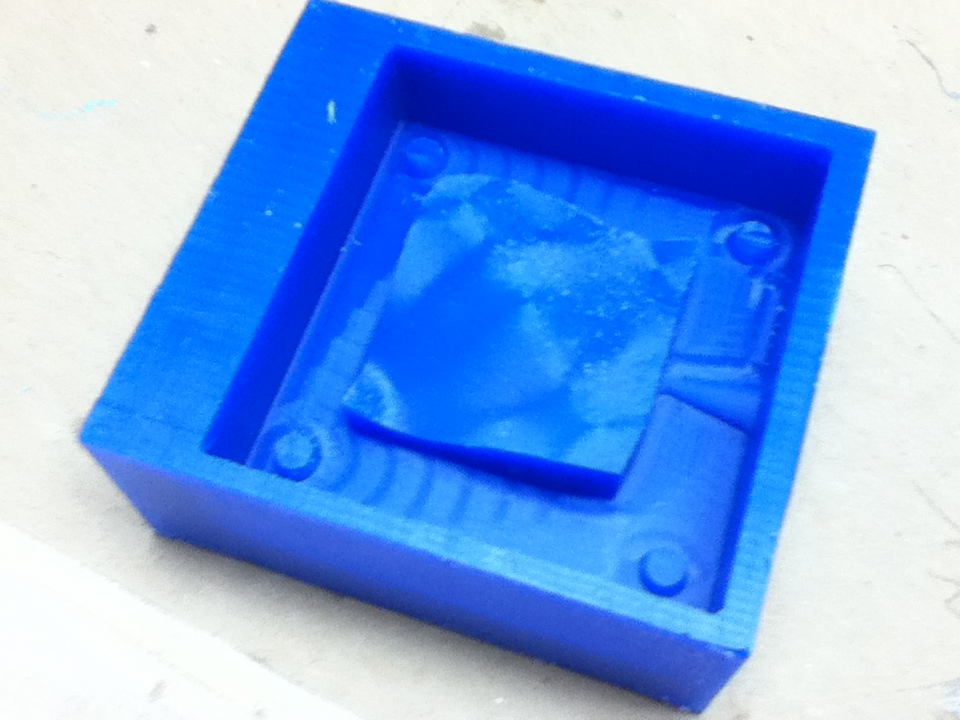

Carving... |

|

|

|

Beautiful roughing path. |

Map from STL to PNG (FINISHING path). |

Finished wax mold (Took 2h in the Modela). |

|

|

|

|

|

|

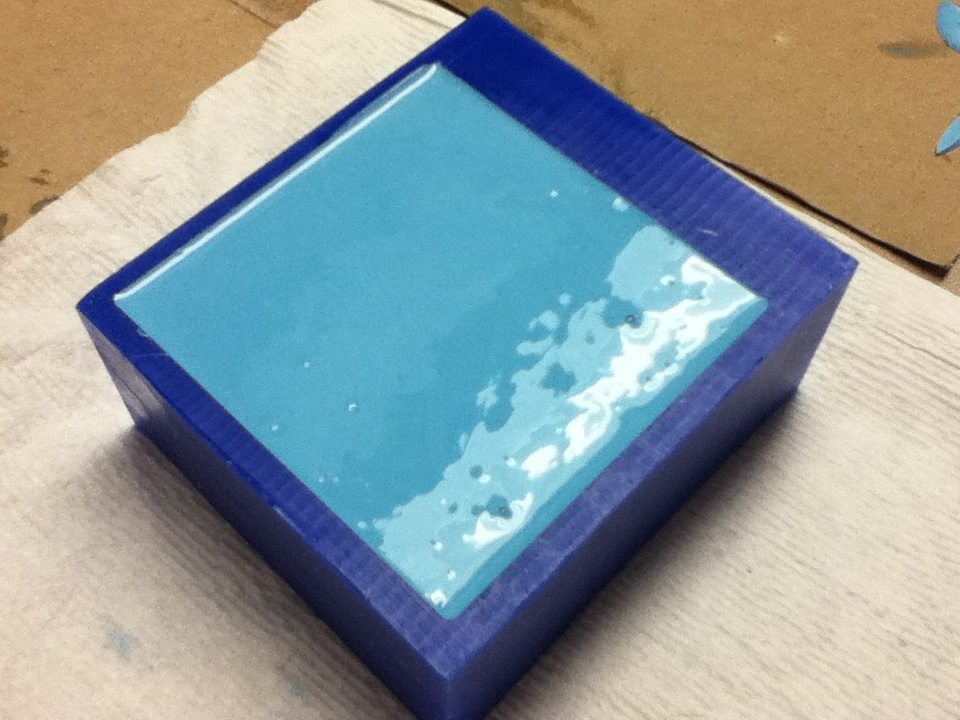

Silicone rubber preparation 2 types -> OOMOO/PMC. |

1:1 -> 70g each. Curation time 75min. |

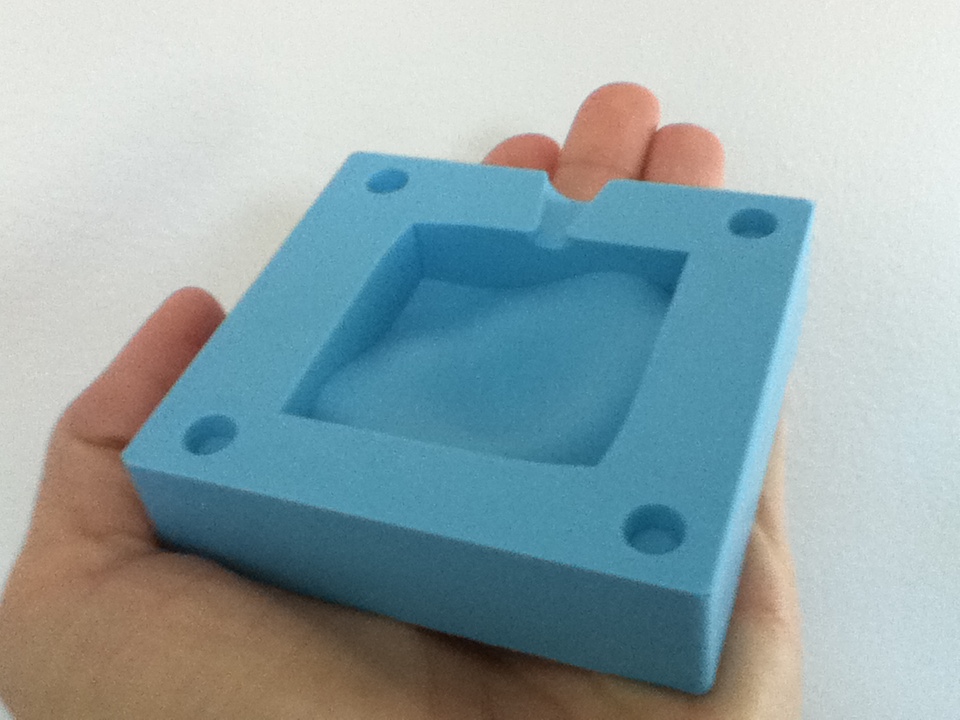

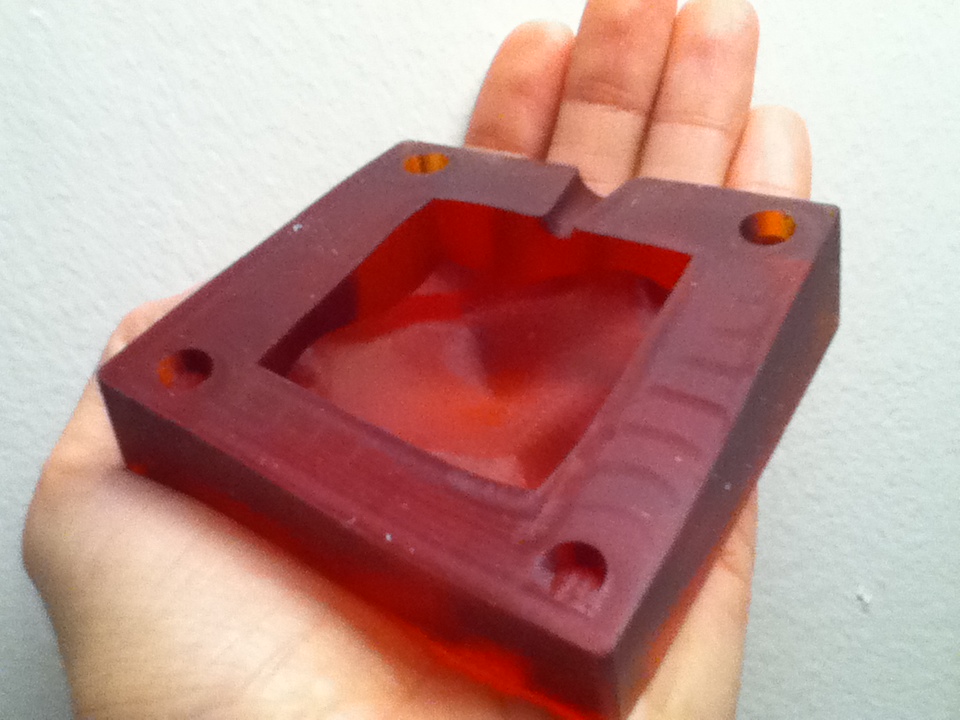

Flexible molds. |

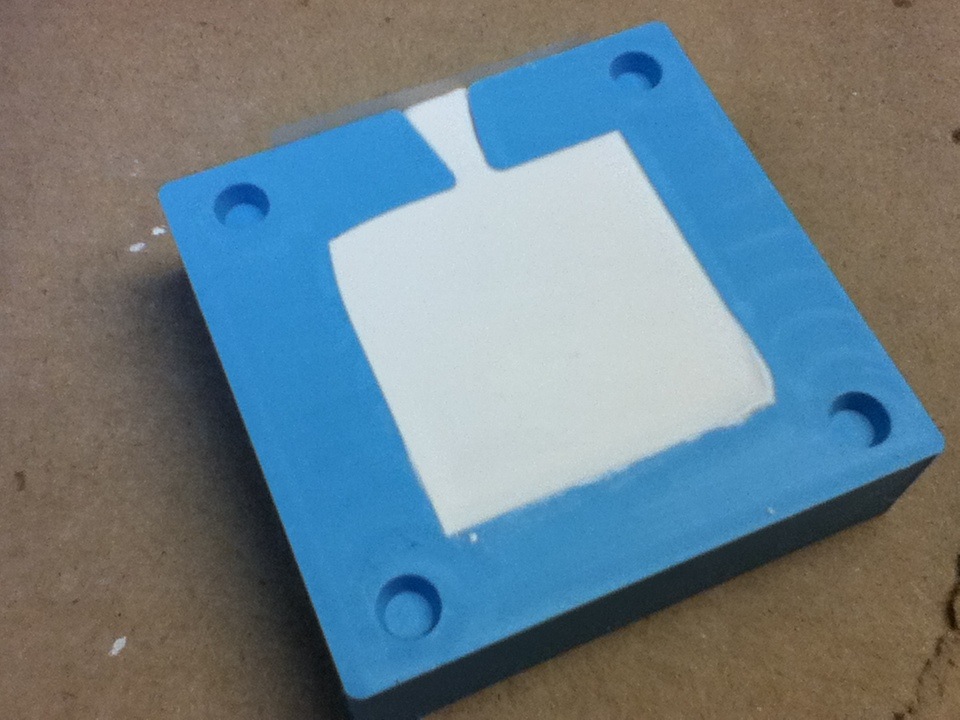

For the dry stone casting, I started with one sided piece production. Then transitioned to a two sided mold for a complete 3d tile.

How to avoid air bubbles: 1-when mixing the powder with the water, make sure you pour it in like if you were salting food, 2-pour the mixture slowly into the rubber mold, 3-vibrate the table arround it once pourred.

|

|

|

Dry stone solution. (20g water->100g powder) |

Curation time 60min. (Don't forget to vibrate!) |

Final one sided piece. |

|

|

|

Two sided mold (low tech fixture). |

Curation time 120min. |

Final two sided piece. |

|

|

|

The wax blocks: LINK! |

The silicone rubber: LINK! |

The dry stone: LINK! |