Final Project 1-2 Step

Dancing Bugs

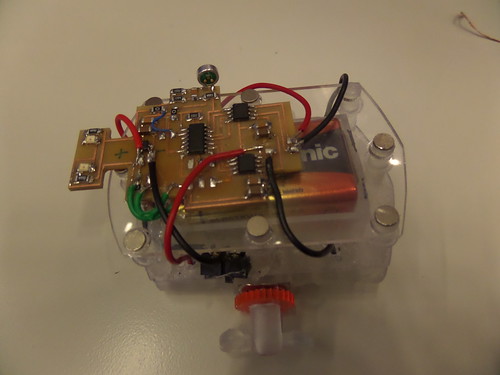

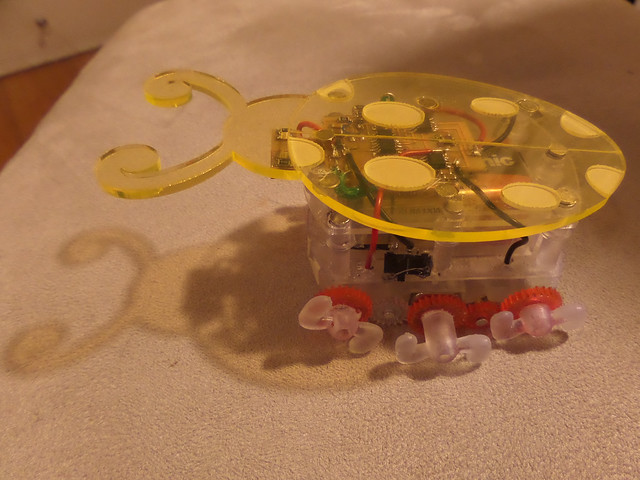

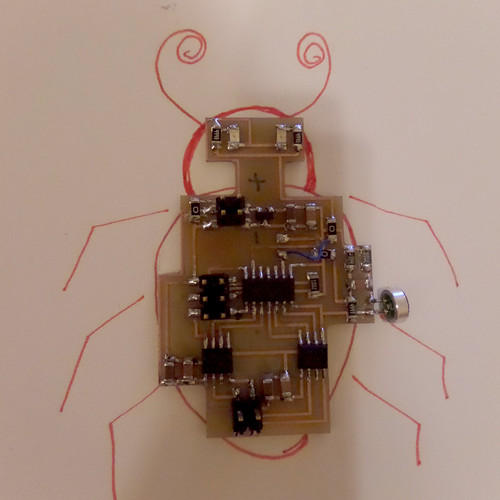

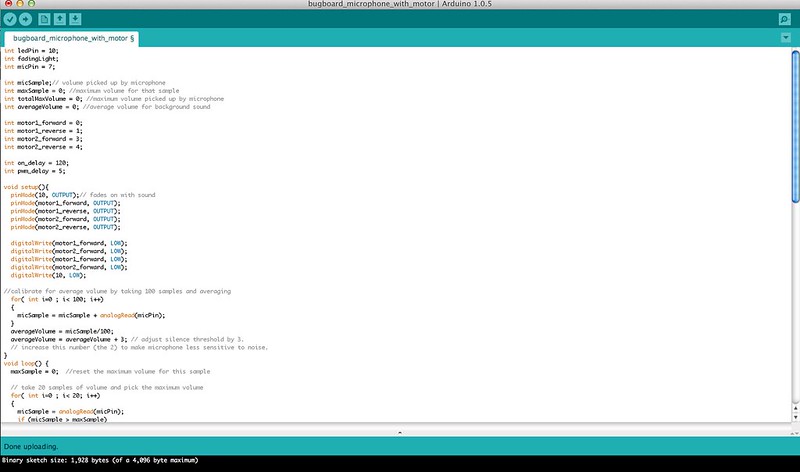

My final project is a dance performance of motorized bugs that responds to your footsteps and moves in certain patterns based on the number of footsteps.

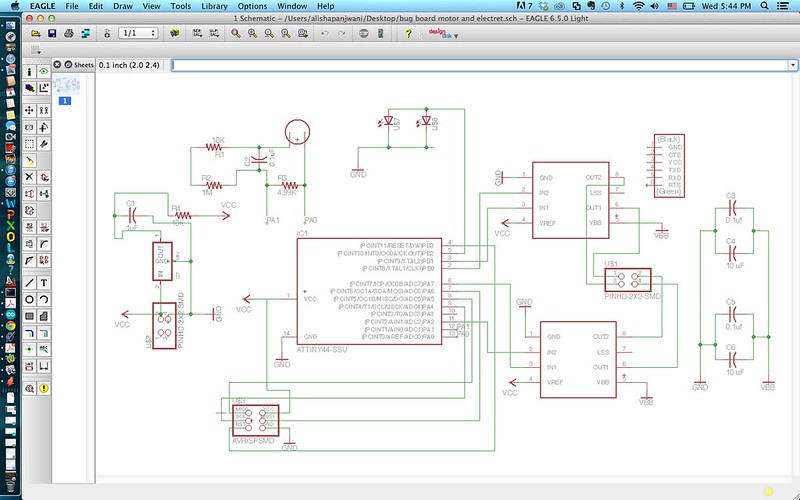

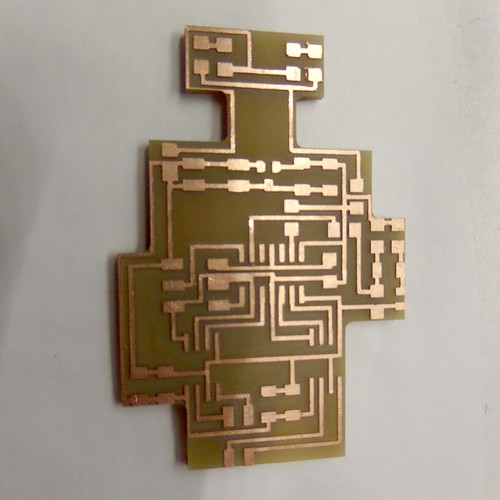

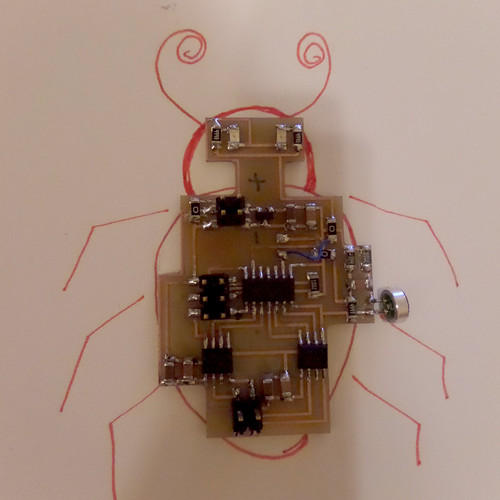

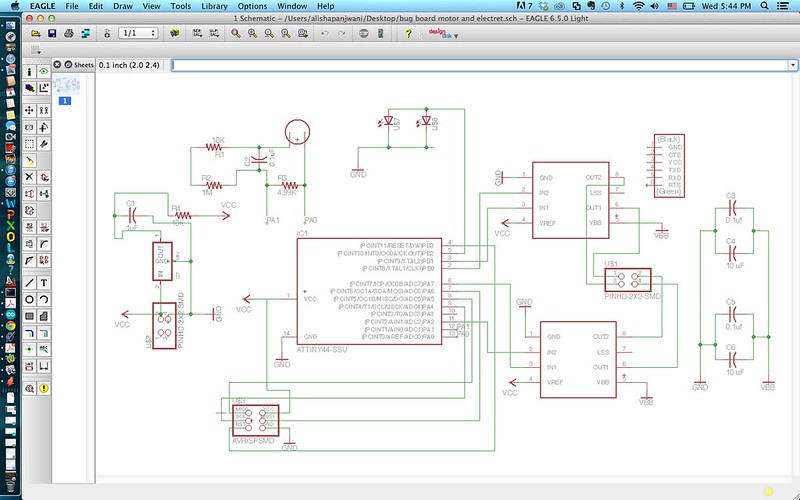

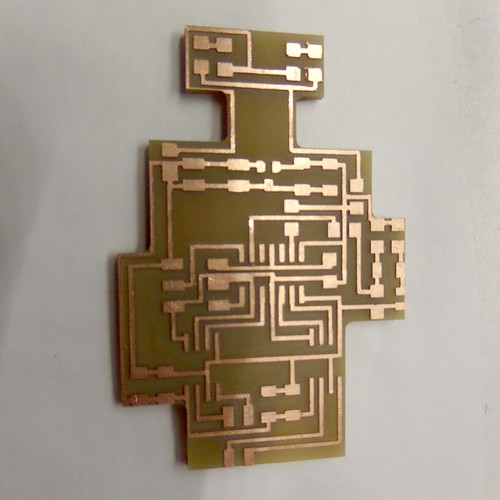

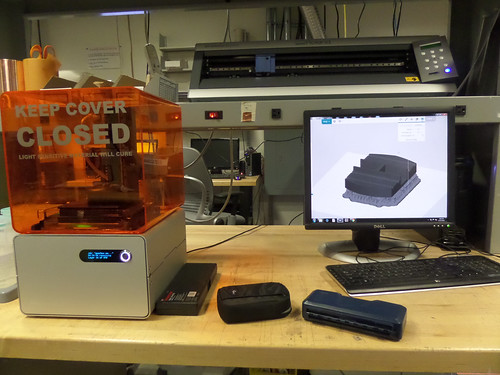

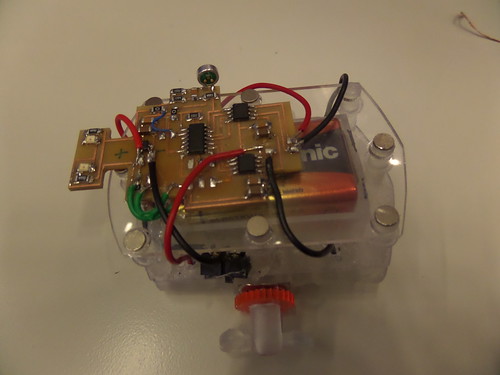

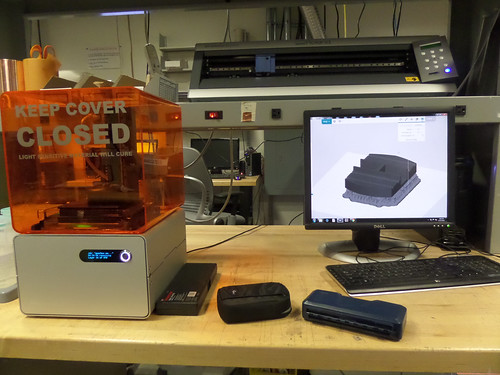

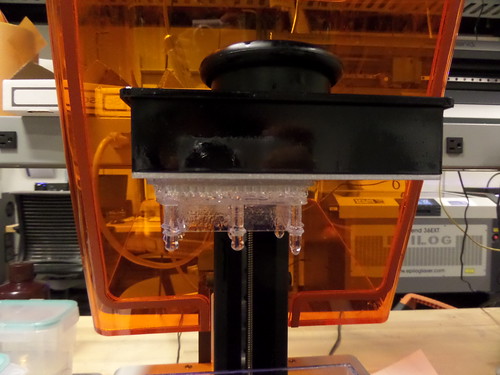

I designed the board using ATtiny 44, electret microphone and 2 DC motors with H bridge and LEDs, milled it and programed it using Arduino. I 3D designed and printed parts of the bug using Formlabs printer. I laser cut gears and the top bug body part.

I designed the board using ATtiny 44, electret microphone and 2 DC motors with H bridge and LEDs, milled it and programed it using Arduino. I 3D designed and printed parts of the bug using Formlabs printer. I laser cut gears and the top bug body part.

Final model

Inspiration

I have always been interested in the idea of kids making their own toys.

Some kids I worked with before were really into critters.

They wanted to create critters that could sense, illuminate, spin, turn and move in all directions.

I love hex bugs. For this project I want to create my own version that responds to sound and can dance.

For the press fit kit assignment I created foam sheet bugs. I am modifying the same design for the final project.

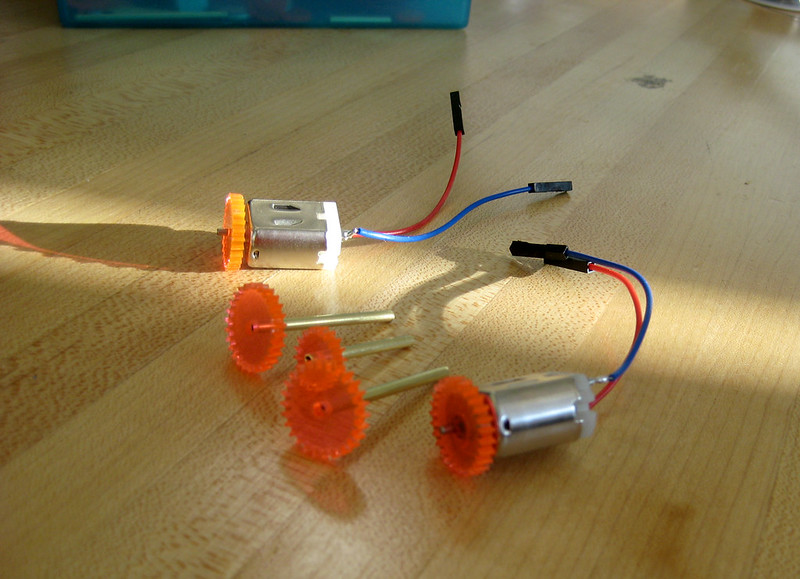

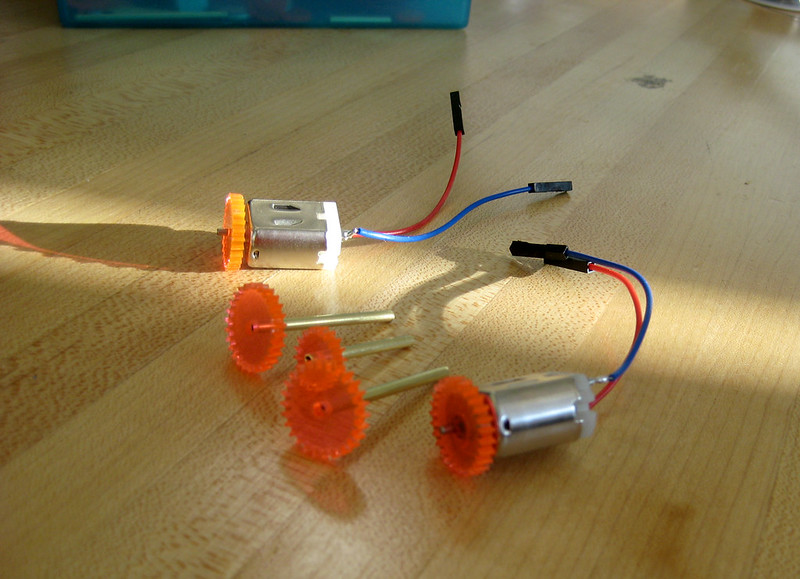

Dancing bug has two DC motors, a sound sensor and an LED array. The most challenging part is designing the physical components. I wanted to focus on the size and make everything smaller. I tried using an extremely small DC motor. But fabricating smaller parts would be really difficult. So I am trying to make it smaller but not super tiny.

I love hex bugs. For this project I want to create my own version that responds to sound and can dance.

For the press fit kit assignment I created foam sheet bugs. I am modifying the same design for the final project.

Dancing bug has two DC motors, a sound sensor and an LED array. The most challenging part is designing the physical components. I wanted to focus on the size and make everything smaller. I tried using an extremely small DC motor. But fabricating smaller parts would be really difficult. So I am trying to make it smaller but not super tiny.

Designing the board

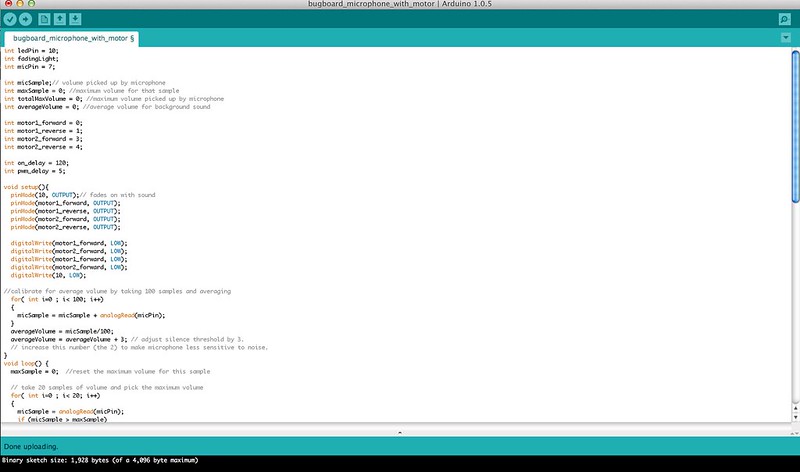

Programming

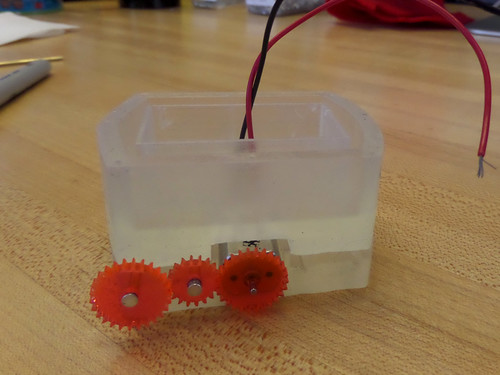

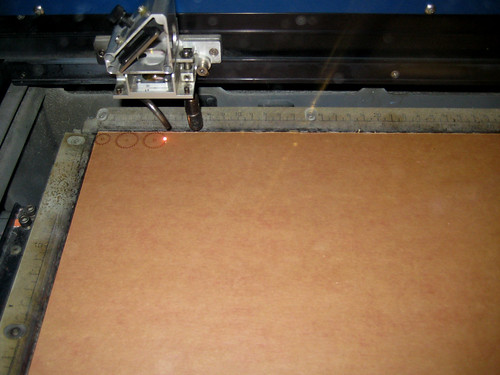

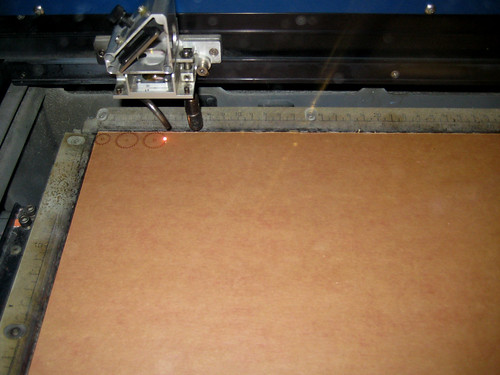

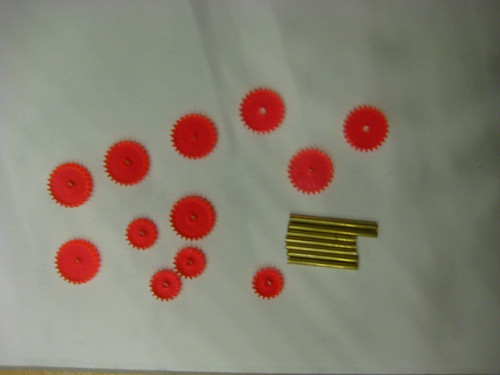

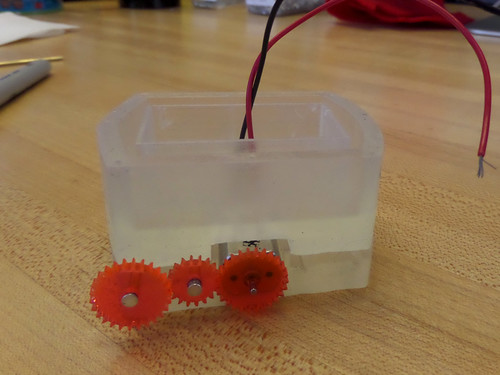

Designing and Laser cutting Gears.

I tried to make a press fit gear with the motor. I used a caliper tool to take measurements and used inkscape to make gears.

Here is a nice tutorial about making own gears.

While designing meshing gears the Diametral Pitch, circular pitch and the pressure angle for both the gears should be the same.

While designing meshing gears the Diametral Pitch, circular pitch and the pressure angle for both the gears should be the same.

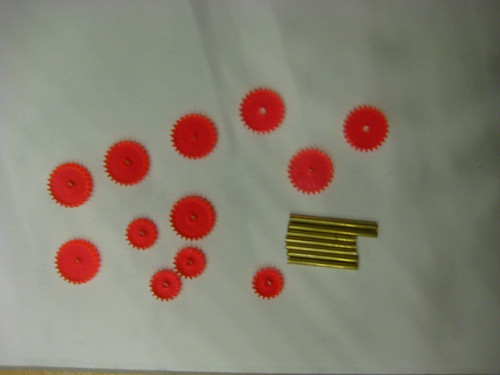

I tried to make the pressfit gears for the motors but only one could fit on the motor. I used epoxy to attach the gears to the motor.

I used 3/32" brass rods to make the shafts and added tiny rivets at the end. Some laser cut gears could fit the rod and some couldn't Also the inner laser cut hole for all the gears wasn't perfect circle. Matt suggested that I use a drill bit. to make holes.

While designing meshing gears the Diametral Pitch, circular pitch and the pressure angle for both the gears should be the same.

While designing meshing gears the Diametral Pitch, circular pitch and the pressure angle for both the gears should be the same.

I tried to make the pressfit gears for the motors but only one could fit on the motor. I used epoxy to attach the gears to the motor.

I used 3/32" brass rods to make the shafts and added tiny rivets at the end. Some laser cut gears could fit the rod and some couldn't Also the inner laser cut hole for all the gears wasn't perfect circle. Matt suggested that I use a drill bit. to make holes.

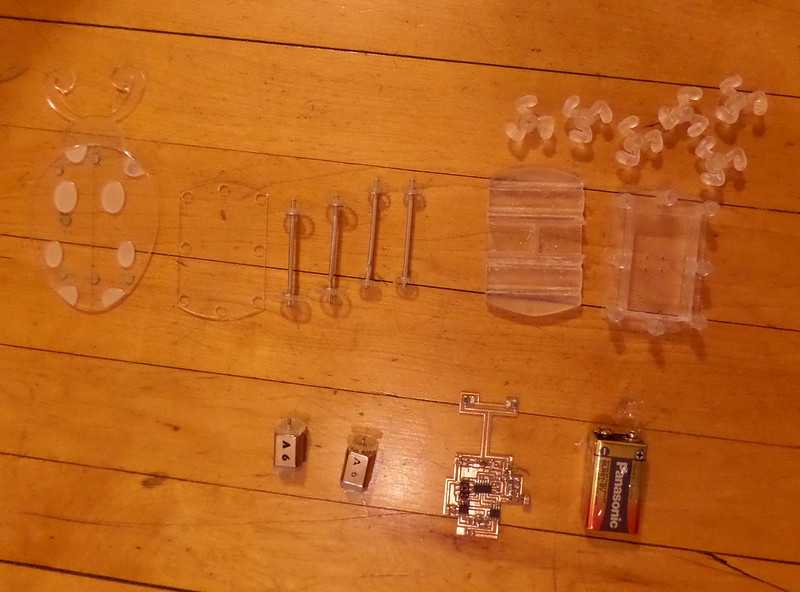

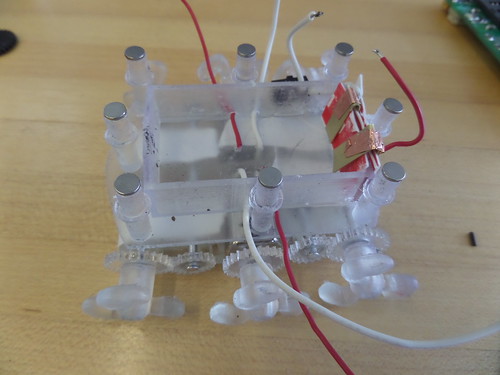

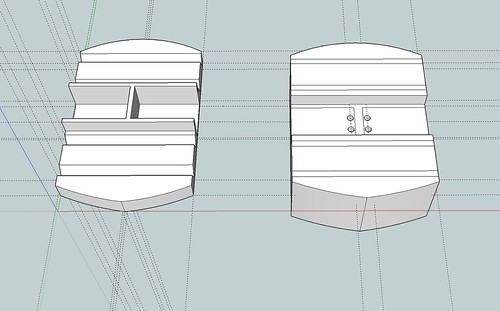

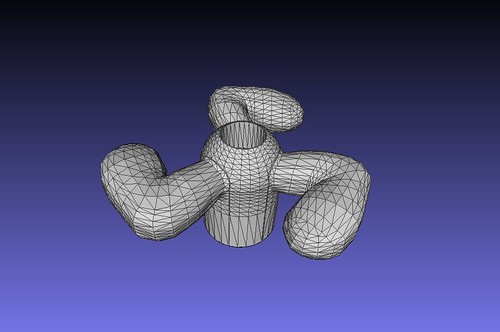

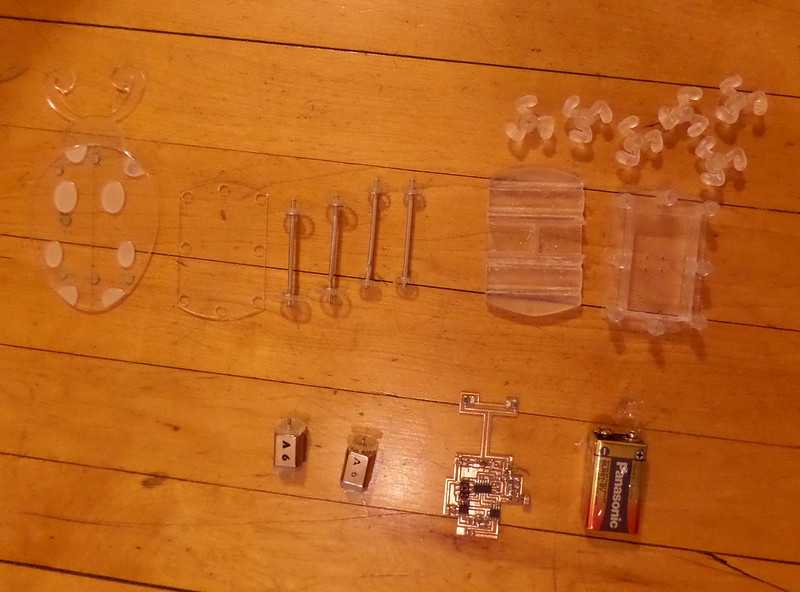

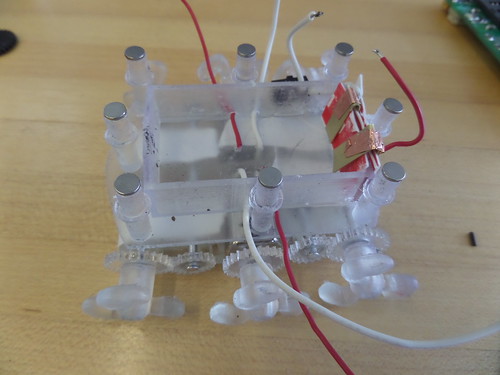

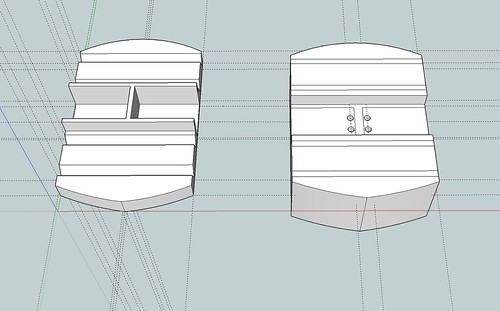

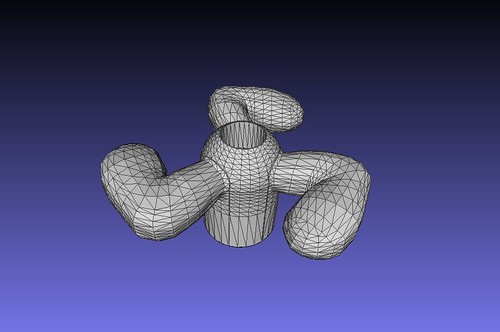

3D Designing and 3D printing the gear box

For my design I wanted to attach two motors to the bug to make it move straight and also to be able to take turns.

I needed a gear box and enclosure for battery.

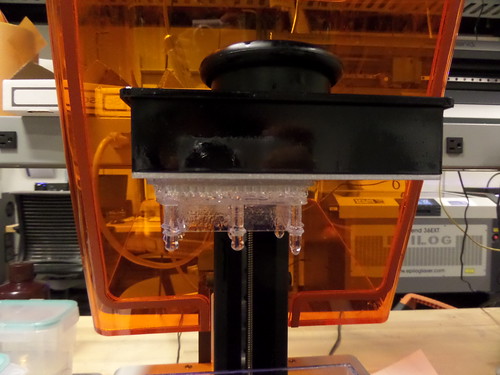

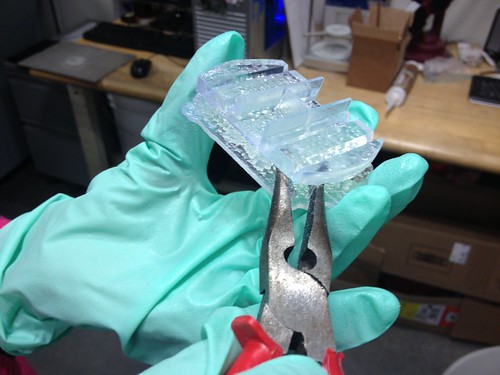

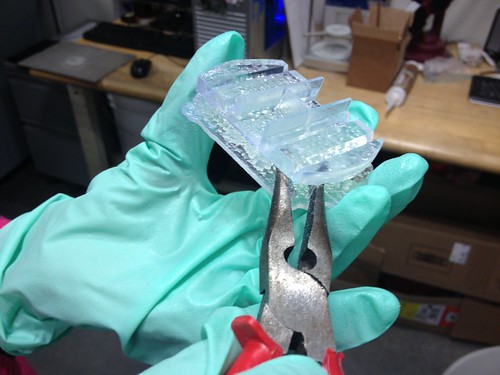

I used Formlabs 3D printer to print my parts. It gives great finish but takes a really long time. Also Some of my parts came broken. Removing the support material is also way too tricky.

I created two versions of the enclosure and legs.

I used Formlabs 3D printer to print my parts. It gives great finish but takes a really long time. Also Some of my parts came broken. Removing the support material is also way too tricky.

I created two versions of the enclosure and legs.