Week 12: Networking and Communications

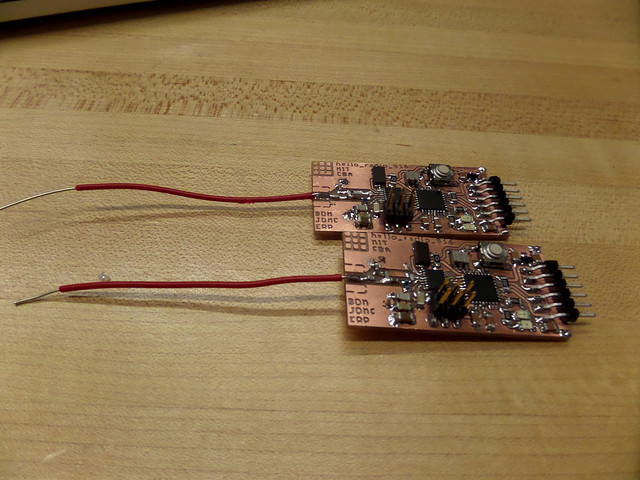

I wanted to experiment with wireless networking. I decided to make the hello radio boards. Hello_radio board is a radio

that can send and receive data in the form of radio waves. It is based on the transceiver MRF49XA.

The entire process took a really long time and I couldn't manage to get it to work.

Milling the board

I used the same steps as suggested on the tutorial page. The traces of the board are really small.

My first board didn't get milled properly and there were some incomplete traces. I reduced the machine

speed from 4 mm/s to 2.8 mm/s. The other boards came out fine.

Stuffing the board

Before stuffing I checked the traces on the board. The components of the boards are super tiny and it took a lot of patience to solder the parts onto the board.

I soldered ATMEGA168 chip first, then MRF49XA and then the rest of the parts. Inductors and some capacitors were super tiny and the most difficult parts to solder on the board.

It was difficult to even hold them in place using tweezers.

Ermal showed me how to fill vias. You need a thin non insulated wire, put it through holes and then solder on both the sides of the board.

Ermal showed me how to fill vias. You need a thin non insulated wire, put it through holes and then solder on both the sides of the board.

Programming the board

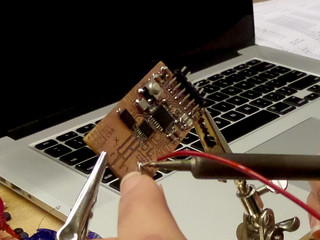

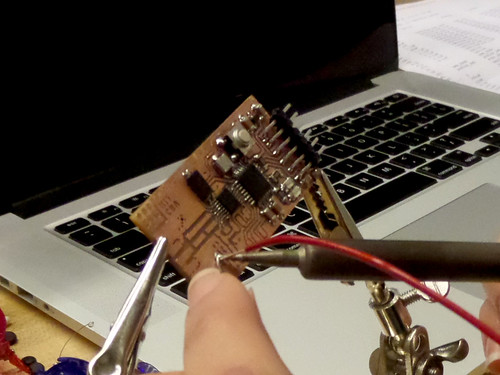

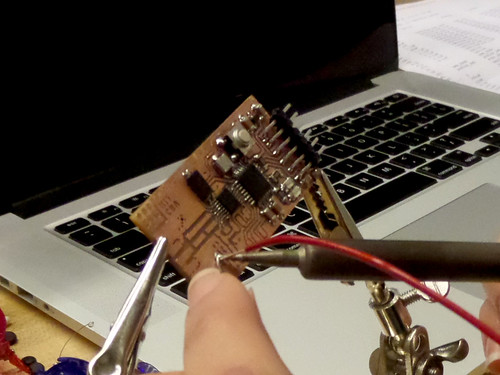

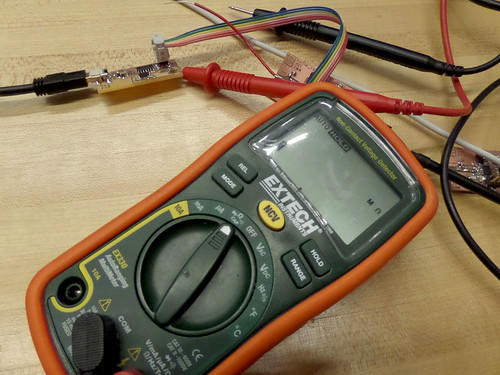

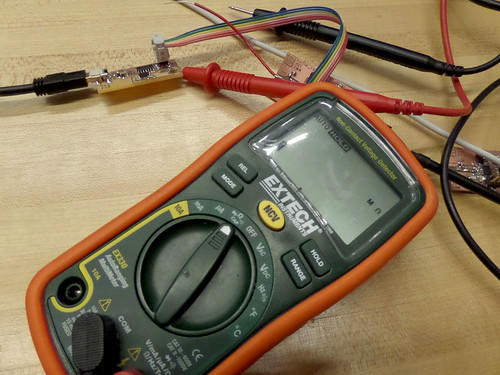

When I plugged the board onto my computer I noticed that there was short circuit in one of the board.

I checked all the connections using multimeter and fixed some errors. Since the traces are so close to each other and the parts

are tiny, you can easily mess up the connections while soldering. Amir suggested to use the microscope in the changing places group.

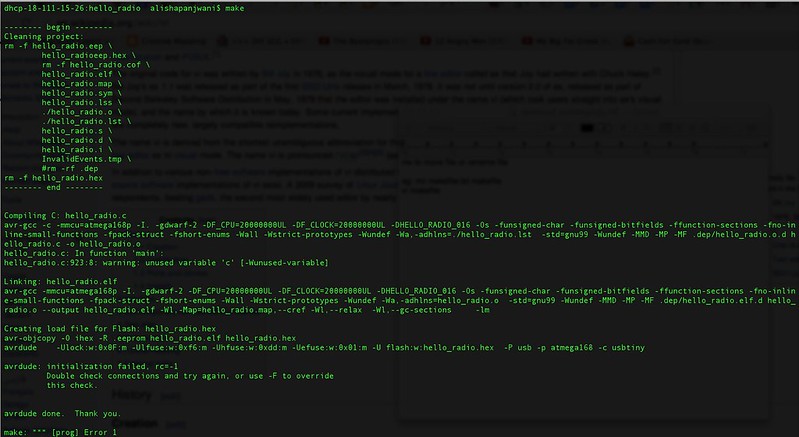

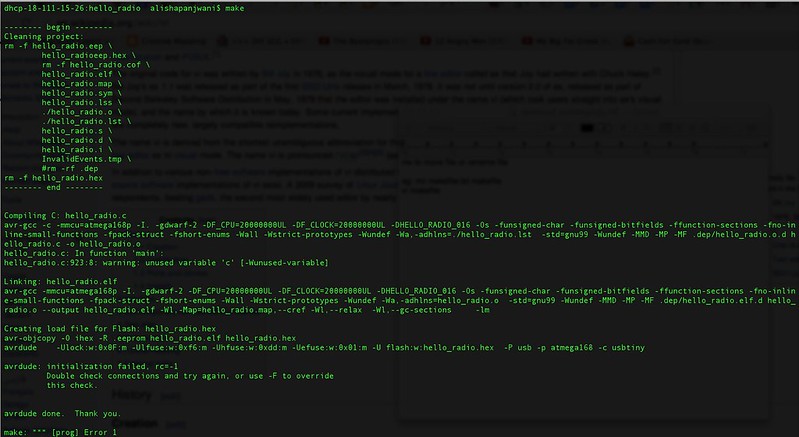

When things seem okay, I attached the board to FTDI cable and Fab ISP to program the board. I kept getting error. I still don't know whats wrong and spent a lot of time fixing the board but no luck.

This was very challenging for me. I made two boards and none of them worked. Soldering took a really long time and debugging even more. I should have just made another board. It is really difficult to make changes once the parts are already soldered. Desoldering is even more tricky and needs lot of patience. I used hot gun to remove some parts to fix a connection but ended up removing other parts and messing up with the correct ones. If I were to do this again, I will check my connections after soldering each part on to the board and not wait till the end.

When things seem okay, I attached the board to FTDI cable and Fab ISP to program the board. I kept getting error. I still don't know whats wrong and spent a lot of time fixing the board but no luck.

This was very challenging for me. I made two boards and none of them worked. Soldering took a really long time and debugging even more. I should have just made another board. It is really difficult to make changes once the parts are already soldered. Desoldering is even more tricky and needs lot of patience. I used hot gun to remove some parts to fix a connection but ended up removing other parts and messing up with the correct ones. If I were to do this again, I will check my connections after soldering each part on to the board and not wait till the end.