Week 2: Press-Fit Construction Kit

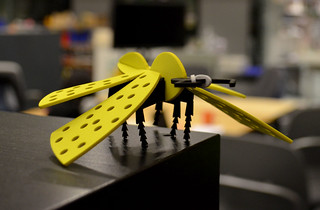

This week for our press-fit construction assignment, I decided to make insect construction kit.

Process

Experimenting with the material

I wanted to make my press fit construction kit using EVA (Ethylene vinyl acetate) foam sheets.

I have used it before in many of my craft workshops with children.

I like it because they are flexible, easy to cut, are available in vibrant colors and can be easily found in any craft store.

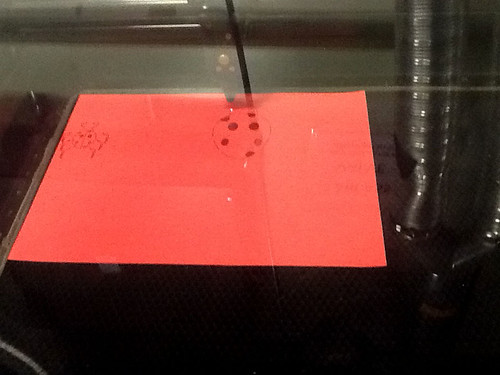

I wasn’t too sure if I could cut it using a laser cutter. I was afraid that it might catch fire. I started using a vinyl cutter to cut the foam sheet.

I changed the knife settings and tried various combinations of force and speed. None of them worked and the edges of the shape were not smooth. Because of the flexibility of the material, vinyl cutter wasn’t the right choice. I checked the

Epilog Laser website to find out if it is okay to cut EVA foam sheets and decided to use the laser cutter.

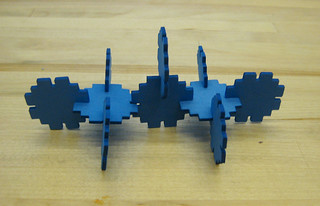

Making the first joint

I wanted to get the joint right before working on the actual design. I drew a basic puzzle block using Adobe illustrator. I first cut a cardboard puzzle block using the following setting for Epilog laser.

Speed: 65, Power: 45, Freq: 700

For EVA sheets I changed the settings to

Speed : 85, Power:12, Freq: 700

Speed: 65, Power: 45, Freq: 700

For EVA sheets I changed the settings to

Speed : 85, Power:12, Freq: 700

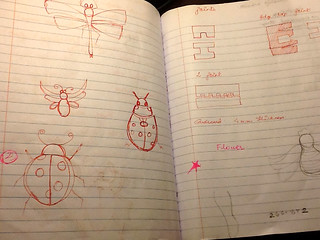

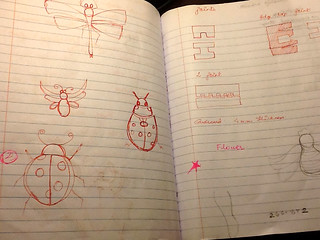

Creating Ilustrations

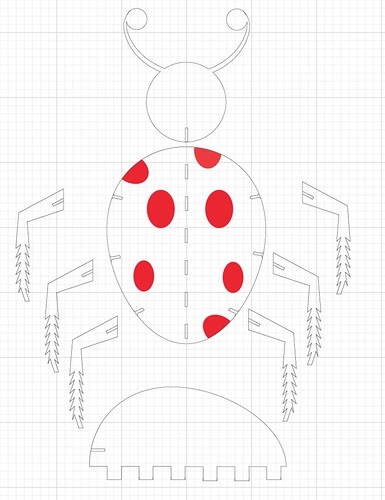

Figuring out parts for the construction kit was the trickiest thing for me. I started with some hand drawn sketches of different kinds of insects and then chose to draw the image of a lady bug using illustrator. Here is the first version of the lady bug.

Making a cardboard model

I made a cardboard model to test the design. After making the first model, I realized that it was a bit wobbly. Since EVA sheets are flexible, the same design for cardboard wouldn’t have worked.

Second version of the Lady Bug

I added a part for the back, changed the antennas, increased the depth of joints and made the legs broader.

I tried various settings for both the laser cutters. Here are the Epilog laser cutter settings that work for 0.04” thick EVA sheets

For cutting:

Speed: 65

Power: 12

Freq: 700

For engraving:

Speed: 88

Power: 7

Freq: 700

Series of iterations