CNC Milling - Make Something Big

This week we "made something big". My technology stack looked like this:

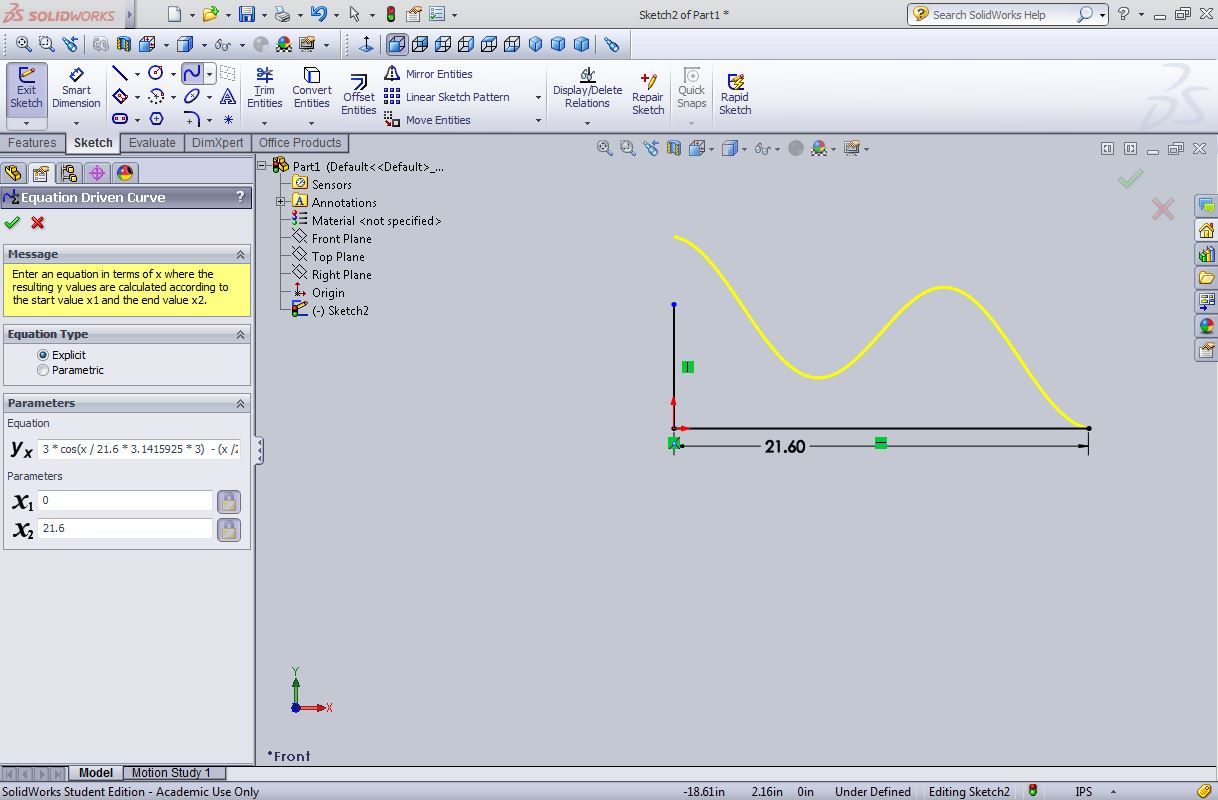

- Model in SolidWorks

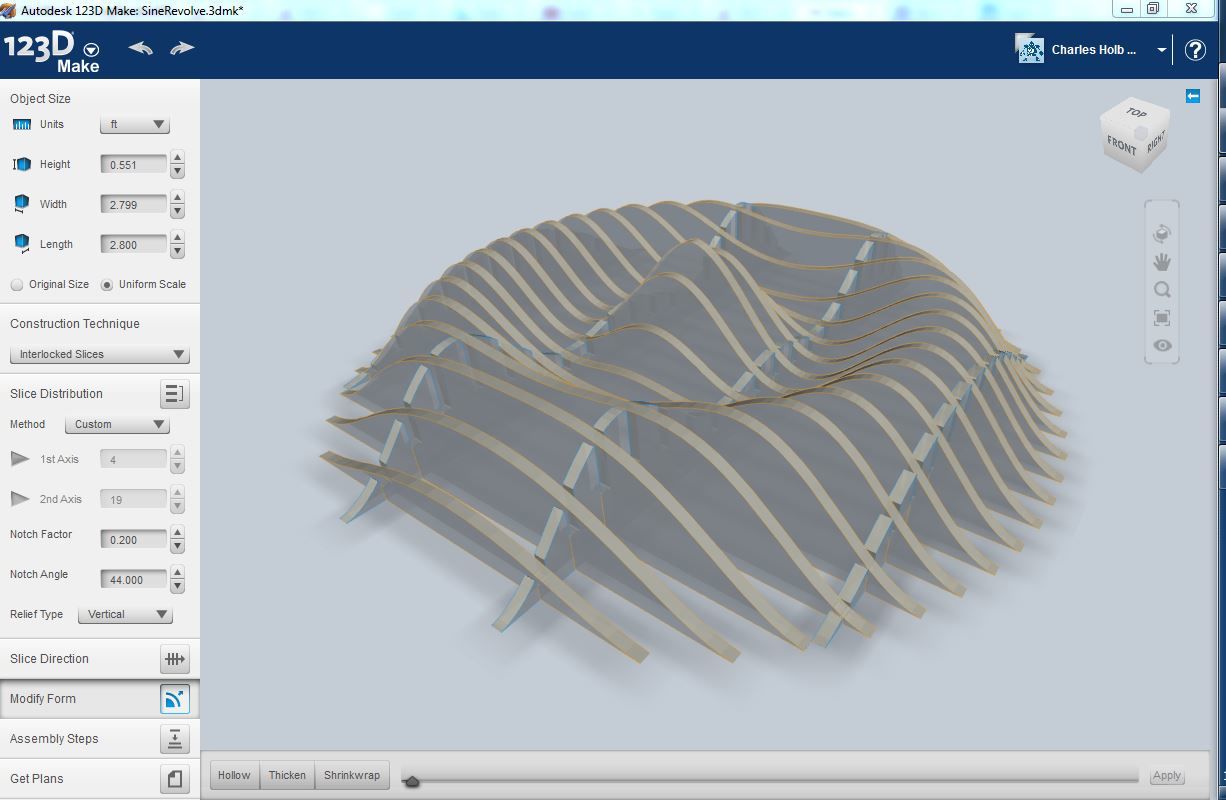

- Slice the model using 123D Make

- Edit the slices, and create the tool path in PartWorks

- Cut slices from OSB using the ShopBot

- Assemble

This sculpture models a dampened sinusoidal wave revolved around the z axis - like the pattern left by a drop of rain in a puddle. Seen below modeled in SolidWorks.

I exported a .stl from SolidWorks, and imported it into AutoDesk 123D Make. 123D Make has accessible parametric slicing tools for making press-fit kits from 3D Models.

Sophia warned me that when she used 123D Make to slice for her project the exported files contained inaccuracies. 123D Make lets you specify the thickness of your material so that it can create press-fit slots of the correct size. Sophia warned me that this feature did not work correctly - the sizes of her slots were did not match the specified material thickness.

I knew to verify the slot size before cutting. My slot size seemed to be working correctly, but I experienced a different bug:

- Tolerance setting in 123D Make is Inverted

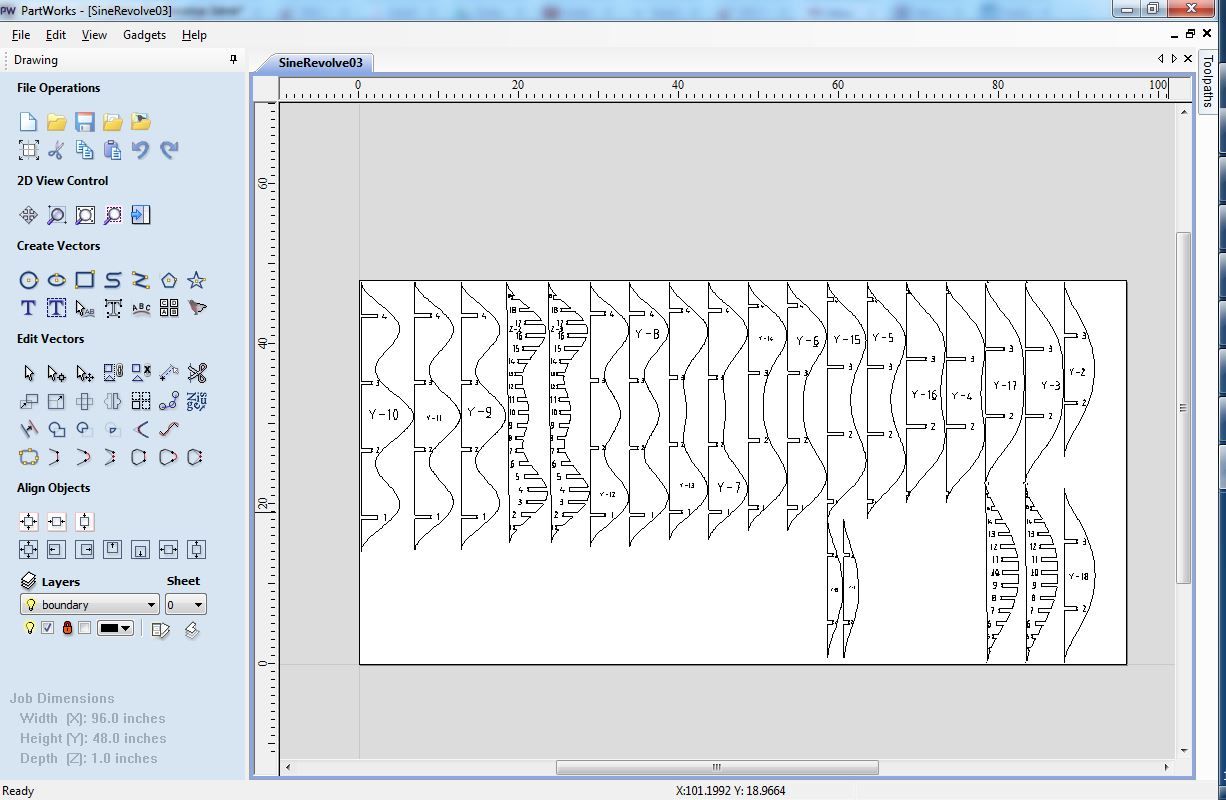

The next step was to clean up the output from 123D Make, and create the tool path. I used PartWorks to:

- Delete all the numbers that identify the parts

- Verify that the slits are the correct size

- Move the slices on the layout - By default 123D Make only leaves the width of the bit between the parts. This is sub-optimal for the shop bot.

- Iterate on the number and positioning of slices on each axis

This shop bot did it's work - Now I can cut out and assemble the parts.

Take away from this week:

- 123D Make is simplifies the slicing process but don't blindly trust its decisions - very that slot sizes are correct before milling.

- Measure the thickness of the OSB before determining slot sizes. Mine varied from 440 mills to 480 mills. I set my slot thinkness to 475, and it's a little loose, but everything holds together okay